Are you diving into the world of 3D printing and wondering about the technical requirements, especially RAM? You’re not alone!

Most consumer 3D printers use microcontrollers with very limited RAM, often around 16KB. This is generally sufficient for basic operations like interpreting G-code and controlling motors. Industrial-grade printers may require more RAM due to handling complex tasks.

While basic 3D printers manage with minimal RAM, understanding the nuances of different setups can greatly influence your 3D printing experience. Dive deeper into this post to discover why RAM is not as critical for 3D printers as it is for PCs and what factors actually matter.

Consumer 3D printers typically use microcontrollers with 16KB RAM.True

Most consumer 3D printers use ATmega microcontrollers with limited RAM, around 16KB.

What Role Does RAM Play in Consumer 3D Printers?

Curious about how RAM impacts your consumer 3D printer’s performance? Let’s explore its role in depth.

RAM in consumer 3D printers is minimal, typically integrated into microcontrollers, not separate modules like in PCs. It supports basic tasks like processing G-code and controlling motors without virtual memory or large-scale data handling, making it sufficient for everyday 3D printing operations.

Understanding RAM in Consumer 3D Printers

In consumer-grade 3D printers, the use of RAM is quite distinct from what we observe in conventional computers. Most of these printers employ microcontrollers like the ATmega series, which contain limited RAM, typically around 16KB. This contrasts sharply with the gigabytes of RAM found in modern PCs.

Microcontroller Architecture

Consumer 3D printers rely on a simplified architecture. The microcontrollers used come with three main types of memory:

- Registers: Extremely fast, small storage for immediate calculations.

- SRAM (Static RAM): Used for active program data during printing operations.

- EEPROM (Electrically Erasable Programmable Read-Only Memory): Stores settings and configuration data.

Because these components lack the sophisticated memory management systems seen in PCs, they cannot swap data in and out of RAM to simulate more capacity (virtual memory).

Basic Operations

Despite the limited RAM, consumer 3D printers perform essential tasks effectively. These include interpreting G-code instructions1 to guide the printer’s movements and control elements like heaters and motors. The firmware, such as Marlin, is optimized to run directly from flash memory, allowing efficient static memory allocation.

Comparing Consumer and Industrial Printers

| Feature | Consumer 3D Printers | Industrial 3D Printers |

|---|---|---|

| RAM Size | ~16KB on microcontrollers | Varies; generally more significant |

| Task Complexity | Basic tasks (e.g., toys) | Complex tasks (e.g., aerospace parts) |

| Memory Management | No virtual memory | May have advanced features |

Consumer printers are designed for simple jobs, often requiring less computational power than industrial counterparts. The latter may utilize more advanced processors to accommodate larger models and detailed printing requirements.

Practical Implications for Users

For most hobbyists and home users, the inherent limitations of RAM in consumer 3D printers do not impede typical printing projects. However, understanding these constraints can aid in troubleshooting and optimizing printer performance. Users looking to print more intricate designs may consider upgrading to a model with better specifications or learning how to optimize slicing software settings for their specific printer capabilities.

Consumer 3D printers use microcontrollers with ~16KB RAM.True

Consumer 3D printers typically integrate microcontrollers with limited RAM.

Consumer 3D printers utilize virtual memory for data handling.False

These printers lack virtual memory capabilities, unlike PCs.

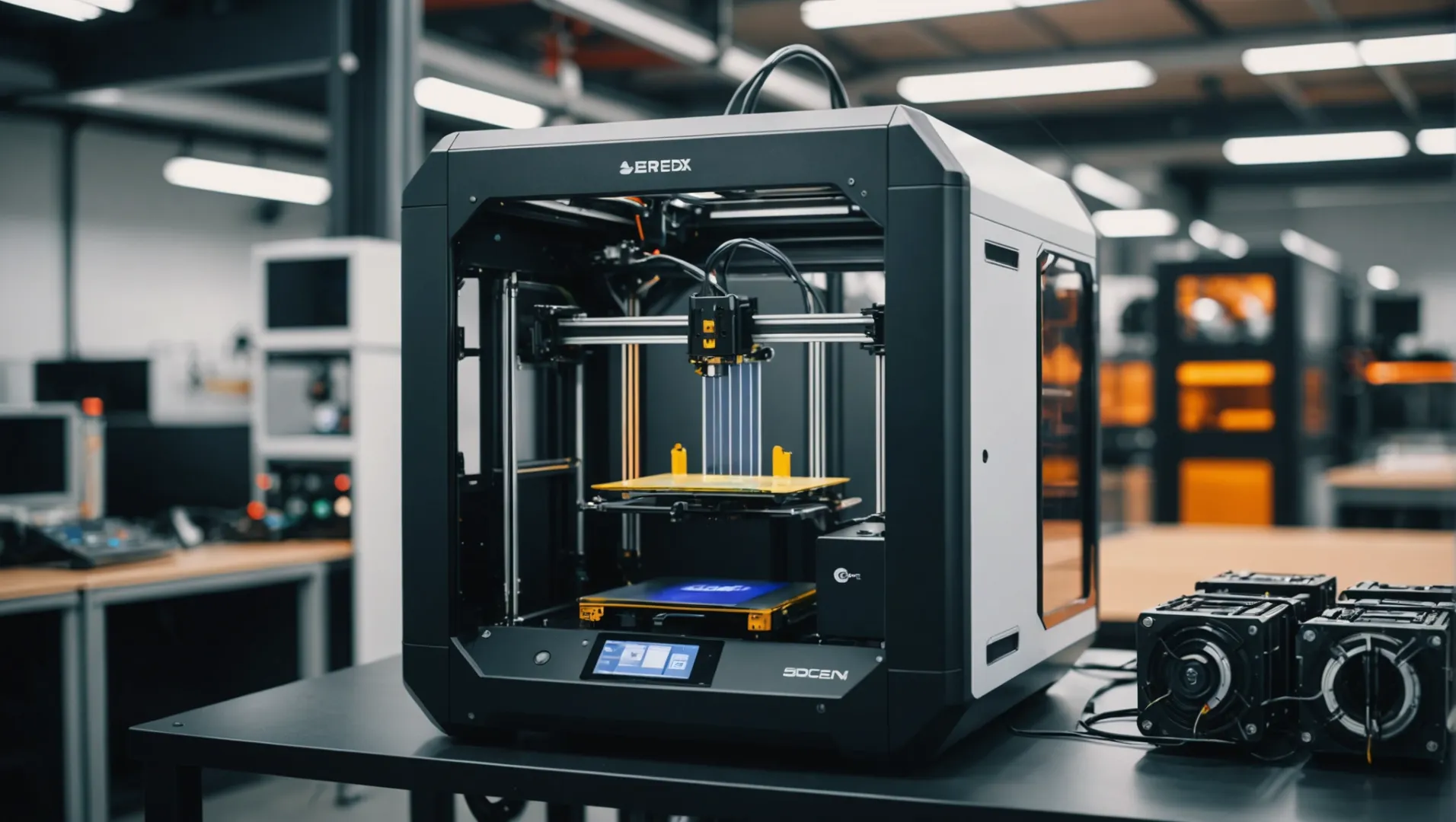

How Do Industrial 3D Printers Differ in RAM Needs?

Industrial 3D printers, unlike their consumer-grade counterparts, often require more advanced processing capabilities to handle complex tasks efficiently.

Industrial 3D printers differ in RAM needs due to their ability to handle larger, more complex tasks. They typically use more powerful processors and have greater storage capacity, allowing them to manage detailed printing instructions and complex model data efficiently.

Understanding RAM in Industrial 3D Printers

Industrial 3D printers are designed to tackle more demanding and intricate tasks compared to consumer-grade models. This need for advanced capability translates into different requirements for RAM, a critical component in ensuring smooth operation.

RAM and Processing Power

Unlike consumer printers that often use microcontrollers with limited RAM, industrial-grade 3D printers may incorporate more sophisticated processors. These processors support higher amounts of RAM to facilitate the management of large and complex 3D models, which are common in industries such as aerospace and automotive.

Table: Comparison of RAM in Consumer vs Industrial 3D Printers

| Type of Printer | Typical RAM Capacity | Common Applications |

|---|---|---|

| Consumer-grade | Up to 16KB | Toys, simple accessories |

| Industrial-grade | Hundreds of MBs to GBs | Prototyping, aerospace parts |

Role of RAM in Handling Complex Tasks

Industrial printers require more RAM primarily because they need to store and process detailed instructions for complex models. For example, the prototyping of an automotive component involves managing thousands of layers, each with specific parameters that dictate the precision and quality of the final product.

In addition to storing printing instructions2, industrial printers often use RAM to maintain calibration data and print parameters for different materials. This ensures that they can switch between diverse tasks smoothly without compromising on quality.

Storage Needs Beyond RAM

While RAM is crucial, industrial 3D printers also rely heavily on other types of memory and storage. They often feature substantial onboard storage capacities, ranging from several hundred megabytes to gigabytes, allowing for offline printing and storage of extensive data sets. This capability is vital in scenarios where continuous connectivity isn’t feasible, such as exhibitions or remote production sites.

Understanding the different aspects of storage in industrial printers3 can help in optimizing their performance and selecting the right model for specific industrial applications.

Conclusion

While consumer-grade 3D printers manage with minimal resources, industrial models illustrate how increased RAM and storage capacities are vital in meeting the demands of advanced manufacturing processes. Recognizing these differences is key to leveraging the full potential of industrial 3D printing technology.

Industrial 3D printers need more RAM than consumer models.True

Industrial printers handle complex tasks, requiring more RAM for processing.

Consumer 3D printers typically have over 1GB of RAM.False

Consumer printers usually have up to 16KB of RAM, much less than 1GB.

Is More RAM Always Better for 3D Printing?

In the realm of 3D printing, understanding the importance of RAM can shape your purchasing decisions. Does more RAM equate to better performance?

For most consumer 3D printers, additional RAM does not significantly improve performance. These devices rely on microcontrollers with limited RAM sufficient for basic tasks. However, in industrial-grade 3D printers, where complex models are processed, more RAM can be beneficial.

Understanding RAM in Consumer 3D Printers

Consumer-grade 3D printers primarily use microcontrollers with minimal RAM, typically around 16KB. This limited amount suffices because these devices are designed to execute specific tasks like interpreting G-code and managing printer operations such as motor control and temperature regulation. Since these operations do not demand extensive computational power, additional RAM in consumer-grade printers does not drastically enhance performance.

The architecture of consumer printers means they do not utilize RAM in the same way a personal computer would. Microcontrollers4 operate within strict resource constraints, managing tasks efficiently with the available memory. For instance, the popular ATmega1284 microcontroller found in many 3D printers efficiently handles typical printing tasks despite its limited RAM capacity.

RAM Requirements for Industrial 3D Printers

Industrial-grade printers are a different story. These machines often tackle complex, large-scale projects that require substantial data processing. Therefore, they may benefit from increased RAM, which can facilitate smoother operation when handling larger files and intricate designs.

| Printer Type | Typical RAM Usage | Functions |

|---|---|---|

| Consumer Printers | ~16KB | Basic G-code processing, motor control |

| Industrial Printers | Hundreds of MBs | Large file processing, complex model execution |

The increased storage in industrial printers is essential for supporting the diverse and demanding requirements of sectors like aerospace or automotive manufacturing. Larger RAM capacities can store extensive calibration data and multiple printing parameters tailored to different materials and project types.

When More RAM Can Be Beneficial

While more RAM isn’t a universal necessity for all 3D printers, certain scenarios justify its inclusion:

- Advanced Customization: If you are working with customized firmware or developing unique solutions, additional RAM might be needed to support added functionalities or innovative features.

- Complex Designs: Handling complex designs with high-resolution details could demand more RAM for efficient data processing.

- Future-Proofing: As 3D printing technology evolves, having extra RAM might help accommodate future software updates that require more resources.

Ultimately, while more RAM can be advantageous in specific contexts, it should not be the primary focus when considering a 3D printer purchase. Instead, prioritize features that align with your printing needs and goals. For further exploration of the role of microcontrollers in 3D printers, see this detailed guide5.

Consumer 3D printers benefit from extra RAM.False

Consumer printers have limited RAM needs, as they handle basic tasks.

Industrial 3D printers use more RAM for complex designs.True

Industrial printers process large files, needing more RAM for efficiency.

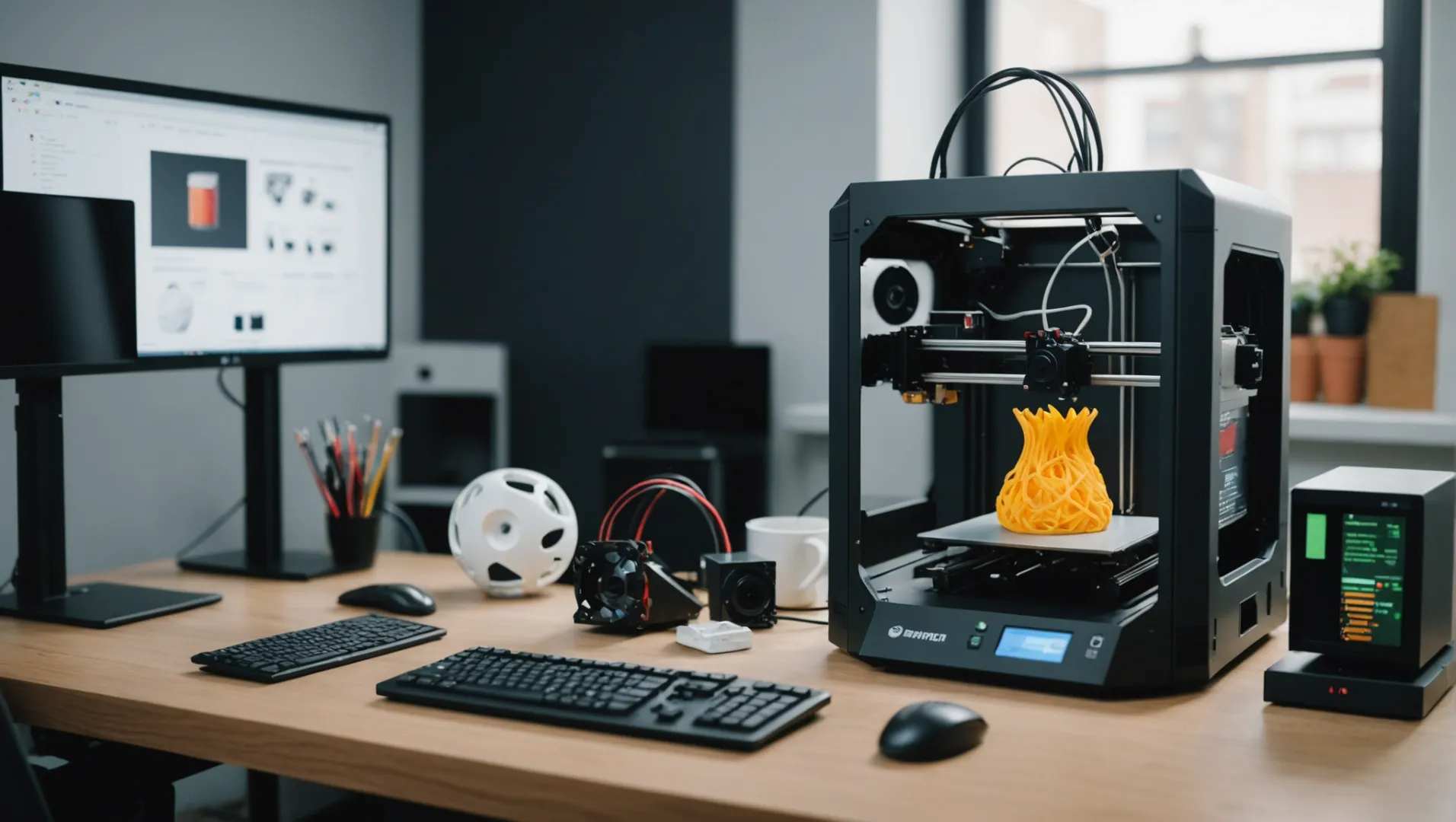

What Should You Consider When Setting Up a Computer for 3D Printing?

Setting up a computer for 3D printing requires careful consideration of several factors to ensure optimal performance.

Consider the compatibility of software and hardware, processing power, and connectivity options when setting up a computer for 3D printing. A balanced setup will help in efficient slicing of 3D models and managing print tasks effectively.

Understanding Software Requirements

The first step in setting up a computer for 3D printing is to evaluate the software requirements6. Most 3D printing processes rely on software for slicing models into layers, which then guides the printer. Popular slicing software includes Cura, PrusaSlicer, and Simplify3D, each having specific system requirements.

| Software | Minimum RAM | Recommended Processor |

|---|---|---|

| Cura | 4GB | Dual-core 2.4GHz |

| PrusaSlicer | 4GB | Dual-core 2.0GHz |

| Simplify3D | 4GB | Dual-core 2.2GHz |

Ensure your computer meets or exceeds these requirements to avoid lags during slicing.

Evaluating Hardware Specifications

While RAM isn’t a critical component for the printer itself, it plays a significant role in the computer managing 3D print tasks. Aim for at least 8GB of RAM for efficient multitasking between slicing, modeling, and running other applications simultaneously.

- Processor: A multi-core processor will speed up slicing times, especially for large or complex models.

- Graphics Card: Not essential but can enhance performance if you’re using CAD software to design models.

- Storage: SSDs are recommended over HDDs for faster data retrieval when dealing with large model files.

Ensuring Proper Connectivity

Connectivity is crucial in ensuring seamless communication between the computer and the printer. Consider whether the printer supports USB, Wi-Fi, or Ethernet connections. Ensure your computer has the necessary ports or capabilities to match the printer’s connectivity options.

Exploring Additional Tools

- Backup Power Supply: Protects against data loss during unexpected power outages.

- Cooling Solutions: Prevents overheating during long print jobs.

By considering these factors, you’ll create an efficient setup for your 3D printing needs, enabling smoother operation and better print quality.

8GB RAM is recommended for 3D printing computers.True

8GB RAM allows efficient multitasking and smooth slicing operations.

A graphics card is essential for 3D printing setup.False

Graphics cards enhance CAD performance but aren't essential for printing.

Conclusion

In summary, consumer-grade 3D printers require minimal RAM, while industrial models may need more. Focus on microcontroller capabilities rather than upgrading RAM to enhance your 3D printing setup.

-

Understand G-code as it dictates your printer’s every move.: Today, many desktop 3D printers use a numerically controlled programming language made up of a series of commands called G-Code. Most of these commands start … ↩

-

Explore why RAM is crucial for handling complex printing tasks.: The RAM system hosts a floor-mounted pumping system which measures and controls the short glass fiber-reinforced vinyl ester resin and peroxide … ↩

-

Learn how storage impacts efficiency in industrial printing.: The ideal storage temperature for 3D printing materials is typically between 59°-77° Fahrenheit. It is hard to achieve this consistently without a temperature … ↩

-

Gain insight into microcontroller roles and their RAM management.: The "universal standard" solution for electronic control of 3D printing is an Arduino Mega with a "RAMPS" add-on board. ↩

-

Learn about the importance of microcontrollers in printing efficiency.: Most use an Arduino-based board with built-in stepper drivers and temperature control interface. Marlin firmware, for example, allows monitoring … ↩

-

Discover compatible software requirements for optimal 3D printing performance.: Minimum system requirements · PC class computer running Windows 10 (64-bit version) with access to administrative account · Intel i3 2.4 GHz processor or … ↩