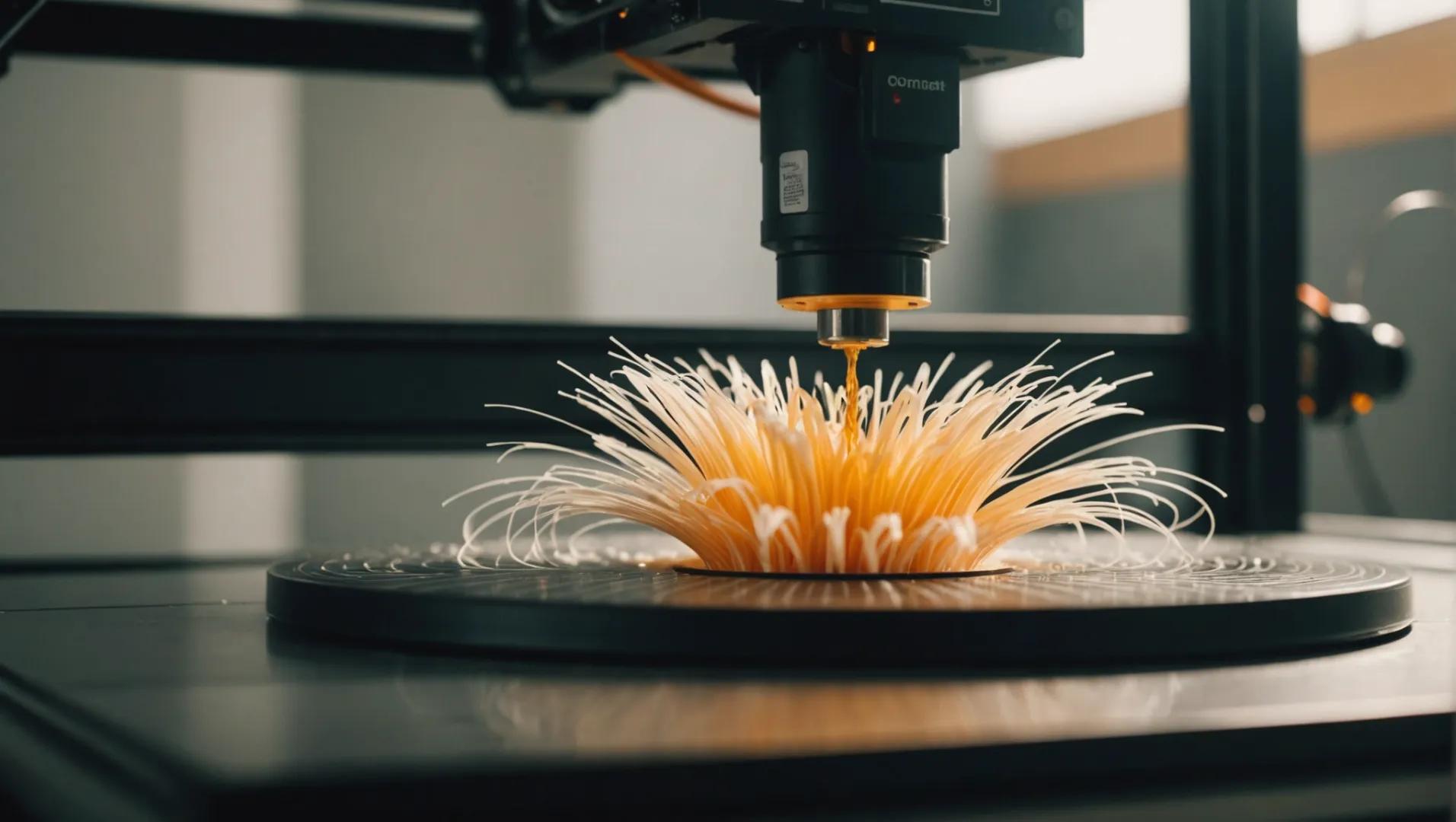

Feeling frustrated by your slow 3D printer? You’re definitely not alone!

3D printing is inherently slow due to its layer-by-layer construction method, cooling requirements, and complex material properties. To speed up the process, you can adjust settings such as layer height and nozzle diameter, use faster printing materials, and ensure proper printer maintenance.

While these adjustments can help, there’s more to speeding up your 3D printing than meets the eye. Dive deeper into the intricacies of 3D printing speed to unlock the potential for faster production times without compromising on quality.

Adjusting nozzle diameter affects 3D printing speed.True

A larger nozzle diameter extrudes more material, reducing print time.

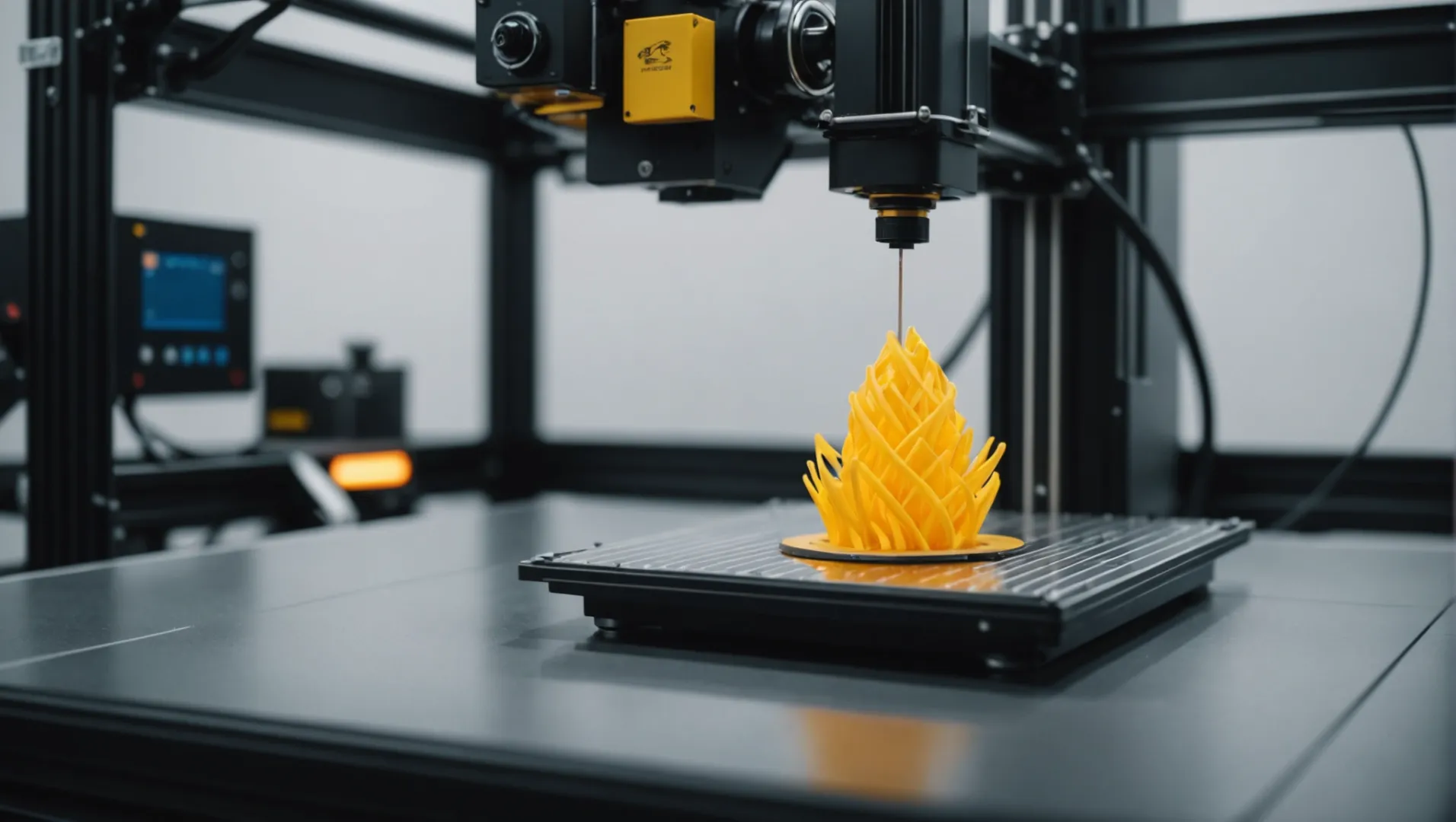

How Do Printer Settings Impact Print Speed?

Ever wondered how a simple tweak in your printer settings could drastically change print speed?

Printer settings significantly impact print speed by controlling factors like layer height, infill density, and print head speed. Lowering layer height and increasing infill density can slow down printing, while adjusting print head speed can optimize balance between speed and quality.

Understanding the Basics of Printer Settings

Printer settings are the backbone of any successful 3D printing project. They define how the printer operates, affecting both speed and quality. Key settings include layer height, infill density, print speed, and nozzle diameter. By adjusting these parameters, you can either hasten or hinder the printing process.

Layer Height: Precision vs. Speed

Layer height determines the thickness of each printed layer. A smaller layer height results in more layers for the same object, increasing print time but enhancing detail. Conversely, a larger layer height reduces the number of layers, speeding up the process but potentially sacrificing precision. For instance, reducing layer height from 0.3mm to 0.1mm can triple the printing time but significantly improve surface finish.

The Impact of Infill Density

Infill density refers to how solid the inside of your print is. Higher infill densities lead to stronger objects but require more time and material. Reducing infill density from 50% to 20% can dramatically cut down print time without compromising structural integrity for less demanding applications. Here’s a quick look at the impact of different infill densities:

| Infill Density | Print Time Increase | Strength Gain |

|---|---|---|

| 10% | Minimal | Low |

| 30% | Moderate | Moderate |

| 50% | Significant | High |

Print Speed: Finding the Sweet Spot

Print speed is how fast the printer’s nozzle moves while printing. Higher speeds decrease print time but may reduce print quality due to increased vibrations and reduced cooling time for each layer. Testing various speeds to find a sweet spot that offers a balance between time efficiency and acceptable quality is crucial.

Nozzle Diameter: Bigger Isn’t Always Better

The diameter of the nozzle affects how much material is extruded at once. A larger diameter means more material per pass, which can reduce printing time but may impact detail resolution. For example, switching from a 0.4mm to a 0.8mm nozzle can halve the print time for non-detailed objects but will not be suitable for intricate designs.

Customizing Settings for Different Materials

Different materials have distinct properties that necessitate unique settings. For example, PLA may allow faster speeds and lower temperatures compared to ABS, which requires slower speeds and higher temperatures to prevent warping.

Adjusting these settings appropriately can make a significant difference in print efficiency and output quality, helping you tailor your 3D printing experience1 to meet specific needs.

Reducing layer height increases print speed.False

Reducing layer height increases print time as more layers are needed.

Higher infill density strengthens prints but slows speed.True

Higher infill density requires more material, increasing strength and print time.

What Role Does Material Choice Play in 3D Printing Speed?

Ever wondered how the material you choose affects your 3D printing speed?

Material choice significantly influences 3D printing speed due to variations in melting points, fluidity, and cooling requirements. Selecting materials with optimal characteristics for your printer can enhance efficiency, reducing overall print time without sacrificing quality.

Understanding Material Properties

Materials used in 3D printing vary widely, each bringing unique properties that affect print speed. For instance, thermoplastics like PLA and ABS have different melting points and cooling times2, which directly influence how fast layers can be deposited and solidified. Generally, materials with lower melting points cool faster, allowing for quicker layering.

Fluidity and Print Speed

Fluidity or viscosity of a material impacts how easily it can be extruded through the printer’s nozzle. Materials with higher fluidity require less force to extrude, enabling faster printing speeds. For example, PLA3, known for its smooth extrusion and low-temperature requirements, often prints faster than materials like nylon or TPU, which may require slower speeds to ensure precision.

| Material | Melting Point | Cooling Time | Fluidity Rating |

|---|---|---|---|

| PLA | Low | Quick | High |

| ABS | Moderate | Moderate | Moderate |

| Nylon | High | Slow | Low |

The Impact of Material Additives

Some materials include additives to enhance strength or flexibility, but these can also affect print speed. For instance, composite filaments containing carbon fiber or metal particles might require slower print speeds to maintain accuracy due to their increased density and reduced fluidity.

Choosing the Right Material for Your Printer

Each 3D printer model is optimized for specific material types. Some printers handle high-temperature materials better due to enhanced cooling systems, while others excel with standard plastics. Understanding your printer’s capabilities can help you select the best material4 to maximize speed without compromising on print quality.

Balancing Quality and Speed

It’s crucial to balance the desire for speed with the need for quality. Materials that allow for faster printing might result in lower resolution or weaker structures if not properly managed. Adjusting printer settings in conjunction with material choice can help achieve an optimal balance for your projects.

PLA prints faster than Nylon due to its fluidity.True

PLA's high fluidity and low melting point enable quicker extrusion.

Materials with higher melting points print faster.False

Higher melting points require more energy and time, slowing print speed.

How Can Printer Maintenance Enhance Performance?

Is your printer slowing down your workflow? Maintenance might be the key to better performance.

Regular printer maintenance enhances performance by preventing clogs, ensuring smooth operation, and prolonging the printer’s lifespan. Key maintenance tasks include cleaning nozzles, aligning print heads, and updating firmware.

Importance of Regular Cleaning

Dust and debris accumulation can lead to poor printing quality and increased wear and tear on your printer. Regular cleaning of components like the print head and rollers ensures that your printer operates smoothly. Neglecting this can result in clogged nozzles, which often require costly repairs or replacements. For a step-by-step guide on cleaning procedures, see our detailed maintenance checklist5.

Alignment and Calibration

Proper alignment of the print heads is crucial for maintaining sharp and clear prints. Misaligned heads can cause blurring or double lines, reducing the quality of your prints. Regular calibration helps in optimizing print speeds and improving accuracy. Learn more about the calibration process6 and how it affects your printer’s performance.

Firmware Updates

Printer manufacturers frequently release firmware updates to improve performance, fix bugs, and enhance security. Keeping your firmware up-to-date ensures that your printer runs efficiently and that you have access to the latest features. For guidance on checking for updates, visit our firmware update guide7.

Replacing Worn Out Parts

Over time, certain parts of the printer, such as belts or gears, may wear out and need replacement to maintain optimal functionality. Keeping a schedule for checking these parts can prevent unexpected breakdowns. Discover more about identifying worn-out components8 in your printer.

Lubrication of Moving Parts

Lubricating the moving parts of a printer can prevent friction-related issues that slow down printing processes. Use manufacturer-recommended lubricants to avoid damage to the printer components. See our tips on proper lubrication techniques9.

Regular cleaning prevents printer clogs.True

Cleaning removes dust and debris, preventing clogs in nozzles.

Firmware updates can reduce printer speed.False

Firmware updates typically enhance performance and fix issues.

What Are the Latest Technological Advances in 3D Printing Speed?

Eager to see your 3D projects come to life faster? Discover groundbreaking advancements in 3D printing speed.

Recent technological advances in 3D printing have dramatically increased printing speeds through innovations like continuous liquid interface production (CLIP), multi-jet fusion (MJF), and advanced software algorithms that optimize print paths. These technologies reduce the time required for each layer, offering faster print times without sacrificing quality.

Continuous Liquid Interface Production (CLIP)

CLIP technology revolutionizes 3D printing by utilizing a continuous flow of liquid resin to build objects, as opposed to traditional layer-by-layer methods. This approach significantly reduces layer curing time, allowing prints to be completed up to 100 times faster than conventional methods. The continuous nature of the process minimizes the appearance of layer lines, enhancing the surface finish and mechanical properties of printed objects.

Learn more about how CLIP technology is transforming 3D printing10 with its rapid curing capabilities and seamless object creation.

Multi-Jet Fusion (MJF)

Developed by HP, MJF technology offers another leap in 3D printing speed by simultaneously laying down multiple agents across the print bed. This method involves fusing layers together quickly and efficiently, making it ideal for producing large batches of high-quality parts. MJF technology is particularly advantageous for industrial applications where both speed and precision are crucial.

Discover the benefits of MJF technology in accelerating production11 while maintaining top-tier quality.

Advanced Software Algorithms

Software advancements have also played a critical role in enhancing 3D printing speed. New algorithms optimize print paths and adjust settings in real-time based on sensor feedback. This not only reduces the print time but also improves accuracy and material efficiency. Many modern printers come equipped with machine learning capabilities that allow them to learn from previous prints and refine their processes over time.

Explore how smart software algorithms12 are reshaping the future of 3D printing with intelligent path optimization and adaptive control.

High-Speed Extrusion Systems

To address the mechanical limitations that often slow down printing, high-speed extrusion systems have been developed. These systems utilize lighter materials and advanced motor technologies to move the print head rapidly without sacrificing precision. By reducing the mass of moving parts, these systems can achieve faster acceleration and deceleration, further decreasing print times.

Read about how high-speed extrusion13 systems are overcoming traditional mechanical constraints for faster production.

Continuous Fiber Reinforcement

Another innovative advancement is the integration of continuous fiber reinforcement in 3D prints. This technique enhances the structural integrity of printed objects while reducing the need for dense infill, thus shortening print times. By embedding strong fibers like carbon or glass into the material during printing, manufacturers can produce lightweight yet robust components quickly and efficiently.

Learn how continuous fiber reinforcement14 is enabling faster and stronger 3D prints through strategic material enhancements.

CLIP reduces 3D print times by 100x.True

CLIP's continuous resin flow minimizes layer curing, speeding up prints.

MJF is slower than traditional 3D printing methods.False

MJF fuses layers quickly, making it faster than conventional methods.

Conclusion

By understanding and optimizing key factors affecting print speed, you can significantly enhance your 3D printing experience. Apply these insights to achieve faster print times and better efficiency.

-

Explore detailed guides on optimizing 3D printing settings for various materials.: 3D Printing Settings and Parameters: Types and Optimization … This guide is crafted to shed light on the crucial 3D printer … What are the best 3d printer … ↩

-

Learn how melting points affect print speed and layer adhesion.: Find the Right Material for Your Application ; PLA, ABS ; Extruder Temperature, 190 – 220°C · 220 – 250°C ; Bed temperature, 45 – 60°C · 95 – 110°C … ↩

-

Compare fluidity of common 3D printing materials for faster prints.: PLA is easy to print with and has a higher stiffness than ABS and other materials like nylon, though it doesn’t handle high temperatures or significant stress … ↩

-

Discover materials that enhance printing speed on various printers.: So far I had good results with eryone filaments. I have used their rainbow, tricolor and regular PLA. I have used over 25 rolls from them and … ↩

-

Discover step-by-step cleaning procedures for optimal printer performance.: 1. Update your printer’s software · 2. Check for any physical damage to the printer · 3. Clean out the printer’s paper feeder · 4. Check the ink levels · 5. Clean … ↩

-

Understand the process of calibrating printers for enhanced output quality.: 3D printer calibration site V2 – Still free and better than ever! It aims to make calibrating your 3D printer as easy as possible. ↩

-

Stay updated with the latest features by following our firmware guide.: Go to HP Software and Driver Downloads, and then enter your printer model. Select Firmware from the list of drivers, click Download next to the update, and then … ↩

-

Learn how to detect parts needing replacement to avoid breakdowns.: If your printer suddenly becomes slow or unresponsive, it could be a sign that one or more parts are wearing out or malfunctioning. While … ↩

-

Get tips on lubricating printers to prevent friction-related issues.: Apply suitable lubricants like PTFE-based or silicone-based options to components such as rails, screws, bearings, and extruder gears. ↩

-

Discover CLIP’s fast curing method and seamless object creation.: The new 3D-printing method sees researchers use mounted syringe pumps to add additional resin at key points. ↩

-

Explore MJF’s efficiency in producing high-quality parts quickly.: Advantages of Multi Jet Fusion 3D Printing · MJF Eliminates the Need for Support Structures · MJF Prints Parts Directly in Colour · MJF Has Good Physical and … ↩

-

Learn about smart path optimization and adaptive control features.: In 3D printing, ML algorithms can take center stage, allowing users to fine-tune printing parameters, resulting in improved print quality and operational … ↩

-

Understand how new systems overcome mechanical constraints.: Rapid Build Speeds Extrusion 3D printing enables quick turnaround times, making it an ideal technology for rapid prototyping and final part production. Post- … ↩

-

See how fiber integration enhances strength and reduces print time.: 3d printing fibers can be used to reinforce parts strategically. Continuous fibers act strongest in tension, just like raw spaghetti. ↩