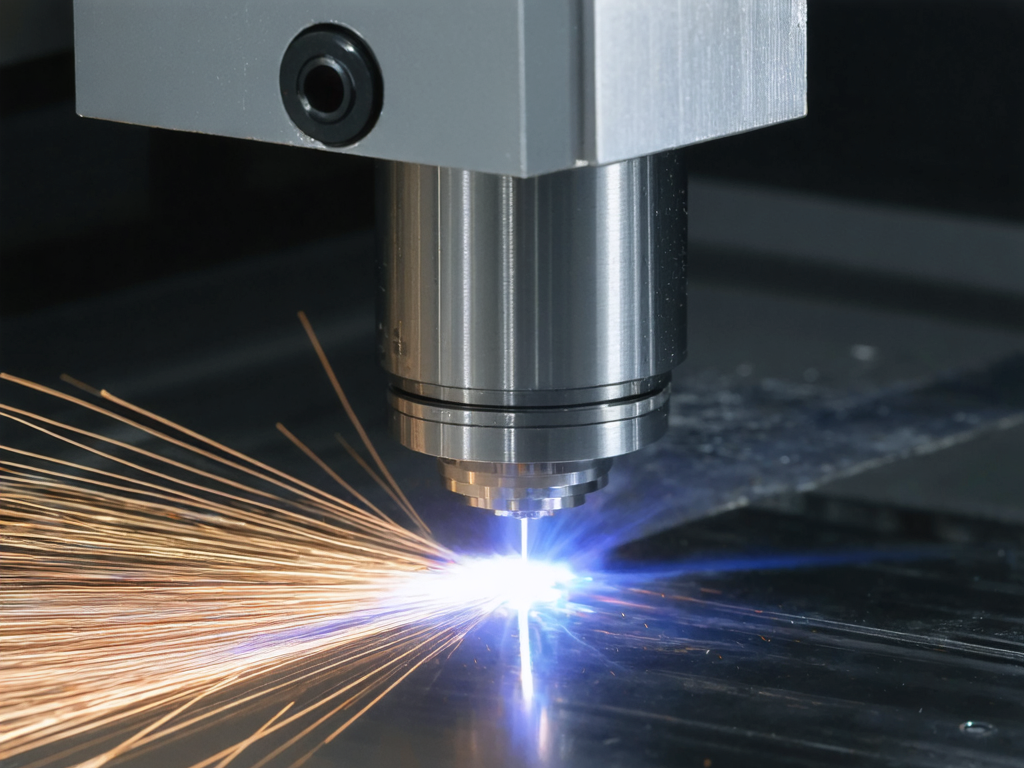

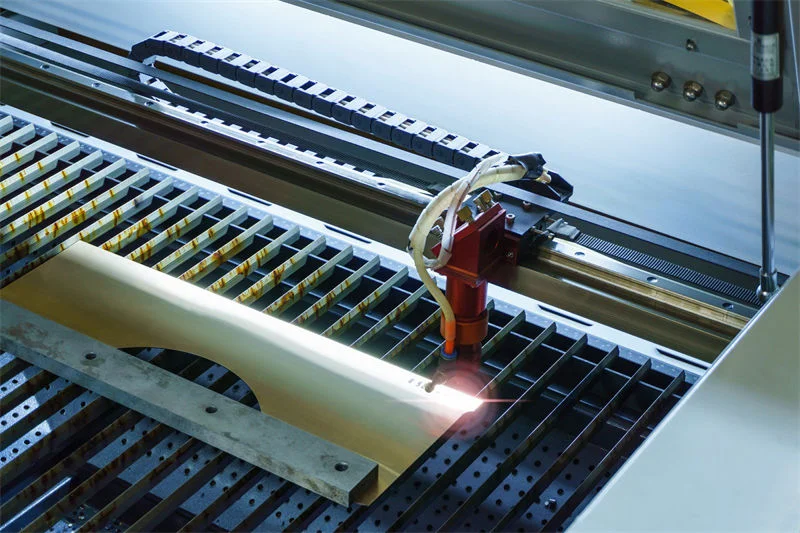

In the world of engraving, CO2 laser engravers stand out as versatile tools that cater to both hobbyists and professionals alike. These machines offer exceptional precision and can work with a variety of materials including wood, acrylic, and glass. They not only enhance creative potential but also significantly improve efficiency in production. Whether you are a small business owner or a passionate hobbyist, understanding the benefits of CO2 laser engravers can help you unlock new possibilities for your projects.