Have you ever wondered how advanced technology can breathe new life into rusty surfaces? Laser rust removal is doing just that!

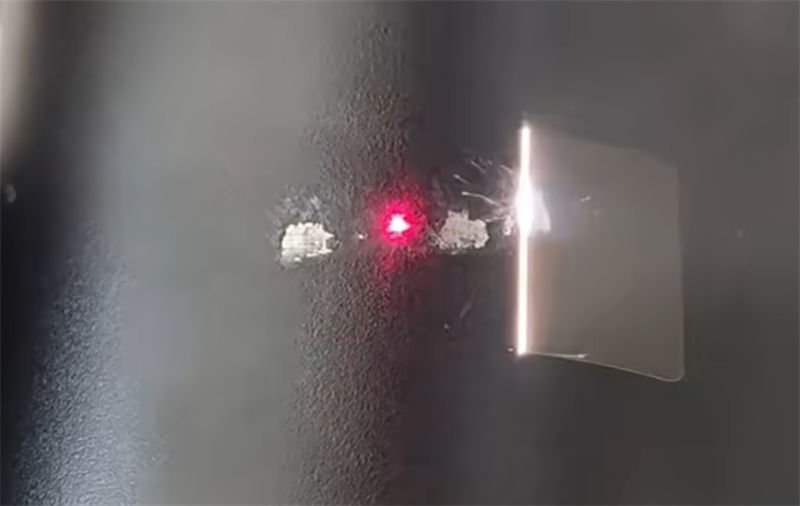

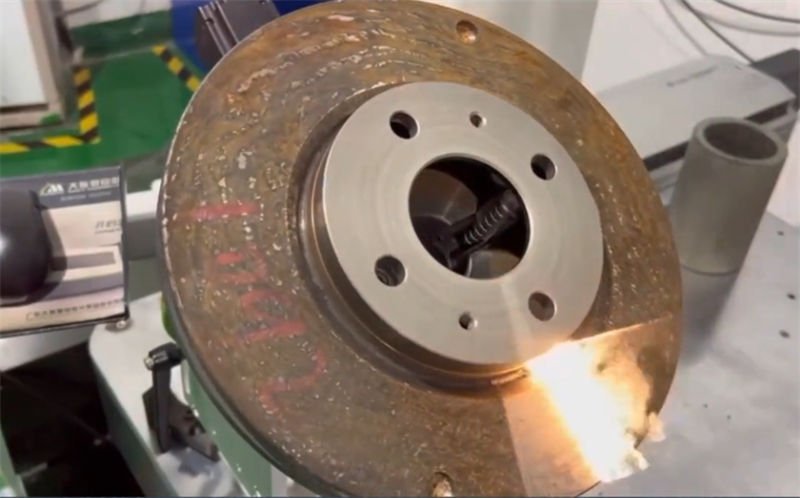

Laser rust removal works by directing high-energy laser beams onto rusted surfaces, converting light energy into thermal energy. This process causes the rust to heat up, melt, and eventually gasify, effectively removing it without damaging the underlying metal.

But wait, there’s so much more to uncover! Let’s dive deeper into the world of laser rust removal and explore its mechanics, applications, and why it’s making waves in various industries.

Laser rust removal is environmentally friendly.True

Laser rust removal produces minimal waste, using no consumables.

What Are the Key Advantages of Laser Rust Removal?

Laser rust removal is transforming rust removal practices with its efficiency and precision. What makes this technology so advantageous?

Laser rust removal offers several key advantages: precision, environmental friendliness, and non-contact cleaning. This technique effectively removes rust without damaging the metal substrate, making it ideal for delicate or valuable surfaces.

Precision and Accuracy in Rust Removal

One of the most significant advantages of laser rust removal1 is its precision. Unlike traditional methods such as sandblasting or chemical treatments, laser technology can target specific areas without affecting the surrounding material. This precision is particularly beneficial for delicate or complex components in industries like aerospace and automotive, where maintaining the integrity of the metal substrate is crucial.

Environmental Friendliness

Laser rust removal stands out as an environmentally friendly option. Traditional methods often involve chemicals that can be harmful to both operators and the environment. In contrast, lasers operate without consumables, producing minimal waste and eliminating the need for hazardous materials. This makes it an excellent choice for industries aiming to reduce their environmental footprint.

Non-contact Cleaning

Another key advantage is the non-contact nature of laser cleaning. Since the laser never physically touches the material surface, there’s no risk of scratching or abrading the metal. This non-invasive approach is ideal for high-value items like historical artifacts or intricate machinery parts, where preserving the original material is paramount.

Versatility Across Materials

Laser rust removal is incredibly versatile, capable of treating a wide variety of metals without altering their properties. From common metals like steel and aluminum to specialized alloys used in aerospace, lasers can effectively remove rust while maintaining material integrity.

Cost-effectiveness Over Time

While the initial investment in laser equipment can be higher than other methods, the long-term cost-effectiveness of laser rust removal is noteworthy. Reduced labor costs, decreased downtime, and the elimination of consumable materials contribute to overall savings. Additionally, the extended lifespan of equipment maintained with laser technology adds further financial benefits.

In conclusion, while these advantages highlight the appeal of laser rust removal, understanding its full potential requires examining its differences from traditional methods and assessing its effectiveness across various materials.

Laser rust removal is environmentally friendly.True

It uses no chemicals and produces minimal waste.

Laser rust removal damages delicate surfaces.False

The non-contact method preserves delicate materials.

How Does Laser Rust Removal Differ from Traditional Methods?

Laser rust removal is not just a modern marvel; it fundamentally changes how we approach derusting.

Laser rust removal differs from traditional methods by utilizing high-energy laser beams to precisely target and gasify rust without harming the underlying metal. This non-contact process is more efficient, environmentally friendly, and suitable for complex geometries compared to abrasive or chemical techniques.

The Science Behind Laser Rust Removal

Unlike traditional methods like sandblasting or chemical pickling, which rely on mechanical or chemical reactions to remove rust, laser rust removal uses a focused beam of light energy. This laser light is absorbed by the rust, causing it to heat up and evaporate without damaging the metal beneath. The principle of laser derusting2 revolves around converting light energy into thermal energy, which resonates with the molecular structure of rust, leading to a rapid increase in temperature and subsequent gasification.

Efficiency and Precision

One of the standout differences is the precision offered by laser rust removal. Traditional methods often result in material loss or damage to delicate surfaces. In contrast, lasers can be finely tuned to target only the rust, leaving the underlying substrate intact. This is particularly advantageous in industries where maintaining the integrity of the base material is crucial, such as in aerospace applications3.

Environmental Impact

Traditional rust removal techniques often involve chemicals that can be hazardous to the environment and workers. Laser rust removal, on the other hand, is an eco-friendly alternative. It produces no secondary waste like grit or chemical residues, significantly reducing its environmental footprint.

Suitability for Complex Geometries

Lasers can be used on intricate shapes and hard-to-reach areas where traditional methods might struggle or fail entirely. The non-contact nature of laser derusting makes it ideal for complex components where mechanical methods could cause damage.

| Aspect | Laser Rust Removal | Traditional Methods |

|---|---|---|

| Method | Light-induced heating and gasification | Mechanical abrasion or chemical reaction |

| Precision | High | Moderate to Low |

| Environmental Impact | Low | High |

| Material Loss | Minimal | Significant |

| Application Flexibility | Suitable for complex shapes | Limited |

Limitations and Considerations

While laser technology offers many advantages, it is important to acknowledge its limitations. The initial cost of laser equipment can be higher compared to traditional tools. Additionally, operators require specialized training to safely and effectively use laser systems. It’s also essential to consider the specific requirements of each application, as some traditional methods might still be more appropriate for certain scenarios.

In conclusion, laser rust removal represents a significant advancement over traditional techniques, offering precision, efficiency, and environmental benefits. As technology progresses, its application is expected to expand further across various industries.

Laser rust removal is more precise than traditional methods.True

Lasers can target only rust, preserving the metal beneath.

Traditional methods are more eco-friendly than laser rust removal.False

Laser rust removal produces no secondary waste, unlike chemicals.

Is Laser Rust Removal Effective on All Types of Metals?

Laser rust removal is celebrated for its precision and environmental benefits, but is it universally effective across all metals?

Laser rust removal is highly effective on most metals, including iron, steel, and alloys. However, its efficiency may vary based on the metal’s properties, such as thermal conductivity and reflectivity, requiring tailored laser parameters for optimal results.

Understanding Metal Properties and Laser Interaction

Different metals possess unique thermal and physical properties that influence how they interact with laser beams. Metals like iron and steel are excellent candidates for laser rust removal due to their ability to absorb laser energy effectively. This absorption leads to efficient heating and vaporization of the rust without harming the substrate.

However, metals with high reflectivity, such as aluminum and copper, pose challenges. These materials tend to reflect a significant portion of the laser energy, reducing the process’s efficiency. To address this, adjustments in laser wavelength and intensity may be necessary to enhance absorption and achieve effective rust removal.

Tailoring Laser Parameters for Different Metals

For successful laser rust removal, it’s crucial to customize the laser parameters according to the specific metal being treated. Factors such as laser wavelength, pulse duration, and energy density must be carefully calibrated. For instance, iron and its alloys4 often require a different setup compared to more reflective metals like copper5.

The table below provides a simplified overview of how different metals respond to laser rust removal:

| Metal Type | Absorption Rate | Ideal Laser Wavelength (nm) | Special Considerations |

|---|---|---|---|

| Iron | High | 1064 | Standard settings are effective. |

| Steel | High | 1064 | Similar to iron with minor tweaks. |

| Aluminum | Low | 532 | Requires higher energy density. |

| Copper | Low | 355 | Needs precise parameter adjustment. |

Special Cases: Alloys and Composite Materials

Alloys and composite materials present another layer of complexity. The presence of various elements can alter the material’s reaction to laser exposure. For example, stainless steel, which contains chromium, may require different settings compared to plain carbon steel due to its reflective properties. Composite materials6 might need even more specialized approaches to ensure that both the matrix and reinforcement elements are effectively cleaned without damage.

Conclusion: A Case-by-Case Approach

While laser rust removal is a powerful technology applicable to many types of metals, its success largely depends on understanding the specific properties of each metal. By tailoring laser settings for each unique situation, industries can maximize the effectiveness of this innovative rust removal method.

Laser rust removal is effective on all metals.False

Laser rust removal's effectiveness varies; reflective metals like copper need adjustments.

Iron absorbs laser energy efficiently for rust removal.True

Iron's high absorption rate allows effective heating and rust vaporization.

What Are the Potential Drawbacks of Using Laser Rust Removal?

Laser rust removal offers precise and eco-friendly cleaning, but are there hidden downsides to this technology?

While laser rust removal is highly effective, potential drawbacks include high initial costs, limited surface area coverage, and safety concerns due to high energy beams.

Cost Considerations

One of the most significant drawbacks of laser rust removal is its high initial cost. The equipment required for laser cleaning is expensive compared to traditional methods like sandblasting or chemical treatments. This can be a barrier for small businesses or individual users looking to adopt this technology. Furthermore, the need for specialized training to operate these machines adds an extra layer of expense.

Limited Surface Area Coverage

Laser rust removal is typically more effective on smaller areas rather than large surfaces. The precision that makes it ideal for delicate parts also means that cleaning large expanses, such as industrial tanks or pipelines, can be time-consuming and less practical. In industrial settings7, where rapid cleaning of extensive surfaces is required, alternative methods may still be preferable.

Safety Concerns

The use of high-energy laser beams introduces certain safety risks. Operators must be trained to handle the equipment safely to prevent accidents. Direct exposure to laser beams can cause serious injuries, including eye damage, and adequate protective measures are necessary. The need for stringent safety protocols can complicate the implementation of laser rust removal in workplaces.

Material-Specific Limitations

While laser rust removal works effectively on many metals, it’s not universally applicable. Certain materials may not react well to laser treatment or could suffer from unintended damage. It’s crucial to assess material compatibility before opting for laser cleaning. For example, some delicate or reflective surfaces might not be suitable candidates for this process.

Environmental and Operational Constraints

Laser systems require controlled environments to function optimally, meaning that field applications may face challenges. High humidity or dusty conditions can interfere with laser performance, reducing efficacy and increasing maintenance needs. These factors must be taken into account when planning operations in diverse environmental settings.

In conclusion, while laser rust removal is a powerful tool with numerous benefits, it’s essential to consider these potential drawbacks carefully. Industries should weigh these factors against their specific needs to determine the most suitable rust removal method for their applications.

Laser rust removal is cost-effective for small businesses.False

High initial costs make it less accessible for small businesses.

Laser rust removal is ideal for cleaning large surfaces quickly.False

It is more effective on smaller areas, making large surface cleaning impractical.

Conclusion

In a nutshell, laser rust removal is a game-changer for sustainable and effective rust management. It not only protects metal substrates but also offers a cleaner approach for industries.

-

Discover why laser rust removal offers superior precision and efficiency.: Compared to traditional cleaning methods, laser cleaning equipment has advantages such as efficiency, non-destructive, and environmental protection. ↩

-

Understand the underlying science that makes laser derusting effective.: When the beam hits the surface, molecular bonds in the dust or rust layer are broken and ejected from the substrate. In less technical terms, … ↩

-

Explore how this technology benefits precision-focused industries.: At Adapt Laser, we understand that laser cleaning in the aerospace industry requires precision and care to not alter the delicate substrates. ↩

-

Explore how laser settings vary for different iron alloys.: Rust Cleaning? Remove rust easily from metals using a 1000 Watt Laser. When aimed at a … ↩

-

Discover methods to enhance laser rust removal on copper.: Rust Cleaning? Remove rust easily from metals using a 1000 Watt Laser. When aimed at a … ↩

-

Learn about strategies for using lasers on composites.: Laser cleaning of composite surfaces would get rid of the contamination layer, and would increase the adhesive bond strength without inflicting damage. ↩

-

Discover how laser rust removal is utilized in large-scale industrial settings.: Laser cleaning can remove rust, oxides, paints, coats, electrolytes, and other contaminants from metal surfaces. Emerging applications include weld cleaning, … ↩