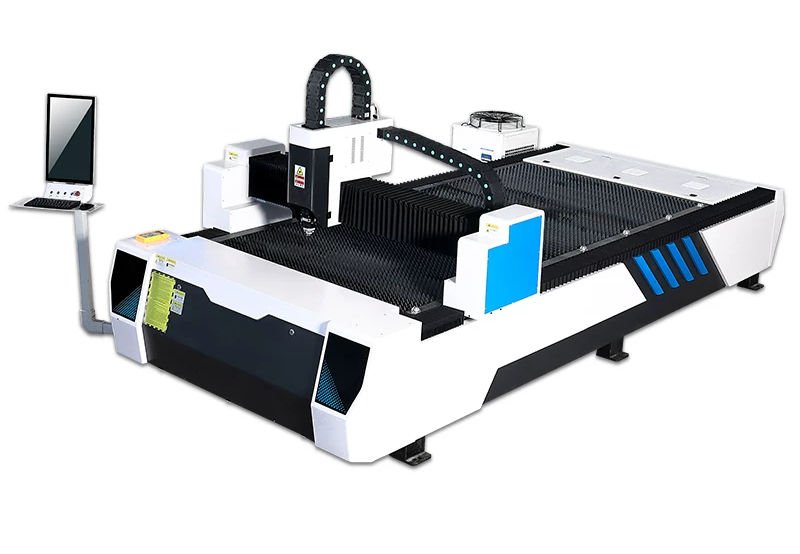

Finding the top laser fiber cutting machine feels like picking the right tool in a craftsman’s shop. It must suit your needs precisely.

Germany’s Trumpf, Switzerland’s Bystronic, China’s Hans Laser and Japan’s Amada stand at the forefront of laser fiber cutting machine production. Each company provides unique benefits suited for different industrial needs.

I recall diving into the world of laser fiber cutting machines. The experience felt thrilling, almost like a kid surrounded by candy choices. Each brand offered something special. Trumpf had precise German technology. Bystronic came with innovative Swiss designs. Hans Laser promised low costs with strong Chinese tech support. Amada, with its Japanese build quality, appealed to those who valued very strong reliability.

The decision involved more than picking a popular name. Understanding my specific needs was key. The types of materials I used mattered a lot, as did the support after buying. These aspects were crucial in my choice. I soon realized that thinking beyond brands was vital. How a machine would fit into my work and budget was important.

Trumpf is a leading manufacturer from Germany.True

Trumpf is indeed a renowned German company specializing in laser technology.

Bystronic is a Japanese company.False

Bystronic is actually based in Switzerland, not Japan.

Why is Germany’s Trumpf a leader in laser cutting?

Trumpf from Germany leads the laser cutting world. Their technology seems magical. Their service feels welcoming. But why is everyone talking about them in this crowded market?

Germany’s Trumpf dominates the laser cutting industry. Their advanced technology helps them excel. Their machines perform exceptionally well. Customers receive excellent service. Trumpf invests a lot in research and development. This keeps them in front. Their precision and efficiency are unmatched. Trumpf sets a global standard.

Innovation and Technology

Imagine this: I have always been intrigued by how new ideas change industries, and Trumpf is a great example of this happening. With a strong desire to explore new limits, they put a lot of money into research and development1, especially in fiber laser technology. The first time I watched one of their machines, the accuracy amazed me; it was like watching an artist create. Their love of new ideas keeps their machines very advanced. They stay top-of-the-line.

Robust Performance

Have you ever owned something that just keeps going? Trumpf’s machines are made to do that. They use first-rate materials and complex engineering processes. This way, their equipment stays just as dependable as an old, favorite jacket. A unique feature, adaptive beam shaping, adjusts cutting for different materials. It changes the game for anyone who needs to switch tasks quickly. It’s very efficient.

| Feature | Trumpf Advantage |

|---|---|

| Beam Quality | High consistency |

| Maintenance | Low frequency |

| Efficiency | Energy saving |

Comprehensive Customer Support

I once felt really supported by a company. It changes everything. Trumpf provides a wide customer service2 network, including remote diagnostics and on-site help. It feels like having a reliable friend always ready, reducing downtime so progress continues without issues.

Global Influence and Reach

Trumpf doesn’t only achieve success in Germany – they succeed all around the world. With a smart presence across Europe, Asia, and North America, they adjust to different market needs and laws. This reminds me of times when being adaptable meant succeeding rather than failing in my own projects.

Collaboration and Ecosystem

I learned that teamwork is powerful. Trumpf teams up with other tech leaders to add helpful technologies to their solutions. They include improvements in automation and AI, which really change manufacturing processes for the better.

Sustainability Commitment

We all wish to help our planet, right? Trumpf shares this commitment to environmental care. They created eco-friendly technologies3 that lower waste and energy use, fitting well with global sustainability goals. It comforts me to know they care about our world as much as they care about new technology.

Trumpf pioneered fiber laser technology.True

Trumpf's focus on fiber laser innovation has set industry standards.

Trumpf machines require frequent maintenance.False

Trumpf machines are known for low maintenance frequency and durability.

What Makes Hans Laser Products Unique in the Market?

Have you ever thought about why some laser products look brighter in a busy market? Let’s explore why China’s Hans Laser stands out.

Hans Laser products stand out with groundbreaking technology. Prices are low and services after buying are excellent. Products offer flexible solutions that satisfy different industry needs. They deliver top quality. They guarantee high efficiency.

Innovative Technology

I remember the first time I saw Hans Laser’s fiber lasers. It felt like finding a hidden gem among many options. These lasers are not just machines; they amaze with their accuracy and dependability4. People in automotive or electronics industries find these lasers make complex tasks simple. Their advanced parts really push the limits of laser technology.

Cost-Effectiveness

Once, I compared Hans Laser’s prices with some European brands. It was like finding a luxury item at a discount. Great quality without the high cost. For small businesses like mine, where money is important, Hans Laser’s affordable solutions really change the game. They offer excellent quality and good prices, helping us invest in top equipment without spending too much.

| Feature | Hans Laser | Other Brands |

|---|---|---|

| Innovation | Advanced fiber laser technology | Varies |

| Price | Competitive and cost-effective | Generally higher |

| After-Sales Support | Comprehensive and accessible | Limited or costly |

Comprehensive After-Sales Support

In my job, we cannot have downtime. Hans Laser’s after-sales support feels like a safety net. They are there when needed, keeping machines working well. It’s like having a reliable friend supporting you, letting you focus on what really matters – growing your business.

Versatile Applications

Hans Laser products remind me of a Swiss army knife. They are really versatile! They handle sheet metal processing and electronics manufacturing with ease. Various materials and industry requirements don’t challenge them. This adaptability5 is very valuable, especially when market needs always change.

Environmental Considerations

Today, sustainability is not just a trend – it is very necessary. Hans Laser understands this with their eco-friendly methods. Their energy-saving machines help lower carbon footprints while keeping performance high. It’s comforting to know that as we reach our business goals, we also help the planet by maintaining efficiency6. That’s very reassuring.

Hans Laser's fiber lasers offer exceptional precision.True

Hans Laser is known for its advanced fiber laser technology, enhancing precision.

Hans Laser products are more expensive than European brands.False

Hans Laser offers cost-effective solutions compared to European counterparts.

What Makes Japan’s Amada Machines So Special?

Have you ever wondered why Amada machines are famous in the metalworking world? Let’s explore their special features that have everyone talking.

Amada machines shine with their blend of advanced technology, extraordinary precision and sturdy build. These machines have modern CNC systems and automation features. They really increase productivity and reduce operational expenses.

Advanced CNC Integration

The first time I saw an Amada machine, it felt like stepping into the future. Their CNC systems offer precise control over machining. It’s as if the machine understands your desires before you do. Imagine shaping detailed designs with little effort. This happens because their CNC technology constantly updates with new automation features. I watched their fiber laser cutting machines in action. The machines used advanced optics to cut precisely, leaving barely any waste.

Exceptional Build Quality

When I first touched an Amada machine, its strength surprised me. Built from top-quality materials, these machines handle heavy work for long periods without any issues. It’s like having a reliable friend always ready for action. Their durability means less downtime and fewer maintenance problems. Every technician appreciates this.

Automation Capabilities

Amada machines blend automation seamlessly. It’s like having a hidden team working with you, managing tough tasks easily and keeping quality high. Precision is crucial in industries like automotive or aerospace. This feature changes the game for them.

| Feature | Description |

|---|---|

| CNC Systems | Provides precise control and updates with the latest automation technologies |

| Build Quality | High-grade materials ensure durability and lower maintenance costs |

| Automation | Reduces manual labor and increases consistency in high-precision industries |

Energy Efficiency

Today, sustainability matters a lot. Amada understands this by creating energy-saving machines that still perform well. They use eco-friendly technology to reduce power usage, cutting operational costs and meeting global environmental standards.

Amada’s focus on innovation and responsibility stands out in the industry. These machines address today’s needs while considering future challenges.

For more on energy efficiency in industrial machines7, look at how Amada compares to other global leaders.

User-Friendly Interfaces

Amada machines are sophisticated yet simple to use. When I began using them, I found the user interfaces very intuitive. It felt like using a new gadget and instantly knowing all the secrets. This simplicity is important for quickly training new operators, ensuring productivity stays high.

To learn more about user-friendly CNC systems8, discover why Amada’s interfaces are popular among operators worldwide.

Amada machines use outdated CNC systems.False

Amada machines use cutting-edge CNC systems, consistently updated with innovations.

Amada machines reduce power consumption significantly.True

They incorporate eco-friendly technologies to reduce power consumption without performance loss.

How Do I Choose Between Bystronic and Other Top Brands?

Picking between Bystronic and other leading brands feels like choosing your dream car. It is exciting but also overwhelming. I have experienced this. I went through all the features and specifications. I tried to find the ideal fit for what my business really needs.

Choose between Bystronic and top brands like Trumpf and Amada based on several key points. Look at technological progress and cost-efficiency. Think about after-sales support, too. Check if they suit your specific needs. Evaluate all these carefully. Really consider them.

Evaluating Technological Innovation

Exploring brands like Bystronic, Trumpf, and Amada was exciting. So many choices, each with modern technology. Bystronic impressed with precise laser cutting solutions9. The automation was great for speeding up work. Trumpf, famous for laser technology, offered flexible machines for many industrial tasks.

- Bystronic: Famous for automation and precision.

- Trumpf: Offers flexible solutions with advanced laser technology.

- Amada: Known for easy use and strong performance.

Assessing Cost-Effectiveness

I felt like buying my first car when I checked costs. German brands like Trumpf are pricey but reliable with advanced features and durable parts. Chinese brands cost less but offer different performance guarantees though.

| Brand | Initial Cost | Running Cost | Maintenance |

|---|---|---|---|

| Bystronic | High | Moderate | Moderate |

| Trumpf | High | High | High |

| Amada | Moderate | Moderate | High |

Importance of After-Sales Support

After-sales support changes everything. Bystronic provides full service, including maintenance and spare parts. Very reassuring. Japanese brands like Amada are also excellent, offering services that reduce downtime through robust after-sales services10.

Alignment with Specific Operational Needs

Looking at my own operational needs was important. Efficiency matters most in my work, so speed and automation are key. Precision and complex designs? Go for brands known for accuracy.

Think about what fits with your business priorities and goals. Each brand has unique benefits that might suit different business needs. Take your time, consider options, and find the right choice.

Bystronic offers more automation than Trumpf.True

Bystronic is known for its innovation in automation and precision.

Amada has the highest initial cost among top brands.False

Amada's initial cost is moderate compared to Bystronic and Trumpf.

Conclusion

Leading manufacturers of laser fiber cutting machines include Germany’s Trumpf, Switzerland’s Bystronic, China’s Hans Laser, and Japan’s Amada, each offering unique advantages for various industrial needs.

-

Explore Trumpf’s groundbreaking advancements in laser technology, showcasing their commitment to staying at the industry’s cutting edge. ↩

-

Learn how Trumpf’s extensive customer service network enhances equipment reliability and user satisfaction. ↩

-

Discover how Trumpf is leading the way with sustainable technologies that minimize environmental impact. ↩

-

Discover how Hans Laser’s fiber lasers provide unmatched precision, enhancing industrial processes effectively. ↩

-

Learn about the wide range of applications that Hans Laser products can cater to across various industries. ↩

-

Understand how Hans Laser’s machines contribute to sustainable manufacturing through energy efficiency. ↩

-

Learn how Amada’s machines compare in energy efficiency, helping you lower operational costs and meet sustainability goals. ↩

-

Discover why Amada’s CNC interfaces are favored by operators for their ease of use and productivity enhancements. ↩

-

Discover Bystronic’s advanced automation and precision features that enhance production efficiency. ↩

-

Explore how Amada’s after-sales support can minimize downtime and maintain operational efficiency. ↩