Have you ever wondered how some products seem to carry information with such clarity and durability?

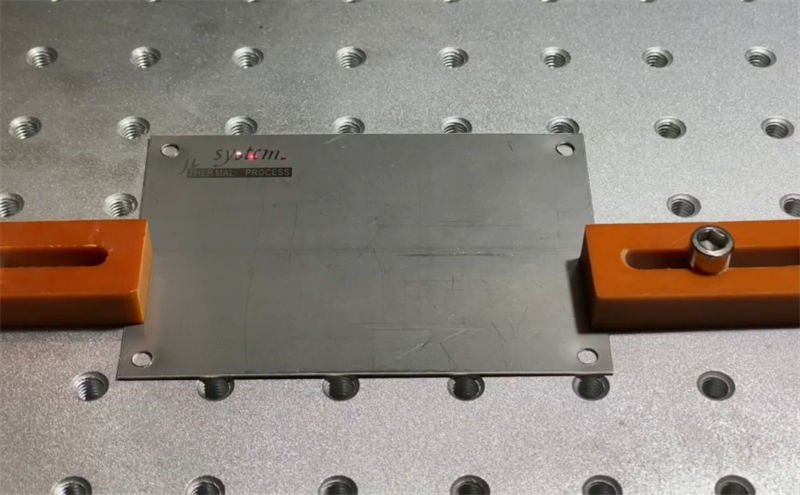

Hardware products, electronic components, integrated circuits, auto parts, and plastic products all benefit from laser marking machines, which can be used for identification, tracking, personalized engraving, etc. In addition, surgical instruments and implants in the medical industry use them to mark key information, ensuring safety and traceability and improving quality control and brand image.

While this quick overview gives you a glimpse, let’s dive deeper into the fascinating world of laser marking technology and its impact across various sectors.

Laser marking improves medical device compliance.True

Laser marking ensures traceability and durability of device information.

How Does Laser Marking Improve Medical Device Compliance?

Laser marking plays a pivotal role in enhancing medical device compliance by ensuring traceability and durability of crucial information.

Laser marking can accurately mark legal information such as the specification, model, batch number, and expiration date of medical devices, making the content complete and clear, like the serial number and production date of a pacemaker. It has strong durability and can resist the influence of medical environmental factors. It can also be connected to a database for easy life-cycle management and traceability to ensure compliance.

Importance of Traceability in Medical Devices

In the medical industry, traceability is not just a regulatory requirement but a fundamental aspect of patient safety and product efficacy. Laser marking enhances traceability by offering a reliable method to imprint essential information such as unique device identifiers1, serial numbers, and batch codes on medical devices. This ensures that each device can be accurately traced back through the supply chain.

Meeting Regulatory Standards

Laser marking technology aids in compliance with various international standards such as the FDA’s Unique Device Identification (UDI) system. The UDI system requires medical devices to bear a unique identifier that is both human-readable and machine-readable. Laser marking meets these requirements by providing high-contrast, precise markings that are resistant to wear and tear, ensuring they remain legible throughout the device’s lifespan.

Enhancing Durability and Legibility

The permanence of laser markings is critical for medical devices that undergo harsh sterilization processes. Traditional methods like ink printing can fade or become illegible, compromising compliance. Laser marking provides a durable solution as it engraves information directly onto the surface without using chemicals or consumables, reducing the risk of tampering or fading.

Application in Various Medical Devices

Different types of laser marking machines cater to specific needs within the medical sector:

- Fiber Laser Markers: Ideal for marking surgical instruments, orthopedic implants, and dental devices due to their ability to engrave metal surfaces with precision.

- CO2 Laser Markers: Suitable for non-metal components like plastic casings and packaging materials.

- UV Laser Markers: Perfect for ultra-fine markings on delicate materials such as catheters and other polymer-based devices.

Supporting Data Integrity

The integration of laser marking with digital data management systems2 helps ensure data integrity. By linking marked identifiers with digital records, healthcare providers can track usage patterns, maintenance histories, and recall information efficiently. This seamless integration enhances operational efficiency and minimizes errors in device handling.

Laser marking ensures medical device traceability.True

It provides permanent, precise markings crucial for tracking devices.

Ink printing is more durable than laser marking.False

Laser marking is more resistant to wear, ensuring lasting legibility.

Why Are Electronics Manufacturers Adopting Laser Marking?

In the fast-paced world of electronics manufacturing, precision and traceability are key. Laser marking offers both, making it a preferred choice for many.

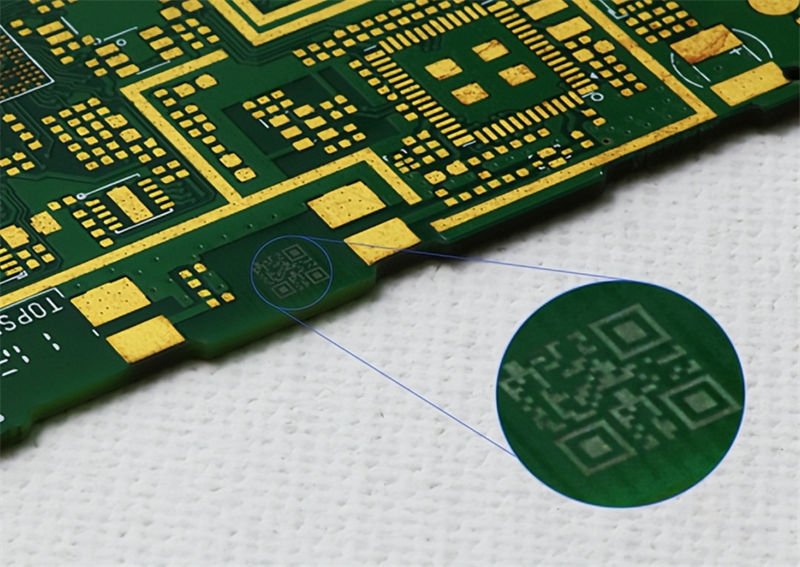

Electronic product manufacturers use laser marking. Firstly, it has high precision and can clearly mark information on tiny components. Secondly, the marking is durable and can withstand various environments without wearing or fading. At the same time, it is non-contact processing and will not damage components. It can also perform automated high-speed marking and mark complex patterns and QR codes, which is beneficial for tracking and anti-counterfeiting.

Precision and Versatility

One of the primary reasons electronics manufacturers are turning to laser marking is its unparalleled precision and versatility3. Laser technology allows manufacturers to imprint intricate designs, barcodes, and alphanumeric codes with high accuracy, regardless of the material. This capability is crucial in electronics, where components are often small and require detailed markings.

Speed and Efficiency

Laser marking systems are known for their speed, which significantly reduces production times. A laser marker can quickly imprint necessary information on electronic components without the need for additional processing steps. This efficiency not only speeds up production but also reduces operational costs, making it an economically attractive option.

| Advantages | Details |

|---|---|

| Speed | Rapid marking reduces production time. |

| Cost-effective | Eliminates need for additional processing steps. |

Durability and Longevity

Markings made by lasers are incredibly durable, resisting wear and tear over time. This durability is particularly valuable in the electronics industry, where components may face various environmental conditions. Permanent markings ensure that product information remains readable throughout the product’s life cycle.

Enhanced Traceability

With increasing regulatory requirements, traceability in electronics manufacturing has become more critical than ever. Laser marking enables manufacturers to add unique identifiers such as serial numbers and QR codes, facilitating easy tracking of components from production through to end-user delivery. This enhances both inventory management and post-sales service.

For more information on how this technology integrates into existing systems, check out our section on application areas and recommendations4 for different types of laser markers.

Environmental Considerations

Laser marking is a non-contact process that does not require additional chemicals or consumables, making it an environmentally friendly choice. As sustainability becomes a priority for many companies, adopting eco-friendly technologies like laser marking aligns with broader corporate responsibility goals.

Laser marking enhances traceability in electronics.True

Laser marking allows for precise, durable markings, aiding traceability.

Laser marking requires additional chemicals for durability.False

Laser marking is chemical-free, using only laser technology for durability.

What Role Does Laser Marking Play in the Automotive Industry?

Laser marking is revolutionizing the automotive industry by enhancing traceability, compliance, and product customization.

In the automotive industry, laser marking plays a significant role. It can permanently mark models, batches, etc. on parts for easy quality tracing and management. On decorative parts, personalized patterns can be engraved to enhance aesthetics and brand recognition. It is also used for interior part identification, such as marking the functions of seat adjustment buttons to enhance user experience.

Enhancing Traceability and Compliance

Laser marking is pivotal in the automotive sector for maintaining rigorous traceability and compliance standards. Each component within a vehicle often requires unique identification numbers and codes for tracking through manufacturing and supply chains. This need is efficiently met by fiber laser markers5, which engrave detailed information without compromising the integrity of the part.

Traceability is not just about tracking; it’s also about safety. In case of a recall, knowing exactly which batch or series a part belongs to can prevent widespread issues. Compliance with international safety standards is non-negotiable in the automotive industry, and laser marking ensures that these standards are consistently met by providing legible and durable engravings on materials ranging from metals to plastics.

Customization and Personalization

With consumers increasingly demanding personalized experiences, automotive manufacturers are turning to laser marking for customization. From custom-engraved dashboard panels to personalized seatbelt buckles, CO2 laser markers6 allow manufacturers to offer bespoke options without compromising on speed or cost efficiency.

This capability extends beyond aesthetics; for instance, personalized markings can include functional information like calibration settings or maintenance schedules, enhancing user experience and vehicle performance.

Material Versatility and Efficiency

Laser marking’s versatility across various materials is particularly beneficial for the automotive industry. Materials like steel, aluminum, plastic, and glass are frequently used in vehicle manufacturing. UV laser markers7 are ideal for ultra-fine marking, especially on delicate components like airbags or electronic circuits, where precision is paramount.

Efficiency is another advantage; laser marking machines operate quickly and reduce downtime compared to traditional methods like inkjet printing or embossing. This speed not only boosts productivity but also helps in maintaining lean manufacturing processes.

| Type of Laser Marker | Ideal For | Advantages |

|---|---|---|

| Fiber Laser Marker | Metals, detailed component marking | Durable, precise engravings |

| CO2 Laser Marker | Plastics, glass, customization tasks | Versatile, cost-effective |

| UV Laser Marker | Fine marking on delicate components | High precision, low impact |

The adaptability of laser technology allows manufacturers to switch seamlessly between different marking tasks without the need for extensive retooling or adjustments. This flexibility is crucial in an industry characterized by rapid technological advancements and evolving consumer preferences.

Laser marking ensures automotive traceability and compliance.True

Laser marking provides permanent, precise markings for traceability and compliance.

CO2 lasers are not used for automotive customization.False

CO2 lasers are used for customization, offering bespoke options efficiently.

Can Personalized Products Benefit from Laser Marking Technology?

In a world increasingly leaning towards customization, laser marking technology emerges as a key player.

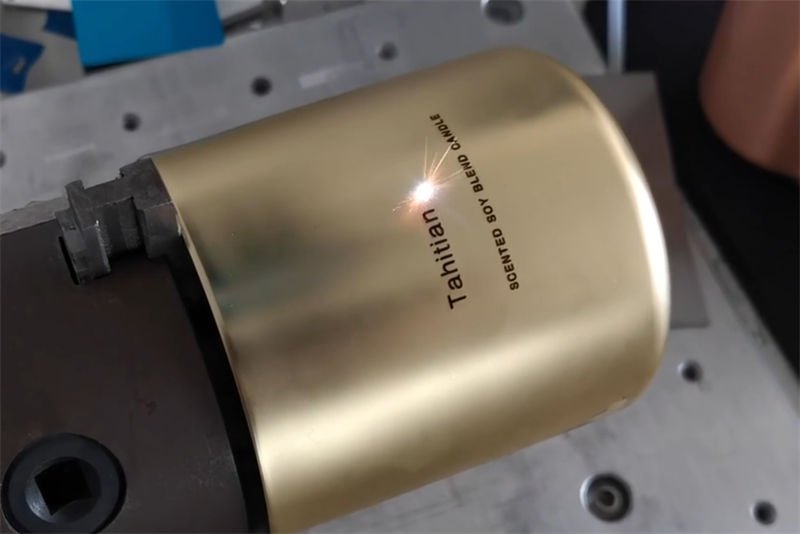

Yes,Personalized products can greatly benefit from laser marking technology. It has high precision and can engrave names, patterns, dates, etc. on custom jewelry. In the gift field, it can create unique marking effects on wooden, leather, and ceramic products according to the design, increasing individuality and commemorative value. Its flexibility can also quickly adapt to different personalized needs.

Why Laser Marking is Ideal for Personalization

Personalization has become a significant trend, with consumers seeking unique products that reflect their identity. Laser marking8 stands out as an optimal solution due to its ability to produce clear, precise markings on various materials. Unlike traditional methods such as screen printing or engraving, laser marking offers:

- Durability: The marks made by lasers are resistant to wear and tear, making them ideal for everyday items.

- Precision: Whether it’s a small piece of jewelry or a large sign, lasers can handle intricate details without sacrificing quality.

- Versatility: From metals to plastics and even fabrics, laser marking can be used on a wide range of materials.

Applications in Personalized Products

The versatility of laser marking opens up numerous possibilities for creating personalized products:

| Product Type | Materials Used | Laser Marking Advantages |

|---|---|---|

| Jewelry | Gold, Silver, Stainless Steel | Intricate designs without damaging the material |

| Electronics | Plastics, Metals | Branding and custom designs on casings |

| Home Décor | Wood, Glass | Elegant patterns and text |

Jewelry: Laser marking is perfect for engraving names or messages on rings and necklaces.

Electronics: Custom phone cases can be marked with personal photos or designs using CO2 lasers.

Home Décor: Unique patterns can be etched onto glassware or wooden frames, enhancing their aesthetic appeal.

Economic and Creative Impacts

The use of laser marking in personalization is not just about aesthetics; it also has economic benefits:

- Cost Efficiency: Despite the initial investment in laser marking machines, the reduced need for consumables and faster production times can lower overall costs.

- High Profit Margins: Personalized items often sell at a premium, increasing potential profit margins for businesses.

- Innovation: The precision and flexibility of laser marking encourage creative designs that might be challenging with other methods.

In conclusion, while this technology’s precision and durability make it highly suitable for personalized products, it’s essential to choose the right type of laser for specific materials and applications.

Laser marking is less durable than screen printing.False

Laser marking is more durable, resisting wear and tear effectively.

Laser marking offers precise customization on diverse materials.True

It provides clear, intricate markings on metals, plastics, and fabrics.

Conclusion

In summary, laser marking is not just a trend; it’s a pivotal technology that enhances product quality and brand visibility across multiple industries. Investing in laser technology can position you ahead of the competition.

-

Understand the critical role of UDI in patient safety measures.: UDIs need to be electronically documented when devices are used in patient care, so they are further available for use in patient care, device … ↩

-

Explore how digital systems enhance healthcare operations.: Improved healthcare data management offers significant benefits, including enhanced patient care, more accurate diagnoses, and increased … ↩

-

Understand how laser precision benefits electronics manufacturing.: For example, semiconductor laser marking machines can mark very small parts with a high degree of accuracy. This is a critical requirement of an electronic … ↩

-

Explore diverse applications across industries for laser markers.: It is used in the food, automotive, aerospace, medical, electronics, advertising and semiconductor manufacturing industries among many others. ↩

-

Learn how fiber lasers enhance traceability in automotive parts.: Laser marking automotive parts is a versatile and permanent process that helps identify and track components during and even after the manufacturing process. ↩

-

Explore how CO2 lasers enable automotive personalization.: An effective solution for marking plastic components is the melted engraving by CO2 laser marking … The day/night design marking was created through … ↩

-

Discover UV lasers’ role in precise marking for automotive components.: Explore our UV laser marking solutions for clear color marking and minimal product damage. KEYENCE offers insights on UV laser markers and machines. ↩

-

Explore how laser marking enhances personalized product quality and creativity.: A few laser engraving benefits worth noting include systems’ user-friendliness, precision, versatility, and reliability. ↩