Have you ever felt overwhelmed by the sheer number of options when trying to source machinery from abroad?

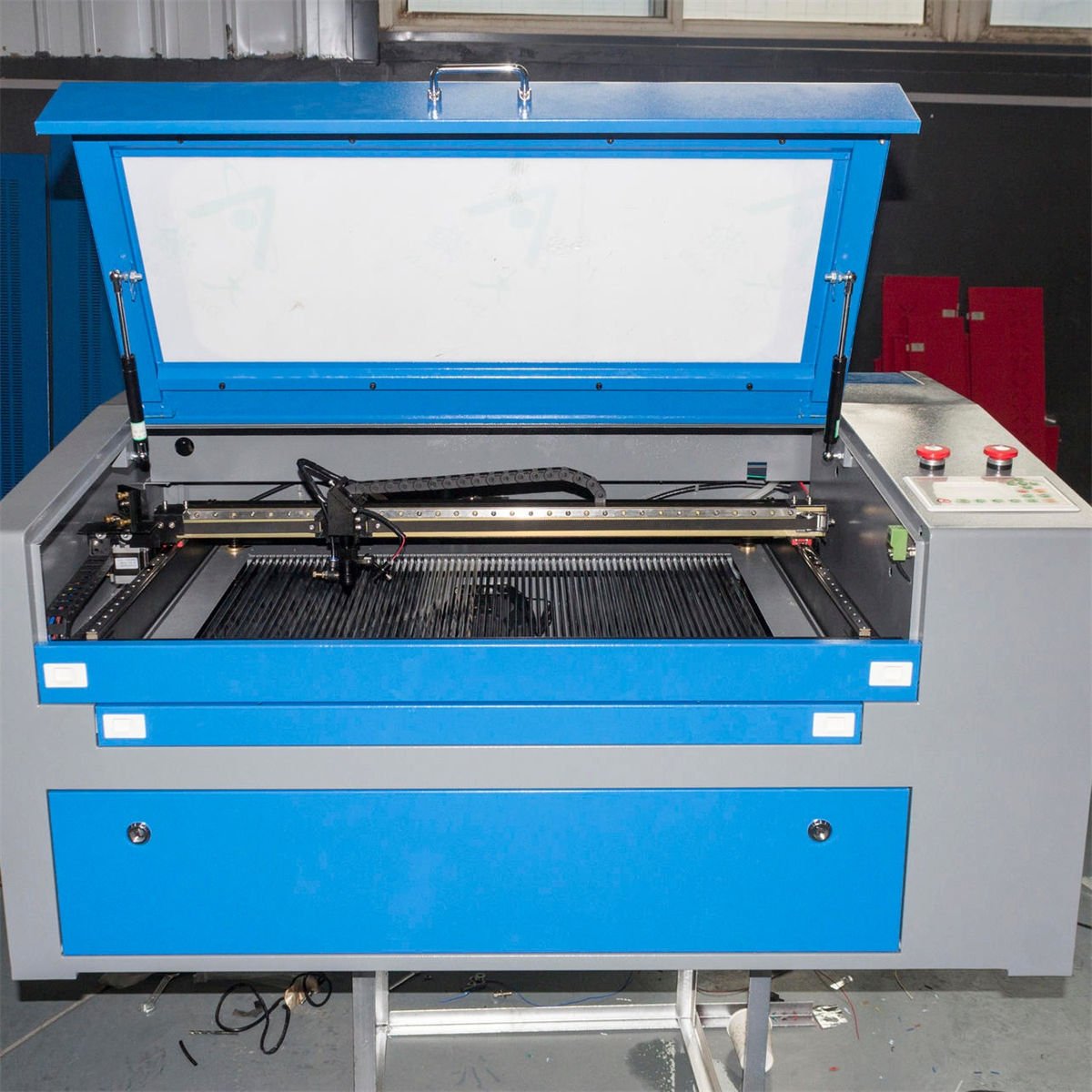

When sourcing Chinese CO2 laser cutting machines for large-scale production, focus on specifications like power output and material compatibility, assess quality and build, consider costs, and ensure robust supplier support. This will help in making a reliable and cost-effective choice.

I remember the first time I was tasked with finding the right equipment for our business. It felt like standing at the edge of a giant maze, unsure of which path to take. Beyond just the initial purchase, I quickly learned that understanding the nuances of machine maintenance, operational costs, and supplier reliability was essential.

Each machine has its quirks, much like a temperamental car that needs the right fuel to run smoothly. I found myself diving into power outputs and material compatibilities, constantly weighing the pros and cons. Evaluating a machine’s specs was like reading the fine print in a contract; every detail mattered. And let’s not even get started on the importance of after-sales support—it’s like having a lifeline when you’re knee-deep in technical issues.

Through this journey, I realized that with careful consideration and a bit of patience, choosing the right CO2 laser cutting machine can indeed transform production capabilities. So, let’s delve deeper into what really matters in making this pivotal decision.

Chinese CO2 lasers are always cheaper than Western counterparts.False

While often less expensive, not all Chinese CO2 lasers are cheaper.

Supplier support is crucial for CO2 laser machine reliability.True

Good supplier support ensures machine longevity and performance.

How Do Machine Specifications Affect Your Production?

Imagine running a marathon with the wrong shoes. Machine specs are like those shoes—they either propel your production forward or hold you back.

Machine specifications impact production efficiency, quality, and costs. Factors like power output, material compatibility, speed, precision, and automation features determine if a machine meets production needs effectively.

When I first got into the world of laser equipment, I was like a kid in a candy store, overwhelmed by all the options but unsure which ones were worth my time—and investment. It became clear that understanding machine specs wasn’t just a technical requirement; it was the backbone of my business’s success.

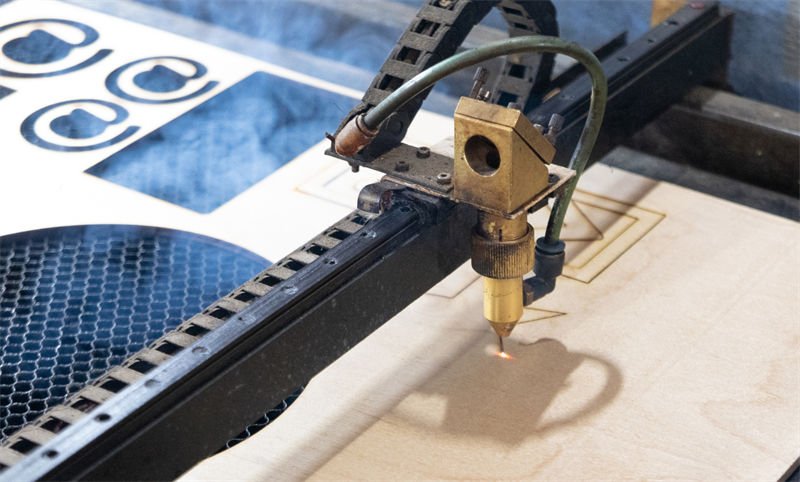

The Power of Power Output

I remember the first time I upgraded to a machine with higher power output. It was like switching from a push mower to a ride-on. Suddenly, I could cut through thicker materials with ease, saving both time and frustration. The ability to efficiently handle tough materials meant I could take on bigger projects that I’d previously shied away from.

| Specification | Impact on Production |

|---|---|

| Power Output | Affects cutting depth |

Material Compatibility Matters

At one point, I took on a project involving a variety of materials—everything from stainless steel to acrylic. A versatile machine that could handle this range was crucial. My CO2 laser cutter had to be adaptable; otherwise, I’d be stuck saying no to jobs or worse, botching them.

| Specification | Impact on Production |

|---|---|

| Material Compatibility | Determines versatility |

Speed and Precision Impact

Speed and precision are like peanut butter and jelly—they just belong together. With advanced motion control systems, my machines are now able to maintain high precision even at top speeds. This not only boosts my production throughput but also ensures the quality is never compromised.

| Specification | Impact on Production |

|---|---|

| Speed & Precision | Influences throughput and quality |

Automation Features

I used to spend hours manually adjusting machines, which was exhausting and left room for errors. Automation features have been a game-changer. With auto-focus and material feeding systems, I’ve reduced downtime dramatically, allowing me to focus more on growing my business than babysitting machines.

Considering Build Quality and Reliability

Investing in machines with high build quality has been one of the smartest decisions I’ve made. They’re reliable workhorses that withstand the rigors of continuous operation. A well-built machine minimizes unexpected downtimes, which is crucial when every minute counts.

Customization and Flexibility

Finding machines that could be customized to fit specific production needs has been invaluable. It’s like having a car that you can modify as your family grows; my machines evolve with my business. Always look for suppliers who offer customization1 options so your equipment can adapt as you scale up.

By digging into these specifications, I’ve aligned my machine purchases with my production goals more effectively, ultimately saving costs and improving operational efficiency. Take it from me: choosing the right machine specs isn’t just about ticking boxes; it’s about setting your business up for long-term success.

Higher power output allows cutting thicker materials.True

Machines with higher power outputs efficiently cut thicker materials.

Automation features increase manual labor in production.False

Automation reduces manual labor by minimizing downtime and errors.

Why Is Quality and Reliability Crucial in Laser Cutting Machines?

Ever tried slicing a cake with a dull knife? It’s not pretty. That’s why laser cutting machines need to be top-notch in quality and reliability.

Quality and reliability in laser cutting machines guarantee precise cuts, operational efficiency, and durability. High-quality machines minimize downtime, boost production accuracy, and reduce maintenance expenses, making them vital for industries that depend on precision cutting.

I remember the first time I encountered a high-quality laser cutting machine. It was like watching a master artist at work—every cut was flawless, every movement precise. Just like how you wouldn’t use a shaky ladder to paint a ceiling, relying on a low-quality machine could lead to costly mishaps and inefficiencies.

Precision and Accuracy

Precision is everything in this game. I’ve seen how advanced motion control systems2 in top-tier machines consistently deliver exact cuts, meeting the meticulous demands of projects time after time.

| Feature | High-Quality Machines | Low-Quality Machines |

|---|---|---|

| Cutting Accuracy | ±0.1mm | ±0.5mm |

| Repeatability | Consistent | Variable |

Operational Efficiency

When reliability is your middle name, downtime becomes a foreign concept. Imagine a machine that just keeps going without those nerve-wracking pauses. High-quality components ensure that smooth, uninterrupted operation that’s essential when production delays3 simply aren’t an option.

Cost Implications

I know what you’re thinking: "Aren’t these machines expensive?" Sure, they might cost more upfront, but think of it like buying a reliable car. You pay more initially but save heaps on repairs and maintenance down the road. Here’s how it breaks down:

| Cost Aspect | High-Quality Machines | Low-Quality Machines |

|---|---|---|

| Initial Purchase | Higher | Lower |

| Maintenance Costs | Lower | Higher |

| Total Cost of Ownership | More economical | More expensive |

Industry Reputation

In my line of work, reputation is everything. Providing products with precision cuts using reliable machines can elevate your standing in the industry. It’s like being known as the friend who always shows up on time—trustworthy and dependable.

For example, feedback from other businesses can attest to the machine’s reliability4.

Safety Standards

Safety isn’t just a checkbox; it’s peace of mind. High-quality machines come with essential safety features like enclosures and emergency stop buttons that keep operators safe, ensuring compliance with safety standards and creating a secure work environment.

When you add it all up, investing in quality and reliability isn’t just smart—it’s essential for anyone serious about laser cutting.

High-quality laser machines reduce downtime.True

Reliable machines are less prone to breakdowns, ensuring continuous operation.

Low-quality machines have consistent repeatability.False

Low-quality machines often have variable repeatability, affecting precision.

How Does Supplier Support Impact Your Business Success?

Ever wondered how supplier support could make or break your business? Let me take you on a journey through my experiences and insights.

Supplier support is like the backbone of business success. It ensures operational efficiency, cuts down on downtimes, and boosts product quality. From timely technical help to reliable parts delivery, these elements collectively enhance productivity and keep you competitive in the market.

Enhancing Operational Efficiency

Picture this: it’s a typical Tuesday afternoon, and suddenly, one of your main machines grinds to a halt. Panic sets in. But then, thanks to rock-solid supplier support, the necessary parts and expertise arrive almost instantly. This scenario isn’t just a dream; it’s the reality when your supply chain5 functions seamlessly. I’ve experienced firsthand how receiving critical components on time keeps operations running smoothly, minimizing those dreaded downtimes that can cost so much more than just money.

Technical Assistance and Training

I’ve always believed that knowledge is power. Remember the first time you tried using a complex CO2 laser cutter? It felt like learning to drive stick in a foreign country. That’s where excellent supplier support steps in with comprehensive technical assistance6 and training services. I recall how the training programs my suppliers provided transformed my team’s skill set, reducing errors and maximizing our output. When issues arise, having experts just a call away ensures that production doesn’t miss a beat.

| Supplier Support Benefits | Impact on Business |

|---|---|

| Technical Assistance | Reduces downtime and maintenance costs |

| Training Programs | Enhances team expertise and productivity |

| Quick Part Replacement | Minimizes operational interruptions |

Building Long-Term Partnerships

Think of your supplier relationships like planting a garden. The more you nurture them, the more they grow into fruitful partnerships. Over the years, I’ve seen how strategic supplier relationships have brought about perks like better pricing7 and early access to new innovations. This mutual trust turns suppliers into collaborators who are genuinely invested in your success.

Innovation and Customization

Suppliers with robust support often become my go-to partners for innovation. Their industry insights have been invaluable in driving product development8, helping me tailor solutions that meet specific market demands. Such collaborations keep my business ahead of the curve, offering that competitive edge we all strive for.

Communication and Relationship Management

Clear communication is the glue that holds these relationships together. Regular updates and transparent dialogue help avert potential issues before they snowball into bigger problems. I ensure all stakeholders are aligned through established communication protocols, which makes operations smoother and builds trust with my suppliers.

For anyone looking to optimize supplier relationships, focusing on these key aspects can significantly enhance operational outcomes and bolster your market position.

Supplier support enhances operational efficiency.True

Suppliers ensure smooth supply chains, reducing downtime and delays.

Technical assistance from suppliers reduces maintenance costs.True

Expert support resolves issues quickly, minimizing downtime and costs.

How Can You Evaluate the Total Cost of Ownership?

Have you ever bought something, only to realize later that the initial price was just the tip of the iceberg?

To evaluate the Total Cost of Ownership (TCO), I consider both direct and indirect costs over the asset’s lifespan. This includes not just the purchase price, but also operating expenses, maintenance, and potential disposal fees.

What is Total Cost of Ownership?

I remember the first time I learned about Total Cost of Ownership (TCO). It was during a conversation with an old friend who was pondering a major purchase—his first car. I thought, "Sure, you pay for the car and you’re done," but then he started listing off things like fuel, insurance, maintenance, and even parking tickets! That was my lightbulb moment. TCO goes beyond just what you pay upfront; it’s about understanding every single cost that comes with owning something over time.

Key Components of TCO

Initial Purchase Cost

When I bought my first laser cutting machine, I quickly learned that the sticker price wasn’t the only cost to consider. Taxes, fees, and shipping added up fast. It’s crucial to get a full quote upfront to avoid surprises.

Operating Costs

I once underestimated the energy costs of my equipment. Let me tell you, those bills can sneak up on you! Evaluating energy efficiency9 can save money in the long run, especially in high-power machinery.

Maintenance Costs

Maintaining my equipment wasn’t something I initially budgeted for, but regular check-ups have saved me from larger issues down the road. Warranties or service agreements are worth considering—they cover parts and labor and give me peace of mind.

| Maintenance Activity | Frequency | Cost |

|---|---|---|

| Software Updates | Monthly | $100/year |

| Part Replacement | Annually | $500/year |

| Technical Support | As Needed | $300/year |

Disposal or End-of-Life Costs

I’ll admit, I hadn’t thought much about what happens when I need to replace equipment. Disposal costs can be significant if you’re not prepared. It’s important to research and plan for these expenses in advance.

Calculating TCO: A Step-by-Step Approach

- Identify All Relevant Costs: I start by listing every possible expense related to acquiring and using the item.

- Categorize Costs: Breaking them down into initial, operational, maintenance, and end-of-life helps me keep track.

- Project Over Time: Forecasting these costs over the asset’s expected lifespan provides clarity.

- Discount Future Costs: Applying a discount rate helps me understand the present value of future expenses.

- Sum Up All Costs: Finally, adding up all these present values gives me a comprehensive view of TCO.

For complex projects, I often use tools and software to assist in TCO calculations (complex projects10).

Benefits of TCO Analysis

Conducting a TCO analysis helps me make more informed decisions11 by understanding the true cost. It allows for better budget allocation and enhances negotiation leverage with suppliers for improved terms. With this holistic approach, I’m better prepared to optimize my procurement strategy.

TCO only includes the initial purchase price.False

TCO includes all costs over the lifecycle, not just the purchase price.

Maintenance costs can affect TCO significantly.True

Regular maintenance impacts TCO by affecting equipment lifespan and performance.

Conclusion

When sourcing Chinese CO2 laser cutting machines, prioritize specifications, quality, supplier support, and total cost of ownership to ensure effective large-scale production and long-term reliability.

-

Explore how customization options in machinery can align equipment capabilities with specific production requirements. ↩

-

Discover how advanced motion control systems enhance precision in laser cutting processes. ↩

-

Explore the financial impact of production delays and the benefits of reliable machinery. ↩

-

Learn how using reliable machines boosts company reputation through quality assurance. ↩

-

Discover how supplier support streamlines operations and minimizes production disruptions. ↩

-

Learn why technical assistance from suppliers is crucial for maintaining efficient operations. ↩

-

Explore how strategic partnerships with suppliers can lead to better pricing and terms. ↩

-

Understand how suppliers contribute to innovation and product customization. ↩

-

Learn methods to assess energy efficiency and discover potential savings on operating costs. ↩

-

Discover tools that simplify TCO calculations for complex projects and enhance accuracy. ↩

-

Explore how TCO analysis leads to informed decision-making and better procurement strategies. ↩