Ever wonder why CNC machining is the buzz in today’s manufacturing world?

CNC processing is popular in today’s market. Firstly, it has high precision and quality. The accuracy can reach a very high level and the quality is stable. Secondly, it’s efficient and cost – effective. It can produce parts quickly and reduce costs. Thirdly, it’s highly flexible to meet different design requirements.

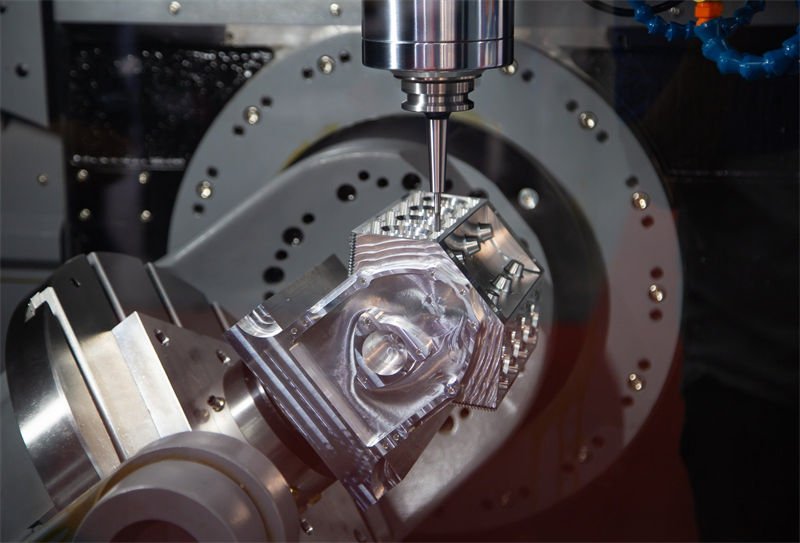

I remember visiting a factory for the first time and being amazed by the CNC machines working tirelessly, like an orchestra of precision and efficiency. Unlike traditional methods where a slight human error could lead to big mishaps, these machines churned out identical parts with near-perfect precision, every single time. It’s like having an unflappable craftsman who never gets tired. But it’s not just about accuracy; the adaptability of CNC machines is a game-changer too. Imagine needing to tweak a design—no problem! Just update the program, and you’re good to go without any major disruptions or costs. This seamless flexibility is why CNC machining has become such a staple in modern manufacturing.

CNC machining achieves dimensional accuracy within ±0.01mm.True

CNC machines use precise computer programs to control tool movements, ensuring high accuracy.

Traditional machining is faster than CNC machining.False

CNC machines have higher spindle speeds and feed rates, reducing machining time.

How Does CNC Machining Ensure High Precision?

Ever wondered how CNC machining achieves its legendary precision? This technology has become a cornerstone in industries needing ultra-accurate components. Let me take you on a journey through its intricacies.

CNC machining achieves high precision through computer-controlled operations that meticulously guide tool paths, ensuring exact dimensional accuracy and exceptional surface quality. By minimizing human error, CNC systems consistently produce intricate components with tolerances as tight as ±0.01mm, critical for fields like aerospace and medical device manufacturing.

The Role of Computer-Controlled Operations

You know those moments when you’re trying to assemble furniture, and even a tiny misalignment makes you question your life choices? CNC (Computer Numerical Control) machining is like the superhero that swoops in to save the day, ensuring everything fits perfectly. With CNC, every movement of the machine is orchestrated by pre-programmed software, like a symphony conducted by a maestro. It’s all about precision, reducing the room for human error and ensuring each part is crafted exactly as intended. Just imagine trying to manually shape an intricate piece for an aerospace project1—one slip, and it could be disastrous!

Dimensional Accuracy and Tolerances

I remember when I tried baking for the first time—every gram mattered, or the cake would end up as either a brick or a gooey mess. Similarly, CNC machining works with such precision that it can hold tolerances as tight as ±0.01mm. This isn’t just impressive—it’s vital for industries like medical device production, where a perfect fit isn’t just a nice-to-have; it’s a must-have for safety and functionality. By minimizing human error, CNC machining allows for a level of consistency and precision that’s simply unmatched.

Enhancing Surface Quality

Picture this: a surface so smooth you could almost see your reflection in it. That’s what CNC machining can achieve by optimizing tool paths and cutting parameters. It’s not just about looking good; this level of surface quality is crucial for performance in industries like automotive manufacturing. A smoother surface can mean better performance and longer lifespan for parts.

Stability and Repeatability

Once upon a time, in my woodworking phase, I learned that stability is key—especially when you want every drawer to open smoothly without a hitch. CNC machining brings this level of reliability to high-volume production with its robust control systems that ensure consistency across varying conditions. Think about watch manufacturing2—every gear must be identical to ensure seamless assembly and precise timekeeping. Thanks to fault diagnosis systems, CNC machines can preemptively address potential issues, keeping everything running smoothly and reducing costly downtimes.

In conclusion, while traditional methods might buckle under the pressure of complex or repetitive tasks, CNC machining thrives, delivering unmatched precision through its advanced technology and meticulous control systems. Whether you’re crafting tiny gears for watches or intricate components for aerospace, CNC ensures that everything clicks into place just right.

CNC machining ensures ±0.01mm dimensional accuracy.True

CNC controls tool movement precisely, achieving high dimensional accuracy.

Traditional methods achieve better surface quality than CNC.False

CNC optimizes tool paths for superior surface finish compared to traditional methods.

Why is CNC Machining More Efficient Than Traditional Methods?

Have you ever wondered why CNC machining is the go-to choice for modern manufacturing?

CNC machining is more efficient than traditional methods because it offers superior precision, automation, and flexibility. It minimizes human error, accelerates production, and easily adapts to design changes, making it perfect for complex projects.

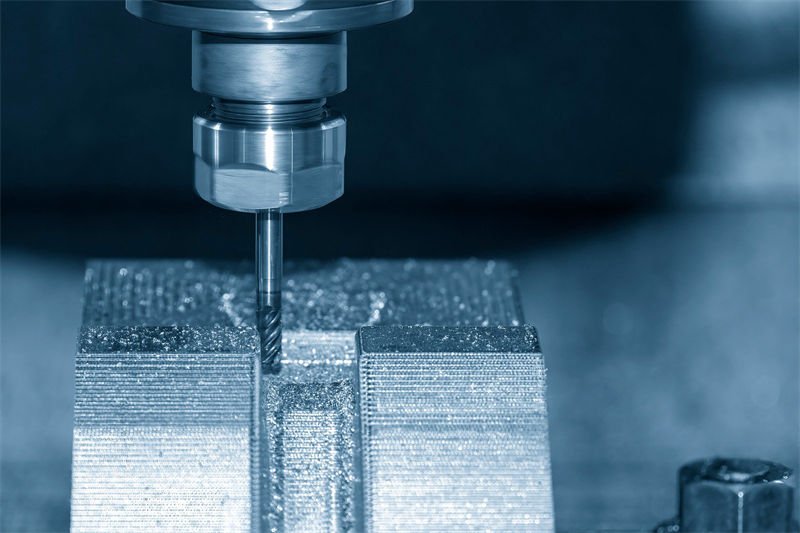

Precision and Quality Control

I remember the first time I watched a CNC machine in action. It was like witnessing a symphony of precision. These machines are programmed to follow detailed instructions, ensuring every cut, every angle is just right. Unlike traditional methods that rely on the operator’s skill, CNC machines consistently deliver high-quality finishes. It’s like baking cookies with a timer versus guessing when they’re done—the timer (or CNC) just gets it right every time. For industries like aerospace or medical devices, where precision is non-negotiable, CNC‘s ability to achieve tolerances as tight as ±0.01mm is a game-changer.

One of the primary reasons CNC machining is more efficient than traditional methods is its unparalleled precision. Unlike manual operations that heavily depend on the skill level of operators, CNC machines follow exact pre-programmed instructions. This leads to consistent outcomes and high-quality finishes, which are crucial in industries such as aerospace and medical devices. For example, CNC machining can achieve dimensional tolerances of ±0.01mm, a feat that’s challenging with manual techniques. This precision ensures a high degree of consistency3 in mass production.

Automation and Labor Efficiency

Picture this: A factory floor where machines hum along smoothly, requiring minimal human intervention. That’s the magic of CNC machining. Once set up, these machines can run independently for hours, even days. I used to think about how much more I could get done with an extra set of hands—CNC provides that and more.

CNC machining reduces the need for constant human oversight by automating the entire process. Once the program is set, machines can operate independently for extended periods, even 24/7 in some cases. This not only boosts production rates but also cuts down labor costs significantly. Traditional machining requires skilled workers to manually control tools and make real-time adjustments, which can be time-consuming and less efficient.

While traditional methods need skilled operators constantly adjusting the tools, CNC frees up labor to focus on higher-level tasks, enhancing overall efficiency and reducing costs.

The automation provided by CNC technology allows operators to oversee multiple machines simultaneously, optimizing labor utilization4.

Speed and Flexibility

Speed isn’t just about how fast you can go—it’s about how quickly you can adapt. CNC machines excel here too.

They operate at high speeds with rapid tool changes, making production fast and flexible.

I recall working on a project where we had to adjust designs mid-way.

With CNC,

it was a matter of updating the software; no need for cumbersome retooling.

This flexibility is invaluable in industries that thrive on quick innovation cycles,

such as electronics or automotive manufacturing.

The speed at which CNC machines operate is another factor contributing to their efficiency.

High spindle speeds and rapid tool changes mean that CNC machines can complete tasks much faster than manual methods.

Additionally,

the flexibility of CNC systems allows for easy modifications to production processes.

When a product design changes,

manufacturers only need to update the machine’s software program rather than retool equipment.

This adaptability is especially beneficial in industries with fast-paced product development cycles,

like electronics or automotive manufacturing5.

Complex Geometries and Versatility

Have you ever tried assembling a puzzle only to find pieces that don’t quite fit? That’s what traditional methods face with complex designs.But CNC machining handles these challenges effortlessly.By performing multi-axis operations,CNC machines can create intricate designs without needing special setups.It’s like having a toolbox that adapts to every job—no matter how intricate the component—from aerospace to high-tech gadgets,CNC can handle it all seamlessly.CNC machining excels at producing complex shapes that would be incredibly difficult or impossible to achieve with traditional methods.Advanced CNC systems can perform multi-axis operations,machining intricate designs from various angles without needing special fixtures or additional setups.This capability is essential for producing components with complex geometries,such as those found in aerospace and high-tech manufacturing.The ability to handle such complexity6with ease further underscores the efficiency of CNCTechnology.By reducing waste,minimizing errors,and speeding up production,CNC machining significantly outshines traditional methods.It ensures consistent quality across large batches,making it indispensable in today’s manufacturing landscape.

CNC machining achieves ±0.01mm precision.True

CNC machines are designed to control dimensional errors within ±0.01mm.

Traditional machining is faster than CNC.False

CNC machining typically shortens time by 30%-50% compared to traditional methods.

How Does CNC Machining Adapt to Design Changes?

Ever wonder how modern manufacturing keeps up with ever-changing design demands? Enter CNC machining, a true game-changer in adaptability.

CNC machining adapts to design changes by making programmable adjustments, allowing for quick updates without the need for extensive retooling. This adaptability is perfect for rapid prototyping and iterative designs, especially in industries that frequently require modifications.

Programmable Flexibility

Imagine being in the middle of a project and discovering a design change that throws everything off course. I’ve been there, frantically trying to figure out a solution. With CNC machining, the process becomes a lot less stressful. The beauty lies in its programmability—engineers can make adjustments directly through computer code, sidestepping the time-consuming physical changes traditional methods demand. When working on a new electronic device, for instance, if the housing dimensions need tweaking, it’s as simple as updating the CNC program7 to match these new specifications. This not only saves valuable time but also minimizes waste, avoiding the trial-and-error approach that can be both costly and frustrating.

Rapid Prototyping

I remember the rush of seeing a new prototype take shape—it’s exhilarating. With CNC machining, this excitement is magnified because you can quickly iterate designs during the product development8 phase. For industries like automotive or aerospace, where components must meet rigorous standards, CNC machines offer a way to rapidly produce prototypes with precision. Plus, they can handle complex shapes that would stump traditional methods, allowing designers to explore creative possibilities without being boxed in by manufacturing constraints.

Cost Efficiency

Keeping costs down is always a priority in my projects, and CNC machining delivers here too. The ability to adapt without heavy manual intervention means industries like consumer electronics, which face constant design updates due to market demands9, can adjust production lines swiftly and cost-effectively. Once programmed, CNC machines churn out parts consistently with minimal oversight—ideal for large-scale operations where maintaining uniformity across thousands of units is crucial.

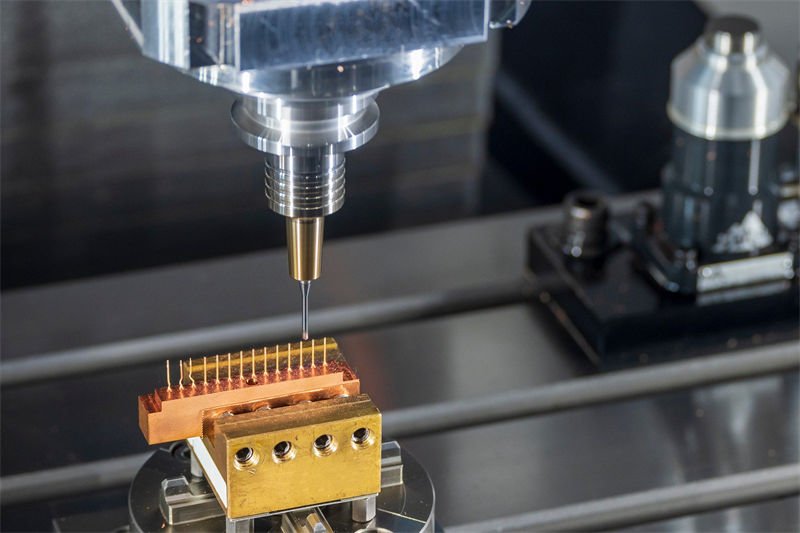

Multi-Material Compatibility

I’ve seen projects where a switch in materials was necessary to enhance performance or reduce costs. CNC machines shine in these scenarios because they’re versatile enough to handle various materials—from metals and plastics to composites. Whether it’s shifting from metal to a biocompatible polymer in medical devices or another material transition, CNC machining accommodates these changes seamlessly through tooling adjustments.

Through advanced software and multi-axis capabilities, CNC machining remains a cornerstone of modern manufacturing, offering the flexibility needed to thrive in dynamic product development environments.

CNC machining achieves ±0.01mm dimensional accuracy.True

CNC machining controls tool movement via computer programs for high precision.

Traditional methods provide better surface quality than CNC.False

CNC machining optimizes tool paths and cutting parameters for superior finish.

How Does CNC Machining Guarantee Consistency in Production?

Ever wondered how a machine could consistently produce perfection? Let’s dive into the magic of CNC machining and its secrets to flawless production.

CNC machining ensures consistency through meticulous computer control, repeatability, and state-of-the-art error detection. By automating processes, it reduces human error and maintains exceptional standards in mass production.

The Role of Computer Control in Precision

Imagine having a tool that performs with unwavering precision, every single time. That’s what CNC, or Computer Numerical Control, does—it takes the guesswork out of machining. I remember the first time I saw a CNC machine in action; it was like watching a choreographed dance, with each move precisely dictated by pre-programmed software. Whether crafting parts for an aircraft or a tiny gear for a watch, CNC machines eliminate human error by precisely controlling every cut and movement. In the aerospace industry10, for example, where tolerances are as tight as ±0.01mm, CNC machining shines, ensuring every component fits just right.

Repeatability and System Stability

I once toured a watch manufacturing facility and was amazed at how identical each gear was—down to the tiniest detail. This is the magic of CNC machining’s repeatability. It’s like having a reliable friend who never forgets a single step in a recipe, ensuring perfect results every time. The stability of these machines is remarkable, too. They operate consistently even when conditions vary, thanks to their robust design and regular updates that keep everything running smoothly through advanced control systems11.

Advanced Error Detection and Automation

Modern CNC machines are like having an extra pair of eyes that never blink. They’re equipped with advanced error detection systems that catch potential issues before they become problems, much like how my car alerts me when it’s time for an oil change. For instance, sensors can monitor tool wear and notify operators when it’s time for maintenance, keeping production flowing without a hitch. This automation means machines can work around the clock with minimal oversight—a game-changer for batch production of small metal parts12.

Flexibility and Adaptability

One of my favorite things about CNC machining is its flexibility. It’s like having a wardrobe full of clothes that adapt to any occasion without needing to buy new outfits. When product designs change, all it takes is a quick software update—no need for major hardware overhauls. This is especially handy in industries like electronics manufacturing where design tweaks are frequent. With multi-axis machining13, complex shapes are crafted with ease, meeting diverse design needs without compromising quality.

In essence, CNC machining’s consistency is no accident. It’s the result of sophisticated technology that combines computer control, repeatability, and automation to deliver high-quality outputs with incredible uniformity across vast production scales. It’s fascinating to think how such precise machinery ensures every intricate component meets exact specifications time and again.

CNC machining achieves tolerance of ±0.01mm.True

CNC machines use computer programs to control tool movement, ensuring high precision.

Traditional methods match CNC machining in surface quality.False

CNC optimizes tool paths for superior surface finish compared to traditional methods.

Conclusion

CNC machining is popular for its precision, efficiency, and adaptability, enabling high-quality production of complex shapes while minimizing human error and reducing costs in modern manufacturing.

-

Explore how CNC machining’s precision supports aerospace innovations. ↩

-

Discover the role of CNC in producing consistent watch components. ↩

-

Explore how CNC maintains uniformity across products, crucial for quality assurance. ↩

-

Learn how automation optimizes labor use and boosts production efficiency. ↩

-

Discover how CNC easily adjusts to new designs, enhancing manufacturing agility. ↩

-

Understand CNC’s capability to produce intricate shapes efficiently. ↩

-

Learn how CNC programming updates accommodate design changes efficiently. ↩

-

Discover why rapid prototyping is crucial in product development. ↩

-

Understand how market demands drive frequent product design changes. ↩

-

Discover how CNC achieves tight tolerances in aerospace parts. ↩

-

Learn about the stability features in CNC control systems. ↩

-

Explore CNC’s role in efficient batch production of metal parts. ↩

-

Understand how multi-axis CNC machining handles complex shapes. ↩