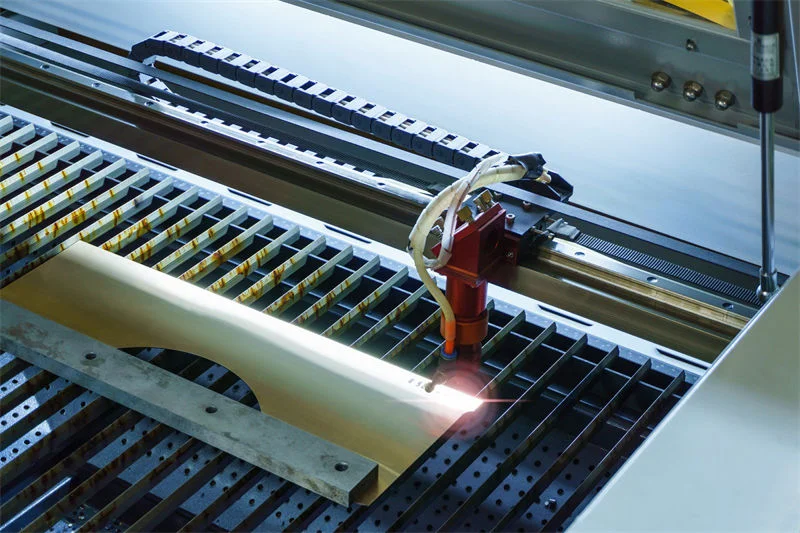

Ever gazed at a beautifully cut piece of metal or acrylic and wondered how it was made? Laser cutting machines are behind that magic! Let’s unravel their secrets together.

The key components of a laser cutting machine include the laser generator, CNC system, machine tool mainframe, external optical path system, cutting head, chiller unit, auxiliary gas system, regulated power supply, air compression and treatment equipment, and waste material handling equipment. Each plays a vital role in the machine’s operation.

Dive deeper with me as we explore how each of these components works in harmony to create precise cuts and maintain optimal performance.

The laser generator is the core of a laser cutting machine.True

The laser generator produces the high-energy beam essential for cutting.

How Does Each Component Contribute to the Machine’s Functionality?

Laser cutting machines boast a complex array of components, each crucial to their operation. How do these parts work together?

Each component of a laser cutting machine contributes to its functionality by performing specific tasks: the laser generator produces energy, the CNC system controls movements, and the cutting head focuses the beam. Together, they enable precise and efficient cutting.

The Laser Generator: Heart of the Machine

At the core of any laser cutting machine lies the laser generator1. This component is responsible for creating the laser beam, the primary tool for cutting materials. Whether using CO2, fiber, or diode lasers, this generator provides the high-energy laser beam required to cut through various materials with precision.

CNC System: The Brain Behind Precision

The CNC (Computer Numerical Control) system2 acts as the brain of the laser cutting machine. It precisely directs the machine’s movements along the X, Y, and Z axes. This system ensures that the laser follows an exact path, enabling intricate cuts and patterns on the material.

Machine Tool Mainframe: Supporting Structure

The machine tool mainframe3 provides structural support and mechanical movement. It holds the workpiece steady and allows for precise positioning of the cutting head. Servo motors drive this frame, ensuring stability and accuracy during the cutting process.

Cutting Head: Focused Efficiency

Equipped with lenses and sensors, the cutting head4 focuses the laser beam onto the material. This focus allows for high-precision cuts. The cutting head also ejects auxiliary gases like oxygen or nitrogen, which aid in enhancing cutting quality and efficiency.

External Optical Path System: Guiding the Beam

The external optical path system5 uses mirrors and lenses to guide and focus the laser beam from the generator to the cutting head. This ensures that the laser remains stable and precise throughout its journey.

Chiller Unit: Maintaining Stability

The chiller unit6 plays a critical role in maintaining operational stability by cooling down both the laser generator and optical components. This prevents overheating and ensures consistent laser output during prolonged operations.

Auxiliary Gas System: Enhancing Quality

The auxiliary gas system7 supplies gases that assist in improving cutting performance. These gases blow away molten slag and prevent oxidation, thus enhancing speed and quality.

Regulated Power Supply: Ensuring Smooth Operation

The regulated power supply connects to both the laser and CNC systems. Its role is to protect against electrical fluctuations, ensuring that external power surges do not interfere with machine operations.

Air Compression and Treatment Equipment: Purity in Operations

This equipment supplies clean, dry air to protect sensitive components from dust and moisture. It ensures that air used in operations does not affect precision or cause damage.

Waste Material Handling Equipment: Cleanliness Is Key

Finally, waste material handling systems, like dust collectors and slag removers, maintain a clean workspace by managing debris produced during cutting. This not only ensures a tidy work environment but also adheres to environmental standards.

The laser generator produces the laser beam.True

The laser generator is responsible for creating the high-energy laser beam.

CNC systems manage power supply fluctuations.False

CNC systems control movement, not power supply fluctuations.

What Are the Maintenance Tips for Key Laser Cutting Machine Components?

Ensuring the longevity and efficiency of a laser cutting machine hinges on proper maintenance. Learn essential tips to keep your equipment in top condition.

Regular maintenance of a laser cutting machine involves checking the cooling system, cleaning lenses, lubricating guide rails, and inspecting electrical components. Following these steps prevents failures, extends component life, and maintains cutting quality.

Laser Generator Maintenance

The laser generator8 is the heart of the machine. Regular checks on its cooling system are crucial. Ensure the cooling water is clean and at optimal temperature to prevent overheating. Monthly replacement of the cooling water and cleaning of the water tank and filter helps in avoiding scale buildup.

Dust Cleaning: Accumulation of dust can deteriorate the performance of the laser. Therefore, routinely clean the dust inside the generator to maintain optimal functioning.

Machine Tool Mainframe Care

The mainframe’s precision is vital for accurate cuts. Regularly clean and lubricate the guide rails to prevent friction and ensure smooth movements. This process should be done weekly.

Fasteners Check: Inspect screws and couplings to ensure they remain tight, preventing mechanical instability.

Cutting Head Preservation

The cutting head requires daily attention. Use specialized cleaners and lint-free cloths to clean lenses, avoiding any scratches.

Wear Inspection: Regular checks for wear or damage are necessary. Replace parts as needed to maintain cutting efficiency.

External Optical Path System

Maintaining optical clarity is essential. Daily clean the optical lenses using soft cloths without directly touching them to prevent contamination.

CNC System Evaluation

A well-maintained CNC system9 ensures precise cutting paths. Regularly check for loose connections or aged components within the electrical cabinet. Keeping it dust-free reduces risks of short circuits or signal interference.

Chiller Unit Maintenance

The chiller unit prevents overheating of laser components. Use compressed air or a brush to clean dust from the condenser regularly. Replace circulation water every six months to ensure efficient heat dissipation.

Auxiliary Gas System Check

Daily inspections ensure that gas supply pressures are normal and pipes are leak-free, ensuring proper functionality.

Waste Material Handling Equipment

Cleaning fans and exhaust pipes monthly enhances ventilation and improves dust removal efficiency, maintaining a clean work environment.

Adhering to these maintenance tips not only prolongs the lifespan of your laser cutting machine but also ensures consistent quality and efficiency in its operation.

Replacing cooling water monthly prevents scale buildup.True

Regular water replacement avoids mineral deposits, ensuring efficient cooling.

Lubricating guide rails daily is recommended.False

Guide rails should be lubricated weekly to prevent friction and wear.

How Do the Costs of Core Components Vary Across Different Models?

Purchasing a laser cutting machine involves understanding the costs of its core components, which can vary widely between different models. Here’s what you need to know.

The cost of core components in laser cutting machines varies significantly across different models due to factors like technology, brand, and functionality. For instance, CO2 lasers are generally less expensive than fiber lasers, and advanced CNC systems can cost substantially more than basic ones. Evaluating these costs is crucial for informed purchasing decisions.

Cost Variations by Laser Type

One of the primary determinants of a laser cutting machine’s cost is the type of laser generator used. CO2 lasers, for example, are often less expensive, typically ranging from $8,000 to $50,000, primarily used for cutting non-metallic materials. In contrast, fiber lasers are more costly, from $20,000 to $500,000, but they offer faster cutting speeds and are ideal for metals.

These price differences stem from the materials each laser is best suited for and their respective efficiencies. Understanding laser types10 is essential when considering the long-term cost-effectiveness of your machine.

Machine Tool Mainframe Costs

The machine tool mainframe, responsible for the mechanical movements along various axes, also shows significant cost variations. Entry-level models may cost between $3,000 to $10,000, while more complex industrial-grade models can exceed $200,000. The variation in pricing is due to differences in precision, size, and durability.

Cutting Head Pricing

While often integrated into the machine, the cutting head can dramatically affect overall costs, especially when equipped with advanced features like auto-focus. High-end machines with such cutting heads can command higher prices due to enhanced precision and automation capabilities. Exploring cutting head technology11 can provide insights into potential benefits versus costs.

CNC System Price Range

The complexity of a CNC system dictates its price. Basic systems might only be a few thousand dollars, but advanced systems with intricate programming capabilities can reach tens of thousands. The choice here impacts not only initial costs but also operational efficiency.

Auxiliary and Support Systems

Components like the chiller unit, auxiliary gas system, and waste material handling equipment also contribute to cost disparities. A chiller unit ranges from $1,000 to $5,000 depending on its cooling capacity, whereas waste handling equipment costs between $500 to $5,000 based on size and technology.

Considering these auxiliary systems’ roles can help optimize your budget allocation when purchasing a machine.

Evaluating Total Investment

When assessing total investment costs, it’s crucial to factor in not just the initial purchase price but also ongoing expenses related to maintenance and consumables. Choosing components that align with your operational needs ensures a balance between performance and cost-efficiency.

For further detailed analysis on component costs across models, explore our comprehensive guide12 that breaks down pricing by brand and specific functionalities.

CO2 lasers are more expensive than fiber lasers.False

CO2 lasers are generally less expensive than fiber lasers.

CNC systems can cost tens of thousands of dollars.True

Advanced CNC systems with intricate programming can reach high costs.

When Should Key Parts of a Laser Cutting Machine Be Replaced?

Understanding the replacement schedule for laser cutting machine components is crucial for maintaining optimal performance and avoiding costly downtime.

Key parts of a laser cutting machine, like the ceramic ring, nozzle, protective lens, and sensors, have varied replacement schedules. Regular inspections based on usage intensity and environmental conditions ensure timely replacements, enhancing machine longevity and efficiency.

Understanding Replacement Intervals for Laser Cutting Machine Components

Laser cutting machines consist of several critical components that require periodic replacements to maintain peak efficiency. The frequency of replacement depends on the component’s wear and tear, usage intensity, and environmental conditions. Here’s a breakdown:

Ceramic Ring: Typically replaced once a year or longer, the ceramic ring collects electrical signals from the laser head nozzle. Wear or damage necessitates its timely replacement to ensure signal integrity.

Nozzle: The nozzle’s exposure to heat and slag during cutting demands regular checks. Replacement should occur based on visible wear or when the cutting quality diminishes. Frequent inspections can prevent cutting inconsistencies.

Protective Lens: This lens shields the focusing lens from debris and dust. Regular cleaning and replacements are crucial, especially in environments with high levels of contaminants.

Focusing and Collimating Lenses: Generally durable, these lenses require replacements only if issues arise. Professional technicians should handle this in controlled environments to prevent contamination.

Sealing Ring: While not prone to immediate issues, sealing rings must be regularly checked for fit with the ceramic ring to prevent leaks.

Sensors: Usually robust, sensors require replacements if malfunctions or alarms occur to avoid production disruptions.

Factors Influencing Replacement Frequency

-

Usage Intensity: Machines used continuously in high-volume production settings may require more frequent component inspections and replacements compared to those used intermittently.

-

Environmental Conditions: Dusty or harsh environments can accelerate wear on components like lenses and nozzles. Implementing stringent cleaning protocols can extend their lifespan.

-

Material Types Processed: Processing abrasive or thick materials might lead to quicker degradation of components like the nozzle or ceramic ring.

-

Maintenance Practices: Regular maintenance, including cleaning and lubrication, can significantly impact the longevity of components. Adhering to maintenance schedules helps in early detection of wear signs.

Practical Table for Replacement Guide

| Component | Typical Replacement Interval | Factors Affecting Frequency |

|---|---|---|

| Ceramic Ring | Annually or longer | Material type, cleaning |

| Nozzle | Based on use | Usage intensity, inspection |

| Protective Lens | Regularly as needed | Environment, maintenance |

| Focusing Lens | Rarely, if issues arise | Professional handling |

| Sealing Ring | As needed | Regular checks |

| Sensors | Upon malfunction | Prompt checks |

By understanding these factors and following recommended guidelines, businesses can ensure their laser cutting machines operate smoothly and efficiently. For more insights into maintenance practices13, consider exploring further resources on machine care strategies.

Ceramic rings in laser cutters need annual replacement.True

Ceramic rings typically require replacement once a year or longer.

Nozzles should be replaced only if issues arise.False

Nozzles need regular checks and replacements based on wear.

Conclusion

Understanding each component’s function is crucial for effective operation and maintenance of laser cutting machines. Equip yourself with this knowledge to optimize your decision-making.

-

Learn how laser generators create powerful beams for precision cutting.: Diode laser generator is a laser system that uses semiconductor materials as the working substance. There are three excitation modes: electric … ↩

-

Discover how CNC systems control precise movement in laser cutters.: What is a CNC Laser Cutter? It is a piece of CNC equipment that uses a focused, high-powered laser beam to mark, cut, or engrave a material. ↩

-

Understand how mainframes support precise cutting operations.: 1) Machine tool mainframe: The machine tool part of the laser cutting machine, the mechanical part that realizes the movement of the X, Y, and Z … ↩

-

Explore how cutting heads focus beams for high-precision cuts.: A fiber laser cutting head is specially designed for high-precision cutting applications. It delivers and focuses the laser beam onto the workpiece. ↩

-

See how optical systems guide beams precisely to targets.: At present, the outer optical path portion of the laser cutting machine mainly uses a flying optical path system. The beam emitted from the … ↩

-

Learn how chillers prevent overheating for stable operations.: Water chillers ensure that the laser cutter operates under optimal conditions, producing uniform and precise cuts, and minimising the risk of … ↩

-

Find out how gases enhance speed and quality in cuts.: During the cutting process, the auxiliary gas can prevent slag return and protect the lens inside the laser head. In other words, under the same … ↩

-

Learn detailed procedures for cleaning and maintaining a laser generator.: Regularly cleaning your machine, both inside and out, is essential for optimal performance. Pay special attention to the inside of the machine … ↩

-

Understand why CNC system upkeep is critical for precision cutting.: CNC machines need proper care to optimize their performance and avoid frustrating failures with the stress of daily operations. ↩

-

Discover how different laser types impact cost and efficiency.: 4 Types of Laser Cutters That You Need To Know · 1. Fiber Lasers · 2. CO2 Lasers · 3. Nd:YAG/Nd:YVO Lasers · 4. Direct Diode Lasers. ↩

-

Learn about cutting head features that enhance precision.: Evolution T Tube Cutting Enclosed Cutting Head which is FDA approved. Max Travel Speed is 1,653 IPM & 1 G acceleration. Max laser capacity is 6,000 Watt. ↩

-

Get a thorough breakdown of component costs by model.: CO2 laser cutter costs around $8000 to $50,000, and the power output ranges between 100W and 500W. It is commonly used for non-metal materials. ↩

-

Discover strategies to extend machine lifespan through effective maintenance.: You should do the laser machine maintenance tasks, including cleaning and checking the lens and mirrors. In addition, you should also check the cooling system … ↩