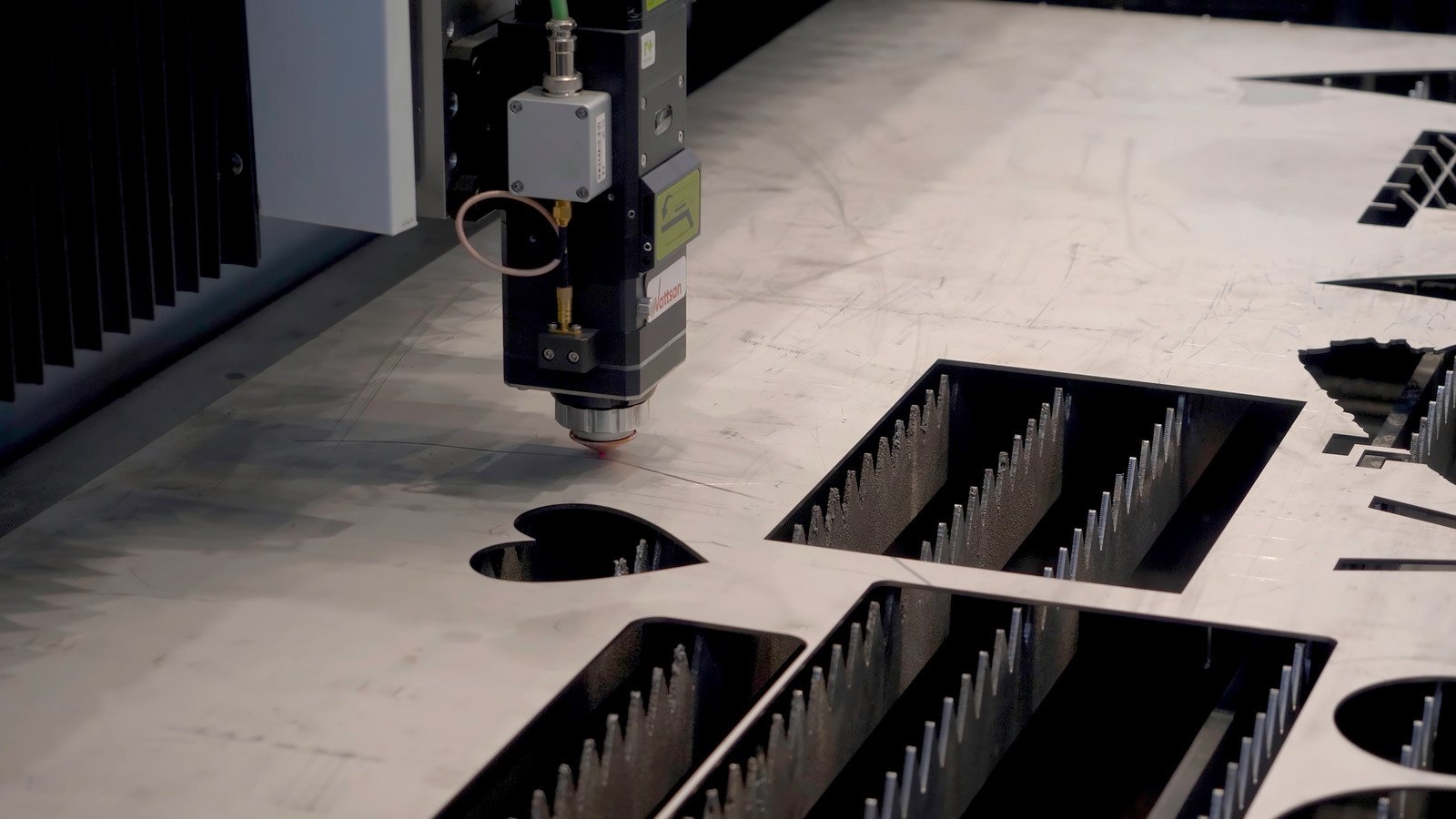

I recall the initial moment I witnessed a laser cutter working – it seemed similar to a light performance that wonderfully changed metal sheets into complex patterns.

Laser cutters effectively cut sheet metal with high accuracy and minimal deformation, achieving tolerances as fine as ±0.05mm. They excel at processing various metal thicknesses by adjusting the pulse frequency and duty cycle for optimal results.

To really use their power, understanding their details is vital. Details like pulse frequencies and material specifics help you not just cut metal, but truly control it.

Laser cutters achieve tolerances as fine as ±0.05mm.True

Laser machines offer high accuracy, allowing detailed patterns with little warping.

What Are the Key Advantages of Using Laser Cutters for Sheet Metal?

Laser cutters change the sheet metal industry through their accuracy, productivity and adaptability.

Laser cutters offer precise cutting, minimal deformation, and enhanced efficiency in sheet metal processing. They accommodate various metal thicknesses and shapes, ensuring high-quality output with reduced waste.

Using Great Accuracy and Quality

Laser cutters offer very high accuracy in sheet metal work. They can achieve tolerances as tight as ±0.05mm. This means they can create detailed designs and complex shapes that are hard to accomplish with older methods. The precision results in clean cuts with smooth edges, lowering the need for extra work afterward.

Quickness and Speed

Laser cutters increase the speed and effectiveness of sheet metal work greatly. Technicians adjust settings like pulse frequency quickly to suit different materials and thicknesses. This flexibility not only speeds up production but also increases adaptability in manufacturing.

| Feature | Traditional Cutting | Laser Cutting |

|---|---|---|

| Cutting Speed | Moderate | Fast |

| Setup Time | Long | Short |

| Precision | ±0.5mm | ±0.05mm |

| Material Waste | High | Low |

Adaptable with Different Materials

Laser cutters manage various metals easily, from thin aluminum sheets to thicker stainless steel. This adaptability comes from the ability to adjust settings such as pulse frequency. Different metals1 need different settings, making laser cutters a versatile tool for many tasks.

Less Waste and Lower Costs

Laser cutters provide precise cuts with little deformation, reducing material waste. This efficiency lowers costs, as fewer raw materials are needed and less time goes into extra work like grinding. The non-contact nature of laser cutting also decreases wear on tools, cutting down maintenance expenses.

Safety and Automation

Modern laser cutters include advanced safety features to protect workers from dangers linked with older cutting methods. Automation allows for continuous use with little human effort, increasing efficiency while keeping safety high. Incorporating these best practices2 assures top performance and safety at work.

Laser cutters achieve tolerances as fine as ±0.05mm.True

Laser cutters deliver exceptional accuracy, reaching tolerances of ±0.05mm.

Traditional cutting methods produce less waste than laser cutting.False

Laser cutting lowers material waste compared to older techniques.

How Do Different Metals Affect Laser Cutting Performance?

Metal type greatly affects the efficiency, accuracy and quality of the final item while cutting with lasers.

Different metals impact laser cutting performance due to variations in thermal properties and reflectivity. Metals like aluminum require adjustments in laser settings for optimal results.

Thermal Conductivity and Its Impact

The thermal conductivity of a metal helps decide how well it is cut using a laser. Metals like copper and aluminum spread heat fast, which can cause uneven cuts or need more power. On the other hand, metals like stainless steel transfer heat less, focusing it better and often resulting in cleaner cuts.

| Metal Type | Thermal Conductivity (W/m·K) | Cutting Efficiency |

|---|---|---|

| Copper | 401 | Challenging |

| Aluminum | 237 | Moderate |

| Stainless Steel | 16 | High |

Reflectivity: A Key Consideration

Reflectivity is very important in laser cutting. Highly reflective metals like silver and gold bounce back laser beams, causing power problems and possible damage to the machine. Special methods and coatings are usually used with reflective materials to absorb the laser better and stop beam bouncing.

Effect of Metal Thickness on Laser Cutting

Metal thickness also changes how well it cuts. Thicker metals need stronger lasers to slice through. A standard CO2 laser can cut thin stainless steel easily, but fiber lasers are often needed for cutting thicker plates with more precision and speed.

Fine-Tuning Laser Settings for Different Metals

Changing laser settings for different metals is necessary. Adjusting pulse frequency and duty cycle is important. For example, cutting titanium requires changing the duty cycle to avoid overheating and oxidation, which helps achieve smooth cuts.

Exploring detailed information on laser cutting settings3 for specific metals can really improve cutting quality and efficiency when understanding these parameters.

Copper is easy to cut with lasers.False

Copper has excellent thermal conductivity, which means it is hard to slice.

Stainless steel requires less laser power than aluminum.True

Stainless steel's low thermal conductivity requires less energy for cutting.

What Are the Best Practices for Operating a Laser Cutter?

Mastering laser cutter functions needs learning its details and following smart methods.

To operate a laser cutter effectively, ensure precise frequency adjustments, maintain a clean lens, regularly check alignment, and follow safety protocols. These practices enhance performance and prevent equipment damage.

Understanding Laser Frequency and Duty Cycle

Operating a laser cutter effectively involves mastering two key concepts: pulse frequency and duty cycle.

-

Pulse Frequency: Often measured in hertz (Hz), this denotes the number of times the laser emits light per second. A higher pulse frequency, such as 500Hz, allows for a more continuous beam, resulting in a smooth cut. Conversely, reducing the frequency from 500Hz to 200Hz can enhance the delicacy of the cut and improve the reduction of delamination. However, setting the frequency too low, such as 100Hz, may lead to ineffective cutting and issues like back reflections.

-

Duty Cycle: This is the proportion of time during which the laser is active within a given period. The relationship between the pulse period ( T ) and frequency is given by ( T = \frac{1}{\text{frequency}} ). The pulse width ( t ) can then be calculated by ( t = T \times \text{duty cycle} ). For example, with a frequency of 500Hz and a 50% duty cycle, the pulse period ( T ) calculates to 2 milliseconds, and the pulse width ( t ) is 1 millisecond.

By adjusting these parameters, you can ensure precise cuts without overheating or damaging the material, making it crucial to find the optimal frequency and duty cycle to match the number of pulses and the energy of each pulse perfectly.

Proper Alignment and Lens Cleaning

Checking and setting the alignment of your laser cutter’s parts is crucial. If not aligned properly, cutting becomes less efficient, and the machine wears faster. Alignment tools can help maintain precision.

Keeping the laser lens free from dirt is equally important. Dust on the lens can alter the beam’s path, reducing cutting accuracy and potentially damaging the lens. Use appropriate cleaning tools and liquids designed for delicate optics.

Safety Guidelines and File Organization

Safety should be a primary concern when using a laser cutter. Wear safety goggles designed for laser protection. Keep a fire extinguisher nearby for unexpected events.

Organize your cutting files efficiently as well. Save your work frequently to prevent data loss from sudden computer failures. Systematically sort files for easy access and updates.

Adjusting to Varied Materials

Laser cutters handle different materials; however, each type may require special settings for optimal results. For example, cutting metals might need different frequency settings compared to plastics or wood. Conduct test cuts to determine the best settings for each material type.

Following these best practices4 helps in using your laser cutter effectively while prolonging its lifespan.

A clean lens improves laser cutting accuracy.True

Dust on the lens scatters the beam, lowering precision.

Higher frequencies always enhance laser cutting precision.False

Reduced frequencies increase section gentleness by decreasing layer separation.

Can Home-Based Projects Benefit from Laser Cutting Technology?

Laser cutting technology is now easier to reach, creating interest among home project fans.

Yes, home-based projects can significantly benefit from laser cutting technology by enhancing precision, creativity, and efficiency. This technology allows hobbyists to experiment with complex designs and materials that were once difficult to manipulate, providing a professional finish to DIY endeavors.

Precision and Creativity in Home Projects

Laser cutting technology offers unparalleled precision and flexibility for home-based projects. With an accuracy of ±0.05mm, hobbyists can achieve intricate details in materials like wood, acrylic, and even light metals. This level of detail opens up creative possibilities, allowing for the production of custom jewelry designs5 or personalized decorative items.

Additionally, laser cutting allows for quick prototyping, enabling enthusiasts to iterate designs efficiently. This is particularly beneficial in crafting and model-making, where precision and creativity are paramount.

Material Versatility

One of the major advantages is the ability to work with a diverse range of materials. From wood and plastics to thin metals, laser cutters can handle various substrates. This versatility means home-based creators can experiment with different textures and finishes, which can be especially useful in furniture design6 and interior décor.

Cost-Effectiveness and Efficiency

While initial investment in a laser cutter might seem high, the long-term benefits often justify the cost. The speed and precision of laser cutting reduce material waste, which can result in cost savings over time. For those frequently engaged in DIY projects, this can lead to significant savings on materials.

Moreover, the ability to save digital files for repeated use means that once a design is perfected, it can be reproduced easily and consistently without additional setup time.

Safety Considerations and Learning Curve

Operating a laser cutter at home requires attention to safety. Proper ventilation and protective eyewear are essential to avoid exposure to harmful fumes and light. Additionally, understanding the settings—such as pulse frequency and duty cycle—is critical for optimal results.

For beginners, many resources and communities offer support and guidance on safely using laser cutters at home. Engaging with these communities can accelerate the learning process and enhance project outcomes.

In conclusion, while laser cutting technology demands an initial learning curve and safety considerations, its potential to transform home-based projects is substantial. Whether for creative expression or functional DIY tasks, incorporating this technology can elevate the quality and scope of personal projects.

Laser cutting enhances creativity in home projects.True

Laser cutting permits fine details and different materials, increasing imagination.

Laser cutting is cost-effective for all home projects.False

Initial costs can be high; savings depend on project frequency and material use.

Conclusion

Laser cutters provide accuracy in processing sheet metal. Knowing their abilities helps your work. Learn laser cutting details to achieve really good results.

-

Explore how various metals respond to laser cutting processes.: One of the big advantages to laser cutting, is that almost any material can be cut, from thin metals to thick ones, as well as wood and certain types of … ↩

-

Learn essential safety measures for operating laser cutters effectively.: NEVER operate system unattended. Properly maintained fire extinguisher should always be in the area. Always keep the area around cutter free of debris, clutter, … ↩

-

Explore expert recommendations on adjusting laser settings for various metals.: Generally, the recommended speed for cutting stainless steel with a laser cutter is between 10 and 20 mm/s. ↩

-

Discover specific settings for various materials to optimize your laser cuts.: 1. Use the thinnest sheet possible. · 2. Ensure you select the appropriate material thickness for your project, as it affects both the engraving quality and the … ↩

-

Discover creative jewelry design possibilities using laser cutting.: May 7, 2021 – Explore Sandi Marlowe’s board "Laser Jewelry Ideas" on Pinterest. See more ideas about jewelry, laser cut jewelry, laser. ↩

-

Explore innovative furniture designs achieved through laser cutting.: Nov 11, 2014 – Explore Kawther Saffar’s board "laser cut furniture" on Pinterest. See more ideas about laser cut furniture, cnc furniture, furniture. ↩