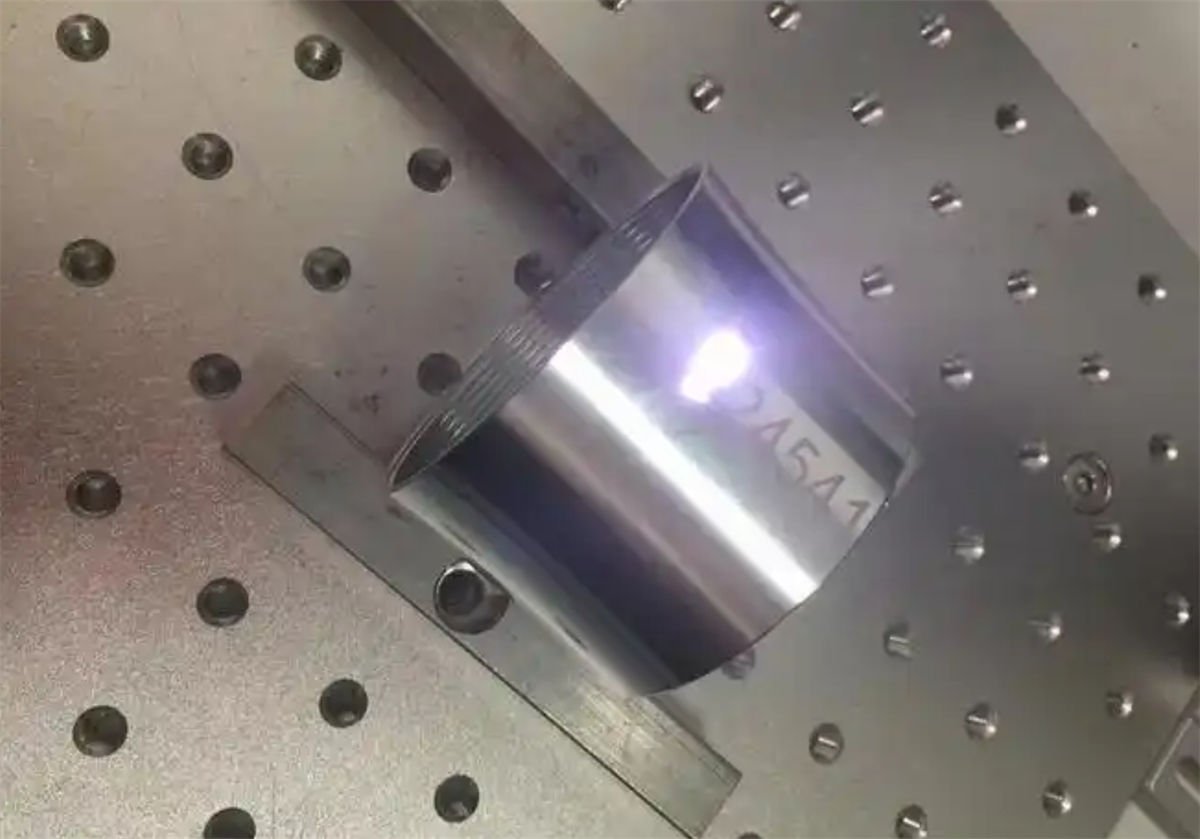

Choosing between permanent and temporary laser marking can feel like deciding between a tattoo and a temporary sticker. Both have their own charm, but they serve very different purposes.

Permanent laser marking provides long-lasting durability, perfect for product identification and regulatory compliance. In contrast, temporary laser marking is suited for short-term visibility, ideal for testing or manufacturing processes.

I remember when I first encountered laser marking, it was like discovering a new language. Permanent markings are like the bold statements we want to stand the test of time, etched into the very fabric of our lives—or in this case, the product. They endure through wear and tear, just like a cherished family heirloom.

On the other hand, temporary marks are akin to those fleeting messages you jot down during a busy day—vital for the moment but not meant to last forever. They’re perfect for situations where you need something to stand out just temporarily, perhaps like a reminder note on your fridge.

Understanding these differences not only helps in selecting the right marking but also in optimizing costs and ensuring compatibility with various materials. Let’s explore further how these nuances play out in real-world applications.

Permanent laser marking is ideal for regulatory compliance.True

Permanent marks are durable and suitable for compliance needs.

Temporary laser marking is not used in manufacturing processes.False

Temporary marking is often used for testing in manufacturing.

How do Permanent and Temporary Laser Markings Compare in Durability?

Ever wondered how laser markings withstand the test of time—or don’t? Here’s a peek into the durability dance between permanent and temporary marks.

Permanent laser markings endure wear, extreme conditions, and last a product’s lifetime, while temporary ones are designed to be easily removed after short-term use.

Durability Aspects

When I first dived into the world of laser marking, I was amazed by how these little beams of light could create such lasting impressions. Permanent laser markings are the stalwarts of durability1. They’re like that trusty old leather jacket that just gets better with age—resistant to scratches, corrosion, and even the harshest environmental elements. This makes them a go-to for industries like automotive and aerospace, where identification needs to survive the long haul.

On the flip side, temporary laser markings remind me of those trendy stickers my kids love—fun for now but not built to last. They fade away under physical wear or chemical exposure, perfect for when you need something temporary, like during a product’s early stages or for short-lived promotional events.

Material Interactions

The way these markings interact with different materials is quite fascinating. Permanent markings dive deep, often through engraving or ablation2, transforming the material at its core. It’s like etching a promise into stone—meant to stay. Metals, plastics, and ceramics are common canvases for these enduring marks.

Temporary markings, however, barely scratch the surface. They might cause a color change without altering the material significantly, making them easy to remove or allowing them to naturally fade away. It’s akin to writing in sand—a temporary message soon washed away.

| Type | Durability | Common Uses |

|---|---|---|

| Permanent | High resistance to wear | Serial numbers, barcodes |

| Temporary | Easily removable | Testing, short-term ID |

Environmental Impact

I remember the time I left a metal piece with permanent laser markings outside in the garden as an experiment. Despite sun, rain, and wind, those marks stood firm. They shrug off UV radiation, moisture, and temperature swings like seasoned adventurers.

In contrast, temporary markings are like fair-weather friends—they fade quickly under similar conditions. Sunlight or chemical exposure can make them disappear faster than you’d expect, which is why they’re not reliable for outdoor or long-term use.

Application Suitability

Choosing between permanent and temporary laser marking often depends on what I need. If compliance and traceability are at stake, permanent markings3 are my rock-solid choice—unremovable and regulation-friendly.

But in ever-changing environments like assembly lines or quality control processes where information shifts rapidly, temporary markings are heroes. They let me mark things without leaving a lasting scar.

When deciding on permanent or temporary laser marking, I consider factors like material type, environmental exposure, and how long I need the marking to last. By weighing these elements carefully against industry needs for efficiency and compliance.

Permanent laser markings resist extreme temperatures.True

Permanent laser markings are designed to withstand harsh conditions, including extreme temperatures.

Temporary laser markings last longer than permanent ones.False

Temporary markings fade quickly, unlike permanent ones which are designed for longevity.

How Do Application Needs Influence Your Laser Marking Choice?

When it comes to laser marking, the right choice can feel like picking the perfect coffee brew—tailored to your specific needs.

Application needs dictate the choice of laser marking by affecting considerations such as material type, permanence, speed, and cost. These factors determine whether to opt for permanent or temporary marks.

Understanding Material Compatibility

I remember the first time I had to choose a laser for marking metal parts. It was like finding the right tool for a job I’d never done before. Metals, for instance, usually call for fiber lasers4 because they create high-contrast marks that last. On the other hand, when working with plastics5, CO2 lasers are my go-to—they’re gentle enough to prevent any unwanted melting.

| Material | Recommended Laser |

|---|---|

| Metal | Fiber Laser |

| Plastic | CO2 Laser |

Assessing Marking Quality and Duration

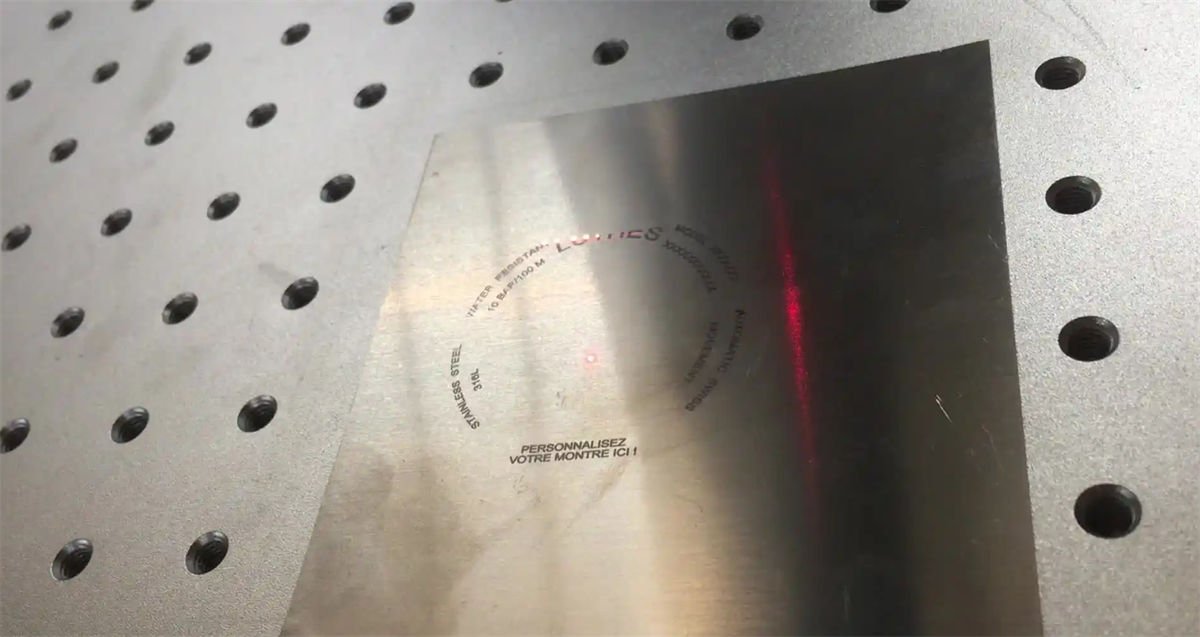

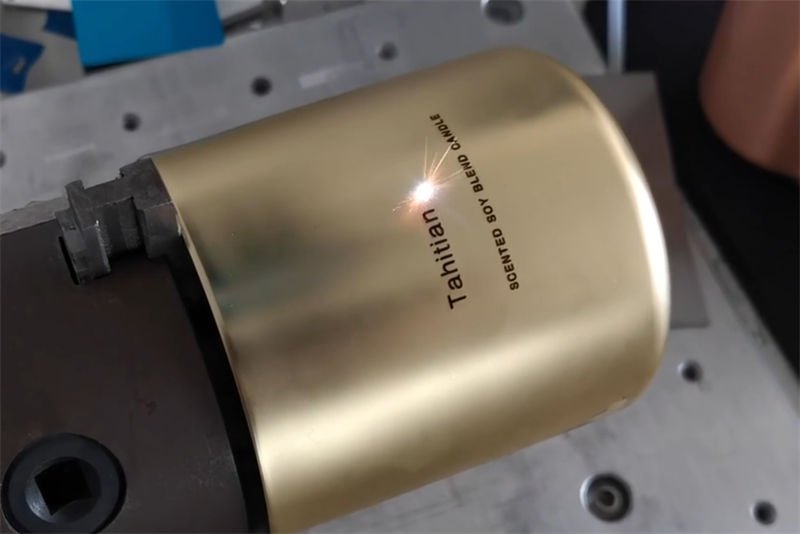

In my line of work, there are times when I need markings to last as long as the product itself, like with automotive parts. Here, permanent marks that withstand environmental challenges are crucial. Other times, temporary marks do the trick—perfect for tracking items during the manufacturing process.

Evaluating Operational Speed and Efficiency

Speed matters. I’ve seen high-speed production lines where UV lasers6 excel, delivering quick results without compromising quality. Yet, for projects requiring intricate detail, slower, precise methods are often more fitting.

Balancing Cost and Benefits

Finding cost-effective solutions is like balancing on a tightrope. Permanent laser systems might have steep upfront costs but often prove more economical over time due to their durability. Meanwhile, temporary systems might start cheap but can rack up costs if frequent reapplication is needed.

Environmental Considerations

Work environments also play a big role. Conditions like fluctuating temperatures or high moisture demand resilient marking solutions. In such cases, permanent marks are typically more reliable than their temporary counterparts, which can fade under these conditions.

Take the automotive industry7, for example. It demands markings that endure throughout a vehicle’s lifespan, facing various stresses along the way.

Metals require fiber lasers for high-contrast marks.True

Fiber lasers are ideal for metals due to their precision and contrast.

CO2 lasers are suitable for marking ceramics.False

YAG lasers are recommended for ceramics, not CO2 lasers.

How do I choose the best technique for different materials?

Ever wondered how to make the perfect cut or mark on different materials?

Choosing the right technique for each material depends on properties like hardness and conductivity. Metals benefit from high-power lasers, while plastics require lower intensity to avoid melting. Techniques like laser cutting, engraving, and annealing are tailored to these differences for optimal results.

When I first started working with different materials, I realized that not all cutting and engraving techniques are created equal. It’s like cooking; you wouldn’t use a steak knife to slice a tomato, right? Similarly, understanding the unique characteristics of each material ensures you pick the right tool for the job.

Techniques for Metals

When I work with metals, I find that high-power laser techniques are my go-to. Laser engraving gives me deep, lasting marks, perfect for durable materials like stainless steel and titanium. It’s like carving your name into a tree trunk—there for the ages. Learn more about laser engraving8.

For sheet metals, laser cutting is essential. Imagine trying to cut a piece of paper with blunt scissors—precision is key! Adjusting factors like beam focus ensures the metal’s thickness and type guide me to a clean cut.

Techniques for Plastics

Plastics are a different beast. They’re more delicate, like handling a fragile vase. Laser marking lets me create contrast without damaging the surface, ideal for materials like ABS and polycarbonate.

I’ve found laser annealing incredibly useful for branding without engraving. It’s like painting a design on a window—visible but leaving the glass untouched.

Techniques for Ceramics and Glass

Ceramics and glass are the prima donnas of materials—brittle and demanding specialized care. Laser etching helps me avoid cracking while still achieving detailed designs, akin to sketching on a fragile eggshell.

For ceramics, laser ablation is my precision tool, allowing me to remove material without compromising its integrity.

A table can help summarize these techniques:

| Material | Technique | Application |

|---|---|---|

| Metals | Engraving | Permanent marking |

| Plastics | Marking | Surface contrast |

| Ceramics | Etching | Detailed design |

Factors to Consider

In my experience, choosing the right technique involves considering material thickness, thermal conductivity, and desired outcomes. Conductive materials might need different settings to prevent heat damage.

By understanding these nuances, I’ve been able to explore new possibilities in my projects, whether in manufacturing or artistic endeavors. Experimenting with these techniques is like unlocking new levels in a game—each one brings fresh challenges and rewards in material processing9.

Laser engraving is ideal for stainless steel.True

Laser engraving creates deep, permanent marks on stainless steel.

Laser annealing damages plastic surfaces.False

Laser annealing changes color without damaging the plastic surface.

What Are the Cost Implications of Each Laser Marking Type?

Ever wondered how laser marking costs impact your business? It’s like choosing a car—do you go for a flashy sports car, a reliable sedan, or something in between?

The cost implications of laser marking vary by type: fiber lasers are pricier but highly durable, CO2 lasers are budget-friendly for organic materials, and UV lasers excel at delicate surfaces but come at a higher price.

Fiber Laser Marking Costs

When I first started exploring laser technologies, fiber lasers caught my attention with their promise of durability and efficiency. Initially, I was taken aback by the steep upfront cost—it’s like investing in a high-end tool that seems expensive but pays off in the long run. Fiber lasers are built to last, demanding little maintenance, and they can handle a variety of materials, which adds to their versatility. It’s like buying a Swiss army knife—it might cost more initially, but it’s invaluable in the long run.

| Cost Factor | Description |

|---|---|

| Initial Setup | High; due to advanced technology and quality components. |

| Maintenance | Low; fiber lasers require minimal upkeep. |

| Material Versatility | High; marks various materials with excellent precision. |

CO2 Laser Marking Costs

I remember considering CO2 lasers when budgeting was my main concern. They’re akin to a trusty old sedan—reliable for everyday needs without breaking the bank. Ideal for organic materials like wood and leather, CO2 lasers offer a more wallet-friendly initial setup. However, just like with an older car, you might find yourself scheduling more frequent maintenance check-ups to keep everything running smoothly.

| Cost Factor | Description |

|---|---|

| Initial Setup | Moderate; suitable for non-metallic materials. |

| Maintenance | Moderate; requires regular checks to ensure performance. |

| Material Compatibility | Ideal for organic materials like wood and leather. |

UV Laser Marking Costs

Venturing into UV lasers was like eyeing the latest tech gadget—expensive but packed with cutting-edge features. These lasers are perfect for delicate tasks, marking sensitive surfaces without causing any damage. Think of them as the specialists—more costly upfront due to their precision technology but essential for niche applications like electronics.

| Cost Factor | Description |

|---|---|

| Initial Setup | High; precision technology for sensitive materials. |

| Maintenance | Moderate; requires specialized knowledge for upkeep. |

| Niche Applications | Ideal for electronics and delicate materials marking. |

Considerations for Operational Costs

As I navigated through the options, I quickly learned that it’s not just about the initial price tag. You have to think beyond the purchase—consider energy consumption, maintenance schedules, and material waste total cost evaluations10. It’s like planning a road trip where you need to account for fuel, snacks, and even tolls along the way.

By understanding these operational costs, I could align my choices with both financial goals and the practical demands of my work.

Evaluating these aspects will help you determine the best laser type for your needs while ensuring that financial and operational expectations are met efficiently.

Fiber lasers have high initial setup costs.True

Fiber lasers require advanced technology and quality components, increasing initial costs.

CO2 lasers are ideal for marking metals.False

CO2 lasers are better suited for organic materials like wood and leather.

Conclusion

Permanent laser marking offers durability for long-term use, while temporary marking is suited for short-term applications. Understanding their differences aids in selecting the right method for specific needs.

-

Learn how permanent laser marks withstand harsh environments due to robust material interaction. ↩

-

Discover the methods like engraving that make permanent marks durable. ↩

-

Explore how permanent marks ensure compliance with industry regulations. ↩

-

Discover which fiber lasers excel in producing high-contrast marks on metal surfaces for durable applications. ↩

-

Explore top CO2 lasers suited for gentle marking on plastics, preventing material damage. ↩

-

Learn how UV lasers offer rapid marking solutions without compromising precision. ↩

-

Understand the importance of laser marking in ensuring part traceability and durability in vehicles. ↩

-

Discover how laser engraving creates durable, detailed markings on metal surfaces. ↩

-

Explore various methods used in industrial and artistic material processing. ↩

-

Learn strategies to assess total cost ownership effectively, ensuring budget-friendly decisions. ↩