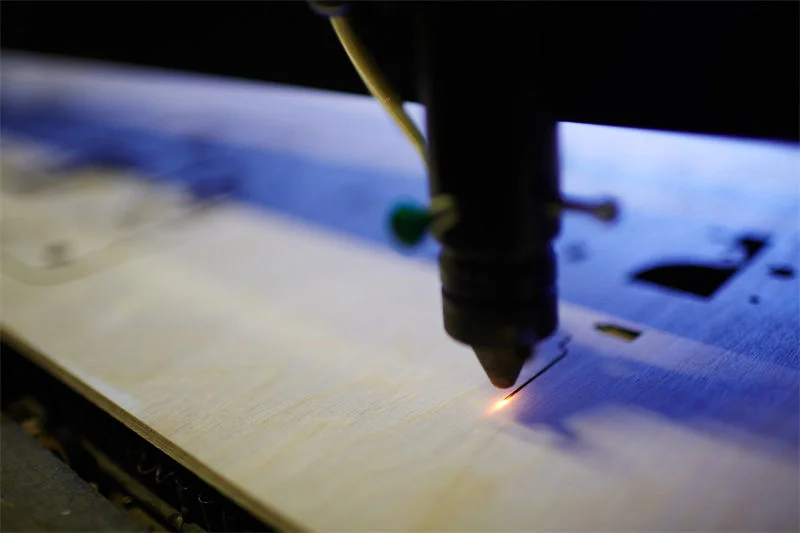

As someone who has invested in a CO2 laser cutting machine, knowing its service life feels like holding a treasure map for my business.

The service life of a CO2 laser cutting machine is usually about 5 to 10 years. However, the service lives of various components are not the same. For example, the service lives of carbon dioxide focusing lenses, reflectors, laser tubes, etc. range from 6 months to 2 years, which are affected by factors such as usage frequency, working environment, and maintenance conditions. High-quality components, reasonable use, and careful maintenance can extend their service lives.

But there’s more to the story! Let’s dive deeper into what influences these lifespans and how you can ensure your machine runs smoothly for years.

CO2 laser cutting machines last 5 years without maintenance.False

Without maintenance, components like lenses and tubes degrade faster.

How Do Usage Rates Affect Component Lifespan?

Understanding how usage rates influence the lifespan of components is essential for optimizing the performance of your CO2 laser cutting machine.

Usage rates significantly affect component lifespan; higher usage reduces longevity, while less frequent use extends it. Regular monitoring and maintenance can mitigate these effects.

The Impact of Usage Rates on CO2 Laser Components

When it comes to CO2 laser cutting machines, each component has a distinct lifespan influenced by how frequently the machine is used. For instance, focusing lenses and mirrors typically last between 6 to 12 months under normal operating conditions. However, these timelines can be shortened by continuous, heavy-duty use, as the components wear out faster due to increased heat and stress.

Consider this: if a machine is used intensively on a daily basis, components like focusing lenses might need replacing every 3 to 4 months instead of lasting up to a year. On the other hand, if the machine is used sparingly, these parts can exceed their average lifespan, offering more value.

Factors Influencing Component Wear

Several factors contribute to how usage rates impact component lifespan:

- Operational Hours: Machines running for long periods experience more wear and tear.

- Material Type: Cutting harder materials accelerates component degradation.

- Environment: Dusty or humid environments can also affect component longevity.

Increased usage doesn’t just wear components faster; it can also lead to misalignments or calibration issues over time. Therefore, regular maintenance becomes crucial in extending the lifespan despite high usage rates. Explore maintenance tips1 that can help you maintain optimal performance.

Case Study: Glass Laser Tubes

Glass laser tubes have a lifespan of 1 to 2 years but are sensitive to usage patterns. Frequent use maintains optimal gas pressure and functionality within the tube. Interestingly, if these tubes are left unused for extended periods, the gases within can slowly dissipate, reducing efficiency and lifespan.

A practical approach is to schedule regular operations to ensure consistent use, preventing gas dispersion and preserving tube longevity. Discover strategies2 for efficient use of laser tubes to maximize their life span.

By understanding the relationship between usage rates and component life, businesses can better plan for replacements and maintenance schedules, ultimately saving costs and improving machine reliability.

Higher usage rates reduce CO2 laser component lifespan.True

Frequent use increases wear and tear, shortening component life.

Sporadic use of glass laser tubes increases their lifespan.False

Infrequent use can lead to gas dissipation, reducing efficiency.

What Maintenance Practices Can Extend the Lifespan?

Extending the lifespan of your CO2 laser cutting machine is not just about minimizing costs but also ensuring efficient operation and product quality.

To extend the service life of a carbon dioxide laser cutting machine, multiple aspects of maintenance are needed, such as cleaning and adjusting optical components, cooling laser tubes, avoiding frequent switching, lubricating mechanical parts, and cleaning and tightening the machine body.

Routine Cleaning and Dust Management

Dust and debris are the enemies of any precision machine, especially for CO2 laser cutters3. Regularly clean all optical components, such as lenses and mirrors, to prevent build-up that can scatter laser beams and reduce efficiency. Use appropriate cleaning solutions and follow manufacturer guidelines to avoid damage.

Consider installing air filtration systems or dust collectors to reduce airborne particles that can settle on sensitive parts, enhancing overall longevity.

Proper Alignment Techniques

Maintaining the correct alignment of mirrors and lenses is crucial for maximizing the performance and lifespan of a CO2 laser cutter. Misalignment can lead to inefficient cutting and potential damage to components. Regularly check and adjust the alignment using a test pattern provided by the manufacturer or a reliable laser alignment tool.

Training operators in precise alignment techniques can prevent costly downtime and extend component life.

Scheduled Inspections and Replacements

Implement a scheduled maintenance4 plan to routinely inspect vital components. Keep a detailed log of usage hours to anticipate when parts like focusing lenses or mirrors may need replacement.

Proactively replacing parts before they fail can prevent unexpected breakdowns, which often lead to more significant damage and costly repairs.

Temperature and Humidity Control

Environmental factors such as temperature and humidity can affect the performance of CO2 laser machines. High humidity can cause corrosion, while temperature fluctuations may affect electrical components. Ensure your machine operates in a controlled environment with stable conditions.

Installing air conditioning or dehumidifiers in the laser cutting area can safeguard against environmental risks.

Operator Training and Best Practices

Invest in comprehensive training for all operators. Understanding the proper handling, operation, and maintenance protocols will minimize human error, which is a leading cause of equipment wear.

Encourage operators to report any irregularities immediately, fostering a proactive maintenance culture that addresses issues before they escalate.

Routine cleaning prevents laser beam scattering.True

Cleaning removes debris that can scatter laser beams, ensuring efficiency.

Misalignment does not affect CO2 laser performance.False

Misalignment reduces efficiency and may damage components, affecting performance.

How Does Downtime Impact Glass Laser Tubes?

Extended periods of inactivity can surprisingly affect the longevity of your glass laser tubes.

Downtime has different impacts on glass laser tubes of carbon dioxide laser cutters. Short downtime may cause condensation risk if temperature and humidity change greatly. Medium downtime may affect gas composition and electrode filament performance. Long downtime may lead to gas leakage and component oxidation.

Understanding the Dynamics of Downtime

In laser technology, particularly with glass laser tubes, extended downtime can be more than just a pause in operation; it can actively contribute to the degradation of the tube’s functionality. This happens because the gas mixture inside the tube, crucial for generating laser beams, can escape or become imbalanced when not used regularly.

The Chemistry Behind Gas Dispersion

Glass laser tubes rely on a precise mixture of gases such as carbon dioxide (CO2), nitrogen (N2), and helium (He) to function efficiently. When a laser machine sits idle for long periods, the gases can diffuse through the glass walls—a phenomenon known as permeation. This results in a gradual loss of pressure and changes in gas composition, diminishing the tube’s performance and lifespan.

Here’s a simplified breakdown:

| Gas Component | Function in Laser Tube | Impact of Downtime |

|---|---|---|

| CO2 | Generates laser beam | Reduced efficiency |

| N2 | Increases energy transfer | Loss of power |

| He | Helps cooling and uniformity | Imbalance in gas mix |

Usage Recommendations

To mitigate the impact of downtime, it’s advisable to use the laser machine regularly. Even if not for full production, a periodic run can help maintain the integrity of the gas mixture and preserve the tube’s lifespan. This practice ensures that the gases remain balanced and functional.

For more insights into maintaining the efficiency of glass laser tubes during inactive periods, consider exploring maintenance strategies5 that focus on preventing gas loss.

Real-World Implications and Solutions

Manufacturers facing unavoidable downtime should consider implementing maintenance protocols that include scheduled operation times to prevent gas diffusion. Furthermore, storing laser machines in environments where temperature and humidity are controlled can also help minimize this effect. For example, maintaining a stable room temperature can slow down the rate of gas permeation significantly.

Additionally, investing in high-quality glass tubes with better sealing properties can reduce the risk of gas escape. To learn about advanced sealing techniques and their benefits, you might want to check out sealing technology innovations6.

Downtime causes gas loss in laser tubes.True

Extended inactivity leads to gas permeation, reducing efficiency.

Regular use prolongs laser tube lifespan.True

Frequent operation maintains gas balance and optimal performance.

What Are the Signs of Component Wear and Tear?

Identifying signs of wear and tear in CO2 laser cutting machines can prevent unexpected breakdowns and costly repairs.

Wear signs of CO2 laser cutting machine include: decreased cutting quality with rough edges, uneven kerf widths and more burn marks; reduced precision like worse repeat positioning and dimensional accuracy; increased abnormal sounds and vibrations; component wear such as damaged optical parts and decreased laser tube power.

Reduced Cutting Precision

One of the first indicators of component wear in a CO2 laser cutting machine is a noticeable reduction in cutting precision. This often manifests as rough or uneven edges on the cut material, which can be attributed to worn-out focusing lenses or mirrors. Over time, the optical surfaces7 may become degraded due to dirt accumulation or scratches, leading to diminished beam quality.

Increased Power Consumption

A spike in power consumption can also signal wear and tear. As components age, they might require more energy to produce the same results. This is particularly true for glass laser tubes as they near the end of their life cycle. Monitoring energy usage can help detect inefficiencies early on, allowing for timely maintenance.

Visual Inspection for Damage

Regular visual inspections are essential for detecting early signs of wear. Check for any discoloration or physical damage on the lenses and mirrors, such as chips or cracks. The presence of dust or residue can also impair functionality, indicating the need for cleaning or replacement.

Unusual Noises or Vibrations

Listen for unusual noises or vibrations during operation, as these can be a sign of mechanical issues. Components like bearings and fans might wear out over time, causing changes in the machine’s operational sound. Addressing these issues promptly can prevent further damage and maintain performance.

Consistent Output Quality Checks

Implementing a routine for checking output quality can help track any decline in machine performance. Documenting changes in cutting accuracy or speed will provide valuable data to determine when components might need servicing or replacement. Consistency in output is a reliable benchmark for assessing the health of your machine’s parts.

For more detailed maintenance strategies, refer to our section on maintenance practices8.

Reduced precision indicates component wear in CO2 lasers.True

Worn lenses or mirrors cause rough cuts, indicating wear.

Increased power consumption always means component wear.False

Higher power use can also result from external factors.

Conclusion

By adopting these practices and understanding your machine’s components, you can extend its service life and optimize performance.

-

Discover effective maintenance practices to extend machine lifespan.: Every 2 weeks, OMTech recommends that you clean and re-grease the X-axis guide rails, the Y-axis guide rails, and the 4 bed screws. How to … ↩

-

Learn how to use glass laser tubes efficiently to maximize their life.: Thanks to this efficient water cooling system, users can operate laser glass tubes in sites with higher temperatures up to 70-75 degrees. ↩

-

Learn effective cleaning methods for maintaining CO2 laser cutter lenses.: Are you a new OMTech user looking to get started with your laser engraving journey? An … ↩

-

Discover how to set up an effective maintenance schedule.: You should do the laser machine maintenance tasks, including cleaning and checking the lens and mirrors. In addition, you should also check the cooling system … ↩

-

Explore effective strategies to maintain laser tube efficiency.: Cooling Method: Using purified water for cooling can prevent calcification and other deposits in the glass tube, enhancing the laser’s lifespan. ↩

-

Learn about sealing advancements that reduce gas escape risks.: Hermetic glass-to-metal sealing technology combines metal and glass to create vacuum-tight electrical connectors, packaging, feedthroughs, or optical windows … ↩

-

Learn cleaning techniques to maintain optimal lens and mirror performance.: Proper cleaning and maintenance of optical components are crucial for ensuring optimal performance and longevity of fiber laser cutting machines … ↩

-

Explore detailed methods to extend component life effectively.: If dirt/debris is found, clean the water cooling system before you start using the laser machine. How To Clean a Water Pump Laser Cooling System. ↩