Have you ever wondered if laser cutters can tackle tough materials like glass and ceramics? You’re not alone!

Yes, laser cutters can effectively cut through glass and ceramics using specific laser types like UV lasers for glass and pulsed fiber lasers for ceramics. The precision and speed offered by lasers make them a preferred choice over traditional methods.

But there’s so much more to explore! Let’s dive deeper into the fascinating world of laser cutting, where the type of laser, material thickness, and unique challenges come together to create exceptional results.

UV lasers are best for cutting glass.True

UV lasers minimize thermal stress, ideal for glass cutting.

What Are the Best Laser Types for Cutting Glass and Ceramics?

Choosing the right laser type is crucial for cutting glass and ceramics effectively. Let’s explore the best options!

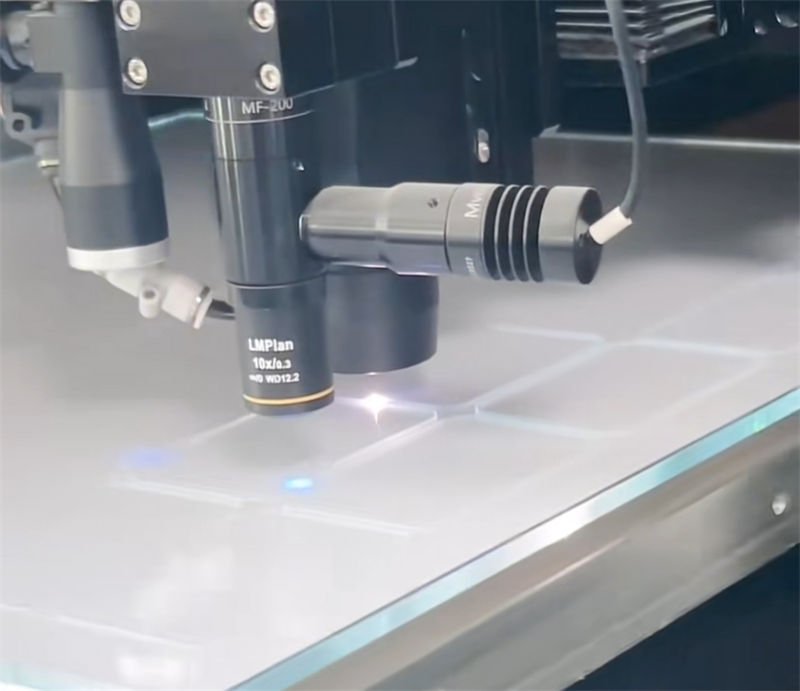

For cutting glass, ultraviolet (UV) lasers are optimal, offering precision with minimal thermal stress. For ceramics, pulsed fiber lasers excel by providing high power and control. Both laser types ensure clean cuts and smooth edges, crucial for handling these delicate materials.

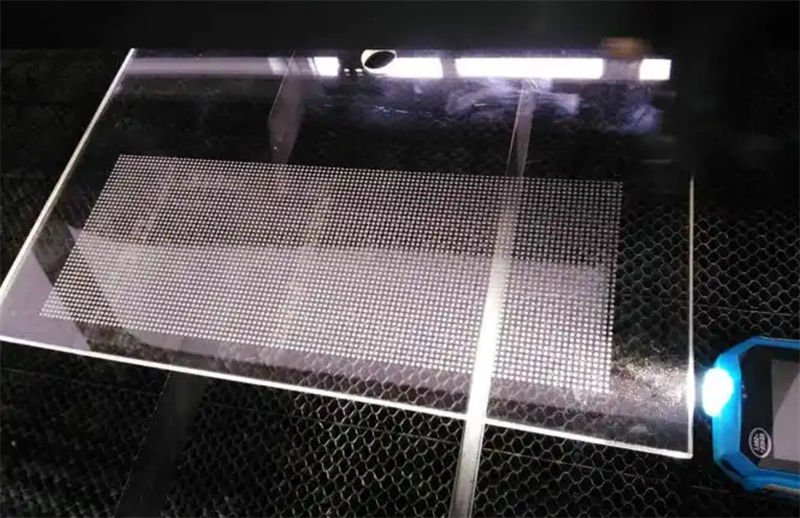

Ultraviolet (UV) Lasers for Glass

UV lasers are ideal for glass cutting due to their high photon energy and ability to minimize thermal stress, which is crucial given glass’s brittleness. UV lasers operate at wavelengths between 193 and 355 nm, making them particularly effective at being absorbed by glass materials. When the laser hits the glass surface, it quickly heats and vaporizes the material, allowing for precise cuts.

-

Precision & Thickness: UV lasers can achieve a cutting precision of about ±0.1 mm and are suitable for glass thicknesses ranging from 1 to 10 mm. This precision is especially beneficial in industries like electronics, where exact measurements are essential for components such as screens with narrow bezels.

-

Limitations: It’s important to manage the laser’s energy and speed to avoid cracking due to thermal stress. The absorption rate also varies with different glass types, such as quartz versus soda-lime glass.

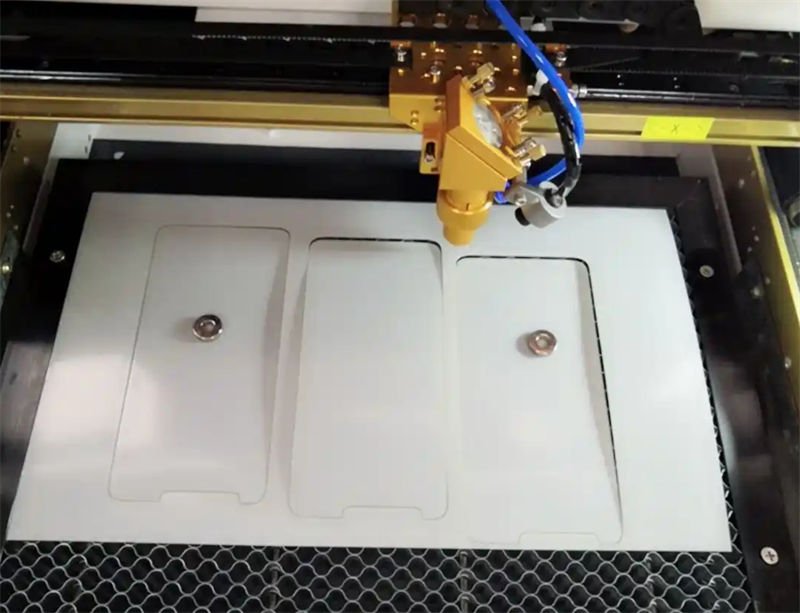

Pulsed Fiber Lasers for Ceramics

Pulsed fiber lasers stand out when it comes to cutting ceramics. These lasers deliver high peak power in short bursts, which is perfect for handling the high hardness and low toughness of ceramics. The pulse width ranges from nanoseconds to microseconds, ensuring minimal thermal impact while providing enough energy to cut through tough ceramic surfaces.

-

Precision & Thickness: With a cutting precision of approximately ±0.2 mm, pulsed fiber lasers can handle ceramic thicknesses between 0.5 and 5 mm. This is particularly useful in industries like electronics for processing components such as ceramic substrates.

-

Considerations: Different ceramics, such as alumina or silicon nitride, require different laser settings due to varying hardness and melting points. Adjustments in power and speed help in preventing cracks and chipping.

Comparing Laser Types

| Laser Type | Best For | Precision | Thickness Range | Special Considerations |

|---|---|---|---|---|

| UV Lasers | Glass | ±0.1 mm | 1 – 10 mm | Manage energy to prevent cracking; absorption varies with glass type |

| Pulsed Fiber Lasers | Ceramics | ±0.2 mm | 0.5 – 5 mm | Adjust settings based on ceramic type to prevent damage |

Understanding these laser types and their applications can significantly enhance the efficiency and quality of cutting processes for glass and ceramics. The choice depends on material characteristics and desired outcomes, emphasizing the importance of tailored laser solutions for each material type.

To learn more about how these lasers interact with different materials, consider exploring additional resources on UV laser applications1 and fiber laser technology2.

UV lasers are best for cutting ceramics.False

UV lasers are optimal for cutting glass, not ceramics.

Pulsed fiber lasers provide high power in short bursts.True

Pulsed fiber lasers deliver high peak power in short bursts.

How Does Material Thickness Affect Laser Cutting Efficiency?

Does the thickness of your material really matter when laser cutting? Let’s find out!

Material thickness directly impacts laser cutting efficiency, affecting speed, precision, and energy consumption. Thicker materials require more laser power and slower cutting speeds, which may lead to lower efficiency and potential quality issues like rough edges or thermal damage.

The Impact of Material Thickness on Laser Cutting

The thickness of the material you intend to cut is one of the most crucial factors in determining the efficiency of a laser cutting process. As material thickness increases, the challenges and requirements for effective cutting also rise. Here’s a detailed look at how thickness affects various aspects of laser cutting:

Speed and Energy Consumption

Thicker materials generally require more laser power to achieve a clean cut. This is because the laser needs to penetrate deeper into the material, which demands more energy and time. As a result, the cutting speed tends to decrease with increased thickness.

| Material Thickness (mm) | Required Laser Power (W) | Cutting Speed (mm/s) |

|---|---|---|

| 1 | 20 | 10 |

| 5 | 50 | 7 |

| 10 | 100 | 5 |

This table illustrates how increasing thickness requires greater power and reduces speed, impacting efficiency.

Precision and Edge Quality

Thicker materials may lead to less precise cuts, as the laser beam’s focal point becomes less defined over greater depths. This can result in wider kerfs (the width of the cut) and rougher edges. Managing this requires careful adjustment of the focal point and beam quality.

For example, when cutting glass that exceeds 10mm in thickness, achieving smooth edges without cracks or chips becomes challenging due to thermal stress considerations3.

Thermal Effects and Material Deformation

As material thickness increases, so does the risk of thermal effects, such as warping or deformation. Thicker sections retain more heat, leading to potential damage. Using controlled pulse durations can help minimize these effects but may not fully eliminate them, especially in sensitive materials like ceramics.

In ceramic cutting, for instance, excessive thickness can cause microcracks due to differential heating factors4.

Optimizing for Different Thicknesses

To optimize laser cutting for various material thicknesses:

- Adjust Power Settings: Tailor the laser power according to material thickness to maintain efficiency without compromising quality.

- Select Appropriate Laser Types: Different lasers have varying penetration abilities; for example, fiber lasers5 are efficient for thicker metals while UV lasers are better for thinner glass.

- Fine-tune Cutting Speed: Balance speed with quality by adjusting it based on thickness and material type.

By understanding and managing these factors, you can significantly enhance the efficiency of your laser cutting processes across different materials.

Thicker materials decrease laser cutting speed.True

Increased thickness requires more energy, slowing the cutting process.

Thicker materials improve edge precision in laser cutting.False

Thicker materials lead to less precise cuts due to beam focus issues.

What Are the Main Limitations of Laser Cutting Glass and Ceramics?

Laser cutting offers precision and speed, but it’s not without limitations when it comes to glass and ceramics.

Laser cutting glass and ceramics faces limitations such as brittleness, thermal stress, and material-specific absorption characteristics. These challenges can cause cracking, chipping, and affect the quality of the cut, requiring careful selection of laser type and parameters.

Understanding Material Brittleness

One of the primary challenges in laser cutting6 glass and ceramics is dealing with their inherent brittleness. Both materials have a low tolerance for thermal stress, which is generated by the laser’s heat. This brittleness can lead to cracks or chips along the cut edges, especially if the laser energy is too high or the cutting speed is too slow.

Example of Thermal Stress

When a high-powered laser is used on a thin piece of glass, the intense heat can cause thermal expansion in one area while the surrounding material remains cool. This disparity results in internal stress that often leads to cracking.

Variability in Absorption Rates

Different glass compositions—such as quartz versus soda-lime glass—and various ceramics like alumina or silicon nitride have unique absorption rates for laser energy. For instance, while UV lasers are suitable for glass due to their higher photon energy, ceramics may require pulsed fiber lasers for effective cutting. The absorption characteristics significantly impact the choice of laser type and settings.

| Material | Preferred Laser Type | Notes |

|---|---|---|

| Soda-lime Glass | UV Laser | Absorbs UV light well |

| Quartz Glass | UV Laser | Requires precise energy control |

| Alumina Ceramics | Pulsed Fiber Laser | High hardness; needs high energy |

| Silicon Nitride | Ultrashort Pulse Laser | Very hard; prone to microcracks |

Precision Challenges

While lasers offer high precision, achieving this consistently requires meticulous parameter settings. Factors such as laser power, pulse duration, and speed must be carefully balanced to prevent defects. Moreover, different materials demand specific adjustments. For example, alumina ceramics need higher laser energy with reduced speed to avoid cracks.

Impact on Material Thickness

The thickness of glass or ceramic also plays a crucial role in determining cutting efficiency. Generally, thinner materials are easier to cut with lasers, but as thickness increases, so do the potential for thermal stress and cracking. For instance, while UV lasers can cut through 1-10 mm of glass, thicker sections may require slower speeds or multiple passes, increasing the likelihood of errors.

In summary, while laser cutting is highly effective for both glass and ceramics, understanding these limitations is vital for optimizing the process.

Glass and ceramics absorb laser energy uniformly.False

Different materials have unique absorption rates, affecting laser choice.

Thicker glass increases the risk of thermal stress.True

Thicker materials are more prone to cracking due to uneven heat distribution.

Are There Industry-Specific Applications for Laser-Cut Glass and Ceramics?

Ever wondered where laser-cut glass and ceramics find their niche in various industries? Explore their unique applications here!

Laser-cut glass and ceramics are crucial in industries like electronics, automotive, aerospace, and healthcare. Their precision and adaptability to intricate designs make them essential for creating components such as electronic screens, medical devices, and advanced engine parts.

Electronics Industry

In the electronics sector, laser-cut glass is pivotal for manufacturing smartphone screens and other touch-sensitive devices. The precise cutting capabilities ensure that devices can maintain narrow bezels and sleek designs. Ultraviolet laser technology is employed to achieve the high precision needed for these intricate components, while minimizing the risk of micro-cracks or chipping.

Laser-cut ceramics also play a critical role in producing substrates for circuit boards due to their excellent thermal and electrical insulating properties. The ability to cut with minimal heat impact makes lasers ideal for handling sensitive materials without compromising their integrity.

Automotive and Aerospace Industries

In the automotive industry, laser-cut glass is used for creating complex shapes required in modern vehicle designs, like panoramic sunroofs and heads-up displays. These components not only enhance aesthetic appeal but also improve functionality and safety.

The aerospace sector benefits from laser-cut ceramics for turbine blades and heat shields. The high precision of pulsed fiber lasers allows for exact cuts in materials that can withstand extreme conditions, essential for components exposed to high temperatures and pressures.

Healthcare Applications

The healthcare industry utilizes laser-cut ceramics in the production of advanced medical devices such as implants and prosthetics. Their biocompatibility and durability make them suitable for long-term use in the human body. Lasers enable detailed shaping of ceramics to fit individual anatomical requirements, enhancing patient outcomes.

Laser-cut glass is also used in the production of diagnostic equipment, where precision and clarity are crucial. For example, glass slides for microscopes require flawless edges to ensure accurate readings.

Architectural and Decorative Uses

Architects and designers appreciate laser-cut glass for its ability to create intricate patterns and designs that traditional methods cannot achieve. This opens up possibilities for custom windows, partitions, and artistic installations that are both functional and visually stunning.

Similarly, laser-cut ceramics find their place in decorative tiles and panels, offering unique aesthetic options that are durable and easy to maintain. The adaptability of laser cutting allows designers to experiment with patterns and textures that add sophistication to any space.

To summarize, laser-cutting technology has revolutionized how industries approach the design and manufacturing of glass and ceramic components. Its precision and versatility make it indispensable across various fields, from electronics7 to healthcare8. The potential applications continue to expand as technology advances, promising even greater innovation in the future.

Laser-cut glass is used in smartphone screens.True

Laser-cut glass provides precision for sleek designs in smartphones.

Ceramics are unsuitable for medical implants.False

Laser-cut ceramics are biocompatible, suitable for medical implants.

Conclusion

Laser cutters are revolutionizing how we process glass and ceramics. By understanding the right laser types and techniques, you can achieve stunning results in your projects.

-

Discover more about UV laser uses across various industries.: Another application is UV Raman spectroscopy. Both continuous-wave and pulsed UV lasers are used for fabricating fiber Bragg gratings. ↩

-

Understand why fiber lasers are preferred in many precision tasks.: 7 Advantages of Fiber Lasers · 1. Highly Efficient Gain Medium · 2. Smart Feedback Loop through Fiber Bragg Gratings · 3. Robust Optical Cavity · 4. ↩

-

Explore methods to achieve smooth glass edges.: This paper compares the traditional top-down laser ablation methods in the air to those assisted with a flowing water film using picosecond pulses. ↩

-

Learn strategies to avoid cracks in ceramic cutting.: This study is aimed at realizing a crack-free cut of engineering ceramics with high efficiency by using a mechanical chopper Q-switched pulse CO 2 laser with … ↩

-

Discover why fiber lasers excel with thicker materials.: The most powerful fiber laser cutting machines can achieve a maximum thickness of up to 50 mm for certain metals. ↩

-

Explore why brittle materials pose challenges in laser cutting.: Laser cutting becomes less effective when material thickness increases. For instance, lasers may be ineffective for cutting carbon steel thicker than .4 inches. ↩

-

Discover how laser-cut glass enhances electronic device design.: In the automotive industry, laser cutting is used for shaping glass components, ensuring exact fit and finish. Laser technology’s ability to … ↩

-

Learn about innovative medical devices crafted with laser-cut ceramics.: The benefits of laser fabrication and machining of ceramics include high precision, reduced thermal damage, non-contact processing, and the … ↩