Ever been captivated by how a simple machine can revolutionize industries? That’s the magic of laser marking machines! Let’s explore how they work and why they’re so special.

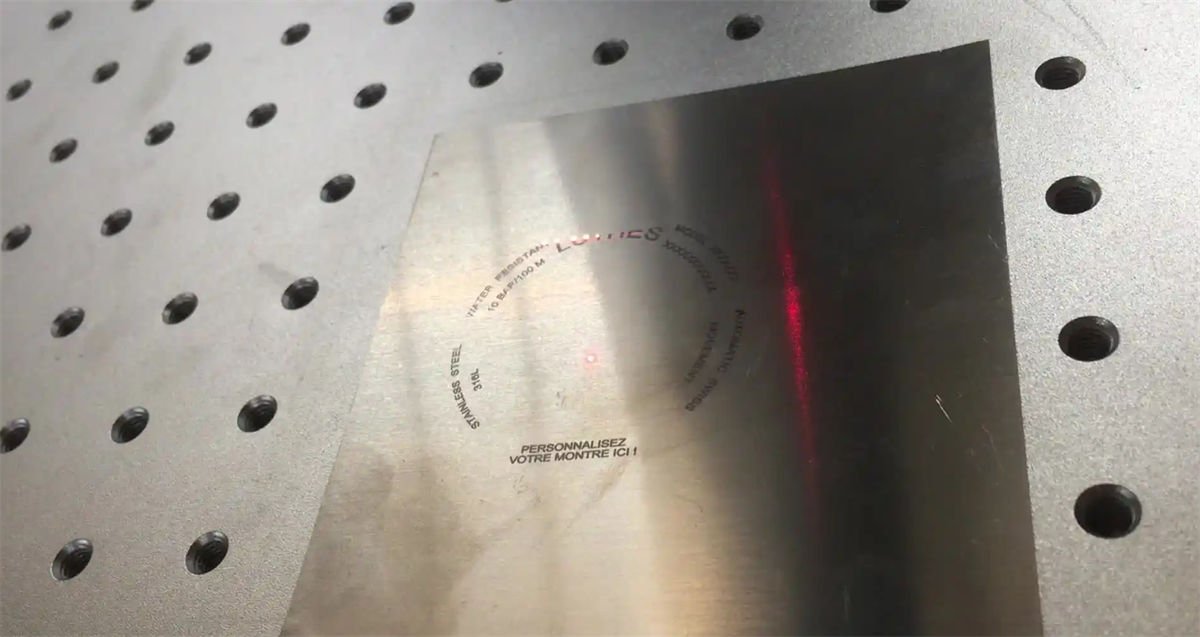

Laser marking machines operate by directing a high-powered laser beam onto a surface, altering its properties to create a mark. The process can be controlled to achieve different depths and styles, depending on the machine type and material.

But there’s so much more beneath the surface! Join me as we uncover the intricate workings of different types of laser marking machines and discover which one fits your unique needs.

CO2 lasers are ideal for marking metals.False

CO2 lasers are best for non-metal materials like wood and leather.

What Are the Different Types of Laser Marking Machines?

Choosing the right laser marking machine depends on understanding various types and their applications. Let’s explore the most common types available today.

Laser marking machines come in various types, including CO2, Fiber, and UV lasers. Each type offers distinct advantages based on material compatibility and application needs. CO2 lasers are ideal for non-metals, Fiber lasers excel with metals, and UV lasers provide precision for delicate materials.

CO2 Laser Markers: Speed Meets Versatility

CO2 laser markers utilize high-quality CO2 RF laser tubes to achieve impressive marking speeds, reaching up to 7,000 mm per second. This capability makes them particularly suitable for marking non-metal materials such as paper packaging, plastics, leather, and fabrics. Their versatility and speed make them an excellent choice for industries focused on rapid production and high-volume tasks. However, they are not recommended for metal marking due to their limitations in handling such materials. For more details on how CO2 laser markers work1, check out our in-depth analysis.

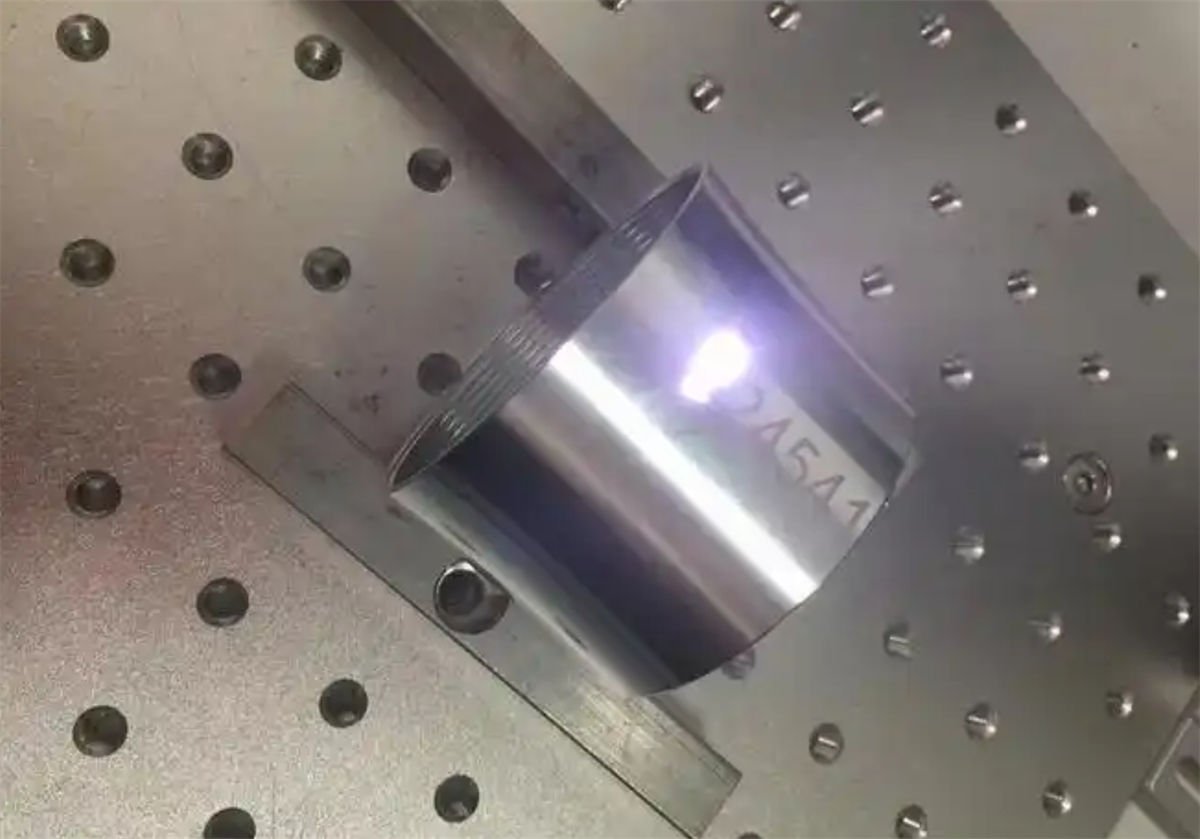

Fiber Laser Markers: Compact Powerhouses

Fiber laser markers are increasingly becoming the mainstream choice in laser marking technology due to their decreasing costs and enhanced capabilities. They employ imported lasers coupled with a high-speed galvo scanning system and professional software to deliver precise markings. These machines are compact and integrate air-cooling systems, making them suitable for a wide range of applications, especially for metals and hard plastics. As they are efficient and require minimal maintenance, they are ideal for businesses seeking durability and reliability. To learn more about Fiber laser markers2, explore our comprehensive guide.

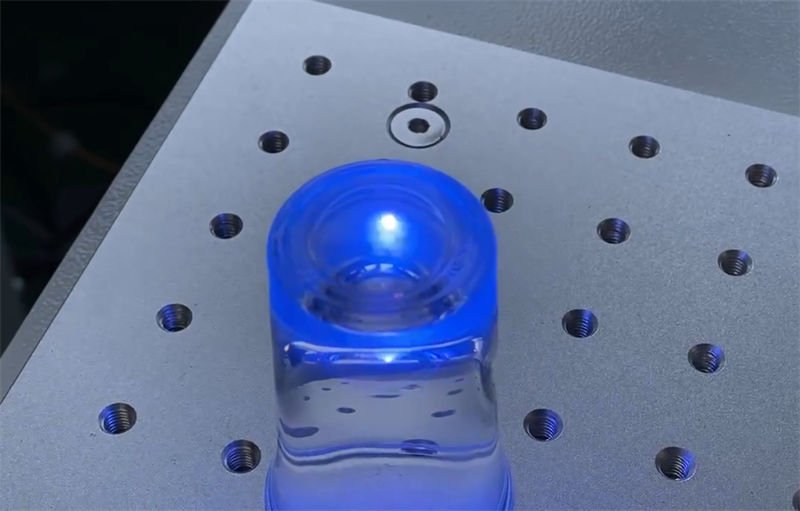

UV Laser Markers: Precision at Its Best

Equipped with a UV laser and an imported high-speed scanning system, UV laser markers are designed for ultra-fine marking with minimal thermal effect. This feature is crucial when working with sensitive materials such as plastics and glass, where precision is paramount. Clients with high demands for marking quality often opt for UV lasers due to their ability to mark nearly all materials without causing damage. When it comes to engraving special items like leaves or glass trophies, UV laser markers are unrivaled. Dive into the specifics of UV laser marker applications3 to understand their unique benefits.

Factors to Consider When Choosing a Laser Marker

-

Budget and Needs: Determine your budget first and assess your marking needs. Depending on your financial capacity and required power, choose different wattage models that best fit your operations.

-

Applicable Materials: Identify the materials you primarily work with. Fiber lasers are best suited for metals and hard plastics, CO2 lasers for wood, leather, acrylic, and silicone, while UV lasers are optimal for fine processing of various materials.

-

Special Applications: For unique marking requirements such as engraving photos or delicate materials, UV lasers stand out as the preferred choice.

This comprehensive understanding of laser marker types will help you make informed decisions when selecting the most suitable equipment for your projects.

CO2 lasers are best for metal marking.False

CO2 lasers are ideal for non-metals like plastics and leather.

UV lasers excel in precision marking.True

UV lasers provide ultra-fine marking with minimal thermal effect.

How Do Fiber Laser Markers Differ From CO2 and UV Lasers?

Navigating the world of laser markers involves understanding the distinct characteristics of fiber, CO2, and UV lasers. Each has unique capabilities that cater to different needs.

Fiber laser markers excel in marking metals and hard plastics due to their compact design and air-cooling system, while CO2 lasers are ideal for non-metals like wood and leather. UV lasers, with minimal thermal effects, offer ultra-fine marking on diverse materials including glass and plastics.

Key Differences in Technology

Understanding the core technology of each laser type is essential for choosing the right tool for your needs.

-

Fiber Lasers: These utilize a solid-state laser source, specifically doped fiber optics as the medium. They are renowned for their high efficiency and compact design, making them suitable for marking metals and some hard plastics. The air-cooling system in fiber lasers adds to their appeal by reducing maintenance needs and operating costs.

-

CO2 Lasers: Operating with gas as the lasing medium, CO2 lasers are perfect for non-metallic materials. They emit light at a wavelength of 10.6 micrometers, which is highly effective on organic materials such as leather, wood, and paper.

-

UV Lasers: Using a shorter wavelength in the ultraviolet spectrum, UV lasers are adept at ultra-fine markings due to minimal thermal damage. This feature makes them ideal for delicate materials like glass or plastics where precision is paramount.

Material Suitability and Applications

The suitability of a laser type largely depends on the material it will be used on:

| Laser Type | Suitable Materials | Typical Applications |

|---|---|---|

| Fiber | Metals, Hard Plastics | Automotive parts, electronics |

| CO2 | Wood, Leather, Acrylic | Packaging, textiles |

| UV | Glass, Plastics | Medical devices, fine art |

Cost Considerations

Budget constraints often dictate the choice between these laser types.

-

Fiber Lasers: Initially expensive but becoming more affordable. Their long lifespan and low maintenance make them cost-effective over time.

-

CO2 Lasers: Generally cheaper upfront, particularly for lower-power models. However, they may incur higher maintenance costs due to their design.

-

UV Lasers: Typically the most expensive due to their advanced capabilities and specialized applications.

Emerging Trends and Future Prospects

With technological advancements, laser marking is evolving rapidly:

-

Fiber Laser Dominance: As prices drop, fiber lasers are expected to become more prevalent due to their versatility and efficiency. Discover more about fiber laser trends4.

-

Environmental Impact: Innovations are focusing on reducing environmental footprints and improving energy efficiency across all types of laser markers. Learn about sustainable laser technology5.

Fiber lasers are suitable for marking metals.True

Fiber lasers efficiently mark metals due to their design and cooling system.

CO2 lasers are best for marking glass materials.False

UV lasers, not CO2, are ideal for glass due to their precision and minimal thermal effect.

What Industries Benefit Most From Laser Marking Technology?

Laser marking technology is transforming industries by offering precision, speed, and versatility. But which sectors gain the most from this innovation?

Industries such as aerospace, automotive, electronics, medical devices, and jewelry benefit significantly from laser marking technology due to its precision, durability, and ability to mark a wide range of materials.

Aerospace Industry

In the aerospace sector, laser marking technology6 is essential for ensuring traceability and compliance with stringent safety standards. Components like engine parts and critical assemblies require precise identification marks that can withstand harsh conditions without degrading.

Automotive Industry

The automotive industry leverages laser marking for VIN (Vehicle Identification Number) plates, parts labeling, and branding. The ability to mark metals and plastics with high precision aids in inventory management and enhances anti-counterfeiting measures.

Electronics Sector

As electronics become more compact, the need for clear and accurate labeling of components grows. Laser marking provides a non-contact solution that ensures high readability without damaging sensitive parts. This is particularly useful in marking circuit boards and microchips.

Medical Devices

In the medical field, laser marking is used to engrave instruments and devices with critical information such as serial numbers and barcodes. The markings must be biocompatible and resistant to sterilization processes. UV laser markers are particularly suitable due to their ability to create ultra-fine markings without thermal damage.

Jewelry Industry

For the jewelry industry, laser marking offers a way to personalize pieces without compromising quality. It enables the engraving of intricate designs and text on precious metals, contributing to the uniqueness of custom pieces. This precision is unattainable through traditional methods.

By understanding the unique advantages that laser marking technology offers these industries, businesses can harness its potential to improve product quality, compliance, and brand integrity.

Laser marking is crucial for aerospace compliance.True

Laser marking ensures traceability and compliance with aerospace safety standards.

Jewelry industry avoids laser marking for personalization.False

Jewelry uses laser marking for intricate, high-quality personalization.

How Does Laser Marking Compare to Laser Etching?

Laser marking and laser etching may sound similar, but they serve different purposes and applications. Here’s how they compare.

Laser marking changes the material’s surface color without removing material, while laser etching removes material to create a shallow depth mark. Both techniques use lasers but differ in depth, application, and durability.

Understanding Laser Marking

Laser marking involves altering the surface of a material to create a visible mark. This is often done without removing any material, which makes it ideal for applications where maintaining surface integrity is crucial. The process can include color changes, foaming, or annealing, and it’s commonly used in industries like electronics and medical devices.

- Depth: Typically does not remove material, resulting in no depth.

- Durability: Marks are permanent but may be less resistant to wear compared to etching.

- Applications: Ideal for items requiring precise identification without compromising surface structure.

Exploring Laser Etching

On the other hand, laser etching is a subset of engraving that removes a small amount of material from the surface. This creates a slightly recessed mark, making it more tactile and often more durable against wear. Etching is frequently used for creating barcodes, serial numbers, and logos on metals and polymers.

- Depth: Removes material, creating a shallow but discernible depth.

- Durability: Offers greater resistance to environmental wear due to its recessed nature.

- Applications: Suitable for parts subjected to friction or exposure to harsh conditions.

| Feature | Laser Marking | Laser Etching |

|---|---|---|

| Material Removal | None | Slight |

| Typical Depth | Surface level | Up to 0.001 inch |

| Durability | Moderate | High |

| Common Uses | Non-invasive marking on medical tools | Industrial parts requiring durability |

Choosing the Right Technique

When deciding between laser marking and laser etching, consider the application requirements. For instance, products needing detailed logos or barcodes might benefit more from laser etching7, whereas components that require non-invasive identification could be better suited for laser marking8.

Factors Influencing Your Decision

- Material Type: Some materials respond better to specific techniques; metals often require etching for clarity and durability.

- Environmental Conditions: Exposure to harsh environments may necessitate the deeper marks of etching.

- Regulatory Requirements: Certain industries may mandate specific marking methods to ensure compliance.

Both laser marking and laser etching offer unique advantages depending on the intended application. Understanding these differences will help you make an informed choice that aligns with your project needs and industry standards.

Laser marking removes material from the surface.False

Laser marking alters the surface without removing material.

Laser etching is more durable than laser marking.True

Etching creates recessed marks, offering greater wear resistance.

Conclusion

With a clearer understanding of laser marking machines, you’re now equipped to choose the perfect one for your needs. Embrace the technology that can elevate your projects!

-

Learn how CO2 lasers operate for effective non-metal marking.: A laser beam hits the material, and its energy creates a reaction that leaves a permanent mark. The speed, power, and focus of the laser beam on … ↩

-

Discover why fiber lasers are becoming a popular choice.: Discover the advantages of a fiber laser marking machine, like precision, versatility, and cost-effectiveness. Elevate your projects now! ↩

-

Explore how UV lasers achieve precision on delicate materials.: UV laser marking is widely used for marking medical equipment and devices, such as surgical instruments, implants, and diagnostic tools, as it … ↩

-

Explore how fiber lasers are shaping future industry standards.: The Single-Clad Fiber Laser market is projected to experience an annual growth rate of 5% from 2024 to 2031. Single-Clad Fiber Laser and its … ↩

-

Discover innovations in reducing the environmental impact of laser marking.: Laser marking is a key technology to accomplish the goals of sustainability within the plastics industry. It reduces the need for labels, provides traceability … ↩

-

Discover how laser marking ensures safety and compliance in aerospace applications.: The Benefits of Aerospace Laser Engraving · High-quality, precise, and reliable marks · Marks that are readable to both humans and machines · Ability to mark on … ↩

-

Explores why laser etching offers superior durability in industrial settings.: Both laser etching and engraving can make intricate patterns and jazz up or personalize things like pens, jewelry, and nameplates, and it can be … ↩

-

Highlights the precision and non-invasiveness ideal for medical tools.: Laser marking offers high-resolution, precise, and permanent marking on medical devices, enhancing their aesthetic appeal and maintenance of logos, branding … ↩