Your Premier Source for Cutting-Edge Laser & CNC Equipment and Spare Parts

High-performance laser cutting machine, laser welding machine, laser marking machine, laser cleaning machine, milling machine and related accessories

Business Partners

What We Do ?

Royelltec is a leading manufacturer and distributor based in China, specializing in advanced laser technology and CNC machinery. We design, research and develop, manufacture, and sell a wide range of products including fiber laser cutting machines, CO2 laser engraving machines, hybrid laser cutters, laser marking machines, fiber laser welding machines, laser cleaning machines, and various CNC milling machines. Our products are suitable for various industries and applications, catering to both small businesses and large industrial manufacturers. With over 25 years of experience, Royelltec has become a trusted name in the laser equipment industry.

Fiber Laser cutting machine

Our fiber laser cutting machines excel in automotive, aerospace, electronics, construction, metal furniture, custom fabrication, medical devices, and advertising. They can process various metals, including stainless steel, carbon steel, aluminum, copper, and brass. These machines offer high precision, versatility, and efficiency, enhancing productivity and quality across diverse industries.

Laser Marking Machine

Our laser marking machines, including fiber laser marking machines, CO2 laser marking machines, and UV laser marking machines, are widely used in automotive, aerospace, electronics, medical devices, jewelry, tool manufacturing, and promotional product industries. They can mark metals like stainless steel, aluminum, copper, and titanium, as well as plastics and ceramics. These machines offer high precision, speed, and durability, ensuring clear, permanent markings that enhance traceability, branding, and quality control.

Laser Welding Machine

Our fiber laser welding machines are widely used in automotive manufacturing, aerospace, electronics, medical devices, metal fabrication, and home appliance industries. They can weld various metals, including stainless steel, carbon steel, aluminum, copper, and titanium. These machines offer high precision, high strength, and high efficiency welding, ensuring excellent weld quality and enhancing productivity and product reliability across various sectors.

Laser Cleaning Machine

Our fiber laser cleaning machines are widely used in aerospace, automotive manufacturing, ship maintenance, heritage restoration, mold cleaning, and electronics industries. They efficiently remove oxidation layers, paint, rust, and other contaminants from metal surfaces. These machines offer high precision, eco-friendliness, and efficiency, ensuring excellent surface treatment quality and enhancing productivity and product quality across diverse sectors.

CNC Milling Machine

Our CNC milling machines are widely used in automotive manufacturing, aerospace, electronics, mold making, mechanical engineering, and medical device industries. They can process a variety of metals, including aluminum, copper, brass, steel, and titanium. These machines offer high precision, efficiency, and durability, ensuring precise parts manufacturing and enhancing productivity and product quality across various sectors.

Accessories and Consumables

Our accessories and consumables are widely used in the previously mentioned equipment, including fiber laser cutting machines, laser marking machines, laser welding machines, laser cleaning machines, and CNC milling machines. We provide high-quality laser cutting heads, nozzles, protective windows, focusing lenses, collimating lenses, laser ceramics, and laser safety glasses. These accessories and consumables ensure optimal performance and longevity of the equipment, enhancing productivity and product quality across various industries.

What Sets Us Apart

Stable Quality

Our commitment to “Stable Quality” is more than a slogan; it’s the backbone of our promise to wholesale clients and distributors, ensuring worry-free sales and sustained growth. Our laser equipment and CNC machinery undergo rigorous quality control and performance testing, guaranteeing zero concerns post-sale and long-term reliability for your customers. This dedication to quality means not only will your clients return for repeat purchases, but they will also become advocates for your business, attracting more opportunities and enhancing your competitive edge in the market. Choosing us is choosing a future of enduring value and success for you and your customers.

Wide Range Of Products

Our extensive product line is designed to meet the diverse needs of wholesale clients and distributors, positioning us as a one-stop shop for all your laser equipment and CNC machinery requirements. With a range that covers everything from fiber laser cutting machines and laser marking machines to CNC milling machines and laser welding machines, we ensure that you can cater to the varied demands of your customer base without the need to source additional suppliers. This breadth of offerings not only simplifies your procurement process but also allows you to focus your energy on expanding your business, secure in the knowledge that our comprehensive selection has all your needs covered.

Competitive Pricing

Our competitively priced product range is strategically crafted to empower wholesalers and distributors, maximizing your profit margins while maintaining high-quality standards. By offering an extensive selection of laser equipment and CNC machinery at prices that challenge the market, we enable you to attract a broader customer base, meeting diverse needs without compromising on performance. This advantage allows you to pass savings onto your customers, fostering loyalty and repeat business. Partner with us to leverage competitive pricing as a tool for business growth, ensuring that you stay ahead in a fiercely competitive landscape.

Fast Delivery

Our quick shipping capabilities directly empower wholesalers and distributors by enabling faster turnover and reduced inventory, alleviating financial pressure. This logistical advantage allows you to capture market demand promptly, keeping you a step ahead of the competition. With our efficient delivery, you can optimize stock levels, minimize capital tied up in inventory, and respond swiftly to market trends, enhancing your competitive edge and customer satisfaction.

Support Your Custom Needs

By partnering with us, you gain the flexibility to create custom products tailored to your specifications, drawing inspiration from top-selling designs in the market. This approach ensures your offerings align with current trends and consumer preferences, significantly increasing their appeal to your customers. Our commitment to customization allows you to capture the attention of a wider audience, enhancing your competitive edge and driving sales.

Good After-Sales Service

Our after-sales service, backed by reliable product quality, minimizes post-purchase issues, ensuring your customers seldom face complaints about quality or service. This excellence in support not only secures repeat business for you but also bolsters your reputation through positive word-of-mouth, enhancing customer loyalty and driving your growth in a competitive market.

Real Factory Based In China

The Royell factory is equipped with advanced production equipment and stringent quality control systems to ensure each product meets the highest standards. Through innovative technology and efficient processes, we provide high-quality laser equipment and CNC machinery that have earned the trust of customers worldwide.

Professionalism Wins Us The Future

Production Line

Product Quality Inspection

Packaging Process

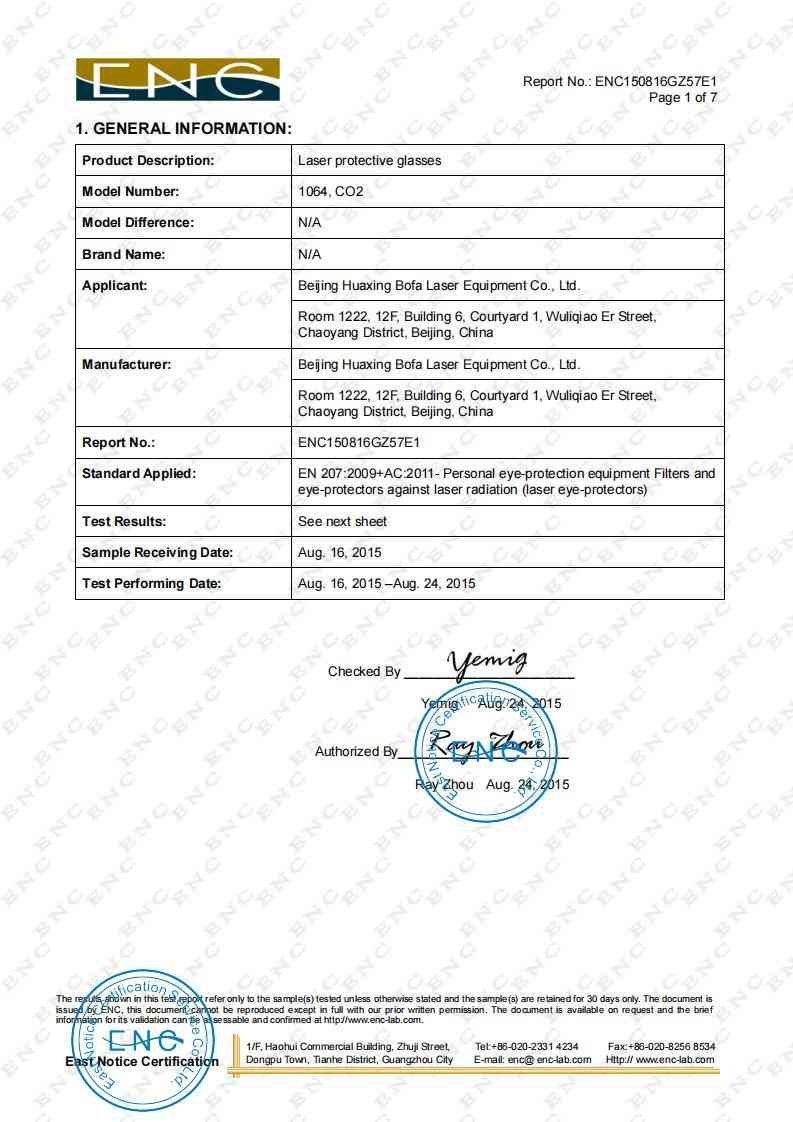

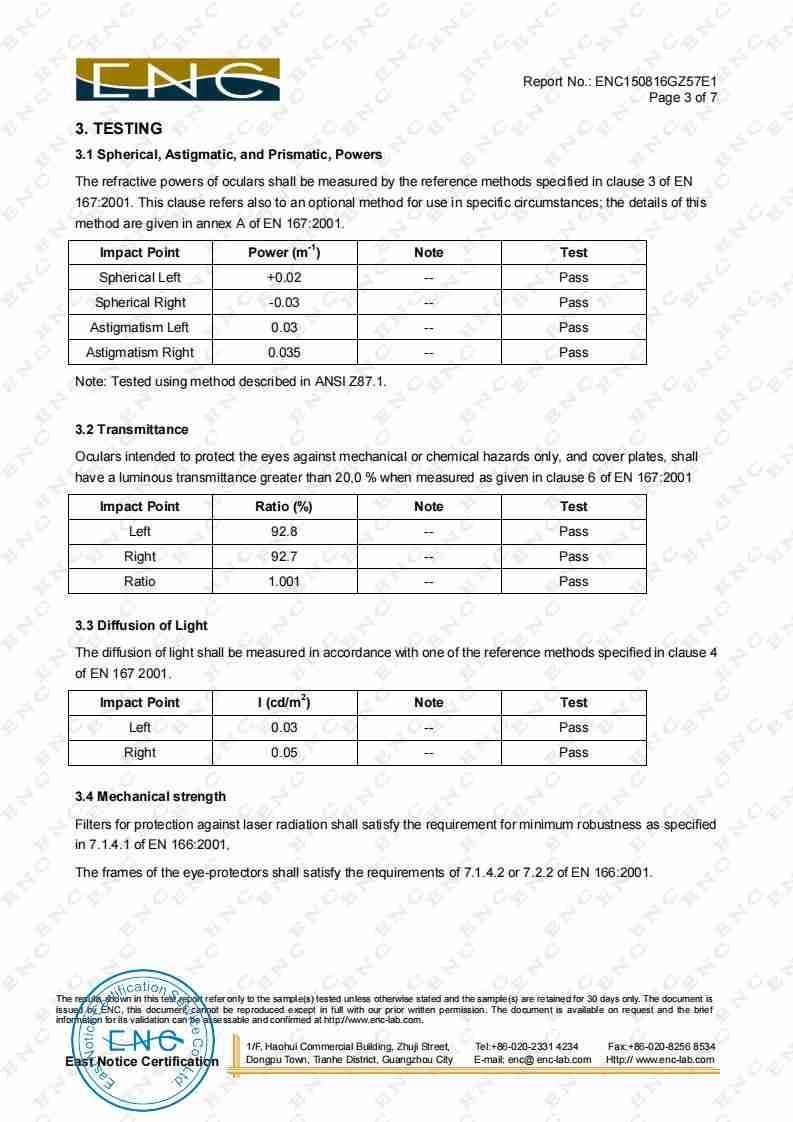

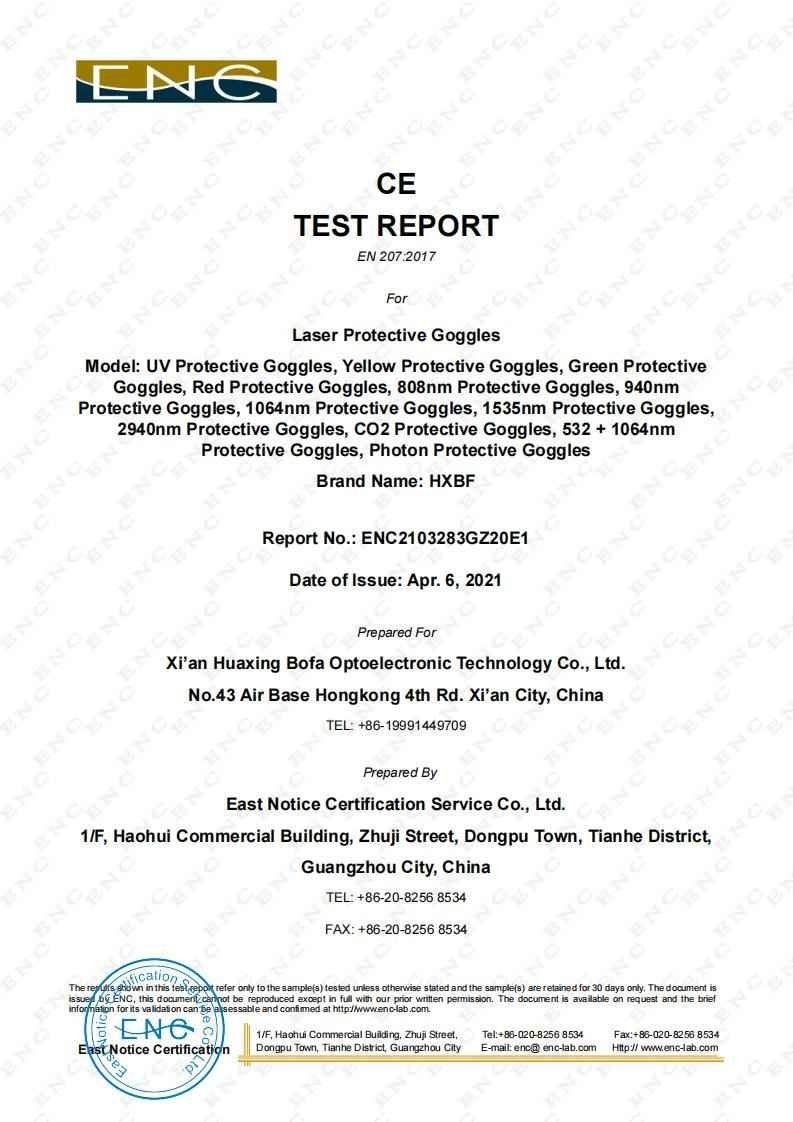

Certificates

Royelltec is committed to quality and excellence, evidenced by our numerous certifications. Our products meet international standards, including ISO9001, CE, and FDA certifications. These certifications guarantee our laser equipment and CNC machinery are reliable, safe, and of the highest quality, ensuring customer satisfaction and trust.

Application

Royelltec is committed to quality and excellence, evidenced by our numerous certifications. Our products meet international standards, including ISO9001, CE, and FDA certifications. These certifications guarantee our laser equipment and CNC machinery are reliable, safe, and of the highest quality, ensuring customer satisfaction and trust.

Client Testimonials

FAQ

What Types of Products Does Royell Offer?

Royell offers a wide range of products, mainly categorized into two groups:

Whole Machines

- Fiber Laser Cutting Machines

- CO2 Laser Cutting Machines

- CO2 Laser Engraving Machines

- Hybrid Laser Cutting Machines

- Laser Marking Machines

- Fiber Laser Marking Machines

- CO2 Laser Marking Machines

- UV Laser Marking Machines

- Fiber Laser Welding Machines

- Fiber Laser Cleaning Machines

- CNC Milling Machines

Accessories

- Milling Cutters

- Fiber Laser Accessories

- Laser Cutting Heads (main brands: Precitec, Raytools, BOCI, WSX, etc.)

- Laser Nozzles

- Laser Lenses (protective lenses, collimating lenses, focusing lenses)

- Laser Ceramic Parts

- Laser Safety Glasses (1064nm, 10600nm, 190-490nm, 532nm, etc.)

- CO2 Laser Equipment Accessories

- Focusing Lenses

- Reflective Mirrors

- Glass Laser Tubes

- Chillers

- Power Supplies

- Control Boards

Royell is dedicated to providing high-quality and cost-effective laser equipment and accessory solutions.

How Can I Choose the Right Machine Parts or Equipment Configuration?

Choosing the right machine parts or equipment configuration can be crucial for the performance and efficiency of your laser cutting or welding systems. Here are some tips to help you make the best decision:

Understand Your Requirements:

- Determine the type of materials you will be working with (e.g., metal, plastic, wood).

- Identify the thickness and size of the materials.

- Define the precision and speed requirements for your applications.

Select the Right Machine:

- For high-precision and high-speed cutting, consider our Fiber Laser Cutting Machines.

- If you need versatility for cutting and engraving, CO2 Laser Cutting and Engraving Machines might be the best option.

- For specific marking applications, choose from our range of Laser Marking Machines (Fiber, CO2, UV).

Choose Compatible Parts:

- Ensure compatibility with your existing equipment. For example, if you are using a Precitec or Raytools laser cutting head, select nozzles and lenses that are compatible with these brands.

- Consult our product specifications for details on compatible parts.

Consider Quality and Cost:

- Balance quality and cost based on your budget and performance needs. Our products are known for their high cost-performance ratio.

- Non-original replacement parts may offer higher profit margins but ensure they meet your quality standards.

Seek Professional Guidance:

- Take advantage of our specialized technical support. Our experts can provide guidance on selecting the right cutting heads, nozzles, lenses, and other accessories.

- We offer professional advice specifically for Precitec and Raytools laser cutting heads.

Evaluate Supplier Support:

- Look for suppliers who can provide not only the products but also technical support and after-sales service.

- Consider logistics, payment methods, and supplier reliability in your decision-making process.

If you have any questions or need further assistance, please contact our team of experts at chen@royelltec.com. We are here to help you optimize your laser cutting and welding operations.

By following these guidelines, you can ensure that you select the most suitable machine parts and equipment configurations for your needs.

What Payment Methods Do We Offer?

We offer a variety of flexible payment methods to accommodate different customer needs:

Telegraphic Transfer (T/T):

- Divided into a prepayment and balance payment, with an initial deposit and the remaining balance paid upon production completion.

Letter of Credit (L/C):

- For large orders, we accept irrevocable letters of credit.

PayPal:

- Suitable for small orders or sample orders, providing a quick and convenient payment method.

Western Union:

- Suitable for small payments, especially for urgent orders.

Alibaba Trade Assurance:

- Payments made through the Alibaba platform to ensure secure and reliable transactions.

Of course if you have more questions you can contact us directly

What Shipping Options Do We Offer?

We provide various shipping options to ensure the safe and timely delivery of products to our customers:

Air Freight:

- Suitable for urgent orders and small-sized shipments, offering fast delivery times.

Sea Freight:

- Ideal for bulk shipments, offering lower costs but longer delivery times.

International Express (DHL, FedEx, UPS, TNT):

- Suitable for small packages, providing fast delivery times and global service coverage.

Rail Transport:

- Suitable for shipments between China and Europe, with delivery times and costs between sea and air freight.

Local Delivery:

- For domestic customers, we offer reliable local logistics and delivery services.

No matter which shipping option you choose, we ensure secure transactions and timely delivery of goods. If you have any questions or special requirements, please feel free to contact our sales team for the best solutions.

What Warranty Services Do We Offer for Our Machines and Parts?

We provide comprehensive warranty services for both our machines and accessories to ensure customer satisfaction and reliable performance:

Warranty Period:

- Our machines come with a 2-year warranty.

Handling Breakdowns:

- If a machine breaks down, our technicians will diagnose the issue based on client feedback.

- If the problem is due to quality faults, parts (excluding consumables) will be replaced free of charge.

Post-Warranty Support:

- Even after the warranty period, we continue to offer technical assistance for orders placed on our website.

Consumable Parts:

- Consumable parts are not covered by the free replacement policy. However, we offer high-quality consumables for purchase.

Our goal is to provide top-notch support and ensure your equipment operates smoothly. For any issues or assistance, please contact our support team.

What Experience and Advantages Does Our Technical Team Have?

Our technical team has extensive experience in equipment repair and assembly, ensuring the highest quality service and support for our customers:

Extensive Repair Experience:

- Our technical team has over 5 years of experience in laser equipment repair, particularly with laser cutting heads from brands like Precitec and Raytools.

- We can quickly diagnose and resolve equipment issues to ensure stable operation.

Professional Assembly Skills:

- Our team is skilled not only in repairs but also in the assembly of laser equipment.

- Whether it’s fiber laser cutting machines, CO2 laser engraving machines, or laser marking machines, we assemble and tune them to the highest standards.

Comprehensive Technical Support:

- We provide comprehensive technical support to our customers, including installation, maintenance, and troubleshooting.

- Even after the warranty period, we are committed to offering ongoing technical support and service.

Our experience and expertise allow us to deliver exceptional products and services to our customers. If you have any questions or need assistance, please feel free to contact our team of experts.

How Long is the Delivery Time?

The delivery time for our products varies depending on the type of equipment or parts and the order quantity:

Standard Products:

- For standard machines and commonly stocked accessories, the delivery time is typically 2-4 weeks after the order is confirmed.

Spare Parts:

- For regular spare parts, the delivery time is usually 1-2 weeks after the order is confirmed.

Customized Products:

- For customized machines or special orders, the delivery time can be 4-8 weeks due to additional design and manufacturing requirements.

Large Orders:

- For bulk orders, the delivery time will depend on the order size and production schedule. We will provide an estimated delivery time once the order details are confirmed.

Express Shipping:

- For urgent orders, express shipping options are available, and delivery times will be shorter. Please contact our sales team for specific arrangements and costs.

We strive to deliver all orders promptly and will keep you informed of the progress throughout the process. If you have any specific deadlines or special requirements, please let us know, and we will do our best to accommodate your needs.

How Does Royell Ensure Product Quality?

At Royell, we are committed to providing high-quality products to our customers. Here’s how we ensure product quality:

Strict Quality Control:

- We implement a rigorous quality control process at every stage of production.

- Each product undergoes thorough inspections and tests to meet our high standards before it leaves the factory.

Advanced Manufacturing Techniques:

- We use the latest manufacturing technologies and equipment to ensure precision and consistency in our products.

- Continuous investment in advanced machinery helps us maintain high production standards.

Certified Materials and Components:

- We source materials and components from reputable suppliers who meet our strict quality criteria.

- All materials and components are certified to ensure they meet international standards.

Experienced Technical Team:

- Our technical team has extensive experience in the laser equipment industry.

- Their expertise ensures that each product is designed, assembled, and tested to the highest quality standards.

Comprehensive Testing Procedures:

- Each product undergoes a series of tests, including performance testing, durability testing, and safety testing.

- We use specialized testing equipment to simulate real-world operating conditions.

Continuous Improvement:

- We continuously collect feedback from our customers to improve our products and processes.

- Our commitment to quality drives us to implement improvements and innovations regularly.

Certifications and Compliance:

- Our products comply with international standards and certifications, ensuring they meet the required safety and performance criteria.

- Certifications include CE, ISO, and other relevant industry standards.

By adhering to these practices, Royell ensures that every product we deliver meets the highest quality standards, providing reliable performance and customer satisfaction. If you have any questions about our quality assurance processes, please contact our support team.

Get Free Quote

Contact us for a free quote and more expertise on customizing Laser Machines & Consumables.Royell will provide the right solution for your project.

Get in Touch

- +853-68274145

- chenly@royelltec.com

Address

- Building 20, Changxing Artron Hi-Tech Intelligent Manufacturing Industrial Park, Li Chen Highway, Hongqiao Town, Changxing County, Huzhou City, Zhejiang Province, China.