Have you ever wondered how modern manufacturing achieves such incredible precision? Let’s dive into the transformative world of laser welding!

Laser welding technology is reshaping industries by delivering precise and efficient welding solutions. Sectors like automotive, electronics, medical devices, and aerospace leverage these machines for high-strength welds with minimal thermal distortion.

In this article, we’ll explore how laser welding machines are making waves across various sectors. Understanding these applications can help guide your strategic decisions.

Laser welding machines improve safety in automotive manufacturing.True

They produce high-strength welds that enhance vehicle safety.

How Do Laser Welding Machines Transform the Automotive Industry?

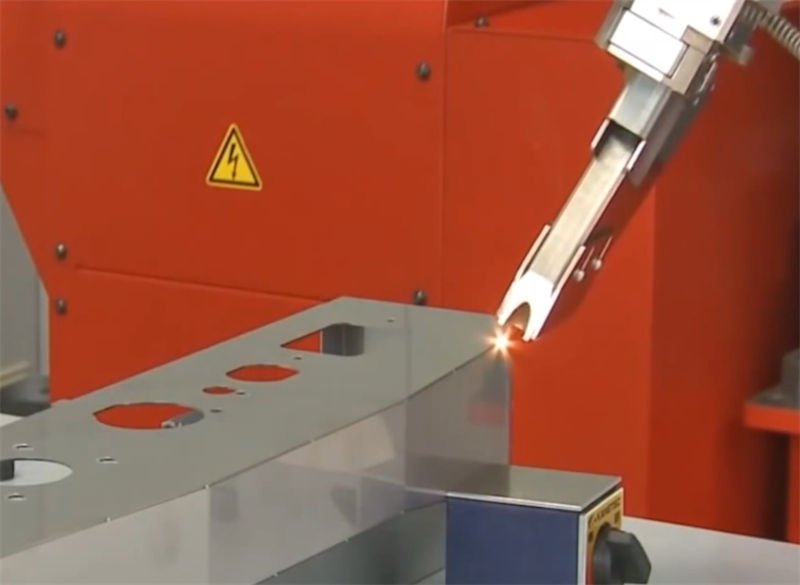

Laser welding machines are revolutionizing automotive manufacturing by enhancing precision, efficiency, and safety.

Laser welding machines enhance automotive manufacturing by enabling precise, high-strength welds, improving safety, reducing production costs, and increasing design flexibility.

Enhanced Precision and Strength in Automotive Assembly

In the automotive industry, laser welding machines are pivotal for their ability to create precise, high-strength welds. They are extensively used in body assembly1, where components such as doors, roofs, and side panels require seamless integration. The high-energy density of laser welding ensures deep penetration with minimal heat distortion, resulting in robust and aesthetically pleasing joints.

For example, the welding of stamped parts like roof covers and vehicle frames is significantly improved with laser technology, ensuring that structural integrity is maintained while reducing overall vehicle weight.

Cost Reduction and Efficiency Boost

One of the major advantages of using laser welding in automotive manufacturing is the reduction of production costs. Laser welding machines complete tasks faster than traditional methods, significantly enhancing production efficiency. This efficiency gain is crucial in high-volume automotive production lines.

Additionally, the precision of laser welding minimizes material waste and reduces the need for post-weld processing. This not only lowers material costs but also decreases labor costs associated with additional finishing processes.

Safety Improvements Through Advanced Welding Techniques

Laser welding contributes to improved vehicle safety by producing stronger joints. For example, components like engine cylinder gaskets2 and hydraulic tappets benefit from laser welding’s ability to create durable seals that withstand high pressures and temperatures. This reliability is essential for maintaining vehicle safety and performance standards.

Design Flexibility and Innovation

The flexibility offered by laser welding allows for innovative design solutions in the automotive industry. Manufacturers can experiment with complex shapes and materials that were previously challenging to weld using traditional methods. For instance, the integration of lightweight materials like aluminum and high-strength steel is facilitated by laser welding, which can handle diverse materials without compromising weld quality.

Moreover, laser technology supports the development of new energy vehicles by enhancing the production processes of lithium-ion batteries. This capability is vital as the industry shifts towards more sustainable transportation solutions.

In conclusion, laser welding machines are not just transforming how vehicles are manufactured; they are also enabling advancements in safety, efficiency, and design innovation that are critical to the future of the automotive industry.

Laser welding reduces automotive production costs.True

Laser welding increases efficiency and minimizes waste, cutting costs.

Traditional welding is more efficient than laser welding.False

Laser welding is faster and more precise, enhancing production efficiency.

Why Is Laser Welding Crucial in Electronics and Medical Device Manufacturing?

Laser welding is revolutionizing electronics and medical device manufacturing with its precision and efficiency.

Laser welding is essential in electronics and medical device manufacturing due to its precision, minimal thermal impact, and ability to join complex, miniaturized components, ensuring product reliability and safety.

Precision in Electronics Manufacturing

Laser welding is instrumental in electronics manufacturing because of its precision and minimal heat-affected zone. This technology enables the welding of delicate components like circuit boards, connectors, and sensor housings. The ability to execute fine-grained welds reduces the risk of thermal damage, which is crucial for maintaining the integrity and functionality of electronic devices. In the production of smartphones3, tablets, and laptops, laser welding ensures a robust connection without compromising the sleek design and compactness that consumers demand.

Enhancing Medical Device Reliability

In the medical field, laser welding stands out for its ability to produce high-strength, hermetic seals necessary for devices like pacemakers and surgical instruments. The precise control over the welding process minimizes the risk of contamination, a critical factor in medical device manufacturing. Laser welding is especially beneficial in the creation of intricate devices such as endoscopes and implants, where precision and reliability are paramount. The process also supports the development of biocompatible materials4, which are essential for ensuring patient safety and device effectiveness.

Comparison of Welding Techniques

| Welding Technique | Heat-Affected Zone | Application Precision | Suitability for Miniaturization |

|---|---|---|---|

| Laser Welding | Minimal | High | Excellent |

| Traditional Welding | Extensive | Moderate | Poor |

| Soldering | Moderate | Low | Moderate |

Cost Efficiency and Scalability

While the initial investment in laser welding equipment may be high, the long-term cost efficiency is notable. Laser welding can automate many processes, reducing labor costs and increasing throughput. This scalability is particularly advantageous in the high-volume production demands of both electronics and medical device sectors.

The transition from traditional methods to laser welding allows manufacturers to meet stringent industry standards more consistently. For instance, the reduced thermal distortion leads to less post-processing, saving time and resources. As a result, laser welding not only improves product quality but also enhances overall production efficiency. By embracing this technology, companies in electronics and medical device manufacturing can maintain a competitive edge in rapidly advancing markets.

Laser welding has a minimal heat-affected zone.True

Laser welding minimizes thermal damage, crucial for delicate electronics.

Traditional welding is more precise than laser welding.False

Laser welding offers higher precision, essential for miniaturized components.

What Role Does Laser Welding Play in Aerospace and Construction?

Laser welding is revolutionizing the aerospace and construction sectors with its precision and efficiency.

In aerospace, laser welding enhances the structural integrity and safety of aircraft components, while in construction, it streamlines processes and improves the durability of steel structures.

Transforming Aerospace Manufacturing

Laser welding technology has become a cornerstone in the aerospace industry due to its ability to produce high-strength, precision welds crucial for aircraft safety. Aircraft components such as wings, fuselage, and landing gear benefit significantly from laser welding. The technology allows for deeper penetration and less thermal distortion, essential for maintaining structural integrity in high-stress environments.

A prime example is the use of laser welding in manufacturing aero-engine turbine blades5. These components operate under extreme temperatures and pressures, requiring robust welds to prevent failures. Laser welding provides a reliable solution by offering precise control over the heat input, thereby reducing the risk of defects like cracking or porosity.

Another critical application is in the assembly of spacecraft structural parts. The precision of laser welding ensures minimal weight addition, which is crucial for space missions where every gram counts. This precision also aids in maintaining the aerodynamic profiles of components, crucial for performance and fuel efficiency.

Enhancing Construction Efficiency

In the construction sector, laser welding is utilized for connecting steel structures such as beams, columns, and supports in high-rise buildings. The speed and accuracy of laser welding improve construction timelines while ensuring the durability and safety of the structures.

For instance, in large-span structures like stadiums and airports6, laser welding facilitates the seamless joining of massive steel beams, which are essential for supporting vast roof spans without the need for additional structural supports. This not only reduces material costs but also enhances architectural aesthetics by allowing more open space designs.

Moreover, laser welding’s ability to work with diverse materials, including high-strength alloys used in modern construction, makes it an indispensable tool for contemporary engineering challenges. Its application in pipe welding and floor slab connections further demonstrates its versatility and effectiveness in reducing labor costs and construction time.

Comparing Laser Welding to Traditional Methods

A comparative analysis between laser welding and traditional methods like arc welding shows distinct advantages. As illustrated below, laser welding offers superior precision, minimal heat-affected zones, and faster processing times:

| Attribute | Laser Welding | Arc Welding |

|---|---|---|

| Precision | High | Moderate |

| Heat-Affected Zone | Minimal | Large |

| Speed | Fast | Moderate |

| Material Versatility | High | Moderate |

These advantages position laser welding as a transformative technology in both aerospace and construction industries, paving the way for innovative designs and improved safety standards.

Laser welding enhances aircraft safety.True

Laser welding provides high-strength, precision welds crucial for aircraft.

Laser welding is slower than arc welding.False

Laser welding is faster with minimal heat-affected zones.

Can Laser Welding Machines Enhance Jewelry and Hardware Production?

Laser welding technology is revolutionizing jewelry and hardware production, offering unmatched precision and efficiency.

Yes, laser welding machines enhance jewelry and hardware production by providing precise, strong welds with minimal thermal impact, improving both aesthetics and durability.

The Precision of Laser Welding in Jewelry Production

In the jewelry industry7, precision and aesthetics are paramount. Laser welding machines cater to these needs by allowing jewelers to perform intricate welds on small and delicate pieces. This technology is particularly beneficial for repairing and assembling fine jewelry, such as gold or platinum rings, necklaces, and bracelets. The laser’s focused heat minimizes the risk of damaging precious stones or sensitive materials adjacent to the weld.

For instance, when setting gemstones, laser welding ensures the metal prongs are securely fastened without affecting the gem’s integrity. Furthermore, the minimal thermal distortion ensures that jewelry retains its shape and finish post-welding, eliminating the need for extensive polishing or adjustments.

Enhancing Durability in Hardware Products

The hardware industry also benefits significantly from laser welding machines. They are used extensively for welding complex parts such as handles, hinges, and locks. These machines provide high-strength joints8 that enhance the durability and functionality of hardware products.

Consider stainless steel kitchenware or bathroom fittings: laser welding not only ensures a seamless appearance but also guarantees a long-lasting product that can withstand regular use and environmental factors. The technology’s ability to produce clean, precise welds reduces the need for additional finishing processes, cutting down production time and costs.

Efficiency Gains in Production Processes

The introduction of laser welding machines into production lines enhances efficiency considerably. Unlike traditional welding methods that require multiple steps to achieve a clean finish, laser welding is typically a one-step process. This reduction in production time translates to increased output and lower labor costs.

Moreover, laser welding’s precision enables manufacturers to work with thinner materials without sacrificing strength, leading to material savings. This is particularly advantageous in high-volume production environments where every saved second and gram counts.

Aesthetic and Environmental Benefits

Laser welding contributes to aesthetic improvements in both jewelry and hardware products by producing fine, seamless joints that enhance product appearance. Additionally, the method is environmentally friendly: it produces less waste than conventional welding techniques and does not require filler materials or fluxes.

Overall, the adoption of laser welding technology in jewelry and hardware manufacturing represents a significant advancement in precision engineering. By leveraging these machines, manufacturers can achieve superior quality products that meet modern consumer demands for durability, efficiency, and sustainability.

Laser welding improves jewelry durability.True

Laser welding provides strong, precise welds, enhancing jewelry's longevity.

Laser welding increases production costs.False

Laser welding reduces production time and costs with its efficiency.

Conclusion

In summary, laser welding machines play a crucial role in various industries by enhancing efficiency and quality. Explore their potential in your sector for future advancements.

-

Learn how laser welding enhances precision and strength in automotive assembly.: Laser welding is also widely used for metal welding of many sub-components, including airbag initiators, motor coil windings, battery tab-to- … ↩

-

Discover why laser welding improves durability in engine components.: The Han’s Laser cylinder gasket laser welding System stands out due to its ease of operation, versatility, safety, and efficiency. ↩

-

Explore how laser welding enhances smartphone durability and design.: The laser welding method is used to weld the metal elastic sheet to the conductive position, which plays the role of oxidation resistance and corrosion … ↩

-

Discover the role of laser welding in developing biocompatible materials.: An innovation in laser welding technology makes it possible to join two optically clear plastic parts for the first time. ↩

-

Explore how laser welding improves turbine blade manufacturing.: This video shows the technology in use on a long weld for the aerospace … Laser Welding … ↩

-

Discover how laser welding supports large-span structures.: The laser cutting structural steel cost price $123077- $246154, depends on the configuration, power size, cutting material. ↩

-

Discover how laser welding offers precision and strength in jewelry making.: Jewelers are discovering that laser welders can save time and money in jewelry manufacture. "With the accuracy of the laser, we can do very complicated pieces … ↩

-

Learn about enhanced durability from laser-welded hardware joints.: Laser precision allows for better quality welds, faster throughput, reduced post-processing costs and access to new domains of application. ↩