Have you ever thought about why IPG fiber laser cutters cost so much?

IPG fiber laser cutters are expensive due to their advanced technology. These machines provide top-notch performance and last a long time. They achieve precise cuts, which is important. Industries that value quality and reliability find them a good investment.

At first, the price of an IPG fiber laser cutter felt like a cold shock. Expensive. But details hold the real magic. These machines cut with very high precision and efficiency, not just any cutting. Imagine it as buying a top car; high initial cost, but performance and lifespan justify every penny.

I dug into what makes these machines work. Their advanced technology is crucial. It’s not just extras. IPG cutters shine because of this. Strong and long-lasting, they lower ownership costs over time. For anyone who values quality and trustworthiness, knowing these details might change how you see their worth. Maybe it’s true. Choosing an IPG fiber laser cutter could become one of the best choices for your business.

IPG fiber lasers have unmatched precision in cutting.True

IPG fiber lasers are known for their precise cutting capabilities, enhancing quality.

The durability of IPG lasers is inferior to other models.False

IPG fiber lasers are renowned for their long-lasting durability compared to others.

What Makes IPG Fiber Laser Technology Advanced?

Do you ever think about why IPG fiber lasers are so popular in the world of laser tech?

IPG fiber laser technology remains advanced. The device shows outstanding beam quality and high energy efficiency. It’s built to last. It serves in many applications. These features allow for exact cutting and welding. They also cut down maintenance needs. Maintenance needs reduce.

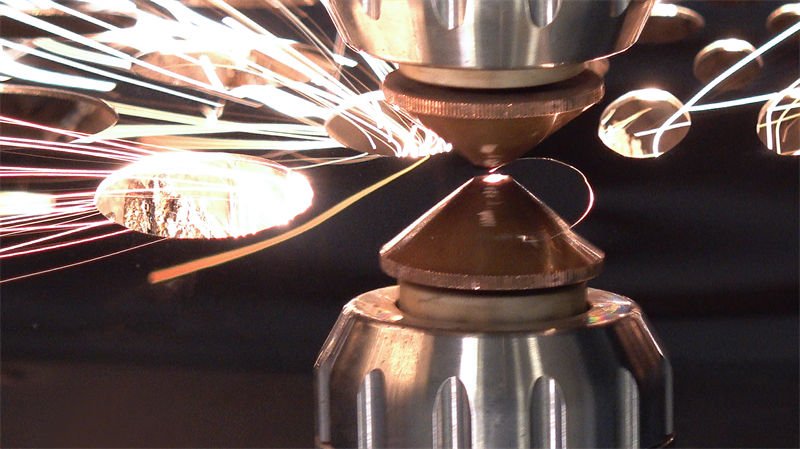

Beam Quality and Precision

I remember seeing an IPG fiber laser for the first time. Watching it felt like seeing a master artist in action. These lasers are famous for their excellent beam quality, giving the precise cuts needed in fields like aerospace and automotive. Imagine cutting metal as if slicing butter and leaving smooth edges behind. It’s pure magic! This accuracy is vital in micromachining and engraving, where every small detail counts.

Energy Efficiency and Cost Savings

IPG fiber lasers use less energy than other options. Last year, during a project, I observed their low power usage compared to our old CO2 lasers. This greatly reduced our electricity costs and matched our company’s green goals. Long-term savings make these lasers a smart, sustainable choice if you have many machines running.

Robust Construction and Longevity

Let me share their strong build with you now. If you’ve paused work when a machine breaks, you will understand this point. IPG’s solid design requires less upkeep. I’ve witnessed how this sturdiness keeps things running smoothly. This means less downtime for businesses.

Versatility Across Applications

The versatility is truly something to see. These lasers handle everything from making small medical tools to cutting large industrial pieces. In one project, we used them on thin and thick materials with ease. It felt like a Swiss Army knife, but in laser form.

Comparisons with Other Laser Technologies

Compared to lasers like CO2 or YAG, IPG fiber lasers have a compact design with more power packed in.

A quick glance at the table below highlights some comparative features:

| Feature | IPG Fiber Lasers | CO2 Lasers | YAG Lasers |

|---|---|---|---|

| Beam Quality | Superior | Good | Moderate |

| Energy Efficiency | High | Moderate | Low |

| Maintenance | Minimal | Frequent | Moderate |

| Size | Compact | Large | Medium |

It’s easy to see why IPG fiber technology1 shines. It excels in areas where old systems fall behind.

In short – not that I’m ending it here – these features make IPG fiber lasers a top choice for those needing efficiency and precision. Their advanced design and wide range of uses mean they’re prepared for the challenges of modern manufacturing.

IPG fiber lasers have superior beam quality.True

IPG fiber lasers are known for their superior beam quality, ensuring precision.

CO2 lasers are more energy efficient than IPG fiber lasers.False

IPG fiber lasers consume less power, making them more energy efficient.

Why Do IPG Lasers Justify Their Cost?

Buying IPG lasers may appear expensive initially. Their performance impresses. Their efficiency and dependability might save money over time.

IPG lasers are worth their price because they are highly efficient, reliable and need little maintenance. These benefits lead to lower running costs over time. Productivity increases and return on investment improves when compared to cheaper options.

Performance Metrics of IPG Lasers

I remember my first time using an IPG laser. It felt like moving from a regular car to a powerful sports car. The strong and precise performance stood out. IPG lasers are known for high power and energy efficiency, which translate into significant operational benefits2 for businesses needing speedy and precise operations. I always watch the power-to-consumption ratio, as this detail affects both electricity costs and cutting speeds greatly.

Reliability and Maintenance

In my experience, reliability stands out in IPG lasers. It’s like having a loyal friend who never disappoints. With fewer parts that could break and a very long lifespan, these lasers need much less maintenance than others. This translates into reduced downtime and lower maintenance costs—a critical factor for businesses looking to optimize operations.

Cost-Benefit Analysis

When deciding on buying an IPG laser, I like to calculate the costs and savings. It’s all about balancing the initial price with potential savings later in operations and maintenance. A table comparing initial investment with potential savings over five years could provide clarity:

| Factor | IPG Lasers | Competitor X |

|---|---|---|

| Initial Investment | High | Medium |

| Energy Consumption | Low | Medium |

| Maintenance Costs | Low | High |

| Downtime | Minimal | Frequent |

Understanding these factors explains the investment. Sometimes, spending more first results in really good savings later.

Comparing with Other Brands

When comparing IPG lasers to other brands, such as Raycus, looking at specific performance parameters3 is crucial. Beam quality and efficiency matter a lot. Integrating the laser system seamlessly with existing operations is important; I personally find that ease of integration often trumps slightly higher energy costs.

By studying these aspects carefully, you decide if IPG lasers are worth the initial investment. Their performance, reliability, and efficiency make them a smart choice for those wanting long-term value.

IPG lasers have a higher power-to-consumption ratio.True

IPG lasers offer superior energy efficiency, reducing electricity costs.

IPG lasers require more frequent maintenance than competitors.False

IPG lasers have fewer components prone to failure, reducing maintenance.

What Are Some Cost-Effective Alternatives to IPG Fiber Lasers?

Finding cheaper options to IPG fiber lasers sometimes feels like discovering a hidden treasure for small businesses.

Cost-effective alternatives to IPG fiber lasers include brands like Raycus, JPT and MOPA lasers. These choices offer reliable performance at a lower price. They are ideal for industrial tasks like cutting and engraving. Really ideal.

Understanding the Market Landscape

Exploring the laser industry resembles a child in a candy shop – so many choices, each offering a wonderful mix of performance and price. At first, when searching for alternatives to expensive fiber lasers, I realized brands like Raycus and JPT provide great value.

| Brand | Key Features | Price Range |

|---|---|---|

| Raycus | High stability, efficiency | $$ |

| JPT | Compact, versatile | $$ |

| MOPA | Pulse duration flexibility | $$-$$$ |

These brands deliver unique benefits for various industrial needs. Once, I needed precision tools for a small project; Raycus impressed me with its high efficiency in cutting tasks4. It’s a great choice for those needing precision in tight operations. Precision matters a lot. Really!

The Technical Edge: What Makes Them Special?

Raycus and JPT have advanced with lasers that provide excellent beam quality and efficient energy use. For cost-conscious people like me, these features are valuable.

- Raycus: Its reliability is something I trust, especially for projects needing stable performance under tough conditions. Known for its stability, the brand supports consistent output even under demanding conditions.

- JPT: I like its compact design5, which offers flexibility for both detailed engraving and simple cutting tasks.

MOPA Lasers: A Flexible Option

MOPA lasers attracted me with their adjustable pulse durations. This flexibility proves vital, especially with different materials or for precise markings.

- Pulse Control: It reminds me of times when I adjusted settings for smooth finishes or detailed engravings – having control really changed everything.

- Versatility: Their ability to adapt across industries like electronics or automotive means they handle almost any challenge effectively.

These options not only match but often surpass what pricey choices offer. For budget-aware people who don’t want to give up quality, knowing what each brand provides leads to smarter choices that fit our operational goals6 perfectly.

Raycus lasers are known for high stability and efficiency.True

Raycus is praised for stability and efficiency, ideal for precision tasks.

MOPA lasers lack pulse duration flexibility.False

MOPA lasers are noted for adjustable pulse durations, enhancing flexibility.

How Do You Compare Fiber Laser Brands?

Selecting the correct fiber laser brand resembles finding a great dance partner. Balance counts. Rhythm counts. Compatibility matters.

When comparing fiber laser brands, it’s important to check laser power, precision, speed and software compatibility. Maintenance needs and cost also matter. Considering these factors helps find a brand meeting your specific operational needs.

Laser Power and Precision

Power and precision matter a lot for success. I recall getting a high-wattage laser; it sliced through materials effortlessly. However, higher energy costs followed. Faster cutting speed might mean spending more money.

| Brand | Wattage Options | Cutting Speed |

|---|---|---|

| Brand A | 500W, 1000W | 20 m/min |

| Brand B | 750W, 1500W | 25 m/min |

Software Compatibility

Imagine this: I bought a machine that did not work with my current systems. It was totally frustrating. Compatibility must always come first. Ensure that the laser’s software is compatible with your existing systems to avoid such issues. Some brands offer proprietary software that may provide enhanced features but limit integration options7 with other platforms.

Maintenance and Cost

Maintenance can surprise you just like sudden home repairs. Some brands simplify things with easy-to-find parts, while others make it tough. Long-term expenses deserve attention as maintenance frequency and associated costs can significantly impact your budget. Look for brands offering models with readily available parts to avoid higher maintenance costs8.

Speed and Efficiency

Efficiency combines speed with ease. Getting the job done without hassles counts most. Evaluate each brand’s efficiency by checking user reviews and performance metrics like average cutting time for common materials.

Reputation and Support

A brand’s reputation is its report card. Positive customer support and warranty feedback matter greatly, saving time and frustration in the long run. Brands with strong histories are the best choice, so look for those with positive feedback regarding customer support and warranty services9.

Higher wattage lasers cut materials faster.True

Higher wattage provides more energy, increasing cutting speed and precision.

Proprietary software limits integration options.True

Proprietary software often lacks compatibility with other systems, limiting integration.

Conclusion

IPG fiber laser cutters are costly due to their advanced technology, precision, energy efficiency, and durability, making them a worthwhile investment for industries prioritizing quality and reliability.

-

Explore detailed comparisons between IPG fiber and CO2 lasers to understand performance differences. ↩

-

Learn how IPG lasers enhance productivity through superior energy efficiency and reliability, impacting your bottom line. ↩

-

Explore detailed comparisons between IPG and Raycus lasers to understand key performance differences. ↩

-

Discover how Raycus lasers are used in various cutting applications and why they are preferred by small enterprises. ↩

-

Learn about the design features of JPT lasers that make them compact and versatile for different applications. ↩

-

Understand how to choose laser technology that matches your business’s operational goals and budget constraints. ↩

-

Discover how different software integrations can enhance your laser system’s capabilities. ↩

-

Learn about maintenance costs to better forecast your total cost of ownership. ↩

-

Explore customer reviews on warranty services to ensure reliable after-sales support. ↩