If you’ve ever marveled at the beauty of a perfectly welded joint, you’re not alone! Laser welding machines are transforming the welding landscape with their precision and efficiency.

Laser welding machines can be categorized into several types: Hand Gesture, Platform with XYZ Axes, Pulsed, and Robotic. Each type is tailored for specific applications, making it essential to understand their unique features to select the right one for your needs.

Let’s dive deeper into each type of laser welding machine and discover how they can elevate your projects!

Hand Gesture Laser Welding is user-friendly for beginners.True

It allows intuitive control via gestures, requiring minimal training.

How Does a Hand Gesture Laser Welding Machine Work?

Have you ever wondered how a hand gesture laser welding machine simplifies complex welding tasks? Let’s delve into its innovative operation and discover its transformative impact on welding processes.

A hand gesture laser welding machine operates by translating user hand movements into precise welding actions, eliminating the need for traditional welding tools. It features a responsive interface that allows for intuitive control, making it accessible to beginners while ensuring high-quality welds.

Understanding the Basics

Hand gesture laser welding machines are groundbreaking in that they allow users to perform welding tasks without direct physical contact with the machine. Instead, they use sensors to interpret gestures made by the user’s hands, converting these movements into specific welding operations.

This intuitive control system enables operators to manage the welding process with minimal training, providing a significant advantage for beginners and professionals alike. The machine’s design emphasizes ease of use and efficiency, removing the barriers typically associated with traditional welding techniques.

How Hand Gesture Control Works

The core of this technology lies in its advanced gesture recognition system. The machine is equipped with sensors that detect and interpret hand movements. These sensors communicate with a central processing unit that translates gestures into commands, directing the laser to perform various tasks such as initiating welds or adjusting intensity.

| Feature | Description |

|---|---|

| Sensor Technology | Utilizes infrared and motion sensors for gesture detection |

| User Interface | Intuitive, allowing for real-time feedback and adjustments |

| Welding Precision | High precision due to responsive sensor feedback |

For instance, a simple motion might start or stop the welding process, while more complex gestures could adjust the parameters of the weld, such as speed or power.

Applications and Advantages

Hand gesture laser welding machines are particularly effective in industries where precision and aesthetics are crucial, such as in manufacturing thin stainless steel or galvanized plates. They provide an efficient alternative to traditional TIG welding methods, offering aesthetic and durable welds without the need for consumables.

Additionally, these machines often come with pre-set modes tailored to common materials and tasks, further simplifying their use. The versatility and ease of operation make them suitable for various applications, from small-scale manufacturing to intricate design work.

Training and Safety Considerations

While these machines are designed to be user-friendly, understanding their safety features is crucial. Many models come with built-in safety mechanisms to prevent accidental operation or overheating, safeguarding both the user and the equipment.

Manufacturers typically offer comprehensive training resources, including tutorials and manuals, to help new users become proficient in operating the machine safely and effectively. Emphasizing safety can prevent accidents and ensure consistent performance over time.

In conclusion, while this overview highlights the innovative nature of hand gesture laser welding machines, it’s clear that they represent a significant step forward in making advanced welding technology accessible and easy to use. For further exploration into their impact on modern manufacturing, consider researching specific case studies1 or user testimonials2.

Gesture welding machines use infrared sensors for control.True

They utilize infrared and motion sensors to detect gestures.

Hand gesture welding requires extensive training for use.False

Minimal training is needed due to the intuitive interface.

What Are the Benefits of Using a Platform Laser Welding Machine with XYZ Axes?

Platform laser welding machines with XYZ axes offer unparalleled precision and versatility, revolutionizing industries with their advanced capabilities.

Platform laser welding machines equipped with XYZ axes provide high precision and adaptability, ideal for intricate projects. They allow precise control over the welding process, accommodating complex shapes and materials, making them indispensable in industries like automotive, medical, and aerospace.

Enhanced Precision and Control

One of the standout advantages of using a platform laser welding machine3 with XYZ axes is the enhanced precision and control it offers. The ability to maneuver in three dimensions (X, Y, and Z) allows for meticulous handling of complex welds on intricate components. For instance, in the medical device industry, where precision is paramount, these machines can weld delicate instruments without compromising their integrity.

Versatility Across Materials

The XYZ axes configuration is particularly beneficial for projects involving diverse materials. Whether working with metals like aluminum and stainless steel or composite materials, the platform laser welding machine can adapt its settings to suit different thermal and physical properties. This adaptability makes it a versatile tool for industries ranging from automotive manufacturing to aerospace engineering4, where material diversity is common.

| Material Type | Application Examples |

|---|---|

| Aluminum | Automotive frames, aerospace components |

| Stainless Steel | Medical devices, kitchenware |

| Composite Materials | Aerospace panels, automotive parts |

Customization Capabilities

Another significant benefit is the ability to customize the machine for specific project needs. The XYZ platform can be tailored with additional features such as a CCD camera system for real-time monitoring and precise positioning during the welding process. This level of customization ensures that even the most demanding projects can be completed with high accuracy and efficiency.

Time and Cost Efficiency

By incorporating automation with XYZ axes, these machines reduce the need for manual intervention, thus minimizing human error. This automation leads to faster production times and consistent output quality, reducing overall project costs. Industries such as automotive manufacturing5 benefit significantly from this efficiency, as it allows for higher throughput without sacrificing quality.

In conclusion, platform laser welding machines with XYZ axes provide remarkable advantages in terms of precision, versatility, customization, and efficiency. Their application across various industries underscores their role as essential tools in modern manufacturing processes.

XYZ axis laser welding machines offer unparalleled precision.True

They allow meticulous handling of complex welds on intricate components.

XYZ axis machines are limited to metal materials only.False

They adapt to diverse materials, including metals and composites.

Where Is Pulsed Laser Welding Most Effective?

Pulsed laser welding is a game-changer in industries requiring precision and delicacy. But where does it truly excel?

Pulsed laser welding is most effective in industries that demand precision, such as microelectronics and fine jewelry. Its ability to weld thin metal sheets and intricate components makes it indispensable in these fields.

Applications in Microelectronics

In the microelectronics industry, the need for precision and control is paramount. Pulsed laser welding offers unparalleled accuracy, making it ideal for tasks involving tiny electronic components and delicate connections. For instance, when assembling sensors or circuit boards, the ability to control the energy output precisely ensures minimal thermal distortion, preserving the integrity of sensitive materials.

Advancements in Medical Device Manufacturing

Medical devices often require joints that are both strong and clean. Pulsed laser welding provides the precision needed to join small components without introducing impurities, essential for devices that come into contact with human tissue. Its use in manufacturing surgical tools and implantable devices highlights its effectiveness in this sector.

The Jewelry Industry’s Precision Needs

In the world of fine jewelry, the aesthetic quality of a weld is just as important as its strength. Pulsed laser welding enables jewelers to create seamless joints on precious metals like gold and platinum, enhancing both the durability and appearance of intricate designs. This technology also allows for repairs without damaging heat-sensitive gemstones.

Aerospace Applications

The aerospace sector benefits from pulsed laser welding due to its ability to produce lightweight yet strong components. In environments where material integrity is critical, such as fuel tanks and aircraft skins, this welding method ensures robust joins while minimizing weight — a crucial factor in aerospace engineering.

Table: Industries Utilizing Pulsed Laser Welding

| Industry | Application | Benefits |

|---|---|---|

| Microelectronics | Sensor assembly, circuit boards | High precision, minimal thermal distortion |

| Medical Devices | Surgical tools, implants | Clean joins, no impurities |

| Jewelry | Seamless joints on precious metals | Enhanced aesthetics and strength |

| Aerospace | Fuel tanks, aircraft skins | Lightweight components with strong joins |

Exploring these applications showcases the versatility6 of pulsed laser welding across diverse fields. Each industry benefits uniquely from its precision capabilities, highlighting its role as a transformative technology.

Pulsed laser welding is ideal for microelectronics.True

It offers precision and control, crucial for tiny components.

Pulsed laser welding is unsuitable for jewelry repairs.False

It allows seamless joints on precious metals without damage.

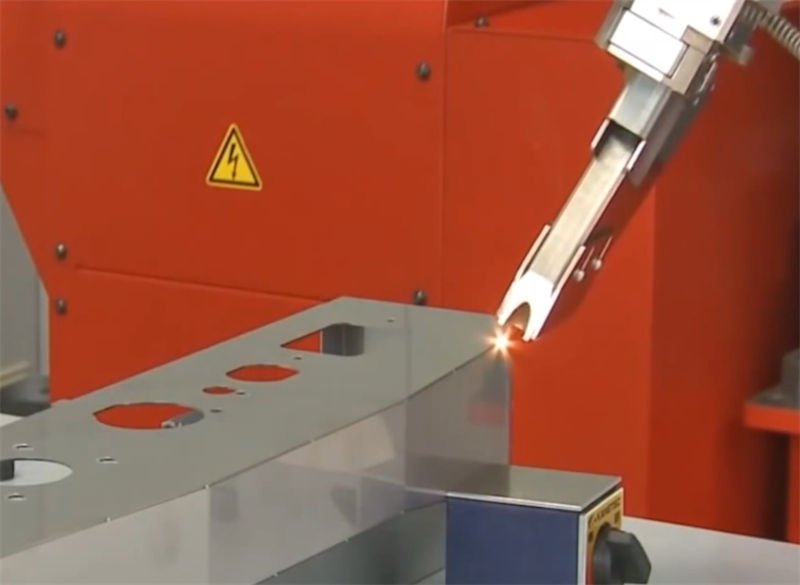

Why Choose a Robotic Laser Welding Machine for Large-Scale Projects?

Discover why robotic laser welding machines are the preferred choice for large-scale industrial applications, offering unmatched precision and efficiency.

Robotic laser welding machines are ideal for large-scale projects due to their ability to enhance productivity, reduce labor costs, and operate in harsh environments. These machines provide consistent weld quality and can replace multiple traditional welders, making them highly efficient for industrial use.

The Rise of Automation in Welding

The advent of robotic laser welding machines has transformed the landscape of industrial welding by automating processes that traditionally required significant manual labor. In large-scale projects, where precision and consistency are paramount, robotic systems excel by minimizing human error and increasing production speeds.

One key advantage is their capacity to work continuously without fatigue, which is crucial for large-scale manufacturing environments such as automotive assembly lines or heavy machinery production. The integration of robotics in welding not only optimizes workflow but also enhances safety by removing human operators from potentially hazardous situations.

Efficiency and Cost Reduction

Robotic laser welding machines significantly reduce labor costs by replacing 3-4 traditional welders with a single automated system. This not only lowers the workforce requirement but also reduces overhead costs associated with employee benefits and training.

Furthermore, these machines provide uniform welds with minimal waste, reducing material costs over time. With precise programming, they can achieve repeatable and accurate welds that would be challenging for human operators to maintain consistently.

Adaptability to Harsh Environments

Robotic systems are designed to operate in environments that may be inhospitable to human workers, such as high-temperature settings or areas with limited access. This adaptability ensures that production can continue uninterrupted in challenging conditions, further enhancing project timelines and outcomes.

For instance, in sectors like aerospace or shipbuilding, where components can be large and difficult to maneuver, robotic laser welders are invaluable. They offer the flexibility needed to handle complex geometries and large assemblies with ease.

Precision and Quality Control

The precision of robotic laser welding is unmatched, providing high-quality welds that meet stringent industry standards. These machines are equipped with advanced sensors and monitoring systems that ensure the integrity of each weld is maintained throughout the process.

The use of such technology allows for real-time adjustments to be made, minimizing defects and ensuring that quality control is maintained at every stage. This level of precision is particularly important in industries where failure is not an option, such as medical device manufacturing or nuclear power plant construction.

Future-Proofing Industrial Welding Operations

As industries move towards Industry 4.07, integrating smart technologies with manufacturing processes, robotic laser welding machines represent a forward-thinking investment. Their ability to integrate with other automated systems makes them a cornerstone of modern manufacturing strategies.

By adopting these systems, companies can future-proof their operations, ensuring they remain competitive in an ever-evolving market landscape. This shift towards automation not only increases efficiency but also enhances the capacity for innovation in product design and manufacturing processes.

Robotic laser welding machines reduce labor costs by 75%.True

These machines replace 3-4 traditional welders, cutting labor expenses.

Robotic welders cannot operate in high-temperature settings.False

They are designed to work in harsh environments, including high temperatures.

Conclusion

Choosing the right laser welding machine can significantly impact your project outcomes. Take time to assess your specific needs and explore the options available!

-

Discover real-world applications and benefits of this technology.: Machine-learned wearable soft sensors have enabled accurate and rapid human-gesture recognition, providing real-time feedback to users. ↩

-

Gain insights from user experiences and feedback.: There are cuffs around your wrists with interlocks provided to keep your eyes protected. Your hands are exposed so they are Class 4 machines. ↩

-

Discover in-depth advantages of using XYZ axis welding machines.: Advantages of Laser Welding Machine for Mold · High Precision: Laser welding technology excels in achieving superior precision. · Low Heat Input: Laser welding … ↩

-

Learn how these machines excel in aerospace engineering.: The use of laser welding technology to connect aluminum alloy aviation components has many advantages such as large weld depth-to-width … ↩

-

Explore efficiency gains in automotive manufacturing.: These are achieved by means of four innovations: 1) Variable focus position of the laser beam along the Z axis, 2) reduced weld penetration, 3) … ↩

-

Explore versatile uses of pulsed laser welding in various industries.: Applications include medical, aerospace, military, alternative energy and many other high profile industry sectors. Tremendously versatile, laser welding is … ↩

-

Understand how Industry 4.0 transforms manufacturing with smart technologies.: Industry 4.0—also called the Fourth Industrial Revolution or 4IR—is the next phase in the digitization of the manufacturing sector, … ↩