Ever wondered how laser engraver and cutter machines are changing the game? You’re in good company! These tools are like magic wands for artists, crafters, and manufacturers alike.

Laser engraver and cutter machines are used for a wide range of applications, including engraving on metals, woods, plastics, glass, and more. They are essential in industries like manufacturing, crafting, and design, offering precision and versatility for intricate projects.

But there’s so much more to discover! Let’s dive deeper into the fascinating world of laser machines and unlock their true potential together.

Laser engravers can process both metals and textiles.True

Laser machines are versatile, processing materials like metals and textiles efficiently.

What Industries Benefit Most from Laser Engraving and Cutting?

Laser engraving and cutting technologies are revolutionizing numerous sectors by enhancing precision and efficiency. Curious about which industries are leveraging these advancements to their fullest potential? Let’s explore.

Industries such as manufacturing, fashion, electronics, and automotive benefit significantly from laser engraving and cutting due to enhanced precision, versatility, and efficiency.

Manufacturing Industry

In the manufacturing sector1, laser engraving and cutting have become indispensable tools. They are used for marking serial numbers, logos, and intricate designs on metals and plastics. The precision offered by laser technology ensures high-quality finishes that are critical for product consistency and brand integrity.

- Metals and Plastics: Lasers engrave metals like steel and aluminum with clarity, making them ideal for parts and components. Plastics are also easily cut and engraved for electronic casings and automotive parts.

Fashion Industry

The fashion industry2 utilizes laser technology for cutting and engraving fabrics, leather, and accessories. Laser cutting provides clean edges without fraying, a critical aspect in fashion design.

- Fabric Cutting: It allows designers to create intricate patterns with ease, reducing waste and increasing production speed.

- Leather Engraving: Lasers engrave detailed patterns on leather goods like bags and shoes, adding unique textures and designs.

Electronics Industry

In electronics, precision is paramount. Laser engraving is used for engraving circuit boards3, labeling components, and creating micro-features on devices.

- Circuit Boards: Lasers ensure precise cuts and engravings that help in optimizing space on compact boards.

- Component Labeling: Durable markings that withstand wear are crucial for identification and safety.

Automotive Industry

The automotive sector4 leverages laser technology for both functionality and aesthetics. From etching VIN numbers to customizing interior components, lasers play a vital role.

- VIN Engraving: Permanent laser markings enhance security by preventing tampering.

- Interior Customization: Offers bespoke designs on dashboard components or upholstery.

Each of these industries benefits from the speed, accuracy, and versatility that laser engraving and cutting provide. Whether for production efficiency or creative expression, the potential applications are vast.

Laser cutting in fashion reduces fabric waste.True

Laser cutting allows precise patterns, minimizing material waste.

Lasers are rarely used for automotive VIN engraving.False

Lasers are commonly used for permanent, tamper-proof VIN markings.

Which Materials Can Be Processed with Laser Machines?

Laser machines have revolutionized material processing, offering precision across a diverse range of materials. But which materials can actually be processed?

Laser machines are versatile tools capable of processing materials such as metals, plastics, wood, glass, ceramics, and textiles. Each type of laser, including fiber, CO2, and UV, is suited for specific materials, enhancing accuracy and efficiency in various applications.

Metals: Precision and Versatility

When it comes to metals, fiber lasers5 are the go-to choice. These powerful machines can engrave and cut a wide range of metals, including steel, aluminum, brass, and copper. Fiber lasers are particularly appreciated for their ability to achieve deep engravings on hard metals without compromising detail.

| Metal Type | Laser Machine | Application |

|---|---|---|

| Steel | Fiber Laser | Deep engraving, cutting |

| Aluminum | Fiber Laser | Marking, intricate designs |

| Copper | Fiber Laser | Engraving, cutting |

Plastics: Adaptability in Engraving

Both CO26 and UV lasers excel at processing plastics. CO2 lasers are perfect for engraving acrylics and some soft plastics, while UV lasers provide high precision for harder plastics like polycarbonate. This adaptability makes them invaluable for producing custom plastic products.

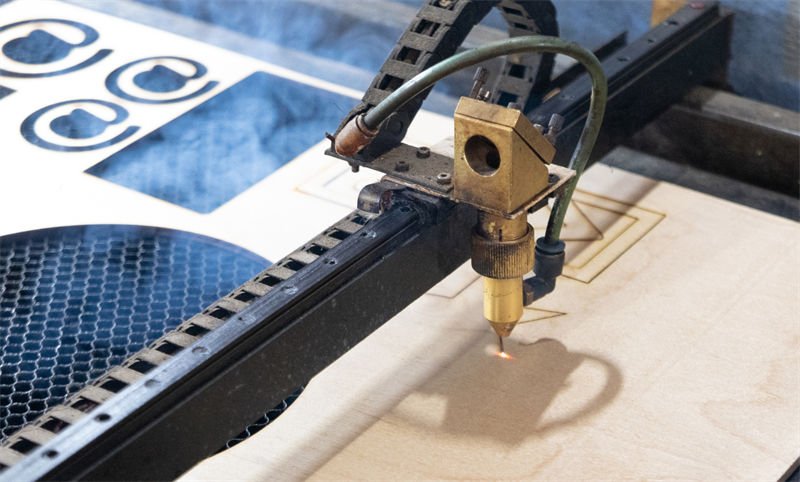

Wood: Craftsmanship and Creativity

Wood is best processed using CO2 lasers due to their ability to cut and engrave with exceptional detail. From crafting detailed patterns on furniture to creating intricate wooden art pieces, CO2 lasers bring creative visions to life with ease.

Glass: Delicate Detailing

For glass materials, UV lasers stand out with their cold light capability. This feature minimizes the risk of cracking or damaging the glass, allowing for precise engraving of glassware, awards, and decorative items.

Ceramics and Stone: Detailed Marking

These hard materials require the power and precision that fiber lasers offer. Whether marking tiles or engraving on stone surfaces, fiber lasers ensure durability and clarity.

Textiles: Innovative Engraving

CO2 lasers are also adept at engraving and cutting textiles. They enable the creation of custom designs on fabrics like felt and leather without fraying the edges. This precision opens up a world of possibilities for fashion and interior design industries.

Understanding which materials can be processed by each type of laser machine not only aids in selecting the right tool for your project but also ensures the highest quality outcomes for your work.

Fiber lasers can engrave hard metals.True

Fiber lasers are known for their precision in engraving hard metals.

UV lasers are ideal for cutting textiles.False

CO2 lasers, not UV lasers, are best suited for cutting textiles.

How Do Different Types of Laser Machines Compare?

Exploring the world of laser engraving machines can be overwhelming with so many options available. Let’s break down the key differences to help you choose the best fit for your needs.

Different laser machines vary in their applications, precision, and suitability for materials. Fiber lasers excel with metals, CO2 lasers are perfect for organic materials, and UV lasers specialize in delicate work. Consider material type, machine size, and mobility needs to make an informed choice.

Comparing Laser Machine Types

Laser machines come in various types, each offering distinct benefits and suited for specific applications. Understanding these differences is crucial for selecting the right machine.

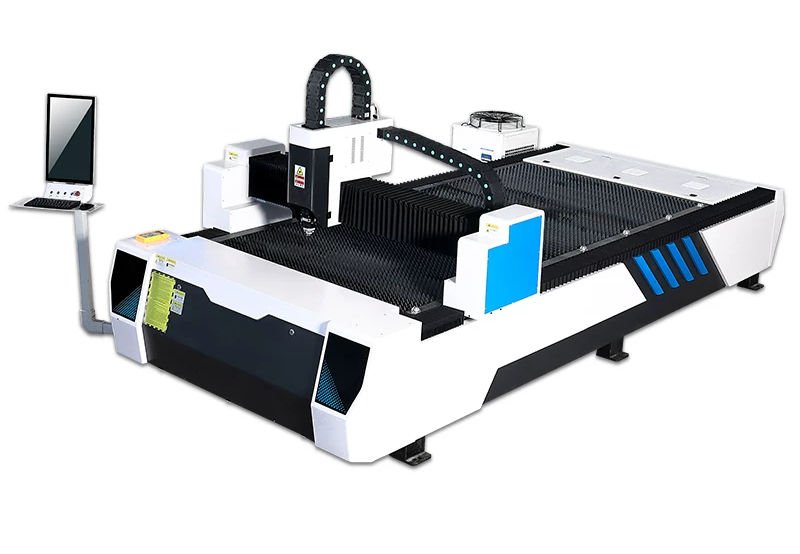

Fiber Laser Machines

Fiber lasers are renowned for their efficiency and capability to engrave on hard materials like metals, ceramics, and some plastics. These machines use a fiber optic medium to amplify the laser beam, providing precision and deep engraving. They are widely used in industries like automotive and aerospace due to their durability and effectiveness on metallic surfaces.

Advantages:

- High precision and deep engraving capabilities

- Suitable for various metals and hard materials

- Efficient energy consumption

CO2 Laser Machines

CO2 lasers excel in engraving non-metal materials such as wood, acrylic, and leather. They operate using a carbon dioxide gas mixture, making them ideal for creative projects involving organic materials. These machines are frequently used in artistic endeavors, signage, and even food decoration.

Advantages:

- Versatile with organic materials

- Ideal for artistic and decorative purposes

- Cost-effective for small businesses

UV Laser Machines

UV lasers are the choice for applications demanding high precision and minimal heat impact. Their cold light operation makes them perfect for delicate materials like glass or certain plastics. UV lasers have gained popularity for niche applications like leaf engraving or intricate jewelry design.

Advantages:

- Precise engraving with minimal thermal damage

- Suitable for heat-sensitive materials

- Popular in fine detailing tasks

Machine Size and Mobility Considerations

Choosing the right machine also involves understanding your size and mobility requirements.

| Machine Type | Characteristics | Best For |

|---|---|---|

| Desktop | Larger, robust | Factories, stationary tasks |

| Portable | Easy setup | On-the-go tasks |

| Handheld | Compact, mobile | Direct marking on large objects |

Decision Factors for Selecting a Laser Machine

- Material Requirements: Evaluate what materials you’ll work with most frequently. For metals, fiber lasers are optimal. CO2 lasers suit organic materials, while UV lasers cater to precision tasks.

- Size and Mobility: Consider where and how you’ll use the machine. Portable or handheld models are suitable for mobility, while desktop models cater to industrial settings.

- Budget: Balance your budget with usage intensity. Handhelds might be cheaper but offer less power than stationary models.

For additional insights on choosing the right machine, explore laser engraving machine selection tips7. This information can guide you through making an informed decision tailored to your needs.

Fiber lasers are best for engraving metals.True

Fiber lasers excel in precision and depth on hard materials like metals.

CO2 lasers are unsuitable for organic materials.False

CO2 lasers are ideal for organic materials, excelling in artistic projects.

What Creative Projects Can You Undertake with a Laser Engraver?

Laser engravers are not just for industrial use; they open up a world of creative possibilities. From personalized gifts to intricate art pieces, explore how you can unleash your creativity with this versatile tool.

With a laser engraver, you can create custom jewelry, personalized home decor, intricate art pieces, and even unique business merchandise. The precision and versatility of laser engraving make it perfect for bringing detailed and unique designs to life across various materials.

Custom Jewelry Design

Laser engravers offer precision that is crucial for creating intricate and customized jewelry pieces. From engraving names on pendants to designing complex patterns on rings, the possibilities are endless. These machines allow for high detail without compromising the integrity of precious metals or gems.

Personalized Home Decor

Transform ordinary home items into personalized treasures. Use a laser engraver to etch family names or inspirational quotes onto wooden plaques, glassware, or coasters. This is particularly popular for creating bespoke gifts for weddings or housewarming parties.

Art and Sculptures

Artists can expand their creative horizons by using laser engravers to cut and etch fine details into a variety of materials. Whether you’re crafting a detailed silhouette from acrylic or etching a design into metal, laser engravers enable artists to achieve precision that is often challenging with traditional tools.

Customized Business Merchandise

Many businesses leverage laser engraving to produce custom merchandise. From branded keychains and pens to elaborate corporate awards, businesses can use these machines to create professional and eye-catching products that stand out in the market.

Innovative Educational Projects

In educational settings, laser engravers are used to bring STEM projects to life. Students can design and create models, prototypes, or even educational tools using laser-cut pieces. This hands-on approach fosters creativity and practical skills.

Engraving on Unconventional Materials8

Laser engravers are capable of working with unconventional materials such as leaves or foods. This opens up opportunities for niche artistic projects like leaf engraving or decorative food presentations, offering a unique twist to traditional engraving techniques.

By exploring these diverse projects, you can fully harness the capabilities of laser engraving technology and discover new creative avenues. The only limit is your imagination!

Laser engravers can engrave on leaves.True

Laser engravers can indeed engrave on unconventional materials like leaves.

Laser engraving cannot be used on glassware.False

Laser engravers are capable of etching designs onto glassware.

Conclusion

Laser engravers and cutters are gateways to creativity and precision. Choose the right machine for your needs, and watch your ideas come to life!

-

Discover how laser technology improves precision and efficiency in manufacturing.: Today’s industrial lasers are better suited for production lines than other marking technologies like inkjet printing, dot peen marking, and printed labels. ↩

-

Explore innovative uses of lasers in modern fashion design.: Recently the use of laser in apparel industry is increasing in cutting garment patterns, patterning designer neckties, 3D body scanning, denim … ↩

-

Learn about precision laser applications in electronics.: This technique is well-known, and it has issues. CO2 lasers have a large spot diameter, and copper itself reflects that particular wavelength. ↩

-

Understand how lasers enhance automotive manufacturing and customization.: Precise and automated production (24/7). Without laser technology, new innovations in the vehicle market are hardly feasible and not economical. This is … ↩

-

Discover the benefits of using fiber lasers for metal projects.: Browse our fiber laser machines that allow you to easily laser etch and engrave on metal materials. From jewelry engravings to kitchenware barcode etching, … ↩

-

Learn why CO2 lasers excel at plastic engraving tasks.: Explore our collection of CO2 laser engraving machines, laser cutters and fiber laser marking machines. Soon, you can laser your dream creations into … ↩

-

Discover expert advice for selecting the best laser engraver.: The strength of the laser is most important for cutting. Remember the thickness of material that a laser can cut is determined by the focal point of the lens … ↩

-

Discover how artists use laser engraving on unexpected materials.: Discover a treasure trove of creative laser engraving and cutting ideas, perfect for products and personalized gifts. ↩