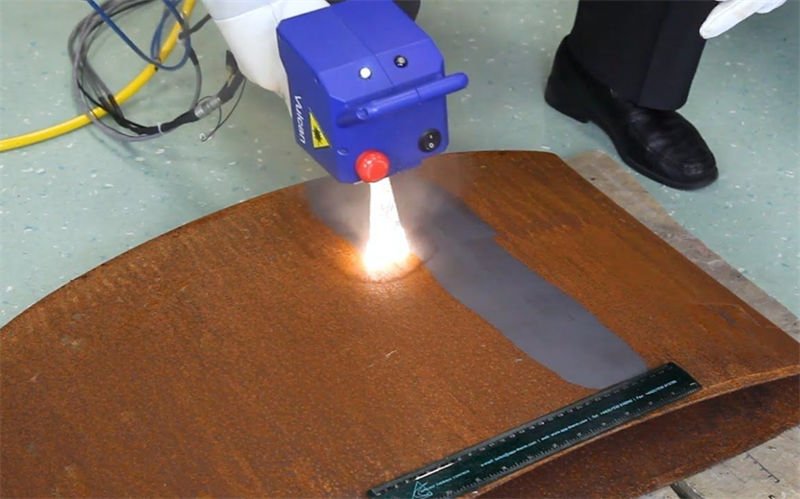

Have you ever seen a beautiful piece of metal tarnished by rust? It’s frustrating! I’m here to share how laser technology can breathe new life into those rusted surfaces.

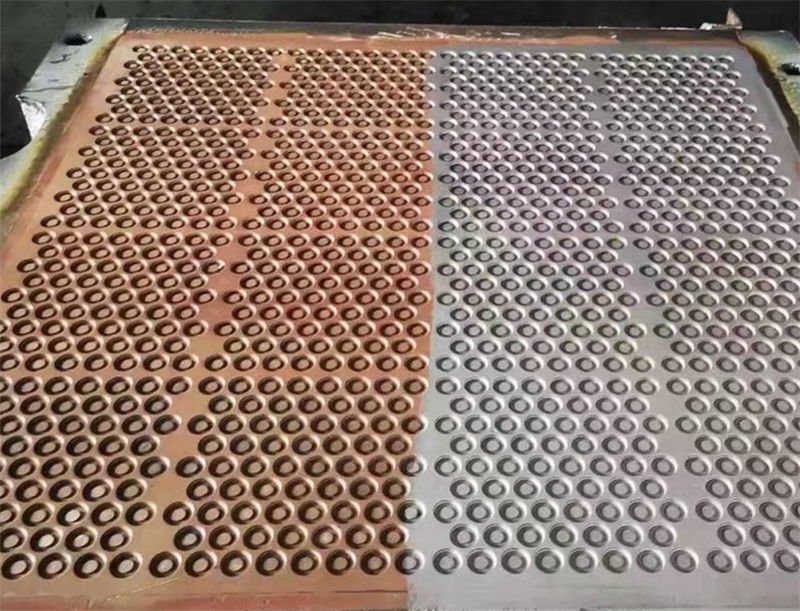

Laser derusting has a good effect. It has a high degree of cleanliness and can accurately remove impurities such as rust and oil stains. It can also handle surfaces with complex shapes and fine structures very cleanly. It causes little damage to the substrate and can remove rust without damaging the material by controlling laser parameters. It is environmentally friendly and pollution-free as it is a physical derusting process without the use of chemical agents. It has a wide range of applications and is suitable for various metal materials, different rust layer thicknesses and working conditions.

So, if you’re as curious as I was about how this cutting-edge technology can work wonders, let’s dive deeper into its mechanics and see if it’s right for your rust removal needs.

Laser rust removal is more precise than sandblasting.True

Lasers target specific areas with minimal impact on surrounding metal, unlike sandblasting.

What Makes Laser Rust Removal Different from Traditional Methods?

Laser rust removal is redefining how we tackle corrosion, but how does it stand apart from traditional techniques?

Laser derusting is different from traditional methods. In principle, laser relies on high-energy beams while traditional mechanical methods use physical friction and chemical methods are reactions. Laser causes little damage to the substrate. Traditional mechanical methods are prone to scratches and chemical methods are prone to corrosion. Laser is environmentally friendly and pollution-free and easy to achieve automation. Traditional methods mostly rely on manual labor.

Precision and Selectivity

Traditional rust removal methods such as sandblasting or chemical treatments often lack precision, affecting not only the rust but also the underlying metal. Laser technology allows for precise targeting of rust-affected areas. This makes it highly suitable for restoring intricate designs or delicate metal parts, where traditional methods might cause irreparable damage.

Minimal Damage to Base Metal

A significant advantage of laser rust removal over traditional methods is the minimal impact on the base metal. The focused laser beam can be adjusted in terms of power, wavelength, and energy density to ensure that only the rust is removed. This means that the metal’s mechanical properties and integrity are preserved, unlike abrasive methods that can weaken or alter the metal structure.

Environmentally Friendly Approach

Chemical rust removal often involves corrosive agents that can be harmful to both the environment and the operator. In contrast, laser rust removal is a cleaner alternative that does not produce hazardous waste. This aligns with modern environmental standards and regulations, making it an attractive option for industries looking to reduce their ecological footprint.

| Aspect | Laser Rust Removal | Traditional Methods |

|---|---|---|

| Precision | High, targets specific areas | Low, affects broader areas |

| Base Metal Impact | Minimal, preserves integrity | Moderate to high, can alter structure |

| Environmental Impact | Low, no chemical waste | High, potential chemical hazards |

Considerations and Limitations

Despite its advantages, laser rust removal is not without its challenges. The cost of equipment can be prohibitive for some applications. Moreover, operating such sophisticated machinery requires trained personnel, adding to the overall cost. In some cases, especially with thick rust layers, a combination of laser and other methods might be necessary for complete rust removal.

While laser technology offers a cleaner and more precise solution, evaluating whether it’s the right fit depends on the specific needs and constraints of your project. To explore more about how laser parameters can be fine-tuned for optimal results, check out this resource on laser parameter optimization1.

Laser rust removal is more precise than sandblasting.True

Laser targets specific areas, unlike sandblasting's broader impact.

Traditional methods are more eco-friendly than laser rust removal.False

Laser rust removal produces no chemical waste, unlike traditional methods.

How Does the Ablation Process Work in Laser Rust Removal?

Discover the science behind laser rust removal and how ablation ensures precision without damaging metal.

The ablation process of laser rust removal is as follows: A high-energy-density laser beam irradiates the rusty metal surface. The rust layer absorbs laser energy which is quickly converted into heat energy. As heat accumulates, the temperature of rust rises sharply. When it reaches the vaporization temperature, the rust layer vaporizes into steam and detaches from the metal surface to complete rust removal. Laser parameters should be well controlled during the process.

The Science of Ablation in Laser Rust Removal

Ablation, at its core, involves the removal of material from a solid surface by vaporization, chipping, or other erosive processes. In the context of laser rust removal2, ablation specifically refers to using a laser’s focused energy to remove rust from metal surfaces. When the laser’s high-energy beam hits the rusted area, it causes rapid heating. This energy absorption results in the rust either vaporizing or breaking down into fine particles that are easily removed.

Key Laser Parameters

-

Wavelength: Different wavelengths interact uniquely with materials. Rust, being primarily iron oxide, absorbs certain wavelengths more efficiently. Infrared lasers3 are commonly used because they effectively target rust while minimizing damage to the metal beneath.

-

Power and Energy Density: The power level determines how much energy is delivered to the surface. Proper adjustment is crucial; too little power might not remove all the rust, whereas excessive power can damage the base metal.

-

Pulse Duration and Frequency: Pulsed lasers deliver energy in bursts. Shorter pulses at optimal frequencies ensure efficient rust removal while keeping the heat-affected zone minimal.

Factors Affecting Ablation Efficiency

- Rust Layer Thickness: Thicker layers might require multiple passes or higher energy settings.

- Metal Type: Different metals have varying heat tolerance and absorption rates.

- Surface Shape and Complexity: Complex geometries might need more precise laser focus adjustments.

| Parameter | Impact on Ablation |

|---|---|

| Wavelength | Determines absorption efficiency |

| Power | Controls depth and speed of rust removal |

| Pulse Frequency | Affects precision and thermal impact |

Practical Considerations in Laser Ablation

While laser ablation is precise, several practical aspects need consideration:

- Cost-Effectiveness: High initial equipment costs can be a barrier. However, when applied to high-value or intricate components, the precision justifies the expense.

- Operator Expertise: Skilled operators are essential for setting appropriate parameters and ensuring safety.

- Environmental Benefits: Unlike chemical methods, laser ablation produces minimal waste, making it an environmentally friendly choice.

Overall, understanding these parameters and considerations is vital for optimizing laser rust removal4 through ablation.

Infrared lasers are preferred for rust removal.True

Infrared lasers effectively target rust while minimizing damage to metal.

Laser ablation produces significant chemical waste.False

Laser ablation produces minimal waste, making it environmentally friendly.

What Are the Costs Involved in Using Laser Technology for Rust Removal?

Laser rust removal offers precision and eco-friendliness, but what are the costs involved?

The costs of laser rust removal include: firstly, equipment purchase cost. High-quality laser rust removal equipment is expensive. Secondly, energy consumption cost. Lasers consume electricity. Thirdly, maintenance cost, such as maintenance and replacement of components like laser generators. Fourthly, personnel training cost. Operating the equipment requires professional knowledge. However, large-scale operations can share the costs.

Initial Investment: Equipment Costs

Purchasing a laser rust removal system involves a significant upfront investment. The price can range from a few thousand to several hundred thousand dollars, depending on factors such as the laser’s power, precision capabilities, and brand reputation. High-power systems designed for industrial applications typically command higher prices.

For example, compact handheld laser rust removers may start at $8,000-$10,000, while high-powered systems for heavy industrial use could exceed $250,000. It’s crucial to assess your specific needs and choose a system that balances cost with required performance.

Operational Expenses: Running the System

Once the laser system is acquired, ongoing operational costs must be considered. These include:

- Electricity Consumption: Laser systems require significant power, impacting electricity bills. The operational cost can vary based on the laser’s power rating and usage frequency.

- Labor Costs: Skilled operators are often necessary to ensure safe and efficient operation. Training and hiring competent personnel contribute to labor expenses.

- Consumables: While lasers themselves don’t require consumables like sandblasting or chemical methods, safety equipment such as goggles and protective gear are essential.

Maintenance and Repairs

Regular maintenance is key to keeping laser systems functional and safe. This includes cleaning optics, checking electrical components, and recalibrating the system. Maintenance contracts with manufacturers can add to costs but ensure the equipment remains in optimal condition.

Repairs due to wear and tear or accidental damage can also contribute to unforeseen expenses. It’s advisable to factor in potential repair costs when budgeting for laser rust removal systems.

Cost-Benefit Analysis

Despite the high initial and operational costs, laser rust removal offers several benefits that can offset these expenses:

- Precision and Efficiency: Reduced material waste and minimized substrate damage can lead to savings in material costs.

- Eco-Friendly: No chemical waste means lower environmental compliance costs.

- Long-Term Savings: Over time, reduced labor costs and minimized damage to parts can provide a return on investment.

When evaluating whether laser rust removal is cost-effective for your needs, consider both short-term expenses and long-term savings. For specialized applications where precision and material preservation are critical, the higher upfront costs may be justified.

Explore further by understanding laser equipment cost comparison5 or evaluating laser rust removal ROI6.

Laser rust removal systems start at $8,000.True

Compact handheld laser rust removers typically start at $8,000-$10,000.

Laser systems require consumables like sandblasting methods.False

Lasers don't need consumables like sandblasting; only safety gear is needed.

Are There Any Safety Concerns When Using Lasers for Rust Removal?

Laser rust removal offers precision and efficiency, but safety is paramount. Are there concerns to consider?

Yes, safety concerns exist when using lasers for rust removal, Lasers themselves have high energy and may cause harm to human eyes and skin, such as retinal burns and skin scalds. Therefore, complete protective equipment and measures are needed. In addition, the steam and smoke generated during the laser rust removal process may contain harmful substances. If inhaled, it will endanger human health. Ventilation equipment is needed to ensure air safety.

Eye and Skin Protection

The laser beam can cause severe eye damage, necessitating the use of appropriate laser-safety goggles. These goggles must be specifically designed to block the laser’s wavelength. For instance, if you’re using an infrared laser, ensure your goggles are rated for infrared light absorption. It’s not just the direct beam that poses a threat; even scattered or reflected light can be harmful. Therefore, all personnel in the vicinity should wear these goggles.

Skin protection is equally vital. The laser’s high energy can burn the skin, so wearing long-sleeved clothing, gloves, and other protective gear is crucial. These should be made from materials that withstand potential laser exposure. Ensure gloves are non-flammable and heat-resistant, as the process may generate heat and sparks.

Ventilation and Respiratory Safety

Laser rust removal generates fumes and fine particles from vaporized rust, which can be harmful if inhaled. Ensuring proper ventilation in the work area is essential. Utilize local exhaust systems like fume hoods or exhaust fans to remove airborne contaminants. In some scenarios, air purifiers with suitable filters (such as HEPA filters) can improve air quality.

Consider monitoring air quality to maintain safe airborne contaminant levels. Depending on the metal type and rust nature, wearing a suitable respirator might be necessary. Choose a respirator with filters for metal fumes and particulate matter, especially if working with alloys.

Fire and Explosion Hazards

The heat from laser rust removal can ignite flammable materials like paper or wood. It’s crucial to clear these materials from the area and keep an appropriate fire extinguisher nearby. Operators should be trained in using fire extinguishers effectively.

Be cautious with metals that might have flammable residues or coatings; pre-cleaning might be needed to mitigate fire risks. If your laser system uses gases, ensure proper installation and maintenance of gas systems to prevent leaks, as some gases may be flammable or toxic.

Equipment Safety Precautions

Only trained and authorized personnel should operate laser rust removal equipment. Familiarity with equipment controls, safety features, and operating procedures is a must. Before starting operations, check that equipment is calibrated and in good working order.

Regular maintenance of laser equipment is critical for safe operation. This includes cleaning optical components, checking electrical connections, and replacing worn parts as per manufacturer recommendations. During maintenance, ensure equipment is powered off and disconnected to avoid accidental activation.

Implementing these safety measures ensures a safer environment while using lasers for rust removal, protecting both personnel and equipment from potential hazards.

Lasers can ignite flammable materials during rust removal.True

Heat from lasers can ignite materials like paper or wood, posing fire risks.

Ventilation is unnecessary for laser rust removal.False

Proper ventilation is crucial to remove harmful fumes and particles generated.

Conclusion

Laser rust removal offers precision and eco-friendliness but requires careful consideration of costs and expertise. For high-value applications, its effectiveness is unmatched.

-

Learn how adjusting laser settings can enhance rust removal efficiency.: Laser parameters can be set so that the laser beam’s intensity is just above the ablation threshold of rust but below that of the metal being cleaned. If the … ↩

-

Learn about the science behind laser ablation for rust removal.: They work by laser ablation. Basically, the laser is bright enough and focused enough that anything that absorbs the light strongly will get heated to a plasma. ↩

-

Understand why infrared lasers are preferred for rust removal.: By using the infrared laser of xTool F1, the rust layer of metals can be removed easily. Its speed can reach up to 4,000 mm/s, so you can remove … ↩

-

Explore why laser ablation is an effective method.: Discover the innovative technology behind laser rust removal and how it works. Learn about the benefits, applications, and limitations of this process to … ↩

-

Understand price differences across various laser equipment brands.: The price for a laser cleaning machine depends on the machine’s functionality, model, and components. The price for a laser cleaning machine is $13,000-$18,000 … ↩

-

Assess potential return on investment for laser rust removal systems.: If you are refurbishing or reworking parts, laser cleaning may not provide a good ROI. For example, laser rust removal is rarely worth the … ↩