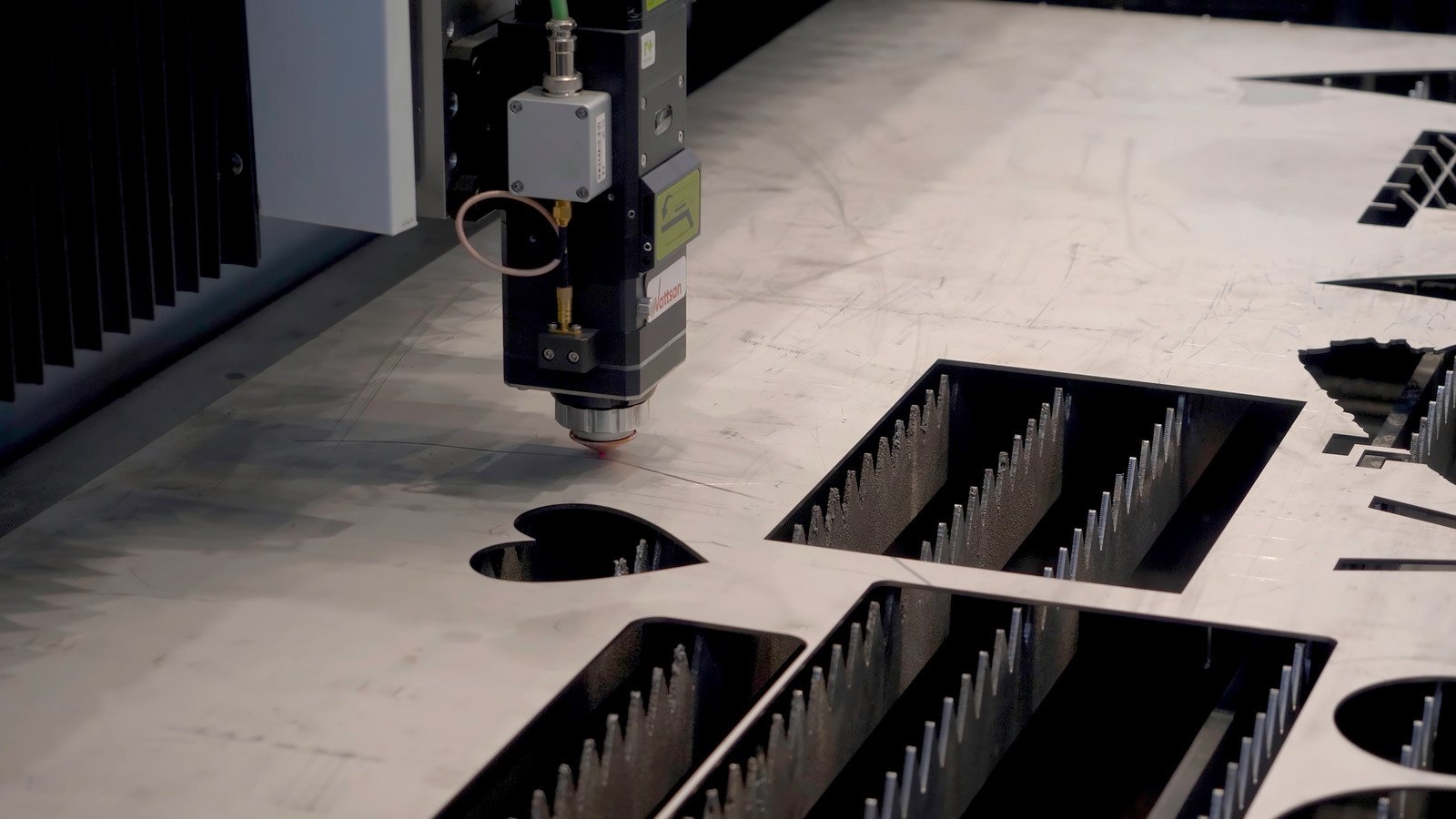

Are you ready to breathe new life into your fiber laser machine? Refurbishing could be your budget-friendly solution!

Successfully refurbishing a fiber laser machine involves a systematic approach: assess the condition, clean and maintain components, replace worn parts, align and calibrate optics, update software, and conduct thorough testing to ensure optimal performance.

While refurbishing may seem daunting, it provides significant benefits in performance and cost savings. Dive deeper into each step of the process to ensure your fiber laser machine functions like new and supports your operational needs efficiently.

Alignment is crucial for refurbishing fiber lasers.True

Proper alignment ensures optimal cutting quality and efficiency.

What Are the Initial Assessment Steps in Refurbishment?

Embarking on a refurbishment journey? Begin with a meticulous assessment to ensure success.

The initial assessment in refurbishment involves inspecting the machine’s condition, evaluating component wear, testing functionality, and identifying any necessary repairs or replacements.

Understanding the Importance of Initial Assessment

Starting a refurbishment project without a thorough initial assessment is like diving into unknown waters. The initial steps are crucial as they set the foundation for all subsequent actions and decisions. This stage helps identify the current state1 of the machine, pinpointing specific areas that need attention and laying out a clear roadmap for the refurbishment process.

Inspecting Physical Components

One of the primary steps is to conduct a visual and physical inspection of the machine components. This includes checking for any visible signs of wear, damage, or misalignment. For instance, guide rails, belts, and optical elements like lenses and mirrors should be meticulously examined for any scratches or dust accumulation. A practical approach is to use a checklist that includes all major components such as:

| Component | Inspection Criteria |

|---|---|

| Laser Head | Check for alignment and wear |

| Nozzles | Look for clogging or damage |

| Electrical Wires | Inspect for fraying or breaks |

| Cooling System | Ensure proper coolant levels |

Evaluating Functional Performance

Beyond physical inspection, assessing the machine’s functionality is essential. This involves testing the laser power output, beam quality, and ensuring that the machine can still perform its core functions effectively. Running diagnostic tests can reveal underlying issues that may not be apparent during a visual inspection.

Identifying Repair and Replacement Needs

Based on the findings from inspections and functional tests, create a list of components that require repair or replacement. This step is critical for budgeting and planning the refurbishment timeline. Common parts that may need replacing include worn bearings, outdated electronic systems, or degraded optical fibers.

Documenting Findings and Creating a Plan

Documentation is key in ensuring nothing gets overlooked. Record all findings from your assessments, including specific measurements and observations. Use this documentation to formulate a detailed refurbishment plan that outlines each step needed to bring the machine back to optimal condition.

In summary, the initial assessment phase is about gathering as much information as possible to make informed decisions throughout the refurbishment process. By following these steps, you can ensure a smoother transition from assessment to action, ultimately leading to a successful refurbishment project.

Initial assessment includes testing machine functionality.True

Testing functionality is part of the initial assessment to ensure performance.

Visual inspection is unnecessary in refurbishment assessment.False

Visual inspection is crucial for identifying wear or damage in components.

How Do You Clean and Maintain a Fiber Laser Machine?

Keeping your fiber laser machine in top condition requires regular cleaning and maintenance.

To clean and maintain a fiber laser machine, regularly clean the laser head and protective windows, remove debris from drawers and surfaces, inspect and clean lenses, and lubricate moving parts. This ensures longevity and optimal performance.

Understanding the Importance of Cleaning and Maintenance

Maintaining a fiber laser machine is crucial to extend its lifespan and ensure it operates efficiently. Regular maintenance prevents buildup that can degrade performance and lead to costly repairs.

Essential Cleaning Techniques

-

Laser Head and Nozzle Cleaning: Use lint-free cloths to wipe down the laser head and nozzle. This removes dust and debris that could obstruct the laser beam, ensuring clear paths for optimal cutting.

-

Cleaning Protective Windows: Regularly clean protective windows with appropriate solutions to avoid scratches that can impact laser focus.

-

Debris Removal: Empty slag drawers and clear work surfaces and tracks of metal shavings and residue to prevent mechanical issues.

Inspecting and Maintaining Optics

-

Lens Inspection and Cleaning: Check lenses for damage or contamination. Clean them carefully using recommended solutions to prevent optical distortion.

-

Lubrication of Moving Parts: Apply light oil to guide rails and moving components to reduce friction and wear over time.

Creating a Maintenance Schedule

Establishing a maintenance schedule2 helps keep tasks organized and ensures nothing is overlooked. Include daily, weekly, and monthly tasks for comprehensive upkeep.

| Task | Frequency |

|---|---|

| Clean Laser Head | Daily |

| Inspect Lenses | Weekly |

| Lubricate Rails | Monthly |

| Remove Debris | After Each Use |

Tools and Products for Effective Maintenance

Invest in quality cleaning products designed specifically for laser machines. These ensure thorough cleaning without causing harm to sensitive components. Regular use of these products can significantly enhance your machine’s performance.

Training and Documentation

Ensure that operators are well-trained in cleaning procedures. Documenting maintenance3 steps not only aids in consistency but also serves as a reference for troubleshooting potential issues.

Incorporating these practices into your routine will help maintain your fiber laser machine’s efficiency and extend its operational life.

Regular cleaning prevents laser performance degradation.True

Cleaning avoids buildup that can obstruct the laser beam.

Lubricating rails weekly ensures optimal machine performance.False

Lubrication is recommended monthly, not weekly, to reduce wear.

When Should You Replace Components During Refurbishment?

Knowing when to replace components during refurbishment is key to ensuring your fiber laser machine runs smoothly and efficiently.

Components should be replaced during refurbishment when they show signs of wear, damage, or reduced performance. Regular assessments can help identify parts like lenses, nozzles, electronic components, and cables that need replacement to maintain optimal machine functionality.

Signs of Wear and Tear

A crucial part of the refurbishment process is identifying components that have succumbed to wear and tear. Lenses and Nozzles, for example, are frequently exposed to high levels of heat and debris, making them prone to scratches and wear over time. Regular inspection can reveal any deterioration in these parts, which can compromise the precision and quality of the laser’s output. Identifying worn parts4 early can prevent bigger issues down the line.

Performance Degradation

Performance degradation is a clear indicator that component replacement may be necessary. This is particularly true for electronic components and control systems. If you notice inconsistent power output or irregular beam quality, it might be time to consider an upgrade or replacement. Replacing outdated electronics with modern counterparts can significantly enhance the machine’s performance, ensuring it meets contemporary manufacturing standards.

Scheduled Replacement of Consumables

Certain parts are considered consumables and should be replaced regularly as part of maintenance routines. These include items such as fiber optic cables and filters, which are crucial for maintaining optimal performance. Scheduled replacements5 help ensure that the machine operates at peak efficiency, minimizing unexpected downtimes.

| Component | Recommended Replacement Interval | Indication for Immediate Replacement |

|---|---|---|

| Lenses | Every 6-12 months | Scratches or coating damage |

| Nozzles | Every 3-6 months | Visible wear or clogging |

| Fiber Optic Cable | Every 1-2 years | Degraded beam quality or transmission |

| Bearings | As needed | Noise or vibration during operation |

Importance of Professional Assessment

While regular checks can be conducted by trained staff, a professional assessment by qualified technicians is recommended at least once a year. These professionals are equipped to diagnose underlying issues that may not be immediately apparent to the untrained eye. They can offer insights into whether an upgrade, rather than a simple replacement, might be more beneficial in certain scenarios, especially with electronic components.

By understanding when and what components need replacing, you ensure the longevity and efficiency of your fiber laser machine. This proactive approach not only enhances performance but also extends the life of the equipment, offering a greater return on investment in the long run.

Lenses should be replaced every 6-12 months.True

Lenses are prone to scratches and coating damage, requiring regular replacement.

Fiber optic cables last over five years without replacement.False

Fiber optic cables need replacing every 1-2 years due to beam quality degradation.

Why Is Alignment and Calibration Crucial in the Process?

Misalignment in your fiber laser machine can lead to inefficiencies and costly errors. Discover why precision is paramount.

Alignment and calibration are critical in refurbishing a fiber laser machine because they ensure the laser beam is accurately focused, maintaining optimal cutting quality and efficiency. Proper calibration also prevents wear on components, extends machine life, and minimizes operational costs.

The Importance of Precision in Laser Refurbishment

In the refurbishment of a fiber laser machine, alignment and calibration are not just procedural steps; they are pivotal to achieving optimal performance. When a laser is misaligned, the beam may not focus correctly on the material surface, leading to poor cuts, increased material wastage6, and potential damage to the workpiece.

How Misalignment Affects Performance

Misalignment can cause several issues, such as:

- Inconsistent Beam Quality: A misaligned laser head can result in an uneven beam profile, affecting the precision of cuts.

- Increased Wear and Tear: Incorrect alignment puts extra strain on the machine’s components, leading to premature wear.

- Operational Inefficiencies: Energy loss due to misalignment can increase operational costs as more power is required to achieve the desired cut quality.

Steps to Ensure Proper Alignment

- Optical Path Verification: Regularly check and adjust mirrors and lenses to ensure the laser beam travels the correct path.

- Use of Alignment Tools: Employ laser alignment tools or jigs specifically designed to aid in precise adjustments.

- Focus Position Adjustment: Ensure that the focus lens is positioned correctly to concentrate the beam’s energy on the material’s surface effectively.

Calibration: Fine-Tuning for Optimal Performance

Calibration complements alignment by fine-tuning the machine settings for various materials and thicknesses. This process involves adjusting power settings, speed, and focus to match specific cutting requirements.

Benefits of Accurate Calibration

- Enhanced Cutting Precision: Proper calibration ensures that cuts are clean and precise, reducing post-processing time.

- Material Versatility: Calibration allows the machine to adapt to different materials, enhancing versatility and expanding operational capabilities.

- Extended Component Lifespan: By operating under optimal settings, wear on components is minimized, extending their service life.

Implementing a Calibration Routine

To maintain peak performance, establish a regular calibration routine:

- Routine Checks: Schedule regular checks and recalibrations based on usage frequency.

- Document Settings: Keep detailed records of settings for different materials to streamline future calibrations.

- Monitor Performance Indicators: Use indicators such as cutting speed and quality as benchmarks for effective calibration adjustments.

Understanding the significance of alignment and calibration7 is essential for anyone looking to refurbish a fiber laser machine successfully. These processes not only enhance performance but also ensure reliability and longevity, making them indispensable steps in machine refurbishment.

Misalignment increases energy consumption in laser machines.True

Misalignment causes energy loss, requiring more power for desired cuts.

Calibration is unnecessary for cutting different materials.False

Calibration adjusts settings for material types, enhancing versatility.

Conclusion

A well-executed refurbishment can extend your machine’s life and efficiency. Consider consulting experts if needed. Keep these guidelines handy for successful refurbishments.

-

Discover why initial assessment is crucial for successful refurbishment.: This initial evaluation sets the foundation for the entire refurbishment project. Its key actions and considerations include: Visual Inspection … ↩

-

Learn how to organize tasks efficiently for consistent machine upkeep.: Clean: Regularly clean the machine (after each use). · Monitor Temperature: · Lubricate: · Check for Debris: · Maintain Grounding: · Replace … ↩

-

Discover the benefits of documenting maintenance steps for troubleshooting.: These eight steps can help a fabricator better manage its maintenance for laser cutting machines and help to reduce the lifetime costs for operating that … ↩

-

Provides detailed insights on recognizing signs of wear in laser components.: A laser marking machine consists of various technical parts. The main cabinet, optical path, galvo scanner, ruler scale, and workstation are noteworthy parts. ↩

-

Lists recommended intervals for replacing key consumable components.: Every six months, the laser marking machine requires more thorough maintenance. During this period, check the exhaust system and safety features … ↩

-

Explore how misalignment leads to increased material waste.: Misaligned shafts can lead to increased friction and excessive wear, which in turn leads to excessive energy consumption. On the flip side, … ↩

-

Understand why precision tuning is crucial for laser performance.: ISO-certified companies are encouraged to calibrate their systems regularly in order to avoid any manufacturing disruptions or downtime from insufficient … ↩