Laser rust removal is transforming the way we tackle rust on metal surfaces, but is it the right choice for you?

Laser rust removal offers several advantages, including being environmentally friendly, non-destructive, and highly precise. However, it also comes with high initial costs, energy consumption, and limited applicability for certain surfaces.

Understanding these pros and cons is just the beginning. Let’s dive deeper into each aspect, from cost implications to environmental impacts, so you can make an informed decision.

Laser rust removal is more precise than sandblasting.True

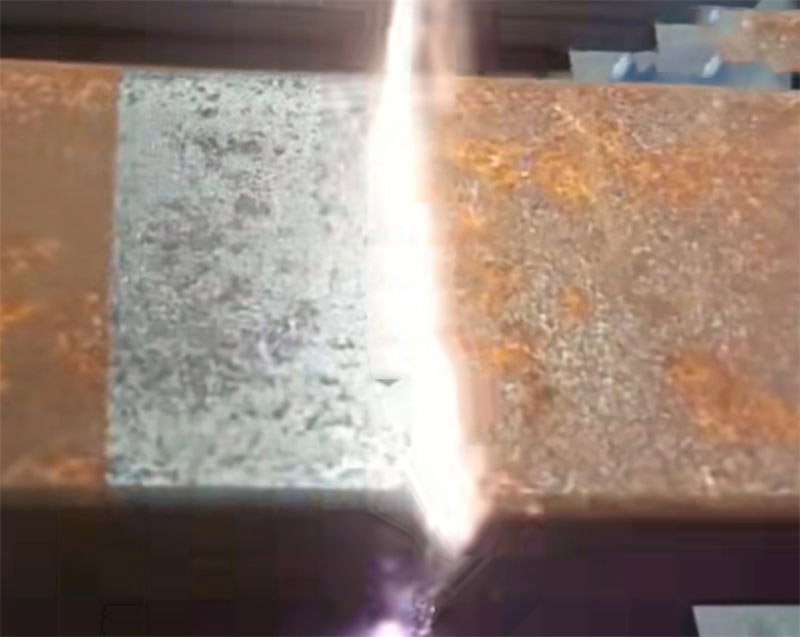

Laser rust removal uses controlled beams for precision, avoiding surface damage.

How Does Laser Rust Removal Compare to Sandblasting?

Rust removal technologies have evolved, with laser methods offering a compelling alternative to sandblasting. But how do they truly compare?

Laser rust removal is a cleaner, more precise method compared to sandblasting. While it is more environmentally friendly and offers non-contact cleaning, it incurs higher initial costs and energy consumption. Sandblasting, on the other hand, is cost-effective for large-scale applications but produces more waste and can damage delicate surfaces.

Environmental Impact

One of the key differentiators between laser rust removal and sandblasting is their environmental impact. Laser rust removal is environmentally friendly1, producing minimal waste in the form of harmless solid powder, whereas sandblasting generates significant dust and waste material that can be detrimental to the environment.

Precision and Surface Integrity

Laser rust removal excels in precision and preserving surface integrity, making it ideal for intricate or delicate surfaces. It uses controlled laser beams to remove rust without touching the metal surface, reducing the risk of damage. Sandblasting, by contrast, uses abrasive materials that can wear down surfaces and cause potential damage, especially to intricate details.

Automation and Versatility

Laser rust removal systems can be automated using advanced robotics, allowing for hands-free operation and increased efficiency in complex structures. This makes it suitable for industries that require precision and versatility in their cleaning processes. Sandblasting is less amenable to automation due to its reliance on manual control, which can limit its versatility.

Cost Considerations

While laser rust removal involves a high upfront cost due to expensive equipment and technology, it can be more cost-effective over time with lower operating expenses and maintenance needs. Sandblasting, however, has lower initial costs but may incur higher costs over time due to frequent maintenance and environmental cleanup requirements.

| Feature | Laser Rust Removal | Sandblasting |

|---|---|---|

| Environmental Impact | Low Waste | High Dust Production |

| Precision | High | Medium |

| Initial Cost | High | Low |

| Automation | Yes | Limited |

| Surface Damage Risk | Low | High |

Energy Consumption

A notable downside to laser rust removal is its energy consumption. The process requires significant power to generate laser beams, which can be a limiting factor in energy-constrained environments. Sandblasting typically uses less energy, relying on mechanical force rather than electrical power.

Applicability to Different Surfaces

Laser rust removal is particularly effective on metal surfaces with specific contaminants. However, it may not perform as well on surfaces with mixed contaminants like paint or concrete residues. Sandblasting is generally more versatile in this regard but can be too aggressive for some sensitive materials.

Safety Considerations

Operating a laser rust remover requires stringent safety measures due to potential eye hazards from the laser beam. Sandblasting presents different safety challenges, primarily related to inhaling dust and requiring protective gear to mitigate health risks.

In summary, both methods have their unique advantages and limitations, making them suited to different applications and requirements.

Laser rust removal is more environmentally friendly than sandblasting.True

Laser rust removal produces minimal waste, unlike sandblasting, which generates dust.

Sandblasting is more precise than laser rust removal.False

Laser rust removal excels in precision, preserving surface integrity better.

What Are the Environmental Benefits of Laser Rust Removal?

Laser rust removal is a game-changer for eco-conscious industries seeking efficient, clean alternatives to traditional methods.

Laser rust removal stands out as an eco-friendly technology by eliminating the need for chemicals and reducing waste. It generates no harmful by-products, minimizes air and water pollution, and ensures safer operations in delicate environments.

Chemical-Free Cleaning Process

Unlike traditional rust removal methods that often rely on harsh chemicals, laser rust removal uses focused light beams to clean surfaces. This eliminates the risk of chemical spills and the subsequent environmental hazards2 associated with chemical disposal. By avoiding chemical agents, laser cleaning not only protects the environment but also reduces health risks for workers involved in the rust removal process.

Reduced Waste Production

Laser rust removal produces solid, inert by-products that are easy to manage and dispose of. This contrasts sharply with methods like sandblasting, which can generate significant dust and debris. The residues from laser cleaning are minimal and non-toxic, further enhancing its appeal as a sustainable solution. These solid particles can often be collected and recycled, thus contributing to a circular economy model.

| Traditional Method | Waste Type | Environmental Impact |

|---|---|---|

| Chemical Cleaning | Liquid Waste | Risk of water and soil pollution |

| Sandblasting | Dust & Debris | Air pollution |

| Laser Cleaning | Solid Particles | Minimal and recyclable |

Energy Efficiency and Safety

While laser systems do consume energy, advancements in technology are continually improving their efficiency. Additionally, laser rust removal can be performed with precision in challenging or sensitive environments, such as historical sites or delicate industrial equipment, without introducing pollutants. This non-contact method ensures that the underlying material remains unharmed, reducing the need for further repairs or replacements.

In settings where safety is paramount—such as near water bodies or protected natural areas—laser cleaning provides a safer alternative by preventing contamination. This capability is especially crucial in industries like maritime maintenance or aerospace, where maintaining environmental integrity is as important as achieving cleanliness.

Learn more about eco-friendly industrial practices3 to understand how laser technology is setting new standards for sustainability across various sectors.

Laser rust removal uses no chemicals.True

Laser rust removal employs focused light beams, eliminating chemical use.

Laser cleaning produces liquid waste.False

Laser cleaning generates solid, inert particles, not liquid waste.

Is Laser Rust Removal Cost-Effective in the Long Run?

Laser rust removal is an innovative technology, but does it justify its cost over time?

Laser rust removal is cost-effective long-term due to low maintenance costs and high efficiency, despite its high initial investment. It offers significant savings in environmental and operational costs compared to traditional methods.

Initial Investment vs. Long-term Savings

Laser rust removal systems typically come with a high initial investment, ranging from tens of thousands to millions, depending on the equipment’s power and model. However, this initial cost is offset by the system’s longevity and low operational expenses. A laser rust remover can operate for up to a decade with minimal maintenance, translating to significant savings over time.

For instance, a 3000-watt laser rust remover priced at around $10,000 can cover approximately 50 square meters per hour. With operational costs largely confined to electricity and occasional maintenance, it stands out as a viable option for large-scale operations.

Operational Efficiency and Productivity

Laser rust removal boasts fast processing times and high precision. This efficiency reduces labor costs and time, making it more productive than traditional methods like sandblasting or chemical rust removal. The table below illustrates a comparison:

| Method | Cost per Square Meter | Efficiency | Environmental Impact |

|---|---|---|---|

| Laser Rust Removal | $4.3 | 50 sqm/hour | Low |

| Sandblasting | $7 – $29 | 60 sqm/hour | High |

| Chemical Rust Removal | Variable | 40 sqm/hour | High |

Environmental and Safety Cost Benefits

Laser rust removal is an environmentally friendly option, as it does not produce hazardous waste or require chemical treatments. This not only reduces environmental compliance costs but also lessens the health risks to operators. Implementing robotic integration4 further enhances safety and operational efficiency.

While the energy consumption5 remains a concern due to high power requirements, advances in technology are expected to lower these costs over time. In the context of sustainability and green initiatives, laser rust removal offers a promising alternative.

Impact of Technological Advancements

Technological improvements are continually reducing the cost of laser systems. As the market for laser rust removers expands, prices are expected to decrease further, making it an increasingly cost-effective solution.

In conclusion, while laser rust removal presents a significant upfront cost, its long-term benefits in operational efficiency, environmental impact, and safety make it a cost-effective choice for many industries. Evaluating these factors can help determine if it aligns with your specific needs and operational goals.

Laser rust removal has lower environmental impact than sandblasting.True

Laser rust removal does not produce hazardous waste, unlike sandblasting.

Initial cost of laser rust removal is lower than traditional methods.False

Laser systems have a high initial investment compared to traditional methods.

What Safety Measures Are Necessary When Using Laser Rust Removal?

Laser rust removal is a groundbreaking technique, but what safety precautions should you take during its use?

The use of laser descaling requires strict adherence to safety protocols, including the wearing of goggles and skin-protective clothing, as well as adequate ventilation, proper operator training and certification. Regular maintenance of equipment, warning signs and barriers, and fire precautions are also essential.

Understanding the Risks of Laser Rust Removal

Laser rust removal involves high-intensity beams that can pose significant risks if not managed properly. Direct exposure to laser beams can lead to severe eye injuries and skin burns. The importance of eye protection6 cannot be overstated, as even brief exposure can cause irreversible damage.In addition, in the process of laser descaling, some smoke will be generated, which contains vaporized rust dust and material particles, which may irritate the respiratory tract and adversely affect the lungs and other respiratory organs after inhalation by the human body. Moreover, when the laser descaling machine is working, its internal high-voltage system and power supply and other parts may also cause electric shock injury if not properly protected.

Essential Personal Protective Equipment (PPE)

Operators must wear suitable PPE, including laser safety goggles specifically designed to filter out harmful wavelengths. The table below outlines essential PPE for laser rust removal:

| Protective Gear | Purpose |

|---|---|

| Laser Safety Goggles | Protects eyes from laser exposure |

| Protective Clothing | Shields skin from potential burns |

| Respirators | Prevents inhalation of dust and particles |

Securing the Workspace

A designated area should be established for laser operations to minimize risks. This includes setting up warning signs and barriers to prevent unauthorized access. The workspace should be free of reflective surfaces, which can scatter laser beams and increase exposure risk.

Ventilation and Dust Control

Laser rust removal generates dust and debris. Ensure adequate ventilation to prevent respiratory issues. Employing a dust extraction system7 can help maintain air quality and reduce inhalation hazards.

Operator Training and Safety Protocols

Training is crucial for anyone operating laser rust removal equipment. Comprehensive training programs should cover equipment handling, emergency procedures, and safety protocols. Regular safety drills can reinforce these practices.

By adhering to these measures, operators can effectively mitigate the risks associated with laser rust removal, ensuring both personal safety and operational efficiency.

Laser rust removal doesn't require eye protection.False

Eye protection is crucial to prevent severe eye injuries from laser exposure.

Ventilation is unnecessary in laser rust removal.False

Proper ventilation prevents respiratory issues from dust and debris.

Conclusion

In conclusion, while laser rust removal boasts efficiency and environmental responsibility, a careful cost-benefit analysis is crucial for your specific needs.

-

Learn how laser rust removal minimizes environmental impact compared to sandblasting.: Eco-friendly technology: Laser cleaning reduces chemical waste and has a lower environmental footprint. Safety and Compliance: Laser cleaning is safer for … ↩

-

Understand the dangers of chemical use in rust removal.: Traditional petroleum derived rust preventatives require expensive degreasers and hazardous disposal methods, while biobased products are inherently. ↩

-

Explore how laser technology enhances sustainability efforts.: The smaller the industrial footprint, the less impact on the environment. Laser technology is exceptionally compact and decreases the space … ↩

-

Explore how robotics enhance safety and efficiency in laser cleaning.: The Robot Cleaning Machine combines the precision of laser technology with the dexterity of robotics. It can be used to clean, texture, and even mark surfaces. ↩

-

Understand energy implications and potential cost-saving measures.: The results shows synergy between cleaning rate and specific energy with the laser pulse frequency and galvo scanning speed as the two most significant factors. ↩

-

Understand why specific eye protection is crucial for laser operations.: Laser safety goggles and glasses are designed to protect the eyes from harmful laser radiation by absorbing or reflecting specific wavelengths of light. ↩

-

Discover systems that enhance air quality during laser operations.: All of our laser dust collectors provide a unique, heavy-duty and effective solution for removing fumes and smoke, as well as filtering dust and other particles … ↩