Have you ever thought about the amazing options with metal 3D printing? I want to share my joy with you!

3D printers sometimes print using metal filaments. This depends on the type of printer. Different printers have special needs for metal filaments. Knowing these details is very important. It helps you succeed in your projects. Understanding this is key.

I first started exploring 3D printing. I was captivated by using metal filaments. Creating durable parts with a sturdy finish thrilled me. However, I quickly discovered that printers have differences. Some printers handle metal filaments beautifully. Others might really struggle. Understanding your printer’s compatibility is very important. Know the specific requirements. With this knowledge, embark on amazing projects. Discover what metal 3D printing probably achieves!

Metal filaments can be used in all 3D printers.False

Not all 3D printers are compatible with metal filaments; specific printer types are required.

Understanding printer compatibility is crucial for metal printing.True

Knowing your printer's compatibility with metal filaments ensures successful 3D printing results.

What Types of 3D Printers Are Compatible with Metal Filaments?

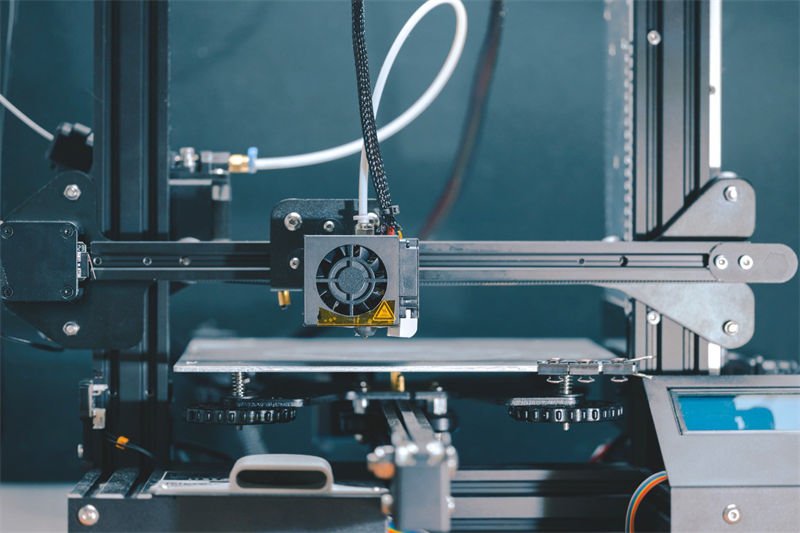

Wondering which 3D printers use metal filaments? I totally understand! This topic might seem confusing. Let’s explore it step by step to discover the top choices for your projects.

If you want to use 3D printing with metal filaments, you have several options. FDM, SLS, Binder Jetting and DED printers are available. Each type offers unique features. Every printer also has specific requirements. Choose according to your project needs. Consider your budget too.

Types of 3D Printers Compatible with Metal Filaments

When I first started with 3D printing, I was really surprised by the possibilities, especially with metal filaments. Creating strong and functional parts right from my desk was very exciting. However, I soon found that not all printers manage metal materials well. As I explored different printers, I learned that each has unique strengths and uses. Let me share what I uncovered about various printers that can use metal filaments.

Fused Deposition Modeling (FDM) Printers

FDM printers were my first interest in the 3D printing world. They are common and often the first choice for beginners. Some FDM printers are tailored specifically for metal filaments. These printers use a material made from plastic mixed with metal powder. High temperatures are essential to melt that filament properly.

Some popular FDM printers that support metal filaments include:

| Printer Model | Max Temperature | Filament Type |

|---|---|---|

| Prusa i3 MK3S+ | 300°C | Metal composite |

| Raise3D Pro2 | 300°C | Metal composite |

| Artillery Sidewinder X1 | 260°C | Metal composite |

You might discover FDM printers that are good for metal filaments. Check technical details at metal filament compatibility1.

Selective Laser Sintering (SLS) Printers

SLS technology amazed me! It employs a laser to join powdered materials layer by layer, including metal powders. Its precision is very impressive. It is great for making intricate and dense designs, which are useful in industrial uses. However, they often cost more than FDM printers.

Some notable SLS printers include:

| Printer Model | Build Volume | Material Types |

|---|---|---|

| Formlabs Fuse 1 | 320 x 320 x 400mm | Metal, plastics |

| Sinterit Lisa | 150 x 200 x 300mm | Metal, nylon |

You may find some SLS printers intriguing. For more on SLS technology, see SLS printing advantages2.

Binder Jetting Printers

Binder Jetting sparked my interest due to its efficiency. This method involves placing a binder onto a powder bed, followed by a sintering process to achieve full density. It offers faster production times and creates complex shapes without needing support structures.

Key examples of Binder Jetting printers include:

| Printer Model | Layer Thickness | Speed |

|---|---|---|

| Desktop Metal Studio System | 50-200 microns | Fast compared to SLS |

| ExOne Innovent+ | Adjustable | High throughput |

Look at examples of Binder Jetting printers. For more on Binder Jetting, check Binder Jetting overview3.

Direct Energy Deposition (DED) Printers

DED is truly fascinating. It uses focused thermal energy to join materials as they are added. This technique is often for fixing or adding to existing parts, making it ideal for aerospace and industrial uses.

Consider these DED printers:

| Printer Model | Technology Type | Applications |

|---|---|---|

| Optomec LENS | Laser-based | Aerospace components |

| Sciaky EBAM | Electron beam | Large metal structures |

Observe DED printers. For further DED tech information, view DED technology insights4.

These varied printing methods each have their benefits and fit different needs and budgets. Whether for prototyping or making functional metal parts, knowing your options empowers you. If you are starting with metal 3D printing like I did, I hope this guide is really helpful.

FDM printers can print with metal composite filaments.True

FDM printers, especially specialized models, can effectively use metal composite filaments for 3D printing.

SLS printers are the cheapest option for metal printing.False

SLS printers are generally more expensive than FDM printers, making them less budget-friendly for metal printing.

What Are the Challenges of Printing with Metal Filaments?

Have you ever thought about what it truly takes to print with metal filaments? The path probably includes surprising obstacles and interesting turns. I will share the challenges I encountered. These challenges transformed my 3D printing projects.

Printing with metal filaments presents challenges. These filaments require higher temperatures for proper material properties. Printers must be compatible with these materials. Necessary post-processing steps are important. Costs are higher when compared to traditional plastics. Many know these details.

Printing with Metal Filaments

Printing with metal filaments feels very exciting, though it has challenges. I started my 3D printing journey and discovered many obstacles with these special materials. Material properties posed complex problems. Printer compatibility created more issues. Each step really taught me patience. Every attempt demanded new solutions. This is what I found during my exploration.

Material Properties and Challenges

Printing with metal filaments presents unique challenges due to their distinct material properties. Metal filaments typically contain metal powders mixed with a polymer binder, which can complicate the printing process. The density and viscosity of these materials can lead to issues like clogging and inconsistent flow rates during printing.

Moreover, these materials often require higher temperatures for melting and extrusion. This necessitates specific printer configurations, such as enhanced heating elements and nozzles capable of withstanding elevated temperatures. Understanding these material properties is crucial for achieving high-quality prints.

For example, if a metal filament requires a nozzle temperature of 250°C, but your printer can only reach 220°C, you may face significant print failures.

Printer Compatibility

Not all 3D printers are designed to handle metal filaments. Many standard FDM printers may struggle with the abrasive nature of metal-filled materials, leading to nozzle wear and tear. It’s essential to ensure that your printer is compatible with metal filaments before proceeding.

Here’s a quick reference table for printer compatibility:

| Printer Type | Compatibility with Metal Filaments | Recommendations |

|---|---|---|

| Standard FDM | Limited (abrasive wear) | Upgrade to hardened nozzles |

| High-Temperature FDM | Good | Use specialized metal filaments |

| SLA/DLP | Not applicable | Use resin-based metal alternatives |

Understanding your printer’s capabilities can prevent costly mistakes.

Post-Processing Requirements

After printing with metal filaments, post-processing is often necessary to achieve the desired finish and strength. This can include:

- Debinding: Removing the polymer binder used in the filament.

- Sintering: Heating the printed object to fuse the metal particles together.

These processes can add significant time and complexity to your project. For instance, sintering typically requires a controlled environment to avoid oxidation, which may necessitate additional equipment.

Cost Considerations

Metal filaments are generally more expensive than their plastic counterparts. The cost of raw materials, along with potential additional equipment needs for sintering or specialized nozzles, should be factored into your budget before deciding to work with metal filaments.

Conclusion (for future reference)

In summary, while metal filaments offer exciting opportunities for creating durable parts, they come with challenges that must be carefully considered. For more insights on optimizing your 3D printing process with metals, check out these resources:

Metal filaments require higher extrusion temperatures than plastics.True

Metal filaments demand elevated nozzle temperatures, often exceeding 250°C, to ensure proper melting and extrusion during the printing process.

All 3D printers can effectively print with metal filaments.False

Not all printers are suitable for metal filaments; many standard FDM printers struggle due to abrasive wear and temperature limitations.

How Do Metal Filaments Compare to Traditional Filaments?

Do you wonder about the differences between metal and traditional filaments in 3D printing? Follow me on this journey. We explore how these materials compare in strength, ease of printing and real-world uses.

Metal filaments differ from traditional ones because of their material and features. They include aspects such as printability, strength and weight. These filaments provide durability for functional parts. Traditional options deliver versatility and are easy to use for many purposes.

Material Composition

When I started exploring 3D printing, I was really surprised by metal filaments. They mix plastic, like PLA or ABS, with small metal powders. It’s similar to adding chocolate chips to cookie dough, turning it into something special. This mixture gives metal filaments amazing qualities. However, they also bring their own obstacles.

Traditional filaments like PLA are easy to use and available everywhere. On the other hand, the rough nature of metal filaments wears down the nozzle quickly. I remember my first try with metal filament. I was so eager to see my print. Later, I found my nozzle was slightly damaged. A lesson learned!

Printability

In terms of printability, traditional filaments perform better. They flow easily during printing, just like syrup on pancakes. Metal filaments, however, need more careful handling.

| Feature | Metal Filaments | Traditional Filaments |

|---|---|---|

| Nozzle Wear | Higher | Lower |

| Bed Adhesion | Can be tricky | Generally easy |

| Extrusion Temperature | Higher (around 200-250°C) | Lower (around 180-220°C) |

| Filament Flexibility | Less flexible | More flexible |

From my experiences, metal filaments result in impressively strong prints. They require special nozzles and a lot of patience.

Strength and Applications

Metal filaments stand out in strength. They work well for high-performance parts that face real-world stress. Think of machine parts or functional prototypes. I once created a tool holder with metal filament. It remains strong after months of use. Conversely, traditional filaments are flexible but not as strong for tough tasks.

For designs focusing on looks, traditional filaments are great. They have a wide range of colors and finishes. I’ve made vibrant decorative items that always bring joy when I look at them.

Weight Considerations

Weight is another important point to consider. Metal filaments can increase the weight of your prints. This is a double-edged sword; it’s excellent for durable projects but not ideal for lightweight designs. For example, some consumer products I’ve studied need lighter materials.

By understanding these differences between metal and traditional filaments, you can better choose what fits your project’s needs. For more information on material types and uses, check these resources: understanding filament types6 and choosing the right filament7.

Choosing filaments goes beyond materials; it’s about discovering what suits your creativity and practical needs. I’m excited for you to dive into these endless possibilities!

Metal filaments require specialized nozzles for printing.True

Due to their abrasive nature, metal filaments can wear out standard nozzles, necessitating specialized ones for effective printing.

Traditional filaments are less flexible than metal filaments.False

Metal filaments generally exhibit less flexibility compared to traditional options like PLA, which are more adaptable in prints.

What Are the Best Practices for Using Metal Filaments in 3D Printing?

Are you curious about how to improve your 3D printing skills with metal filaments? I have personal insights to share. These changed my projects significantly. They could really do the same for you!

Select hardened nozzles for metal filaments in 3D printing. These nozzles resist wear very well. Adjust the temperature settings between 200°C and 250°C. This gives you the best results. Keep print speeds around 30-50 mm/s. This speed is really good for printing. Use techniques like heated beds or adhesives. These help with bed adhesion. Probably try post-processing for really smooth finishes.

Understanding Metal Filaments

When I first started with metal filaments, I felt both excited and slightly scared. Printing solid, metal-like objects seemed magical! I discovered that these filaments mix thermoplastic with metal powders. This mix allows for impressive prints but requires a different method than what I was used to. I remember my first try – I watched the print come to life with joy, yet faced frustrating challenges too.

Key Best Practices

-

Choose the Right Nozzle

Using the right nozzle is very important! Metal filaments are rough. Early on, I learned that a hardened steel nozzle is necessary. A regular brass nozzle wears out quickly. A good nozzle lasts longer and provides consistent prints. -

Adjust Temperature Settings

Each metal filament brand has a perfect temperature. I set my printer between 200°C to 250°C. Following the manufacturer’s advice is really helpful. It saved me from much trial and error! -

Optimize Print Speed

Slower print speeds improve quality. For metal filaments, 30-50 mm/s works well. My first prints were too fast and lacked detail. Slowing down made me enjoy the process more. -

Bed Adhesion Techniques

Warping caused me many headaches! Proper bed adhesion is crucial. A heated bed or PVA glue helped a lot. Using a brim8 or a raft9 gave prints extra stability. -

Post-Processing Options

After printing, metal filaments can look amazing with finishing touches. Sanding or polishing turns rough prints into beautiful pieces. I tried chemical smoothing once – wow! It improved my project greatly.

Troubleshooting Common Issues

| Problem | Potential Cause | Solution |

|---|---|---|

| Poor Layer Adhesion | Incorrect temperature or speed | Adjust settings accordingly |

| Clogging | Abrasive nature of filament | Use a hardened nozzle |

| Warping | Inadequate bed adhesion | Apply adhesives or use a heated bed |

| Surface Imperfections | Fast print speed | Slow down the printing process |

By remembering these best practices, I managed the challenges of printing with metal filaments more easily. If you want to learn more, check out advanced techniques10 or supplier recommendations11. Enjoy the journey and happy printing!

Hardened steel nozzles are essential for metal filaments.True

Metal filaments are abrasive, so hardened steel nozzles prevent wear and ensure consistent printing quality.

Printing speed should exceed 50 mm/s for best results.False

Slower print speeds enhance detail and layer adhesion, making speeds above 50 mm/s ineffective for metal filaments.

Conclusion

Explore the possibilities of 3D printing with metal filaments, including compatible printer types and essential tips for successful projects.

-

Discover the best types of printers for your metal filament projects, enhancing your knowledge for better purchasing decisions. ↩

-

Learn about different printing technologies and their unique benefits in working with metal materials. ↩

-

Explore cost-effective options and specifications to find a printer that fits your budget and requirements. ↩

-

Get in-depth insights into advanced techniques like DED and their industrial applications in manufacturing. ↩

-

Discovering tips on overcoming these challenges can enhance your printing experience and improve outcomes when using metal filaments. ↩

-

Explore this link for a comprehensive overview of different 3D printing materials, including detailed comparisons that can help you choose wisely based on your projects. ↩

-

This resource will guide you on selecting the right filament for your specific needs—vital for achieving optimal results in your printing projects. ↩

-

Discovering these practices will enhance your skills and improve print quality significantly. ↩

-

Learn about effective troubleshooting methods to resolve common metal filament issues. ↩

-

Explore advanced techniques that can further optimize your metal filament usage. ↩

-

Find reliable suppliers for high-quality metal filaments. ↩