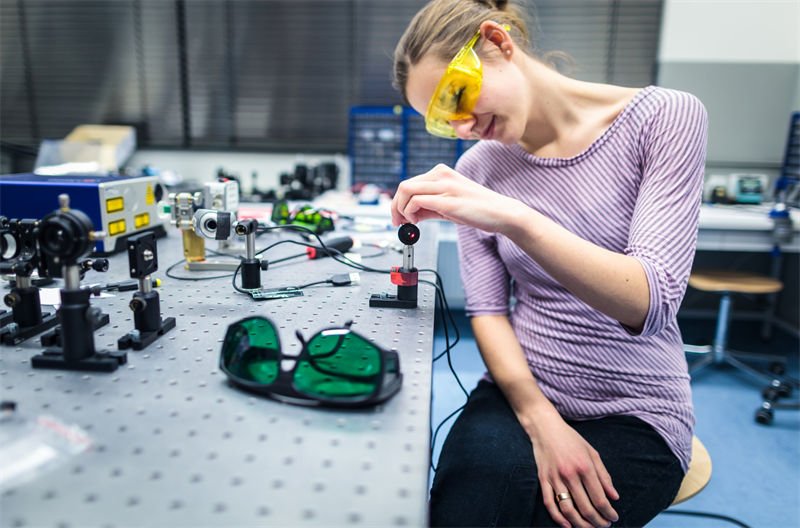

Navigating the world of eye protection can feel overwhelming, but it’s vital for your safety. Let’s explore how safety goggles and glasses differ, and why this choice is more than just a style statement.

Safety goggles and safety glasses differ primarily in protection scope and design. Goggles offer full coverage against chemical splashes and debris, while glasses focus on shielding from light and radiation, providing limited side coverage.

Understanding these differences empowers you to make an informed choice about your eye protection. Let’s dive deeper into their unique features!

Safety goggles provide full coverage against splashes and debris.True

Goggles enclose the eyes, preventing particles and liquids from entering.

How Do Safety Goggles Ensure Full Eye Protection?

Discover how safety goggles offer comprehensive protection against various eye hazards.

Safety goggles provide full eye protection by completely enclosing the eyes, preventing exposure to splashes, dust, fumes, and impacts. They are designed with a snug fit and durable materials to ensure a secure barrier against potential hazards in environments like laboratories and construction sites.

Comprehensive Enclosure for Maximum Protection

Safety goggles are engineered to create a protective seal1 around the eyes, ensuring that no particles or liquids can penetrate from any angle. This feature is crucial in environments where exposure to chemicals or flying debris is prevalent, such as in chemical laboratories or machining workshops.

Durable Materials for Enhanced Safety

The lenses of safety goggles are often made from polycarbonate or other shatter-resistant materials, which provide superior impact resistance. This design is essential in industrial settings where flying particles from tools or machinery are common threats.

| Feature | Description |

|---|---|

| Seal Design | Wrap-around protection to block side impacts |

| Lens Material | Impact-resistant polycarbonate or similar materials |

| Ventilation | Anti-fog vents to maintain visibility and comfort |

Specialized Protection in Various Environments

-

Chemical Laboratories: Here, the risk of chemical splashes is high. Safety goggles protect against corrosive substances that could cause severe eye damage.

-

Construction Sites: Dust, small particles, and debris can cause significant eye injuries if not properly shielded. Goggles ensure these particles are kept at bay.

-

Medical Settings: During surgical procedures or examinations involving bodily fluids, goggles prevent fluid splashes from reaching the eyes, maintaining hygiene and safety.

Adaptability Through Design Variations

Safety goggles come in various designs tailored for specific needs:

- Ventilated Goggles: These have air vents to reduce fogging while maintaining full protection.

- Non-Ventilated Goggles: Used in environments where complete isolation from external elements is required, such as handling volatile chemicals.

Understanding the unique advantages of safety goggles over other protective eyewear options helps in making informed decisions about eye safety in diverse occupational settings. For those requiring all-around protection, these goggles are indispensable.

Safety goggles block all chemical splashes.True

Goggles are designed to enclose the eyes, preventing splash exposure.

Safety goggles are made from glass lenses.False

Goggles use polycarbonate or similar materials for impact resistance.

Why Are Safety Glasses Preferred for Radiation Protection?

In environments where radiation exposure is a concern, choosing the right eyewear is critical for safety.

Safety glasses are preferred for radiation protection due to their specialized lenses and coatings designed to absorb or reflect harmful wavelengths, such as UV or laser radiation, effectively shielding the eyes.

Specialized Lens Technology

Safety glasses are equipped with lenses specifically engineered to protect against various types of radiation. These lenses often incorporate materials that either absorb or reflect specific wavelengths. For instance, ultraviolet (UV) blocking glasses are made with UV absorbers that reduce eye damage from prolonged sun exposure. Similarly, laser safety glasses utilize specialized coatings to reflect particular laser wavelengths, preventing retinal burns.

Comfort and Usability

Unlike safety goggles that can be bulky and less comfortable for extended wear, safety glasses are designed with comfort in mind, making them ideal for long-term use. This comfort is crucial in industries where individuals are exposed to radiation regularly. For example, outdoor workers benefit from wearing sunglasses that shield against UV rays while being lightweight and easy to wear for hours.

Versatile Applications

Protective glasses find extensive use across various fields requiring radiation protection. In medical settings, laser safety glasses are essential for personnel working with laser equipment, such as ophthalmologists performing eye surgeries. Similarly, in industrial settings, workers using high-powered laser cutting tools rely on these glasses for eye safety.

| Field of Application | Type of Radiation | Example of Use Case |

|---|---|---|

| Medical | Laser Radiation | Eye surgeries |

| Industrial | Laser Radiation | Laser cutting tools |

| Outdoor Work | Ultraviolet Light | Sun exposure protection |

Comparing Goggles and Glasses for Radiation Protection

While both goggles and glasses offer protection, their design and functional differences determine their suitability for various environments. Goggles provide comprehensive coverage against splashes and debris, making them suitable for chemical labs. However, for tasks focused on radiation, the specialized lens of safety glasses makes them the preferred choice.

By choosing appropriate eyewear2 tailored to the type of radiation encountered in your specific field, you can ensure optimal eye safety while maintaining comfort and usability.

Safety glasses reflect harmful UV and laser wavelengths.True

Specialized coatings on safety glasses reflect UV and laser radiation.

Safety goggles are preferred over glasses for radiation protection.False

Safety glasses are favored due to specialized lenses for radiation.

In What Situations Should You Choose Goggles Over Glasses?

Choosing the right eye protection can mean the difference between safety and injury in hazardous environments.

Choose goggles over glasses when dealing with environments that pose risks of chemical splashes, flying debris, or fine dust. Goggles provide comprehensive protection by sealing the area around the eyes, making them ideal for industrial, laboratory, and construction settings.

Industrial Environments: Comprehensive Protection Against Particles and Chemicals

In industrial settings, activities such as machining and welding3 generate flying debris, sparks, and fumes. Safety goggles offer a sealed environment around the eyes, preventing these hazards from causing injuries. Unlike protective glasses, goggles are designed to protect against both physical and chemical threats, making them indispensable in environments where molten metals or intense lights are involved.

For example, in machining workshops, safety goggles are crucial as they shield eyes from metal shavings and cooling fluids. Welding processes produce harmful UV and IR radiation, and goggles equipped with special filters can provide effective protection.

Construction Sites: Guarding Against Dust and Debris

Construction sites are rife with potential eye hazards such as dust, wood chips, and small projectiles from cutting or drilling tasks. Goggles are preferred4 here because they enclose the eyes completely, ensuring that particles cannot bypass the protective barrier.

High-elevation work introduces additional risks like wind-blown dust. In such cases, goggles offer a superior level of protection compared to glasses, which may not prevent particles from reaching the eyes from the sides.

Laboratory Safety: Essential for Chemical Handling

In laboratories, the risk of chemical splashes is significant. Safety goggles form an impermeable barrier that prevents chemicals from contacting the eyes. This level of protection is essential when working with volatile substances or during procedures like centrifugation where accidental spills can occur.

Biological laboratories also require the use of goggles to guard against splashes of biological materials or aerosols that might contain harmful pathogens.

Medical Settings: Ensuring Hygiene and Safety

During surgical procedures or certain medical treatments, goggles protect against blood splashes and bodily fluids. They are a key component in maintaining hygiene and preventing infection in medical settings.

For instance, during dental procedures involving high-speed drills, goggles prevent saliva and particles from reaching the eyes, ensuring both patient and practitioner safety.

Sports and Recreation: Shielding from Elements

Certain sports like skiing or motorcycling expose participants to wind, sand, and other elements that could harm the eyes. Goggles are designed to withstand these conditions by creating a barrier against external factors. In contrast, glasses may not offer sufficient coverage or security during high-speed activities.

Agriculture: Protecting Against Natural Hazards

In agricultural work, activities such as pesticide spraying or harvesting generate dust and plant debris that can irritate or damage the eyes. Goggles provide essential protection by sealing out these irritants effectively.

By evaluating the specific risks and requirements of your environment, you can make an informed choice between goggles and glasses to ensure maximum eye protection.

Goggles are always better than glasses for UV protection.False

Glasses with UV filters can also provide adequate UV protection.

Safety goggles seal the area around the eyes completely.True

Goggles are designed to enclose the eyes, blocking out particles.

What Safety Standards Govern Eye Protection Gear?

Understanding safety standards for eye protection gear is crucial for ensuring comprehensive eye safety in various settings.

Safety standards like ANSI Z87.1 and EN166 outline requirements for eye protection gear, ensuring it meets criteria for impact resistance, optical clarity, and coverage. These standards guide manufacturers in designing protective eyewear suitable for different hazards.

Key Safety Standards for Eye Protection

To ensure eye protection gear provides the necessary level of safety and functionality, several key standards have been established worldwide. These standards set forth the minimum requirements for materials, design, testing, and performance of protective eyewear.

ANSI Z87.1

The American National Standards Institute (ANSI) Z87.1 standard is widely recognized in the United States. It focuses on protecting against various hazards such as impact, dust, chemicals, and radiation.

- Impact Resistance: Eyewear must withstand high-velocity impact tests without cracking or breaking.

- Optical Clarity: Lenses must ensure minimal distortion to avoid impairing vision.

- Coverage: The design should provide sufficient coverage to protect against hazards from multiple angles.

Learn more about ANSI Z87.1 requirements5

EN166

In Europe, EN166 is the prevailing standard for personal eye protection. This standard categorizes eyewear based on performance levels for different environmental conditions.

- Protection Levels: Designated by symbols indicating resistance to specific hazards like droplets, molten metal, or large dust particles.

- Mechanical Strength: Varies from low-energy impacts to high-energy impacts, marked by symbols like "S," "F," "B," and "A."

Explore EN166 standard details6

Testing Methods and Certification

Impact Testing

Both ANSI Z87.1 and EN166 require rigorous testing to ensure eyewear can withstand specific impact forces. This typically involves projecting small steel balls at high speeds towards the lenses.

Optical Clarity Assessment

Eyewear must pass clarity tests to ensure that visual acuity is not compromised. This ensures users can perform tasks without experiencing blurred vision or distortion.

Environmental Resistance

Standards also require testing against environmental factors such as chemical exposure and UV radiation to guarantee long-term usability in various conditions.

Importance of Compliance and Certification

Compliance with these standards ensures that eye protection gear effectively reduces the risk of injury in hazardous environments. Employers and individuals should verify that their protective eyewear is certified according to relevant standards before use.

In conclusion, understanding these safety standards helps in selecting the right eye protection gear tailored to specific risks in different occupational settings. Whether it’s ensuring compliance with ANSI standards7 or verifying adherence to European norms, these guidelines are essential for maintaining safety and health at work.

ANSI Z87.1 ensures eyewear withstands high-velocity impacts.True

The standard requires eyewear to pass impact tests without breaking.

EN166 does not categorize eyewear based on hazard resistance.False

EN166 categorizes eyewear by symbols for specific hazard resistances.

Conclusion

Choosing the right eye protection is essential. Goggles offer comprehensive coverage for hazardous environments, while glasses are tailored for radiation protection. Stay safe and informed!

-

Learn how goggle seals prevent exposure to hazardous elements.: Wearing safety goggles correctly involves ensuring they completely encase the eyes and form a tight seal against the face, providing maximum … ↩

-

Learn about various eyewear options for effective radiation protection.: The Phillips Safety Radiation Glasses collection features lead safety glasses with high quality, 0.75mm Pb lead equivalency protection. ↩

-

Learn how safety goggles prevent injuries from machining debris.: These are difficult to use and maintain on manual machines but CNC machines have the doors to protect your eyes. I don’t wear safety goggles … ↩

-

Discover how goggles protect against dust and projectiles.: Scratch-resistant polycarbonate lenses are the finest option in high-impact job situations. Encourage the use of safety glasses at construction … ↩

-

Discover the specific criteria for impact resistance and optical clarity.: Many professionals look to the “Z87” marking on safety glasses and similar eye and face protection apparatus to assure their effectiveness. ANSI … ↩

-

Understand European standards for protective eyewear performance.: EN 166:2001 is the European standard covering the requirements for protective eyewear. It is closely linked to EN 167:2001 and EN 168:2001. ↩

-

Learn how ANSI compliance ensures reliable eye protection.: Plus, they ensure that different products are compatible under one set of instructions, making people’s lives easier, safer, and more enjoyable. ↩