Picture this: You’re racing against the clock in a bustling factory, and every tick echoes like a challenge. Laser marking could be the hero of this story.

Laser marking cuts down production lead times by providing a swift, efficient marking process with minimal setup and labor. It skips drying time, slashes downtime, and fits effortlessly into production lines, guaranteeing high-speed, error-free operations.

But there’s more to laser marking than just speed. Imagine a world where material bottlenecks shrink and product changes are a breeze. This technology can revolutionize the way you run your operations. Let me share some insights on how laser marking can make your production process not just faster, but smarter and more flexible. It’s not just about keeping up; it’s about staying ahead.

Laser marking reduces production lead times significantly.True

Laser marking speeds up processes by minimizing setup and labor time.

Laser marking requires extensive drying time after application.False

Laser marking eliminates drying time, enhancing production speed.

What are the Key Advantages of Laser Marking Over Traditional Methods?

Imagine a world where marking products is swift, accurate, and versatile. Laser marking makes this dream a reality, transforming industries with its cutting-edge technology.

Laser marking stands out over traditional methods by offering unparalleled speed, precision, and versatility without the need for consumables. It’s a cost-effective and efficient solution that caters to various materials seamlessly.

Speed and Efficiency

I remember the first time I watched a laser marking machine in action; it was mesmerizing. It zipped through stacks of products in what felt like the blink of an eye, far quicker than the old ink printers I was used to seeing. This kind of speed is a game-changer in industries like electronics and automotive where time really is money.

Precision and Consistency

In my early days working with traditional marking methods, I can’t tell you how many times I had to redo jobs because of tiny mistakes. But with laser marking, it’s a different story. The precision these systems offer is nothing short of amazing, producing flawless results every time. It’s like having a perfectionist on your team that never gets tired.

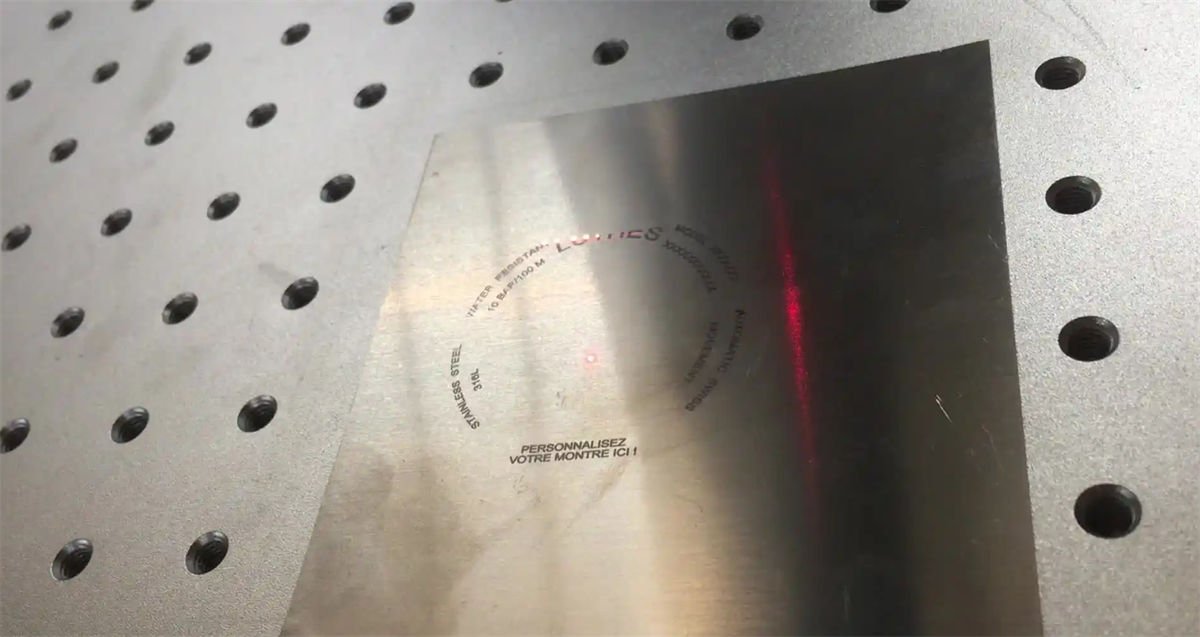

Material Versatility

One of my favorite things about laser marking is its ability to work on so many different materials. Whether it’s metals, plastics, ceramics, or composites, there’s no need to swap out equipment or worry about compatibility. It’s like having a Swiss Army knife of marking solutions!

| Material Type | Applicability |

|---|---|

| Metals | Yes |

| Plastics | Yes |

| Ceramics | Yes |

| Composites | Yes |

Minimal Setup Time

When I first switched to laser systems, the ease of setup was a revelation. Gone were the days of tedious configurations and endless adjustments. With modern laser marking machines, it’s all about quick changes and minimal downtime. It’s like having a personal assistant that’s always ready to go.

No Consumables Needed

One of the best decisions I ever made was moving away from methods that relied on consumables. Laser marking doesn’t need inks or labels, which means no more worrying about running out of supplies or managing stock levels. It’s a relief to have one less thing on my mind.

Flexibility for Customization

Laser systems offer an incredible level of customization without the hassle of physical retooling. I can adjust product specifications with just a few clicks, allowing me to adapt swiftly to any changes in demand or design. This flexibility has been crucial in maintaining agility and responsiveness in my business.

For further insights into the adaptability of laser systems in manufacturing, explore more about laser system integration1.

Laser marking requires no consumables.True

Laser marking uses light to mark surfaces, eliminating the need for inks or labels.

Traditional methods are faster than laser marking.False

Laser marking processes large volumes quickly, surpassing traditional methods in speed.

How Does Laser Marking Enhance Automation in Production?

Ever wondered how laser marking fits into the hustle and bustle of modern production?

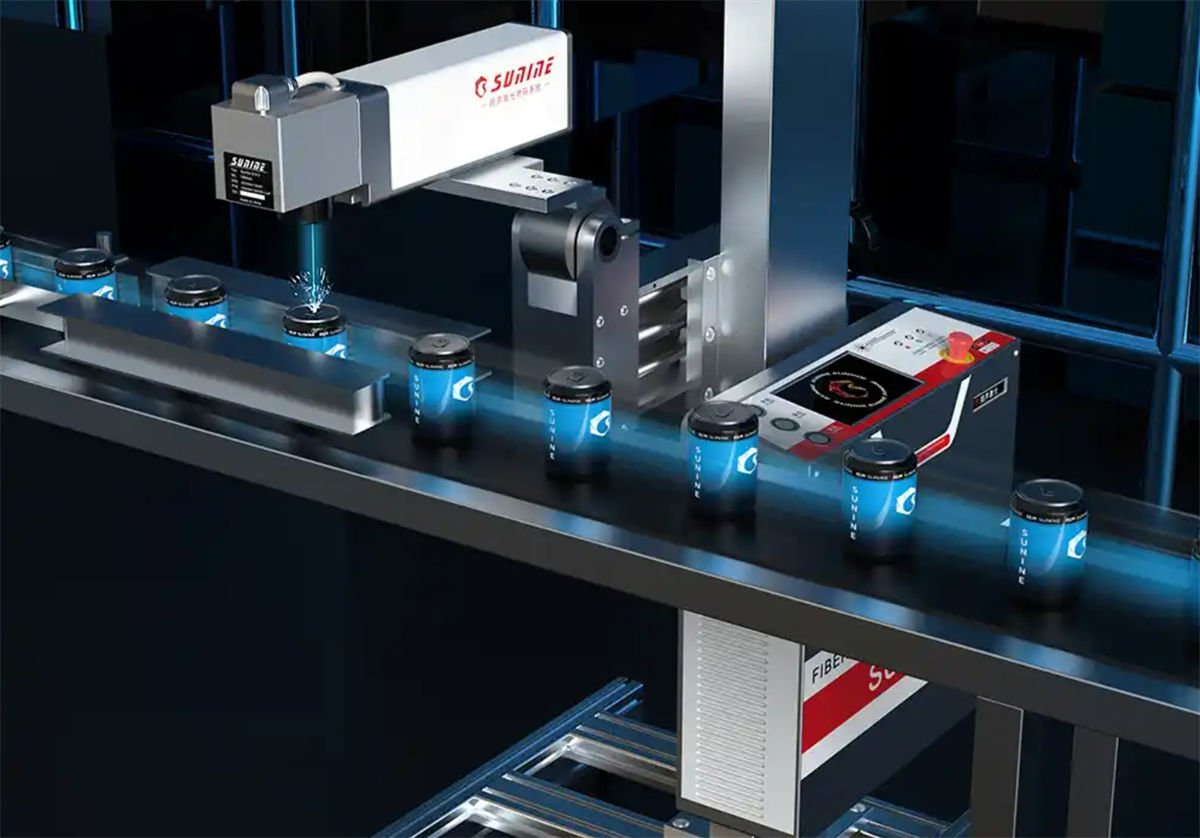

Laser marking boosts automation by delivering precise and rapid product markings without manual effort, integrating seamlessly into production lines to cut costs and enhance efficiency.

Speed and Precision

Let me tell you, the first time I saw a laser marking system in action, I was blown away by its speed and precision. Imagine being able to mark thousands of items2 per hour with pinpoint accuracy. It’s like watching an artist paint at lightning speed but with the consistency of a machine. This technology is a game-changer, especially for industries that thrive on fast throughput, like electronics and automotive.

Seamless Integration

Picture this: you’re watching products glide through a conveyor system, each getting marked by a laser as it passes by. No hiccups, no human error. Just a flawless flow3. This seamless integration into existing automated lines means production keeps moving smoothly, reducing any need for manual handling. It’s like having an extra set of hands that never tire.

Versatility Across Materials

One of the things I love about laser marking is its versatility. Whether it’s metals, plastics, or more, there’s no need to switch marking methods. This flexibility ensures that manufacturers can maintain uniformity across different product lines, making it perfect for multi-material environments4.

Cost Efficiency and Labor Reduction

Here’s a perk that can’t be overlooked: cost efficiency. With minimal setup and maintenance, laser systems reduce downtime significantly. Plus, they cut out the need for consumables like ink or labels. This not only saves money but also allows your team to focus on tasks that require a human touch.

| Benefit | Description |

|---|---|

| Speed | High-speed marking enhances throughput. |

| Precision | Consistent and accurate markings on each product. |

| Integration | Easy integration into automated lines reduces manual handling. |

| Material Versatility | Effective on various materials without changing tools or methods. |

| Cost Efficiency | Reduces labor costs and eliminates consumables. |

Enhanced Traceability

And let’s not forget traceability. Laser marking ensures that every product gets an accurate serial number, barcode, or QR code. These markings are vital for quality assurance5 and inventory management, making it possible to track products in real-time through the supply chain. It’s all about staying on top of every detail without the added stress.

Laser marking systems enhance production speed.True

Laser systems mark thousands of items per hour, boosting throughput.

Laser marking requires high manual intervention.False

Laser marking integrates with automation, reducing manual handling.

How Does Laser Marking Improve Product Quality and Reduce Errors?

Ever wondered how a simple beam of light can make such a difference in manufacturing?

Laser marking significantly reduces errors by ensuring precise and consistent markings on various materials, thereby enhancing traceability and minimizing defects. This process boosts product quality through clear, durable markings that don’t damage the material.

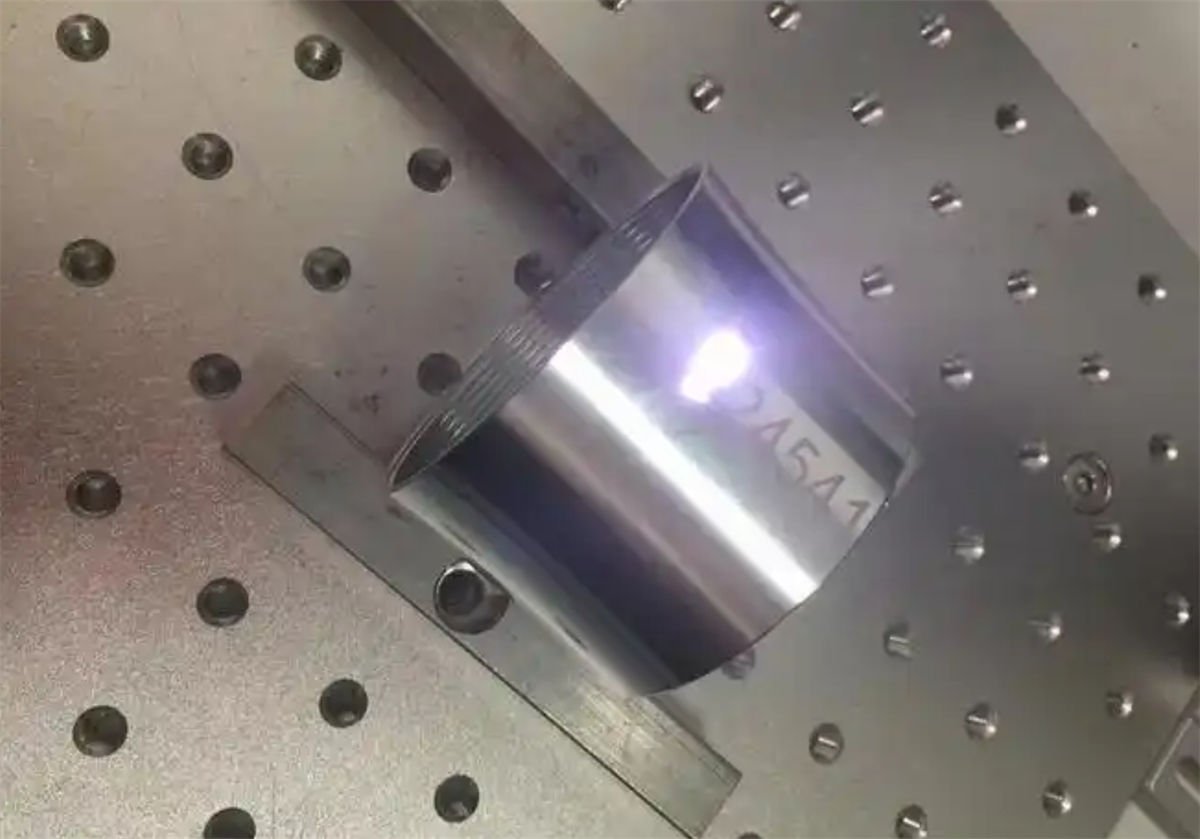

Precision and Consistency

Imagine trying to paint a masterpiece with a shaky hand. That’s how traditional marking methods feel compared to laser marking. I once saw this in action when we tested laser systems on metal components. The laser’s precision was like watching an artist at work, crafting exact marks without a flaw. Whether it’s metals or plastics, laser marking ensures each product comes out with perfect markings every time, reducing any chances of misalignment or illegibility.

| Feature | Traditional Methods | Laser Marking |

|---|---|---|

| Accuracy | Variable | High Precision |

| Consistency | Inconsistent | Consistent |

Enhanced Traceability

In the world of manufacturing, traceability is like having a GPS for every part. I remember a project in aerospace where tracking each component was crucial. With laser marking, we could etch intricate details that made tracking a breeze, providing peace of mind that every piece could be traced back to its origin. This improvement is crucial for industries such as aerospace and healthcare6, where tracking each component is vital for safety and quality.

Error Reduction

Errors are the gremlins of manufacturing, lurking in every corner. Traditional marking methods often invite these gremlins due to human error or mechanical wear. However, when I first witnessed laser marking, it felt like switching from a manual typewriter to a word processor—flawless automation with no direct contact with the material, resulting in fewer defects and reworks.

Material Integrity

Preserving the integrity of materials is paramount. I’ve seen how traditional methods can sometimes damage surfaces, but laser marking acts like a gentle touch—no consumables like ink needed, which means no mess and no alteration to the material’s surface. It’s like leaving a mark without leaving a scar. Explore how non-contact marking7 benefits diverse materials.

Quality Assurance

Implementing laser marking felt like bringing in a seasoned quality inspector who never misses a beat. The consistency in markings simplifies quality checks and assurance processes, leading to fewer recalls and happier customers.

If you’re curious about how laser marking integrates seamlessly with production systems, think of it as adding a turbocharger to your workflow. In automated production lines8, laser marking fits right in, boosting both efficiency and reliability without missing a step.

Laser marking enhances product traceability.True

Laser marking provides detailed, precise marks crucial for tracking components.

Traditional marking methods are more accurate than laser marking.False

Traditional methods vary in accuracy, while laser marking offers high precision.

How Can Laser Marking Save Your Business Money?

Imagine cutting costs while boosting productivity—laser marking makes it possible!

Businesses can save money with laser marking by reducing labor costs, minimizing maintenance, and boosting efficiency. This technology cuts consumable expenses and lowers production downtime, leading to overall financial benefits.

I remember the first time I saw a laser marking machine in action. It was mesmerizing—like watching a sci-fi movie unfold right in front of me. But beyond its cool factor, what really struck me was its potential to revolutionize how businesses manage costs. Here’s how.

Reduced Labor Costs

Once you set up a laser marking system, it practically runs itself, needing only minimal human oversight. I’ve seen firsthand how this frees up employees to focus on more critical tasks, effectively cutting down on wages and training expenses. It’s like having an extra team member who never takes breaks!

| Benefit | Traditional Marking | Laser Marking |

|---|---|---|

| Labor Involvement | High | Low |

| Setup Time | Lengthy | Quick |

Minimal Maintenance

Laser systems are surprisingly low-maintenance. Without the need for frequent repairs, thanks to fewer moving parts and no consumables, the reliability of these systems is a game-changer. I’ve watched businesses flourish as they reduce maintenance costs and keep operations smooth. Minimal setup time9 is another bonus that adds to productivity.

Consumable-Free Operation

Gone are the days of ink and label costs. With laser marking, there’s no need for consumables, which not only saves money but also eases supply chain worries. This shift is like a breath of fresh air for many companies I’ve worked with. Learn more about consumables10 and their impact on production.

Increased Efficiency

Laser marking integrates seamlessly into production lines, cutting down lead times and enhancing throughput. I’ve witnessed how this technology elevates operational efficiency and translates into significant cost savings over time. Picture a 50% reduction in marking time—that’s how businesses reach new heights in productivity. Explore integration benefits11 for your business needs.

Long-Term Savings

While the upfront investment might be daunting, the long-term financial gains are undeniable. Reduced labor, minimal maintenance, and improved efficiency lead to savings that make laser marking a smart choice for any forward-thinking company. I’ve helped clients evaluate their ROI and seen them reap the benefits firsthand. Evaluate your ROI12 with laser systems today.

Laser marking reduces labor costs significantly.True

Automation in laser marking minimizes human intervention, cutting labor costs.

Laser marking requires frequent maintenance.False

Laser systems have fewer parts and no consumables, reducing maintenance needs.

Conclusion

Laser marking significantly enhances production efficiency by reducing lead times, minimizing setup and labor costs, and ensuring precise, consistent markings across various materials without the need for consumables.

-

Discover how laser systems enhance production efficiency through seamless integration with automated lines. ↩

-

Discover the high processing capabilities of laser marking machines, boosting production efficiency. ↩

-

Learn how seamless integration with production lines optimizes manufacturing workflows. ↩

-

Understand the versatility of laser marking across different materials for diverse applications. ↩

-

Explore how traceability enhances quality control and inventory management in production. ↩

-

Learn about the critical role of traceability in maintaining safety and quality in sensitive industries. ↩

-

Understand how non-contact marking preserves material integrity across various applications. ↩

-

Explore the integration of laser marking in automated systems to boost efficiency and reliability. ↩

-

Find out how quick setup time boosts productivity in manufacturing. ↩

-

Understand the impact of consumables on production costs and efficiency. ↩

-

Learn how seamless integration enhances production efficiency. ↩

-

Assess the return on investment when implementing laser marking technology. ↩