Which Products Benefit Most from Laser Marking Machines?

Laser marking machines have transformed how industries approach product identification and personalization. By delivering precision and versatility, they cater to a wide array of products, enhancing compliance and customization. In this article, I’ll share how different sectors are leveraging this technology and the tangible benefits it brings.

Why Is Han’s Laser So Expensive?

Have you ever wondered why Han’s Laser products come with such hefty price tags? It’s not just about the brand name; there are compelling reasons behind the costs. From innovative technology to unparalleled customer support, this article dives deep into what makes Han’s Laser a premium choice in the industry.

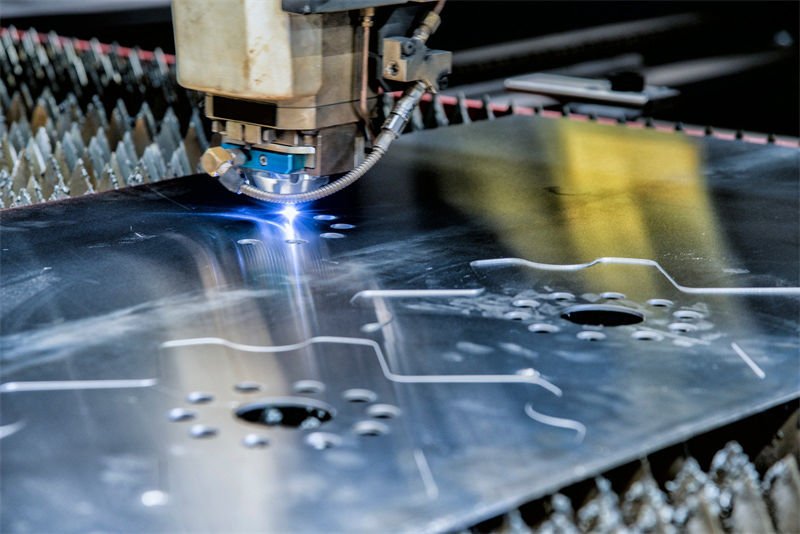

How Does a Fiber Laser Cutting Machine Work?

Fiber laser cutting machines are changing the game in precision and efficiency when it comes to cutting metals and other materials. By understanding how they operate, you can unlock their full potential for your projects. Let’s dive into the key components, differences from CO2 lasers, common issues, and optimization strategies.

How Safe is it to Laser Cut Galvanized Steel?

Laser cutting galvanized steel is a common industrial task, but safety concerns about toxic fumes often arise. Understanding the risks and implementing safety measures is crucial for protecting workers. This article explores the dangers of zinc oxide fumes and offers practical solutions to ensure safe laser cutting practices.

How Effectively Can Aluminium Be Laser Cut?

Aluminium is a popular choice for many manufacturing applications, but its high reflectivity can complicate laser cutting processes. This article explores the challenges of cutting aluminium with lasers and provides insights on optimal settings, equipment choices, and common mistakes to avoid, ensuring high-quality results.

What Are the Applications of Fiber Laser Cutting Machines?

Fiber laser cutting machines are reshaping the landscape of various industries by providing unparalleled precision and efficiency. From manufacturing and automotive to advertising, understanding their diverse applications can lead to significant operational benefits and advancements. This article explores how these machines can be integrated into your operations for enhanced performance.

How Effectively Can a CO2 Laser Cut Metal?

Curious about the potential of CO2 lasers for metal cutting? You’re not alone! These tools have become increasingly popular for their precision and versatility. In this article, I’ll explore how they work, the types of metals they can cut, and what you need to know before diving into a purchase.

What Are the Best Ways to Cool Down a Laser Cutter During Long Cutting Jobs?

Struggling with overheating issues while using your laser cutter for extended periods? Keeping your equipment cool is essential for maintaining its performance and longevity. Discover the best ways to keep your laser cutter at optimal temperatures during long cutting sessions.

What Materials Can Be Cut with a Laser?

Laser cutting technology offers unparalleled precision, making it a go-to solution for intricate designs across numerous industries. From jewelry making to automotive parts, understanding which materials are compatible can enhance project success. This guide dives into laser cutting applications, material limitations, and essential safety precautions to help you leverage this powerful technology effectively.

What is the Service Life of a CO2 Laser Cutting Machine?

Understanding the service life of a CO2 laser cutting machine is crucial for efficient budgeting and maintenance. This guide will help you navigate the lifespan of its components, maintenance practices, and the impact of usage rates on performance.

What Makes the Handheld Laser Welding Machine the Best Choice?

If you’re considering upgrading your welding capabilities, handheld laser welding machines could be just what you need. They combine operational flexibility, cost-effectiveness, and precision, making them an excellent choice for both small and large enterprises. In this article, we’ll explore their benefits, how they operate, and why they are a game-changer in the welding industry.

How Does a Desktop Laser Welder Work?

Curious about the inner workings of a desktop laser welder? This revolutionary tool is transforming small-scale welding with precision and versatility. By utilizing a focused laser beam, it offers an efficient solution for various applications, making it ideal for everything from jewelry making to electronics manufacturing. Dive deeper to discover its components, advantages, and maintenance tips!