Are you considering delving into the world of machining but worried about the challenges that come with learning to operate a milling machine?

Operating a milling machine can be challenging, especially for beginners without a mechanical background. Basic operations are relatively easy to learn, but mastering advanced skills like programming and precision control requires significant practice and understanding.

Keep reading to discover practical insights into the learning curve of operating a milling machine, explore necessary foundational knowledge, and find out what resources can aid in mastering this intricate craft.

Beginners find basic milling operations intuitive.True

Basic tasks like powering on and moving the worktable are straightforward.

What Basic Knowledge is Needed Before Starting?

Before diving into the intricacies of a milling machine, understanding foundational concepts can significantly ease your learning curve.

Before starting with a milling machine, knowledge in mechanical processing, including mechanical drawing, material properties, and cutting principles, is essential. This foundation aids in selecting appropriate cutting parameters, enhancing efficiency and precision during operations.

Understanding Mechanical Drawing

Mechanical drawing is a universal language in the engineering world. It provides detailed specifications necessary for manufacturing parts. Grasping mechanical drawing basics1 allows you to interpret technical drawings accurately, which is critical when setting up milling operations.

Properties of Metallic Materials

Knowing the properties of materials is fundamental in determining how they will react during the milling process. Metals have diverse characteristics like hardness and toughness that influence the choice of cutting tools and parameters2. For instance, a metal with high hardness requires specific tool materials and cutting speeds to avoid tool wear.

Cutting Principles

Understanding basic cutting principles helps in selecting the correct cutting speed, feed rate, and depth of cut. This knowledge is crucial for optimizing efficiency and minimizing tool damage. Familiarity with concepts like chip formation and tool life3 allows for better prediction of outcomes in machining processes.

Basic Operation Skills

Initial operations on a milling machine involve powering on and off, manipulating the worktable, and installing cutting tools. These tasks require minimal mechanical knowledge but learning these basic operations4 thoroughly can prevent costly mistakes during advanced tasks.

The Role of Practice

Mastering these basics isn’t just about understanding theories; practice is paramount. Engaging in hands-on training allows you to apply theoretical knowledge practically. Whether through professional courses or self-directed learning, regular practice helps in refining your skills and overcoming initial challenges.

Mechanical drawing is crucial for milling setup.True

It ensures accurate interpretation of technical drawings for operations.

Material properties don't affect cutting tool choice.False

Material hardness and toughness dictate tool material and speed.

How Do Basic Operations on a Milling Machine Work?

Unravel the fundamental operations of a milling machine and discover how these tasks lay the groundwork for more complex machining skills.

Basic operations on a milling machine include powering on, moving the worktable, and tool installation. These actions are intuitive and can be mastered with practice. Understanding machine controls, worktable movement, and tool setup are essential steps for beginners to progress in milling operations.

Understanding the Milling Machine Control Panel

The control panel of a milling machine is the nerve center of its operations. It typically features buttons, switches, and displays that control spindle speed, direction, and other essential functions. Familiarity with these controls is crucial. For instance, the power button initiates machine operation, while controls for X, Y, and Z-axis movement allow for precise adjustments. Getting accustomed to these controls is often the first step for anyone new to milling machines.

Worktable Movement and Its Importance

Moving the worktable accurately is key to successful milling operations. This involves using the control panel to position the worktable precisely along the X, Y, and Z axes. Practical experience in manipulating these movements helps ensure that materials are correctly aligned for cutting. A beginner might use simple materials to practice basic movements before advancing to more challenging projects.

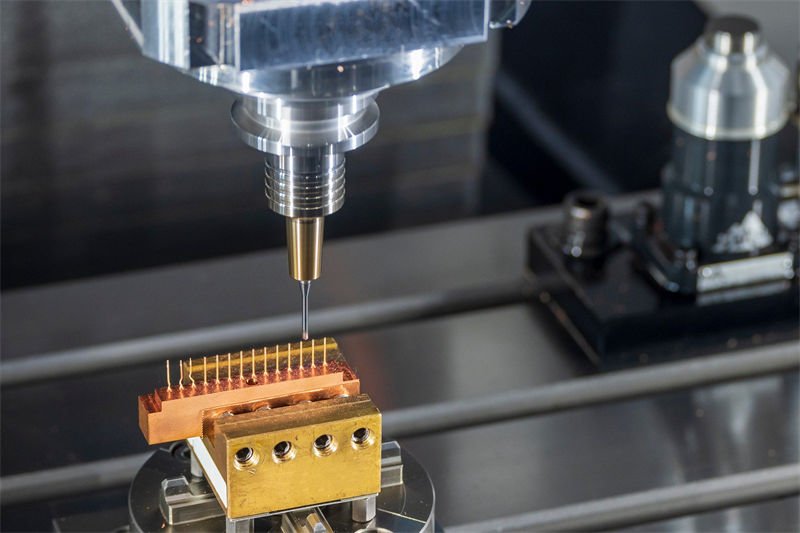

Tool Installation: Precision and Practice

Proper tool installation is vital for safe and efficient machining. Beginners should focus on learning how to mount tools securely. The process includes selecting the appropriate tool based on material properties and ensuring it is firmly attached. Using tool installation guides5 can enhance this learning phase. Mastery comes from understanding not only the mechanical fit but also the reasons behind tool choice.

Hands-On Training: Bridging Theory and Practice

While theoretical knowledge is foundational, hands-on practice is irreplaceable. Engaging in guided training sessions or workshops can accelerate learning. These settings provide opportunities to apply theoretical concepts in real-world scenarios, bridging the gap between understanding and execution. Many educational institutions offer such programs.

Practical Exercises for Skill Development

To effectively master basic milling operations, engaging in practical exercises is beneficial. Consider creating a simple project that involves moving the worktable to specific coordinates or installing various tools to achieve different cuts. This approach not only solidifies fundamental skills but also builds confidence in handling more advanced tasks later on.

Utilizing practical milling exercises6 can provide structured progression in skill development, ensuring a thorough grounding in basic operations.

The power button starts the milling machine.True

Pressing the power button is the initial step to start machine operations.

Tool installation is not crucial for beginners.False

Proper tool installation is essential for safe and effective machining.

Is Manual Programming More Challenging Than Using Software?

In the realm of CNC machining, the debate between manual programming and software-aided programming is ongoing. Which one truly poses more challenges for operators?

Manual programming can be more challenging than using software for complex machining tasks due to its reliance on extensive spatial understanding and precise coding. While software simplifies tasks with graphical interfaces and automated functions, mastering it requires comprehensive knowledge of parameter settings and tool path optimization.

Manual Programming: A Test of Skill and Patience

Manual programming in CNC machining involves the use of G-codes and M-codes to dictate the machine’s actions. This method is often seen as challenging, especially when dealing with complex three-dimensional shapes. Operators must possess a strong grasp of spatial geometry and mathematical concepts. For example, machining a part with intricate curves requires precise calculations and an understanding of advanced interpolation instructions. The task becomes even more daunting when considering factors like tool radius compensation.

Consider this scenario: a machinist needs to create a mold cavity with varying depths and angles. Each movement and cut must be meticulously planned, requiring not only knowledge but also experience to foresee potential issues.

Software-Aided Programming: Simplifying Complexity

On the other hand, automatic programming software like Mastercam or UG offers a different approach. These tools utilize graphical interfaces to simplify program creation. By importing 3D models and setting machining parameters, the software automatically generates tool paths. This process significantly reduces the complexity involved in manual coding.

A key advantage of software is its ability to visualize the machining process before execution, allowing operators to identify errors early. However, mastering such software requires dedication to learn various settings and optimization techniques.

| Manual Programming | Software-Aided Programming |

|---|---|

| Relies on direct coding | Uses graphical interfaces |

| Requires deep spatial knowledge | Simplifies complex processes |

| High precision demands | Allows simulation and error detection |

Factors Influencing Difficulty

Several factors determine whether manual or software programming is more challenging for an individual:

- Prior Experience: Those with a strong background in geometry and coding may find manual programming less daunting.

- Learning Curve: Software requires learning interface-specific operations, which can vary significantly between different platforms.

- Project Complexity: For simpler tasks, manual programming might suffice, but as complexity grows, software becomes more advantageous.

Ultimately, the choice between manual and software-aided programming depends on the machinist’s strengths, project requirements, and available resources. Understanding both methods’ nuances will enhance one’s versatility in the machining field.

Manual programming requires more spatial knowledge than software.True

Manual programming relies on direct coding, demanding deep spatial understanding.

Software-aided programming is less precise than manual methods.False

Software allows simulation and error detection, ensuring high precision.

What Are Common Challenges in Precision Control and Troubleshooting?

Precision control and troubleshooting in milling machines pose significant challenges, demanding expertise and experience.

Achieving precision in milling operations involves understanding machine parameters, selecting appropriate tools, and managing machining processes. Troubleshooting requires multidisciplinary knowledge to identify mechanical, electrical, and programming faults. Mastering these aspects is crucial for ensuring high-quality machining results.

Understanding Precision Control

Precision control in milling machines is a critical aspect that affects the quality of the final product. Operators must have a comprehensive understanding of the precision parameters7 such as positioning precision and repeat positioning precision. These parameters determine how accurately the machine can perform the desired operations. For instance, achieving high precision in cutting requires the correct selection of cutting speed, feed rate, and cutting depth.

A significant challenge is balancing these parameters to maintain dimensional accuracy and surface quality. Even minor miscalculations can lead to significant deviations, affecting the overall quality of the product.

Selecting Appropriate Tools and Processes

Choosing the right cutting tools is crucial for precision control. Different materials require different types of tools, each with specific properties like hardness and toughness. Understanding these properties helps in selecting the optimal tool for a given task.

The machining process also needs careful planning. For high-precision parts, it’s essential to control the tool’s feed rate and cutting depth precisely. This ensures that the final dimensions are within acceptable tolerances.

Troubleshooting Challenges

Troubleshooting in milling operations is another area where operators face numerous challenges. Faults can arise from various sources:

-

Mechanical Faults: These include issues like damage to transmission components or wear of guide rails. Mechanical faults usually manifest through unusual noises or vibrations during operation.

-

Electrical Faults: These are often more complex, involving circuit short circuits or control system failures. Diagnosing electrical faults requires a solid understanding of both the machine’s hardware and software.

-

Programming Errors: Mistakes in programming can lead to incorrect tool paths, causing machining errors. Understanding G-code and M-code intricacies is vital for identifying and correcting these errors.

Building Expertise Through Experience

For beginners, overcoming these challenges requires practice and experience. It’s beneficial to learn from experienced operators who can provide insights into common troubleshooting techniques8. Hands-on experience is invaluable in developing the skills necessary for effectively managing precision control and troubleshooting.

Regular maintenance and calibration of the machine are also essential practices to prevent faults from occurring. By keeping the machine in optimal condition, operators can minimize downtime and maintain high precision levels in their operations.

Tool selection affects milling precision.True

Different materials require specific tools for optimal precision.

Electrical faults in milling are easy to fix.False

Electrical faults require complex understanding of hardware and software.

Conclusion

Operating a milling machine can be mastered with dedication, practice, and the right resources. Embrace the journey, reflect on your progress, and take actionable steps toward enhancing your skills.

-

Learn to interpret technical drawings accurately for effective setup.: Learn how to prepare a mechanical drawing(or technical drawing) so that machinists know … ↩

-

Discover how material properties influence tool selection.: Cutting tool materials have different combinations of hardness, toughness and wear resistance, and are divided into numerous grades with specific properties. ↩

-

Gain insights into optimizing cutting efficiency and durability.: A key indicator of a good chip is shape. The preferred outcome for any application is chips shaped as sixes and nines or a single conical shape. ↩

-

Understand essential tasks to prevent errors in advanced operations.: Share your videos with friends, family, and the world. ↩

-

This guide offers step-by-step instructions on safe tool installation.: Installing mill tool. 413 views · 2 months ago …more. Michael … Vertical (Bridgeport) Milling … ↩

-

Explore practical exercises to develop foundational milling skills.: First projects/exercises should be: Learn to square up a piece of work. Learn how to find an edge. Learn how to center the spindle over a layout line or center … ↩

-

Understand essential parameters for achieving high precision in machining.: Feed Rate: The feed rate is the relative movement speed between the cutter and workpiece during milling operations. This value is measured in … ↩

-

Learn effective methods to diagnose and fix common milling machine issues.: End Mill and Milling Troubleshooting Guide · Premature Tool Wear · End Mill Edge Chipping · Causes · Tool Breakage · Chip Packing · Chatter · Burs. ↩