Have you ever wondered how products are marked so precisely?

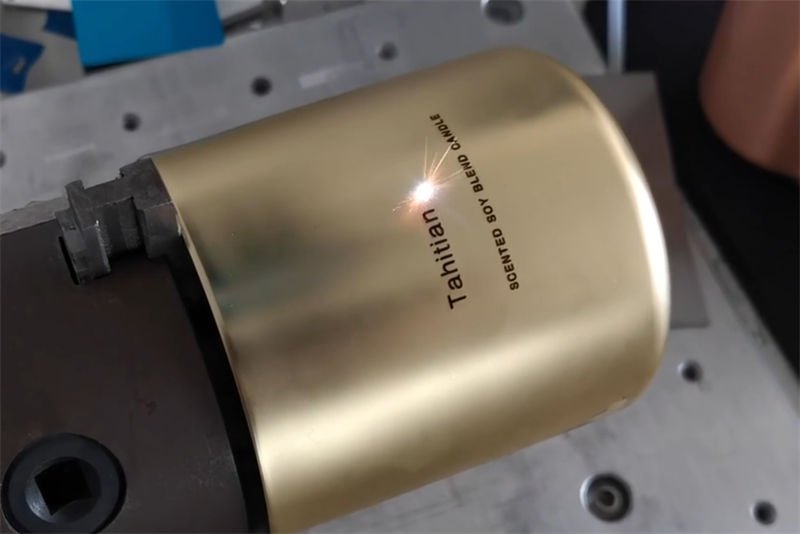

A laser marking machine works by using a high – energy density laser beam. The beam is focused through a lens onto the material’s surface. The intense heat causes the material to vaporize, melt, or chemically react, leaving a permanent mark. It’s controlled by software to achieve precise patterns and texts.

Understanding how these machines operate can significantly influence your purchasing decisions. Let’s dive into the types of lasers, their configurations, and tips for selecting the best system tailored to your needs.

Fiber lasers have a lifespan over 100,000 hours.True

Fiber lasers are known for their durability and longevity, exceeding 100,000 hours.

What Are the Different Types of Laser Marking Machines?

Laser marking machines are versatile tools, offering tailored solutions for diverse marking needs.

Laser marking machines vary based on laser source type and machine configuration, influencing their applications. Fiber, CO2, UV, Nd:YAG, and green lasers cater to different materials and uses, from metals to delicate plastics. Machine types like portable, desktop, vertical, and large-format further define suitability for specific tasks.

Types Based on Laser Source

-

Fiber Laser Marking Machines

Known for their durability, fiber lasers are excellent for marking metals and electronic components. With wavelengths around 1064 nm and power ranging from 20W to 100W, these machines have a long lifespan exceeding 100,000 hours. Their ability to produce high-quality, precise marks makes them a favorite in industrial applications.

-

CO2 Laser Marking Machines

Operating at a wavelength of 10.6 µm, CO2 lasers are adept at handling non-metallic materials like wood, acrylic, and leather. Their power range is 10W to 150W, with a moderate lifespan of 20,000 to 30,000 hours. These machines offer flexibility and efficiency for various creative and industrial uses.

-

UV Laser Marking Machines

UV lasers provide high precision for delicate materials such as semiconductors and certain plastics. With a shorter wavelength of 355 nm and power from 3W to 15W, these machines excel in cold processing, minimizing damage during marking. Lifespan ranges between 15,000 and 20,000 hours.

-

Nd:YAG Laser Marking Machines

Utilizing a similar wavelength as fiber lasers (1064 nm), Nd:YAG machines are suitable for metals, ceramics, and plastics. They are particularly useful for deep engraving applications despite their shorter lifespan of 10,000 to 15,000 hours.

-

Green Light Laser Marking Machines

Operating at 532 nm, these lasers specialize in internal engraving of semiconductors and precious metals. They offer a balance of precision and versatility with a lifespan of 15,000 to 20,000 hours.

Types Based on Machine Configuration

-

Portable Marking Machines

Compact and easy to transport, these handheld machines offer power ranges from 3W to 30W. They are ideal for on-site operations where flexibility is key.

-

Desktop Marking Machines

Offering a good cost-performance ratio, these machines usually have power levels between 20W and 50W. They are simple to operate and perfect for small batch production.

-

Vertical Marking Machines

These are designed for large volume production with power options from 30W to 200W. They provide high automation levels and are known for their stability in demanding environments.

-

Large Laser Marking Machines

Custom-built for large-format tasks such as automotive interior engraving, these machines offer specialized solutions for extensive projects.

Selecting the Right Machine

Choosing the right laser marking machine requires an understanding of your specific needs based on material type, usage frequency, budget constraints, and required service support. For example:

- Metals: Opt for fiber lasers1, known for their efficiency.

- Non-metals: Consider CO2 lasers2 for versatile use cases.

- Precision applications: Explore UV lasers3 for detailed work.

By aligning these factors with your operational goals, you can ensure an effective investment that enhances production efficiency.

Fiber lasers have a lifespan over 100,000 hours.True

Fiber laser machines are known for their long lifespan exceeding 100,000 hours.

CO2 lasers are best for marking metals.False

CO2 lasers are primarily used for non-metallic materials like wood and acrylic.

How Do Material Properties Affect Laser Marking?

Material properties significantly impact the effectiveness and quality of laser marking.

Material properties greatly influence laser marking. Absorptivity matters. High – absorptive materials like metals can better absorb laser energy for clearer marks. Melting point affects melting ease. Low – melting – point materials are easier to mark. Hardness influences deformation under laser. High – reflectivity materials need more laser power for effective marking as they reflect energy.

Understanding Material Reflectivity

Reflectivity is a crucial factor when using laser marking on different materials. Metals, for instance, generally have higher reflectivity compared to non-metals. This means that when marking metals, the laser beam might need to be more powerful or focused to ensure effective marking.

-

Metallic Surfaces: High reflectivity can lead to scattering of the laser beam, which may require higher power settings or specialized laser types like fiber lasers4 that are designed for such materials.

-

Non-Metallic Surfaces: Materials like wood or plastic have lower reflectivity, allowing for more straightforward marking with lasers like CO2.

Thermal Conductivity and Its Effects

Thermal conductivity affects how the material dissipates heat during the laser marking process. Materials with high thermal conductivity, such as aluminum and copper, tend to dissipate heat quickly, requiring adjustments in laser power and speed to prevent incomplete markings.

-

High Thermal Conductivity: Metals need careful calibration to achieve precision without overheating surrounding areas.

-

Low Thermal Conductivity: Non-metals may require less energy but longer exposure times to achieve deep markings.

Surface Texture and Its Influence

The surface texture can also affect the clarity and precision of laser markings. Smooth surfaces generally yield clearer and more precise marks, while rough surfaces might scatter the laser light, resulting in less defined markings.

-

Smooth Surfaces: Ideal for precise, detailed markings often required in electronic components.

-

Rough Surfaces: May require pre-treatment or post-treatment to enhance clarity.

Material Absorption Rates

Different materials absorb laser wavelengths differently. This property determines which type of laser is most effective for a particular material:

-

UV Lasers: Suitable for materials that require low heat processing due to their shorter wavelength, providing high absorption rates even on sensitive materials.

-

Green Light Lasers: Effective on materials where other lasers struggle, such as certain plastics and reflective metals.

Practical Considerations in Laser Marking

Understanding these material properties allows users to select the right laser type and adjust settings for optimal performance. For example, using a fiber laser for metal marking due to its capability to handle high reflectivity efficiently or opting for UV lasers for precision on delicate materials.

Choosing the right combination of laser type, power, and settings based on material properties not only improves marking quality but also enhances efficiency and longevity of the laser marking system.

Reflectivity affects laser marking effectiveness.True

Reflectivity influences how well a laser can penetrate and mark materials.

Non-metals require higher laser power than metals.False

Non-metals usually have lower reflectivity, requiring less power than metals.

What Are the Advantages of Each Laser Type?

Selecting the right laser type can dramatically impact the quality and efficiency of your marking tasks.

There are several types of lasers with different advantages. Fiber lasers have high beam quality and are efficient, suitable for metal marking. CO₂ lasers are excellent for non – metal materials like plastics and wood, with good cutting and engraving capabilities. Diode lasers are compact and cost – effective, often used for low – power applications such as marking on small items. Each type caters to specific industrial and artistic needs.

Fiber Laser Marking Machine

Advantages: Fiber lasers are renowned for their longevity and efficiency, boasting over 100,000 hours of service life. These lasers are highly effective for marking metals and electronic components, offering superior speed and precision. The quality of the markings is unmatched due to the laser’s high beam quality, making it ideal for applications requiring detailed engravings.

For businesses involved in the electronics or automotive industries, opting for a fiber laser5 ensures durable and precise results.

CO2 Laser Marking Machine

Advantages: CO2 lasers are the go-to choice for non-metal materials such as wood, acrylic, and leather. With a power range up to 150W and a lifespan of 20,000-30,000 hours, they excel in applications needing a delicate touch without compromising on speed or accuracy.

This type is particularly beneficial for artisans and manufacturers working with organic materials, providing clean and clear markings every time.

UV Laser Marking Machine

Advantages: Known for their precision, UV lasers operate in a cold processing mode to prevent heat damage to sensitive materials. They are ideal for semiconductors and certain plastics. With power ranging from 3W to 15W, these lasers deliver impeccable results where accuracy is paramount.

Industries focusing on micro-marking or working with temperature-sensitive materials will find UV lasers6 indispensable.

Nd:YAG Laser Marking Machine

Advantages: These lasers offer versatility in marking metals, ceramics, and plastics. Their ability to perform deep engravings makes them suitable for applications where durability is critical. Despite a shorter lifespan of around 10,000-15,000 hours compared to fiber lasers, they remain a cost-effective option for many industrial applications.

Green Light Laser Marking Machine

Advantages: Operating at 532 nm, green lasers are adept at intricate engravings on semiconductors and precious metals. Their unique wavelength allows for high precision internal engraving without causing surface damage. This capability is particularly useful in jewelry manufacturing and electronics where detail is crucial.

When choosing a laser marking machine, it’s essential to align your material type and application needs with the appropriate laser type. By understanding the specific advantages each laser type offers, you can optimize your marking processes for efficiency and quality.

Fiber lasers have a lifespan of over 100,000 hours.True

Fiber lasers are known for their longevity and efficiency.

CO2 lasers are best suited for metal marking tasks.False

CO2 lasers excel in marking non-metal materials like wood and acrylic.

How to Choose the Right Laser Marking Machine?

Choosing the right laser marking machine ensures efficiency and cost-effectiveness in production.

When choosing a laser marking machine, first consider the material. For metal, a fiber – optic laser marking machine is suitable; for non – metals like plastic and wood, a CO₂ laser marking machine is better. Second, think about the precision requirements. Machines with good beam quality are better for high – precision needs. Also, productivity matters. Higher – power machines usually have higher efficiency. Besides, cost – budget including purchase, operation and maintenance costs should also be considered.

Understanding Material Compatibility

The first step in selecting a laser marking machine is understanding the material you will be working with. Different laser types excel with various materials:

- Fiber Lasers: Best for metals and hard plastics. Their high precision and durability make them suitable for marking metal products7 and electronics.

- CO2 Lasers: Ideal for organic materials such as wood, leather, and certain plastics. They work by heating the material to vaporize it, creating a clean cut or mark. When working with wood, CO2 lasers can produce intricate designs and smooth edges. For leather goods, they can mark brand names or decorative patterns without causing excessive damage. In the case of plastics that are suitable for CO2 laser interaction, the marking is both accurate and aesthetically pleasing.

- UV Lasers: Excellent for sensitive materials like glass, ceramics, and some plastics due to their "cold marking" process which minimizes thermal damage. UV lasers have a shorter wavelength compared to other types, which allows for more precise control of the energy deposition. This is crucial for materials like glass where excessive heat can cause cracking. For ceramics used in high – end products like art pieces or electronic substrates, UV lasers can create delicate markings without altering the material’s properties. When it comes to certain plastics that are prone to melting or warping under heat, UV lasers provide a gentle yet effective marking solution.

Application Scenarios

Consider the specific applications you require:

- Engraving: Requires deeper penetration into the material, often needing more powerful lasers.

- Etching and Marking: Generally requires less power but greater precision.

Frequency of Use

The intended frequency of use impacts the machine’s configuration:

- Occasional Use: A portable marking machine8 might suffice, offering flexibility and convenience.

- Regular Use: A desktop machine balances performance and cost, suitable for small to medium-scale operations.

- High Volume Production: A vertical or large-format machine provides high throughput with robust automation features.

Budget Considerations

Budget constraints play a crucial role in decision-making. While upfront costs are important, consider long-term expenses such as maintenance and part replacements. Investing in a reliable brand can lead to lower total costs over time.

Importance of After-Sales Service

Reliable after-sales service ensures that technical issues are resolved promptly, minimizing downtime. Look for providers that offer comprehensive training, easy access to spare parts, and responsive customer support.

By evaluating these factors carefully, you can make an informed decision when selecting a laser marking machine that aligns with your operational needs and financial constraints.

Fiber lasers are best for organic materials.False

Fiber lasers are best for metals and hard plastics, not organic materials.

UV lasers minimize thermal damage on sensitive materials.True

No explanation available.

Conclusion

Choosing the right laser marking machine not only enhances efficiency but also elevates product quality. Reflect on your specific needs and take the next step towards informed decision-making.

-

Discover why fiber lasers excel in industrial applications.: Fiber Laser markings are used in the jewelry industry due to absolute precision, reliability and the fact that it does not damage the surrounding parts only … ↩

-

Learn how CO2 lasers suit diverse non-metal materials.: CO2 or Fiber Laser Marking: Which One Fits Your Project Best? CO2 lasers are versatile … ↩

-

Find out why UV lasers are ideal for precision tasks.: No matter what industry you are in, a UV laser marking machine can improve work time, decrease product damage, and produce higher quality marks or cuts. Using a … ↩

-

Discover how fiber lasers manage high reflectivity for effective metal marking.: Fiber lasers use optic fibers that guide the laser beam, instead of using a complicated mirror system. This type of laser is the fastest and most cost-effective … ↩

-

Discover why fiber lasers are ideal for metal marking applications.: Fiber laser marking machines are known for their excellent energy efficiency. Fiber lasers have a higher electrical-to-optical conversion … ↩

-

Learn how UV lasers excel in precision marking tasks.: Improved Process Efficiency: UV lasers work faster, marking things quicker and reducing time needed for marking. Enhanced Safety Features: UV laser machines … ↩

-

Explore top-rated options for metal marking applications.: While fiber lasers are ideal for metal engraving, CO2 lasers and diode lasers can also be used to create markings on metal. ↩

-

Learn about the advantages of using portable machines.: Laser marking can be a quicker and more efficient marking process than chemical etching and inkjet printing. Chemical etching requires many steps that can last … ↩