Have you ever wondered why some laser equipment comes with a hefty price tag? Let’s dive into the world of Bodor Laser Equipment, where innovation meets investment.

Bodor laser equipment is expensive due to its advanced technology, precision engineering, high-quality materials, and comprehensive customer support. These factors ensure superior performance and longevity, making it a valuable investment for businesses seeking reliable laser solutions.

While we’ve touched on the reasons behind Bodor’s pricing, there’s so much more to uncover. Join me as we explore the specific features that set Bodor apart and determine if the investment truly pays off.

Bodor lasers use CO2 technology for cutting.False

Bodor lasers primarily use fiber laser technology, not CO2, for efficiency.

What Technologies Make Bodor Lasers Stand Out?

Bodor lasers are renowned for their innovative technology, but what sets them apart in the competitive laser market?

Bodor lasers stand out due to their use of fiber laser technology, automatic focusing, and intelligent control systems, ensuring precision and efficiency. These features not only enhance performance but also streamline operations for diverse industrial applications.

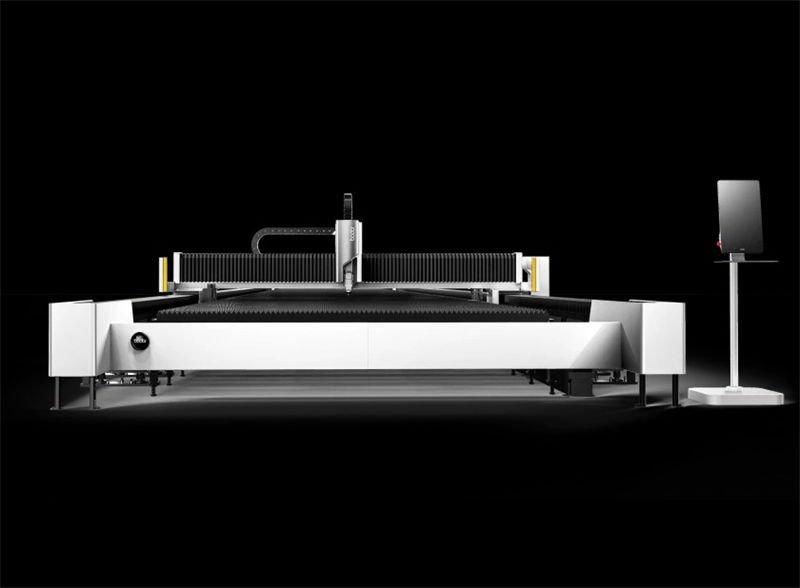

Fiber Laser Technology

One of the core technologies that make Bodor lasers unique is their integration of fiber laser technology. This innovation allows for higher energy efficiency and superior beam quality compared to traditional CO2 lasers. Fiber lasers require less maintenance and offer longer lifespans, making them cost-effective in the long run. Their compact design also contributes to a smaller footprint, which is beneficial for workshops with limited space.

Automatic Focusing

Automatic focusing is a significant advancement that enhances the precision and ease of use of Bodor lasers. This feature automatically adjusts the focal length to suit different materials and thicknesses, reducing manual intervention and minimizing errors. The result is a faster setup process and improved cut quality across various materials, from thin sheets to thicker metals.

Intelligent Control Systems

Bodor has incorporated intelligent control systems into their laser equipment to facilitate user-friendly operation. These systems often include touch-screen interfaces with intuitive software that simplifies programming and operation. Users can easily input parameters and monitor operations in real-time, which increases productivity and reduces downtime. Additionally, these systems can store previous settings, allowing for quick recall when processing similar jobs.

Advanced Cooling Systems

To maintain optimal performance and extend the life of the equipment, Bodor lasers are equipped with advanced cooling systems. These systems efficiently dissipate heat generated during laser operations, preventing overheating and ensuring consistent performance even during prolonged use. This reliability is particularly important in high-demand industrial settings where equipment uptime is critical.

Safety Features

Safety is paramount in industrial environments, and Bodor does not compromise on this aspect. Their lasers come with multiple safety features such as enclosed cutting areas, emergency stop buttons, and smoke extraction systems. These features protect operators and ensure compliance with industry safety standards.

Overall, Bodor’s commitment to integrating state-of-the-art technologies not only enhances the performance of their laser systems but also positions them as leaders in innovation within the industry. These technological advancements allow businesses to achieve high precision and efficiency, which are crucial for maintaining a competitive edge in today’s fast-paced market.

Fiber lasers have higher energy efficiency than CO2 lasers.True

Fiber lasers are more energy-efficient, requiring less power and maintenance.

Bodor lasers lack advanced cooling systems for performance.False

Bodor lasers include advanced cooling to maintain optimal performance.

How Does Bodor’s Quality Control Impact Pricing?

Bodor’s unwavering commitment to quality control significantly influences the pricing of its laser equipment.

Bodor’s stringent quality control processes ensure every laser product meets high standards, contributing to its premium pricing. These measures enhance product reliability and longevity, appealing to businesses willing to invest in superior technology.

Unpacking Bodor’s Quality Assurance Process

At the heart of Bodor’s pricing structure lies a robust quality control framework designed to ensure that every piece of equipment meets the highest standards of reliability and performance. This meticulous approach involves multiple stages of inspection and testing, from initial material selection to final product assembly.

-

Material Selection and Inspection

Bodor places great emphasis on using high-quality materials sourced from reputable suppliers. Each batch undergoes rigorous inspection to check for defects or inconsistencies that could compromise the equipment’s performance.

-

Precision Engineering and Testing

Throughout the manufacturing process, precision engineering plays a crucial role. Bodor employs advanced testing techniques such as laser alignment checks, cutting accuracy assessments, and thermal stability tests to guarantee each unit’s operational excellence.

-

Final Product Evaluation

Before leaving the factory, each laser machine undergoes a comprehensive evaluation to ensure it functions as expected under various conditions. This includes stress testing to simulate real-world usage scenarios, ensuring the product can withstand rigorous operational demands.

The Cost of Excellence

The financial implications of maintaining such a detailed quality control process are significant. However, these investments yield a product that not only performs exceptionally well but also has a longer lifespan, reducing long-term costs for the user. In essence, Bodor’s quality control elevates the initial purchase price but offers substantial value over time.

Customer Perspective: Is It Worth It?

For businesses, investing in Bodor laser equipment means paying a premium upfront for unmatched reliability and durability. Companies can expect fewer downtimes, lower maintenance costs, and higher productivity—factors that justify the higher price point for many.

To further explore the impact of Bodor’s quality control on pricing, you may consider looking into how other industry leaders manage their quality assurance processes and their effects on pricing. Check out similar practices in competitive sectors1 for broader insights.

Bodor's quality control increases product reliability.True

Bodor's stringent processes ensure high standards, enhancing reliability.

Bodor's pricing is unaffected by quality control measures.False

Quality control significantly influences Bodor's premium pricing structure.

Is Bodor’s Customer Support Worth the Cost?

Bodor Laser’s comprehensive customer support is a key factor in its premium pricing. But is it worth it?

Bodor’s customer support offers value through 24/7 assistance, technical expertise, and tailored solutions, justifying its cost by ensuring minimal downtime and maximizing productivity for users.

Understanding Bodor’s Customer Support Offerings

Bodor Laser places a significant emphasis on customer support, which is not only a key selling point but also a crucial component in its overall pricing strategy. The company provides around-the-clock assistance, ensuring that users have access to technical expertise2 whenever needed. This can be particularly beneficial in industries where laser equipment is central to operations, as any downtime could result in substantial losses.

Key Features of Bodor’s Customer Support

-

24/7 Assistance: Bodor offers global support at any hour, ensuring customers can resolve issues promptly.

-

Technical Expertise: Their support team comprises highly trained professionals who can provide solutions and guidance on a range of technical issues.

-

Tailored Solutions: Bodor understands that each business has unique needs; therefore, they offer personalized support plans that cater specifically to different operational requirements.

Evaluating the Cost-Benefit of Bodor’s Support

To determine if Bodor’s customer support is worth the cost, consider the potential savings from reduced downtime and enhanced productivity. For example, having immediate access to technical help can prevent prolonged disruptions, thereby safeguarding revenue streams.

Moreover, customer testimonials3 often highlight the efficacy of Bodor’s support in troubleshooting complex issues swiftly, which not only saves time but also enhances user satisfaction and loyalty.

Comparing with Industry Standards

When comparing Bodor’s support with other laser equipment providers, it’s important to analyze:

- Response Time: How quickly are queries addressed?

- Expertise Level: What qualifications do the support staff hold?

- Customization Options: Are there bespoke solutions available to meet specific business needs?

In conclusion, while Bodor’s customer support adds to the overall cost, its benefits in terms of operational efficiency and peace of mind often outweigh the expense for many businesses. However, it’s essential for potential buyers to weigh these factors against their specific operational needs and budget constraints.

Bodor offers 24/7 global customer support.True

Bodor provides around-the-clock assistance to ensure prompt issue resolution.

Bodor's support team lacks technical expertise.False

Bodor's support team comprises highly trained professionals for technical issues.

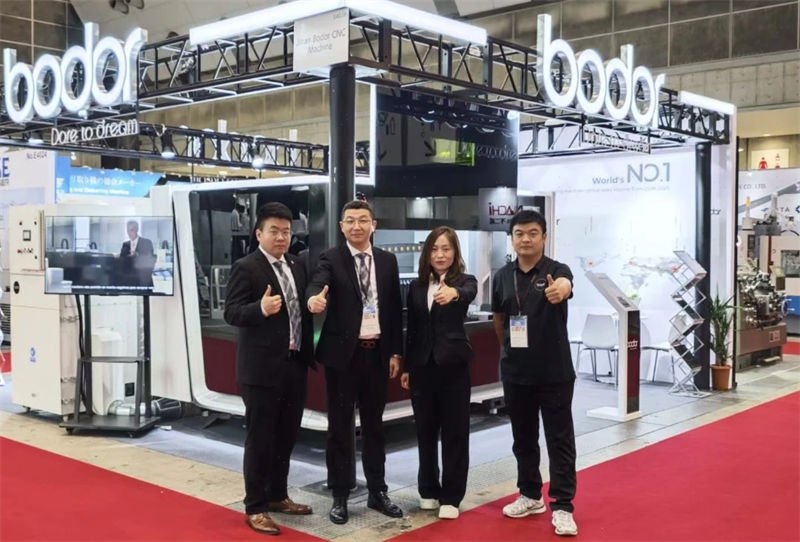

How Do Bodor Lasers Compare to Competitors?

Bodor Laser equipment is known for its premium quality, but how does it stack up against the competition?

Bodor lasers excel in precision, durability, and customer service compared to competitors. Their advanced technology and robust engineering provide superior cutting accuracy and longevity, often justifying the higher investment.

Technological Advancements

Bodor lasers leverage cutting-edge technology like autofocus systems, high-speed motors, and efficient cooling mechanisms. These innovations enhance performance by delivering faster, more precise cuts. Compared to competitors, Bodor’s continuous investment in R&D keeps them at the forefront of laser technology, ensuring that they offer some of the most advanced machines available.

Build Quality and Durability

One of the distinguishing features of Bodor lasers is their robust construction. They use high-grade materials that offer enhanced durability and resistance to wear and tear. While some competitors may cut costs with cheaper materials, Bodor maintains strict standards that ensure their equipment remains operational over extended periods without compromising performance.

Performance Comparison

| Feature | Bodor Lasers | Competitors |

|---|---|---|

| Precision | High | Medium to High |

| Speed | Very Fast | Fast |

| Durability | Long-lasting | Varies |

| Maintenance | Low | Medium to High |

Customer Support Excellence

Bodor is renowned for its comprehensive customer support4, providing extensive training, troubleshooting assistance, and maintenance services. Many competitors offer limited support, which can lead to prolonged downtimes and increased costs. Bodor’s proactive support system ensures users can maximize uptime and efficiency.

Cost vs. Value

Although Bodor’s initial costs are high, the long-term value they provide often outweighs these costs. Their superior technology, reliability, and support translate into reduced operational costs over time. Competitors may offer lower upfront prices but often require more frequent maintenance or have shorter lifespans.

By examining these factors, it’s clear that Bodor’s higher pricing is a reflection of its superior quality and service, making it a strong contender in the laser equipment market.

Bodor lasers offer the fastest cutting speed.True

Bodor lasers are noted for their very fast cutting speeds, surpassing competitors.

Competitors provide better customer support than Bodor.False

Bodor is renowned for its comprehensive customer support, unlike many competitors.

Conclusion

Bodor’s advanced technology and robust support justify its price for many businesses. Take time to assess your needs against these benefits to see if it’s right for you.

-

Discover how top industries maintain quality standards and their pricing impact.: Quality control is a process that uses best practices, strict adherence to standards, and specifications to deliver products without defects. ↩

-

Discover how Bodor’s technical expertise ensures optimal equipment performance.: Bodor Online Service · Problem Feedback. Contact for Timely Repairs · Voice@bodor.com. Answers for Your Needs · Instant Messaging. +86-531-88690051. ↩

-

Read customer reviews on Bodor’s effective support solutions.: Their investment in a Bodor laser cutting machine has significantly increased their production speed and reduced their costs, leading to more satisfied … ↩

-

Explore how Bodor’s support enhances user experience and reduces downtime.: laser cutting machine,metal laser cutting machine ; (630) 339-9088 ; 1690 N Plum Grove Road, Schaumburg IL 60173 ; sales@bodor.com … ↩