Laser marking machines have transformed how industries mark products for identification and traceability. With an array of types like CO2, Fiber, and UV lasers, understanding their unique efficiencies can help you choose the right one for your needs. Let’s dive in!

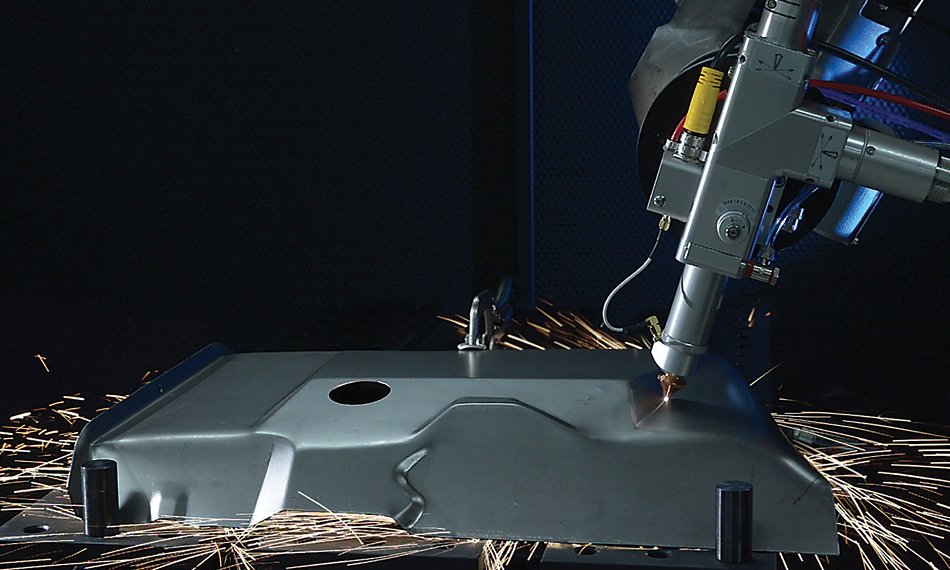

In the competitive world of metal fabrication, precision and efficiency are paramount. Sheet metal laser cutting services stand out as a transformative solution, offering numerous advantages over traditional methods. From superior accuracy to cost-effectiveness, this technology redefines how we approach metalworking. Join me as we explore the compelling benefits of utilizing laser cutting in your projects.

IPG fiber laser cutters are known for their high cost, attributed to advanced technology that ensures precise cuts and long-lasting performance. These machines offer significant energy efficiency and lower maintenance needs compared to alternatives. While the initial investment may be steep, the long-term savings in operational costs make IPG lasers a smart choice for businesses focused on quality and reliability. Their robust construction allows for versatility across various applications, from aerospace to automotive industries. Understanding these factors can help businesses appreciate the value of investing in IPG fiber lasers over cheaper options that may not deliver the same level of performance or longevity.

CNC plasma tables revolutionize metalworking by offering precise cutting capabilities that save time and reduce material waste. These machines automate processes, leading to significant cost savings on labor while enhancing productivity. With advanced software and technology, CNC plasma tables ensure consistent quality across multiple cuts, minimizing human error. They are versatile enough for various applications in both small workshops and large factories. Investing in a CNC plasma table not only boosts efficiency but also increases profit margins by allowing businesses to meet custom demands quickly. Regular maintenance ensures optimal performance, making these machines a valuable asset for any metalworking operation.

Using a plasma cutter on brass can be challenging yet rewarding. This guide explores the intricacies of plasma cutting brass, emphasizing the importance of precise settings, heat control, and safety measures. Achieving clean cuts with minimal waste enhances productivity and allows for intricate designs. Alternative methods like band saws and laser cutters are also discussed for their efficiency in handling brass. Understanding the characteristics of brass and employing proper techniques can significantly improve results in your projects. Whether you’re a hobbyist or professional, mastering these skills will elevate your craftsmanship.

CNC plasma cutting machines offer significant advantages in metal fabrication by providing sharp, fast cuts with minimal waste. They excel at cutting thick metals efficiently and are versatile across various industries. These machines automate processes to reduce human error, increase production speed, and lower labor costs. Their precision ensures high-quality results while minimizing material waste, making them economically beneficial for businesses. Industries such as automotive, construction, aerospace, and art benefit greatly from CNC plasma technology due to its ability to create complex shapes quickly and accurately. By investing in CNC plasma cutters, companies can streamline operations and enhance productivity while meeting market demands effectively.

Using a plasma cutter poses hidden dangers, including toxic fumes and metal particles that can harm your lungs. Wearing a proper mask, such as a P100 respirator, is crucial for safety. This article emphasizes the importance of personal protective equipment (PPE), proper ventilation, and regular maintenance to mitigate risks associated with plasma cutting. It also discusses the types of masks suitable for this task and highlights the need for comprehensive safety measures in the workplace to protect against burns, eye injuries, and respiratory problems. Understanding these hazards can significantly enhance workplace safety during plasma cutting operations.

CNC plasma cutting machines revolutionize metal fabrication by offering high precision and speed. With automated controls and advanced software, these machines minimize human error while maximizing efficiency. They can handle a variety of conductive metals, from mild steel to aluminum, making them essential in industries like automotive and construction. The technology allows for intricate designs and reduces material wastage through optimized cut paths. While they excel in cutting metals up to several inches thick, CNC plasma cutters are not suitable for non-conductive materials. Embracing automation enhances productivity and lowers costs, making CNC plasma cutting a vital tool for modern manufacturing.

The high cost of Prima fiber laser cutters is justified by their cutting-edge technology, unmatched precision, energy efficiency exceeding 40%, and robust construction. These machines excel in performance and reliability, making them a preferred choice for professionals in various industries. Their advanced features reduce waste and operational costs over time, ensuring that the initial investment pays off through increased productivity and lower maintenance needs. Users appreciate the exceptional customer service provided by Prima, further enhancing their value proposition. Understanding these factors helps buyers make informed decisions when investing in laser cutting equipment.

Coherent fiber laser cutters are known for their high costs, attributed to advanced optics and precision engineering. These machines provide exceptional cutting accuracy and energy efficiency, making them valuable investments for businesses. Their unique technology allows for versatile applications across industries, ensuring reliable performance while reducing operational costs. Despite the initial expense, the long-term benefits of improved productivity and reduced waste often justify the investment. Understanding the factors that contribute to their pricing can help businesses make informed decisions about upgrading equipment to enhance operational efficiencies.

Nukon fiber laser cutters command a higher price due to their cutting-edge technology that ensures exceptional precision and energy efficiency. These machines are designed for longevity and require minimal maintenance, making them a valuable investment for businesses. While the upfront costs may be steep, the long-term savings on operational expenses and reduced downtime make Nukon lasers a cost-effective choice in the competitive industrial landscape. Their user-friendly interface also facilitates quick training for operators, enhancing productivity. Overall, investing in Nukon fiber lasers not only boosts operational efficiency but also positions companies favorably within the market.

Intersection of Li chen Highway and Tujing Avenue, changxing County, Huzhou City Zhejiang Province, China

Copyright @ 2025 Royelltec. All Rights Reserved.

WhatsApp us

Send us a message if you have any questions or request a quote. We will be back to you ASAP!