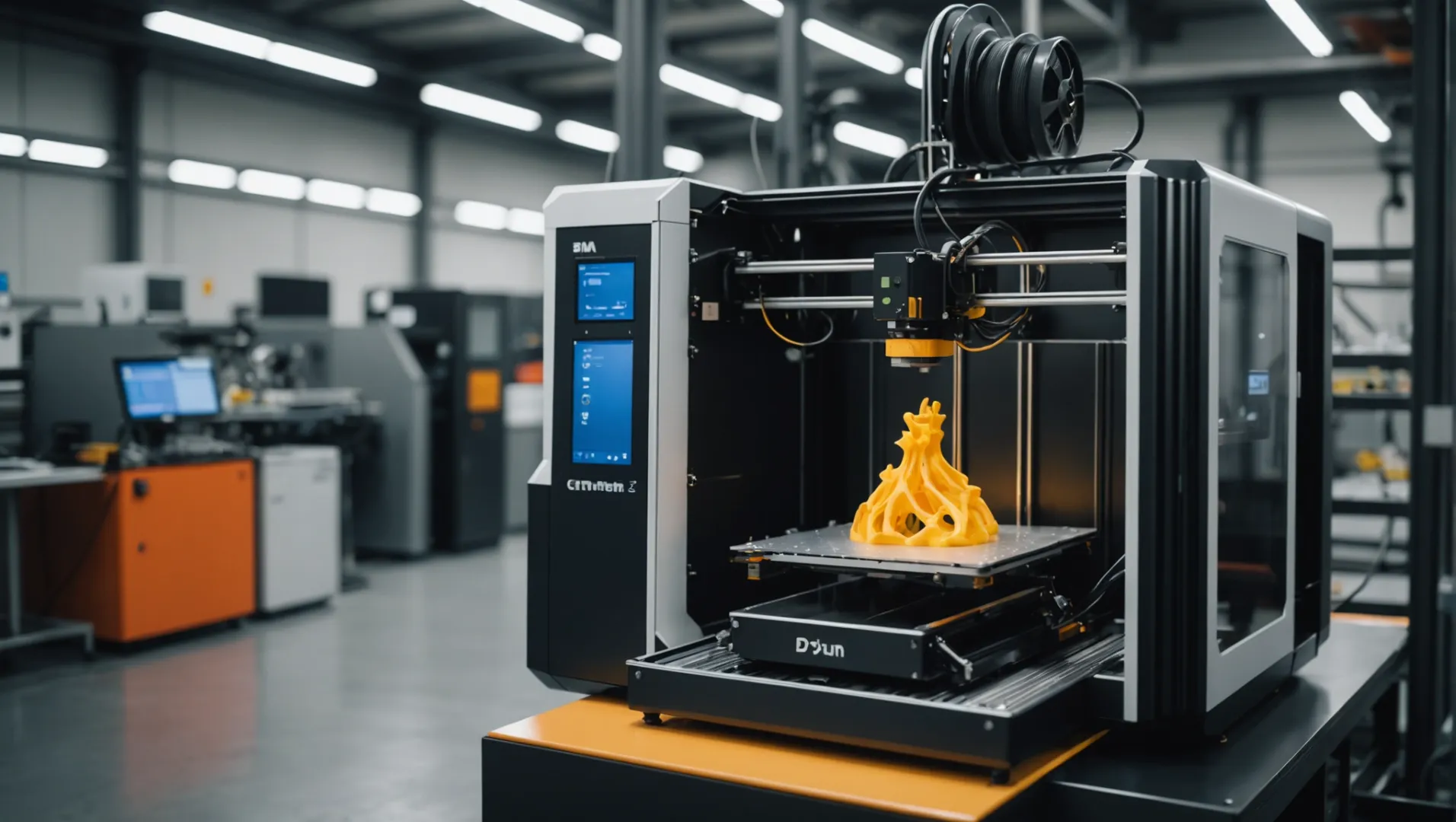

3D printing has taken the world by storm, transforming how we think about manufacturing. But how do we assess the quality of what it produces?

Products made by 3D printing can achieve high quality, comparable to traditional manufacturing, when key factors such as printer calibration, material selection, and post-processing techniques are carefully managed. The technology is continuously improving, making it suitable for diverse applications.

While the potential for high-quality 3D printed products is promising, understanding the nuances that affect quality is essential. Let’s delve deeper into what makes a 3D printed product stand out and explore the factors influencing their performance.

3D printing can achieve high dimensional accuracy.True

Proper calibration and material choice allow for precision within ±0.1mm.

What Factors Influence the Quality of 3D Printed Products?

The quality of 3D printed products hinges on multiple factors, from the technology used to material selection. Understanding these elements is vital for achieving top-notch results.

The quality of 3D printed products is determined by printer calibration, material properties, environmental conditions, and post-processing techniques. By optimizing these factors, manufacturers can produce high-quality parts suitable for various applications.

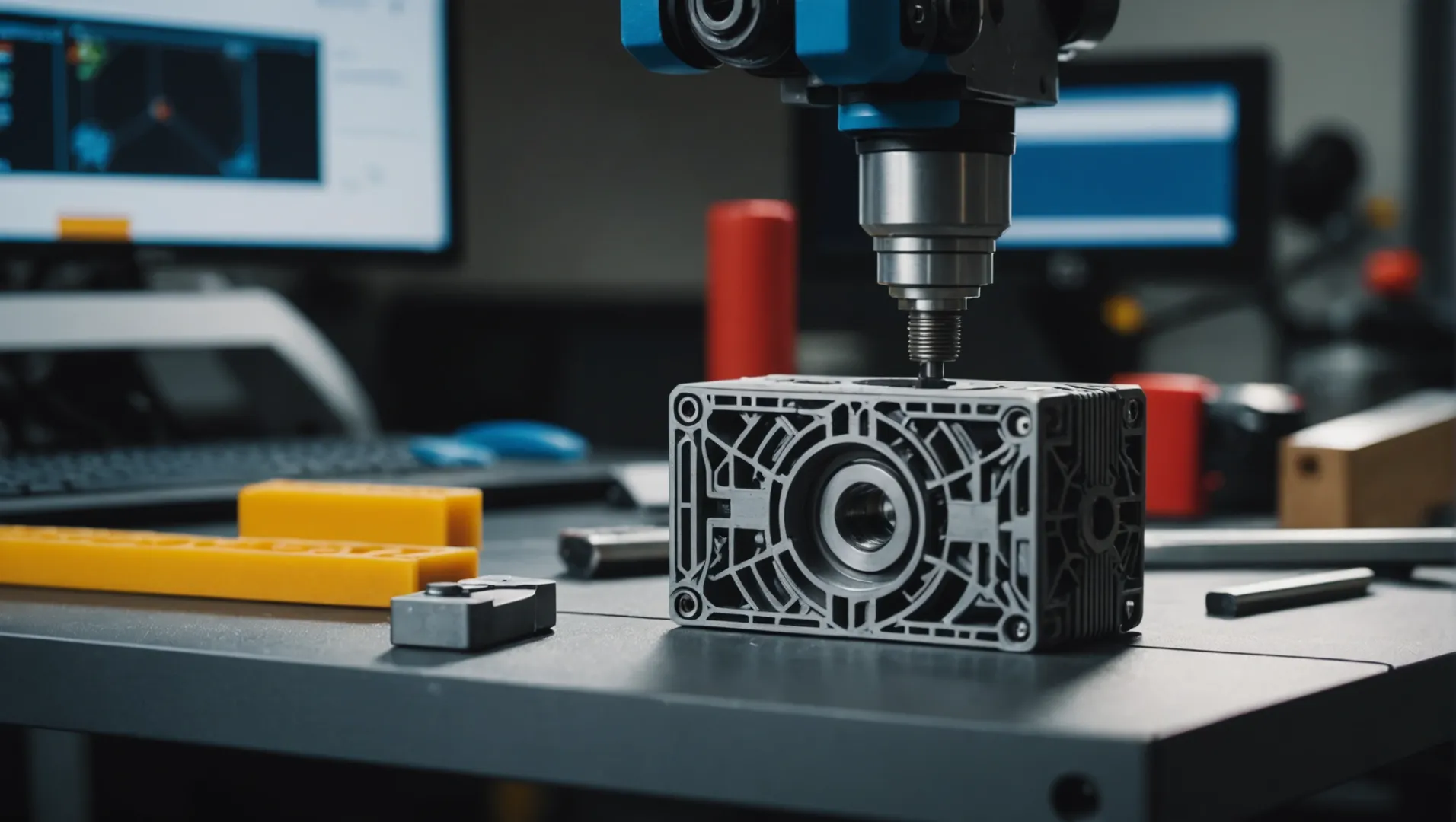

Printer Calibration and Settings

The precision of a 3D printer is crucial for producing parts with accurate dimensions and smooth surfaces. Calibrating your printer ensures that it accurately follows the design specifications. Key calibration areas include:

- Bed leveling: Proper leveling prevents warping and ensures consistent layer deposition.

- Extruder calibration: Ensures the correct amount of material is extruded, affecting both strength and appearance.

Inaccurate calibration can lead to defects such as layer shifting or uneven surfaces. Tools like calipers and optical scanners are often used for verification.

Material Properties

Material choice dramatically impacts the quality of 3D printed products. Factors to consider include:

- Strength and flexibility: Different materials offer varying mechanical properties suitable for specific applications.

- Thermal stability: Affects how materials react during printing and subsequent use.

- Surface finish: Some materials naturally produce smoother surfaces than others.

Exploring different materials1 helps manufacturers select the best option for their needs, balancing cost and performance.

Environmental Conditions

The environment where printing occurs plays a significant role in the outcome:

- Temperature and humidity: These can affect material behavior, especially plastics prone to moisture absorption.

- Airflow: Uncontrolled airflow can lead to cooling inconsistencies and warping.

Using an enclosed print chamber helps maintain a controlled environment, reducing variations in print quality.

Post-Processing Techniques

While a 3D printer lays down the groundwork, post-processing refines the final product. Techniques include:

- Sanding and polishing: Improves surface finish and removes support marks.

- Heat treatment: Enhances mechanical properties by relieving internal stresses.

- Coating or painting: Adds aesthetic appeal and additional protection against environmental factors.

Investing time in post-processing can significantly improve a part’s usability and appearance.

Comprehensive Quality Control Measures

Implementing rigorous quality control protocols ensures consistency and reliability in 3D printed products. This involves:

- Visual inspections: Checking for visible defects and irregularities.

- Dimensional measurements: Ensuring parts meet exact specifications using precision tools.

- Documentation: Keeping detailed records enhances traceability and accountability in production processes.

Manufacturers like Formlabs2 and Hanbang Laser3 exemplify how advanced quality control measures can lead to superior product outcomes.

Proper bed leveling prevents warping in 3D prints.True

Bed leveling ensures even layer deposition, reducing warping risk.

Humidity has no effect on 3D printing quality.False

Humidity affects material behavior, especially moisture-sensitive plastics.

How Does 3D Printing Compare to Traditional Manufacturing Methods?

3D printing is reshaping manufacturing, but how does it really stack up against traditional methods in terms of quality, speed, and versatility?

3D printing offers unique advantages over traditional manufacturing, such as the ability to create complex geometries and reduce material waste. However, it often lags in speed and cost efficiency for large-scale production. Balancing these factors determines its suitability for specific applications.

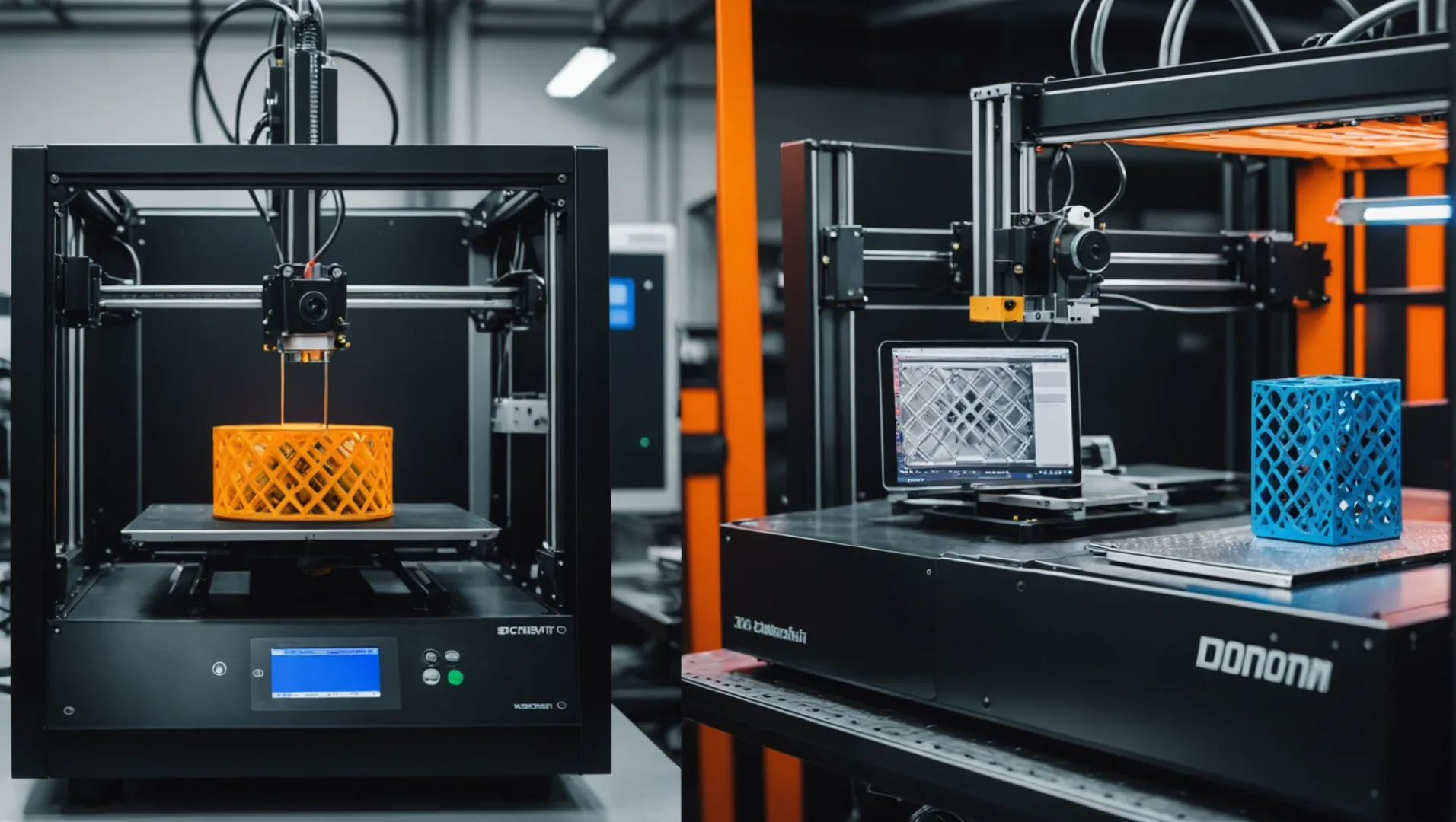

Versatility and Complexity

One of the most significant advantages of 3D printing4 over traditional manufacturing methods is its ability to create intricate and complex designs that would be difficult, if not impossible, to achieve with traditional techniques. This includes producing lightweight structures with internal cavities or detailed lattice frameworks. This flexibility opens up new possibilities for industries such as aerospace, where weight reduction is crucial.

Material and Waste Efficiency

3D printing generally uses less material compared to subtractive methods like CNC machining, which cuts away material from a larger block. This process inherently leads to less waste. Additionally, additive manufacturing5 can utilize a variety of materials ranging from plastics to metals, offering tailored solutions depending on the application.

| Aspect | 3D Printing | Traditional Manufacturing |

|---|---|---|

| Material Waste | Minimal, only what is needed | Often significant due to excess |

| Complexity | High, supports intricate designs | Limited by tooling capabilities |

| Initial Setup Costs | Lower for small batches | High due to tooling/molding |

Speed and Scalability

While 3D printing excels at producing small batches of highly customized products quickly, it typically falls short in terms of speed and cost-efficiency when scaling up for mass production. Traditional methods like injection molding are faster for producing large quantities once the initial setup is complete. This means that while 3D printing is perfect for prototyping and short runs, traditional manufacturing remains dominant in large-scale production scenarios.

Post-Processing Needs

Another consideration is the post-processing requirements. 3D printed parts often need additional finishing steps to achieve desired surface textures or mechanical properties. In contrast, traditional manufacturing methods can produce ready-to-use parts directly from the production line.

Conclusion

Overall, the choice between 3D printing and traditional manufacturing depends heavily on the specific needs of the project. For prototypes, complex designs, or small runs, 3D printing offers unmatched flexibility and innovation potential. However, for high-volume production with consistent quality, traditional methods are often more suitable.

3D printing reduces material waste compared to CNC machining.True

3D printing adds material as needed, unlike CNC, which removes excess.

Traditional manufacturing is faster than 3D printing for mass production.True

Traditional methods like injection molding excel in large-scale production speed.

What Are the Latest Innovations in 3D Printing Technology?

The world of 3D printing is evolving rapidly, with new innovations redefining possibilities across various industries. What are the latest trends in this transformative technology?

Recent innovations in 3D printing include advancements in speed, material diversity, precision, and surface quality. Technologies such as multi-material printing, high-speed FDM, and metal additive manufacturing are paving the way for more efficient and versatile applications.

Multi-Material Printing

One of the groundbreaking developments in 3D printing technology is the ability to print with multiple materials simultaneously. This innovation allows for creating complex structures that integrate various properties, such as flexibility, rigidity, or different colors, within a single print job.

For instance, the latest printers can seamlessly combine plastics and metals, opening new avenues in electronics where conductive pathways can be integrated directly into structural components.

High-Speed FDM Technology

Fused Deposition Modeling (FDM) has traditionally been one of the slower 3D printing methods. However, recent advancements have significantly increased its speed without compromising quality. Intamsys’ new FUNMAT PRO 310 NEO6 exemplifies these advancements with its ability to print at rates much higher than traditional FDM printers, making it ideal for industrial applications that require quick turnarounds.

Metal Additive Manufacturing

Metal 3D printing has seen significant advancements, particularly with the introduction of technologies like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). These methods allow for the creation of highly complex metal parts that are impossible to produce using conventional manufacturing methods.

For example, Hanbang Laser’s innovations7 in unsupported printing and thin-wall forming have resulted in higher precision and reduced material waste, crucial for sectors like aerospace and medical devices.

Surface Finish and Post-Processing Improvements

The surface quality of 3D printed parts is a critical factor that has historically limited the technology’s application in certain industries. Innovations in post-processing techniques and layer resolution have dramatically improved surface finishes.

Techniques like chemical vapor smoothing and advanced sanding methods can now achieve near-mirror finishes, essential for parts requiring high aesthetics or aerodynamic properties.

Diverse Material Options

Material diversity has expanded, with new composites and alloys being developed specifically for 3D printing. Companies like Sino-Platinum Metals8 are advancing metal powders that allow for superior printing quality and mechanical properties.

These innovations in material science not only improve the physical characteristics of printed parts but also broaden the scope of what can be achieved with 3D printing.

Multi-material 3D printing allows combining plastics and metals.True

Multi-material printing enables integration of diverse materials in one job.

High-speed FDM technology compromises print quality for speed.False

Advancements have increased speed without sacrificing print quality.

Can 3D Printing Meet Industrial Quality Standards?

In the evolving landscape of manufacturing, 3D printing stands out as a game-changer. But can it truly meet the stringent quality standards demanded by industry?

Yes, 3D printing can meet industrial quality standards. With advancements in printer technology, material science, and process optimization, 3D printed parts are achieving comparable or even superior quality to traditionally manufactured components. Key factors include accurate calibration, high-quality materials, and rigorous quality control.

Understanding Industrial Quality Requirements

To comprehend whether 3D printing9 meets industrial standards, we must first understand these standards. Industries such as aerospace, automotive, and healthcare have stringent requirements for dimensional accuracy, mechanical properties, and surface finish.

- Dimensional Accuracy: For 3D printing to align with industrial needs, precision is paramount. Technologies like SLM (Selective Laser Melting) and SLA (Stereolithography) offer high levels of accuracy, often achieving tolerances within ±0.1 millimeters.

- Mechanical Properties: Industrial applications demand components that withstand stress and environmental conditions. By selecting appropriate materials and optimizing print parameters, manufacturers can produce parts with desirable mechanical properties.

- Surface Finish: Often overlooked, surface quality affects both aesthetics and function. Advanced post-processing methods enhance surface smoothness, meeting industry expectations.

| Quality Aspect | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Dimensional Accuracy | High with CNC machining | High with SLM/SLA |

| Mechanical Properties | Material-dependent | Material & orientation-dependent |

| Surface Finish | Excellent with finishing | Improved with post-processing |

Examples of Industrial Applications

Aerospace

In aerospace, where safety is non-negotiable, companies are harnessing the potential of 3D printing for parts like brackets and ducts. These components are rigorously tested to ensure they meet FAA standards.

Automotive

The automotive sector benefits from rapid prototyping and production of complex geometries that traditional methods struggle with. Firms like BMW employ 3D printing for both prototype and end-use parts.

Innovations Driving Quality Improvements

Recent innovations have propelled 3D printing towards meeting industrial standards:

- Multi-material printing: Enables blending different properties within a single part.

- Process optimization: Advanced software tools streamline the entire process, from design to final product.

- High-performance materials: Development of heat-resistant and durable materials expands potential applications.

These innovations foster a robust environment for creating parts that not only match but sometimes exceed traditional manufacturing in quality.

The Role of Quality Control

Ensuring every printed part meets specifications requires meticulous quality control. This includes:

- In-process monitoring: Using sensors to track real-time data during printing.

- Post-print inspection: Employing techniques like X-ray CT scanning to detect internal flaws.

- Material consistency: Partnering with certified suppliers ensures material reliability.

By integrating these quality assurance measures, manufacturers can confidently claim that their 3D printed parts align with industrial quality standards.

3D printing meets aerospace quality standards.True

3D printing is used for aerospace parts like brackets, meeting FAA standards.

Surface finish in 3D printing surpasses traditional methods.False

Traditional methods often have superior surface finish without post-processing.

Conclusion

With continuous innovation, 3D printing is becoming a reliable choice for high-quality production across industries.

-

Discover material properties crucial for quality 3D printing outcomes.: The most common FDM 3D printing materials are ABS, PLA, and their various blends. More advanced FDM printers can also print with other specialized materials … ↩

-

Learn how Formlabs ensures high standards in 3D printing.: This guide outlines the steps that healthcare professionals can take to maintain, track and improve the quality of 3D printed SLA parts. ↩

-

Explore Hanbang Laser’s advances in 3D printing technology.: Employing advanced technologies like large layer thickness bidirectional intelligent powder coating, multi-laser scanning, and joining processes, it ensures … ↩

-

Discover more about how 3D printing enables complex design capabilities.: Advantages of 3D Printing Compared to Traditional Manufacturing · More design freedom. · Able to print complex designs at no additional cost. ↩

-

Explore how additive manufacturing minimizes waste effectively.: We undertake a systematic literature review of MAM processes for the aerospace/aeronautic sector focusing on energy and material efficiency. ↩

-

Learn about Intamsys’ cutting-edge high-speed FDM technology.: Offers 8 high-speed material processing options, achieving a productivity range of 500-1000g/day. Doubles capacity for duplicate and mirror mode, reaching 1kg/ … ↩

-

Explore Hanbang Laser’s breakthroughs in metal additive manufacturing.: HBD is committed to further exploring unsupported/less supported printing technology, aiming to pioneer early technological breakthroughs. Our … ↩

-

Discover Sino-Platinum’s advances in metal powder for 3D printing.: Discover Legor’s 950‰ Platinum Alloy Powder for 3D Printing. Innovation in Additive Manufacturing for Jewelry and High-End Watchmaking. ↩

-

Discover how industries ensure 3D printed parts meet strict quality benchmarks.: A new ASME standard, Y14.46, provides guidance for how to relay 3D-printing specific considerations in design documents. ↩