Ever wondered about the magic behind CNC lathes and their role in modern manufacturing? Let’s unravel the fascinating world of parts they can expertly craft.

CNC lathes are adept at processing a wide range of cylindrical and axially symmetrical parts, such as shafts, spindles, flanges, gears, bushings, screws, and nuts. These machines excel in delivering high precision and exceptional surface finishes across various materials.

Reflecting on the projects I’ve worked on, I remember how CNC lathes transformed our approach to production. We tackled everything from intricate gear systems for wind turbines to finely threaded screws for precision instruments. Each time, the lathe’s ability to maintain accuracy and enhance surface quality amazed me. By diving deeper into specific applications, I’ve seen firsthand how these machines not only boost efficiency but also open up new possibilities in manufacturing.

CNC lathes can process shafts with Ra0.8 - Ra1.6μm surface roughness.True

CNC lathes achieve fine surface roughness for shafts, enhancing stability.

Nylon inserts in screws are machined by CNC lathes for anti-loosening.True

CNC lathes create grooves for nylon inserts, ensuring anti-loosening.

How Do CNC Lathes Improve Shaft Machining Efficiency?

Imagine transforming raw metal into precision-engineered components with the touch of a button. CNC lathes make this dream a reality by automating shaft machining, boosting speed and accuracy.

CNC lathes boost shaft machining efficiency by automating processes and providing precision control, reducing errors, and ensuring consistent quality. This technology enhances dimension accuracy, minimizes material waste, and improves surface finishes, making production faster and more reliable.

Precision Control with CNC Lathes

I remember the first time I saw a CNC lathe in action. It was mesmerizing to watch the machine effortlessly sculpt metal into a precisely engineered part. The secret lies in its precision control. The CNC system’s advanced programming meticulously directs the tool paths and movements, which reduces deviations and ensures uniform dimensions1. This level of precision is vital, especially when dealing with complex geometries or tight tolerances.

For example, while working on crankshafts for automotive engines, CNC lathes can maintain the journal dimensions accurately. This precision enhances engine performance by reducing deviations to minimal levels, thus improving the reliability and longevity of the machined shafts.

Automation and High-Speed Operations

The automation capabilities of CNC lathes are nothing short of a game-changer. I recall a project where we had to produce a large batch of shaft-like components. Thanks to CNC’s high-speed cutting technologies2, we managed to significantly reduce cycle times per part while maintaining precision.

Automated tool changers are another blessing. They seamlessly switch between different tools without any manual intervention, reducing downtime and optimizing production flow, ultimately contributing to higher efficiency.

Consistent Quality and Surface Finish

Maintaining consistent quality across production runs is crucial, and CNC lathes excel in this area. They use real-time monitoring and adaptive control systems to ensure each shaft is up to standard. This consistency is especially important for parts like spindles3 in high-precision machinery, where deviations could impact performance.

Moreover, I’ve witnessed CNC lathes achieve remarkable surface finishes using advanced cutting tools and techniques. For example, achieving surface roughness as fine as Ra0.8 – Ra1.6μm enhances the wear resistance and operational stability of shafts during high-speed rotation.

Adaptive Machining for Complex Parts

One of the most fascinating aspects of CNC lathes is their adaptability. Whether it’s alloy steels or stainless steels, these machines handle various materials and complex part geometries with ease. This flexibility is crucial when dealing with specialized shaft designs requiring unique approaches or customized tooling solutions4.

Additionally, CNC lathes can incorporate auxiliary devices like follow-rests to support long shafts during machining. This helps maintain straightness and uniformity, essential for parts like transmission shafts in automotive applications, where deviations could lead to performance issues.

In essence, CNC lathes are not just machines; they are partners in manufacturing excellence, turning intricate designs into tangible products with incredible efficiency.

CNC lathes can machine shafts from carbon steel.True

CNC lathes efficiently process carbon steel shafts due to good machinability.

CNC lathes cannot control the straightness of long shafts.False

CNC lathes use follow-rests to maintain straightness in long shafts.

Why Use CNC Lathes for Spindle Production?

Imagine transforming spindle production from a meticulous chore to a seamless process. That’s the magic of CNC lathes.

CNC lathes enhance spindle production by boosting precision, efficiency, and reducing labor costs, ensuring high-quality outcomes with minimal errors.

Enhanced Precision and Accuracy

I remember the first time I watched a CNC lathe in action. It was mesmerizing to see how it could take a block of material and transform it into something precise and intricate. For spindles, which demand the utmost accuracy, this precision is not just a benefit—it’s a necessity. The advanced computerized controls5 in these machines allow me to program exact dimensions and tolerances, ensuring every spindle meets rigorous specifications.

CNC lathes also shine when it comes to maintaining consistent quality across large batches. I often rely on real-time monitoring systems, which are like having an extra pair of eyes, allowing for adjustments during the machining process. This minimizes errors and ensures that even complex geometries are spot-on every time.

Improved Efficiency and Production Speed

Efficiency is where CNC lathes truly make their mark. I’ve seen firsthand how their automation capabilities reduce the need for manual intervention, allowing operations to run smoothly around the clock. This means I can achieve higher throughput rates compared to traditional methods.

One of the features I find particularly convenient is the ability to pre-program and store tool paths and machining sequences. This drastically cuts down setup times, especially beneficial when switching between different spindle designs. It’s like having a library of setups at my fingertips, ready to go whenever needed.

Cost Reduction and Labor Savings

Reducing labor costs without sacrificing quality is like hitting the jackpot in manufacturing. With CNC lathes, I can oversee multiple machines simultaneously, slashing labor expenses. Plus, their precision in cutting minimizes material waste, saving costs on raw materials.

The ability to predict tool wear and schedule maintenance reduces unexpected downtimes. This kind of predictability in operations has allowed me to optimize costs effectively.

Versatility and Customization

CNC lathes have opened up a world of possibilities for me with their versatility. Whether working with metals like steel or more challenging materials like composites, these machines handle it all. This flexibility is invaluable when producing spindles for diverse applications.

The programmable nature of CNC lathes makes customization a breeze. I’ve been able to create complex geometries that would be nearly impossible with manual machining. Advanced software6 empowers me to innovate spindle designs tailored to specific needs, pushing the boundaries of what’s possible.

CNC lathes can process shafts with Ra0.8 - Ra1.6μm surface roughness.True

CNC lathes achieve fine surface roughness through precise tool path planning.

The taper tolerance in spindle machining is controlled within ±0.02mm.False

The correct taper tolerance is controlled within ±0.002mm for spindles.

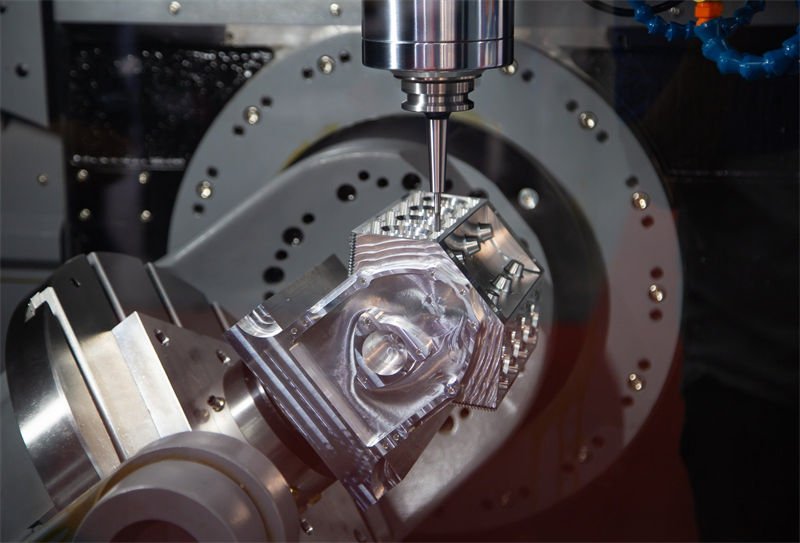

How Do CNC Lathes Precisely Machine Large Flanges?

Ever wondered how those giant flanges in industrial pipelines are made so precisely? Let me take you through the fascinating process using CNC lathes.

Large flanges are precisely machined using CNC lathes by leveraging high rigidity, layered cutting techniques, and precise control systems. The process includes ensuring flatness with face milling cutters and accurate bolt hole positioning using circular indexing, achieving high tolerance levels crucial for industrial applications.

The Role of Rigidity in Machining Large Flanges

When I first saw a CNC lathe in action, it was machining a massive flange, and I was awestruck by how smoothly it handled such a hefty piece of metal. These machines are built with incredibly rigid structures that can withstand the stress of machining large components without warping. I learned that this rigidity is crucial during layered cutting7, which involves slowly peeling away layers of material to preserve the flange’s integrity. Watching those large face milling cutters work their magic to keep flatness errors within a mere ±0.1mm was like witnessing precision engineering at its finest.

Ensuring Bolt Hole Accuracy

One of the most impressive feats I observed was how these machines ensure bolt holes are spot on. With the CNC lathe’s circular indexing feature, each bolt hole is positioned with pinpoint accuracy, usually within ±0.05mm. This precision is vital for making sure everything aligns perfectly when the flange is fitted into a pipeline system, ensuring no leaks or mishaps.

Machining Sealing Grooves for Special Requirements

Some flanges need special sealing grooves, and the CNC lathe handles this task with finesse. I remember watching as the machine precisely controlled the groove’s width and depth, keeping tolerances incredibly tight at around ±0.03mm for width and ±0.02mm for depth. Seeing the gaskets fit seamlessly afterward made me appreciate the level of detail involved in these processes.

Addressing Material Challenges

The choice of material can be a game-changer in flange machining. During my time shadowing an engineer, I noticed how different materials like stainless steel affected machinability and final quality of the flange. The versatility of CNC systems to adjust parameters for different materials enhances both efficiency and precision in flange machining8.

Real-Time Monitoring and Adjustment

What really stood out to me was the real-time monitoring capability of modern CNC lathes. These machines continuously track the machining process, allowing for immediate corrections if things deviate from set tolerances. This kind of technology minimizes errors and material waste, especially important when working with large flanges where even minor mistakes can have significant consequences.

By diving into these key components of CNC machining, I’ve gained a deeper appreciation for how manufacturers maintain the precision and reliability needed for large flanges in essential industries like chemical and petroleum pipelines. Understanding these processes also helps in planning and tool selection9 to boost production efficiency and product quality.

CNC lathes can process large flanges over 3 meters in diameter.True

CNC lathes have the rigidity to handle large-diameter flanges.

The flatness error for large flanges is controlled within ±0.5mm.False

Flatness error for large flanges is controlled within ±0.1mm.

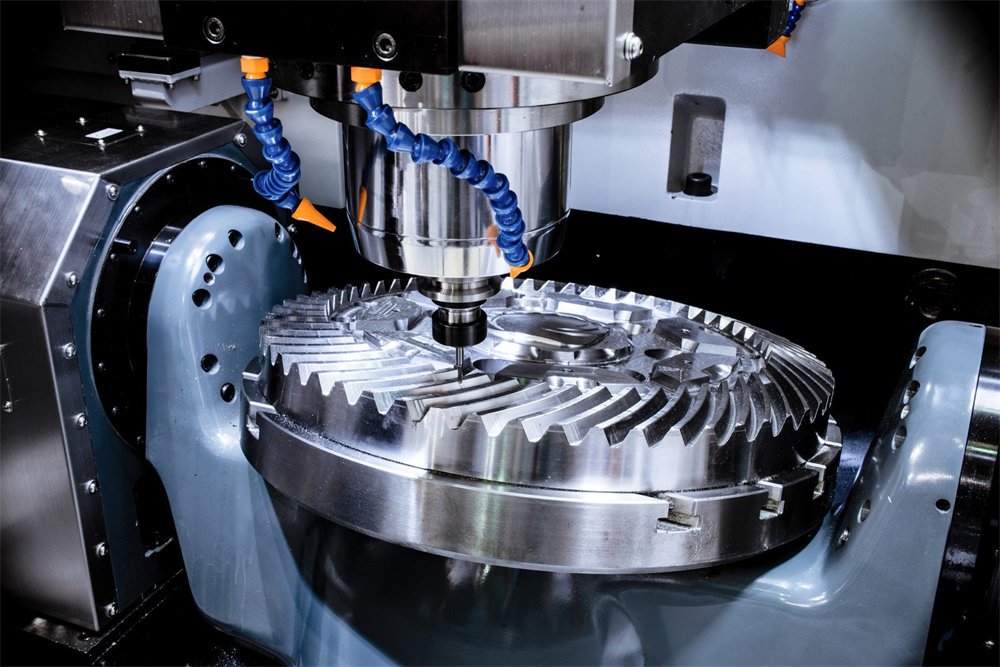

Why are CNC lathes perfect for crafting high-precision screws?

Ever wondered why CNC lathes are the go-to for crafting those precise little screws? Let’s dive into their magic.

CNC lathes excel in producing high-precision screws by achieving tight tolerances, complex geometries, and superior surface finishes. They ensure precise control over the machining process, delivering consistent quality and efficiency. This makes them vital for industries needing top-notch screw production.

Unmatched Precision in Machining

I remember the first time I watched a CNC lathe in action, crafting a screw with such exactness that it was almost mesmerizing. These machines are like the maestros of precision, able to perform with breathtaking accuracy. With computer-controlled systems, every tiny adjustment is meticulously managed, ensuring each screw is just right. I realized how crucial this is when you think about aerospace or medical devices—where even a minuscule error could spell disaster. CNC lathes can control thread form angles with a precision of ±0.5°, which is simply extraordinary for precision engineering10.

Complex Geometries and Versatility

What fascinates me about CNC lathes is their ability to handle complex shapes that would be nearly impossible manually. I once saw a design that required unique threads and anti-loosening features—something that would take forever by hand. But with a CNC lathe, it was like watching a skilled artist at work, easily switching between different designs and materials, from stainless steel to exotic alloys. This flexibility is a game-changer in advanced manufacturing11, allowing manufacturers to quickly adapt to various demands.

Superior Surface Finish and Durability

I can’t overstate the importance of surface finish in screw production. Imagine running your finger over a screw—smoothness is not just about aesthetics; it reduces friction and wear, which is vital in high-stress environments. CNC lathes achieve this with surface roughness levels of Ra0.2 – Ra0.4μm. I once saw this process enhance durability through cold working hardening during thread rolling—a technique that fascinates me every time I learn more about surface treatments12.

Efficiency and Consistency in Production

The beauty of CNC lathes lies in their ability to churn out identical screws without a hiccup once a program is set. It’s like setting a machine on autopilot but with constant quality checks. I’ve seen how this minimizes human error and waste, speeding up production and cutting costs significantly—an obvious win for any business engaged in high-volume screw manufacturing. These machines have real-time monitoring systems that ensure any deviations are promptly corrected, maintaining the quality standards essential for mass production13. Watching CNC technology dominate the high-precision screw landscape is like witnessing the future unfold right before my eyes.

CNC lathes can machine screws as small as 1mm in diameter.True

CNC lathes offer precision machining for micro-screws, enabling production of tiny screws with high accuracy.

CNC lathes cannot achieve Ra0.2μm surface roughness on threads.False

CNC lathes can achieve a surface roughness of Ra0.2μm on rolled threads, enhancing screw quality.

Conclusion

CNC lathes efficiently process various cylindrical parts, including shafts, spindles, flanges, screws, and nuts, delivering high precision and superior surface finishes across multiple materials.

-

Explore how precise CNC programming ensures consistent dimensions. ↩

-

Learn about time-saving benefits of high-speed operations. ↩

-

Understand why consistent quality is crucial for spindles. ↩

-

Discover how custom tooling addresses unique machining needs. ↩

-

Understand how computerized controls boost precision in CNC lathe operations. ↩

-

Discover software that enables customized designs in CNC machining. ↩

-

Explore how layered cutting enhances precision in large flange machining. ↩

-

Discover detailed processes involved in flange machining with CNC lathes. ↩

-

Learn about selecting appropriate tools for effective flange machining. ↩

-

Explore how precision engineering enhances CNC machining outcomes. ↩

-

Learn about the versatile applications of CNC lathes in manufacturing. ↩

-

Discover best practices for enhancing durability through surface treatments. ↩

-

Understand how CNC technology improves mass production efficiency. ↩