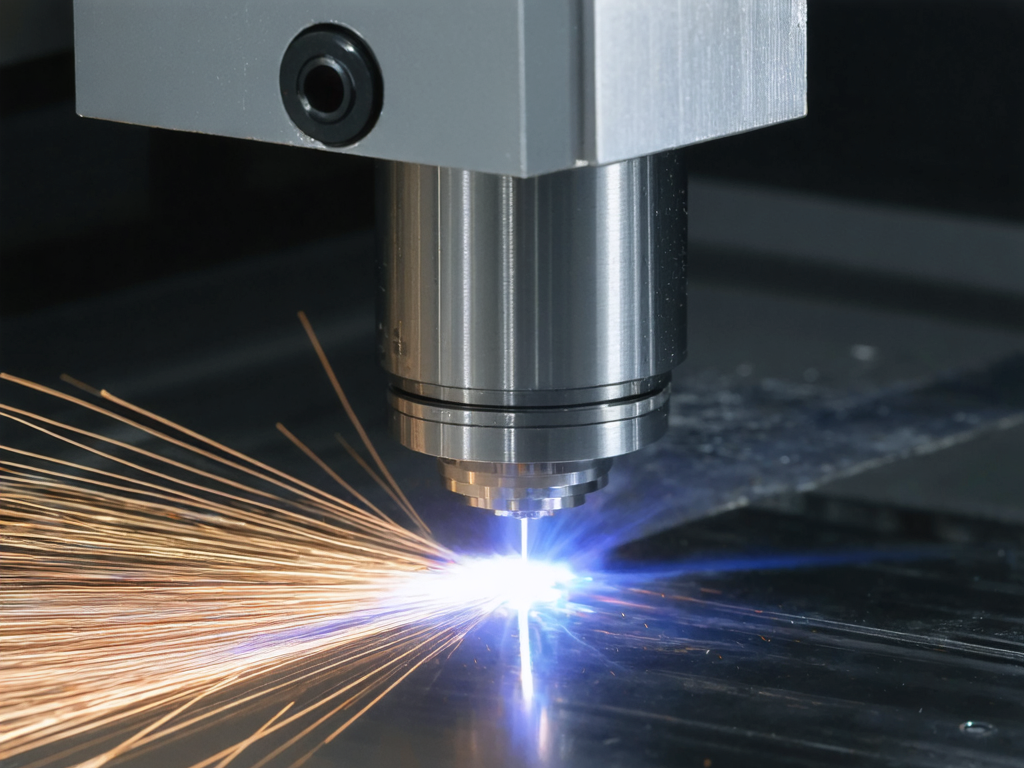

Ever watched a laser cutter1 in action and thought, "Wow, that’s like slicing butter with a hot knife!"? Well, maybe that’s just me. Let’s dive into how fiber laser cutting machines2 work and unravel the magic behind those precise cuts.

Fiber laser cutting machines use high-powered laser beams transmitted through optical fibers to cut materials with extreme precision. The laser’s energy melts or vaporizes the material, and assist gases blow away the residue, leaving clean edges. They’re ideal for cutting metals like steel and aluminum due to their efficiency and accuracy.

Fiber laser cutting machines can cut through metals without direct contact.True

The high-powered laser beams focus on the material, melting or vaporizing it from a distance, which means they do not need to touch the material to cut through it.

Fiber laser cutting machines primarily use mechanical blades to cut materials.False

Fiber laser cutting machines utilize high-powered lasers, not mechanical blades, to cut materials by melting or vaporizing them.

In simpler terms, it’s like using sunlight and a magnifying glass—but on a high-tech, industrial scale.

Which laser machines are best for cutting sheet metal?

When it comes to slicing through sheet metal, not all lasers 3 are created equal.

Fiber laser machines are the best choice for cutting sheet metal because they offer high precision, speed, and energy efficiency. Their wavelength is well-suited for metals, allowing for faster cutting speeds and lower operating costs compared to CO2 lasers or other types.

Diving Deeper into Laser Choices

I’ve had my fair share of experiences with different laser machines. Imagine trying to cut a steak with a butter knife versus a sharp chef’s knife—the difference is night and day. Fiber lasers 4are that sharp chef’s knife for sheet metal.

- Precision and Speed: Fiber lasers can cut thin metals at astonishing speeds without sacrificing accuracy.

- Energy Efficiency: They consume less power, which is kinder to both the environment and your wallet.

- Low Maintenance: Fewer moving parts mean less wear and tear—less downtime, more productivity.

In the grand orchestra of manufacturing, fiber lasers are the virtuoso violinists—precise, reliable, and essential for a harmonious performance.

How to maintain a fiber laser cutter?

Maintenance might not be the most glamorous topic, but it’s the unsung hero of any successful operation.

To maintain a fiber laser cutter, regularly clean the optical components, check and replace filters, ensure proper cooling, and update software as needed. Routine inspections help prevent downtime and extend the machine’s lifespan, ensuring consistent cutting quality.

Keeping Your Laser in Top Shape

Think of your fiber laser cutter5like a high-performance sports car—it needs regular care to run at its best.

- Clean the Optics: Dust and debris can cloud the laser beam, much like a dirty windshield impairs your driving.

- Check Cooling Systems5 Overheating is the nemesis of laser components. Ensure cooling fluids are at proper levels.

- Update Software: Manufacturers release updates that can improve efficiency and add new features.

- Inspect Moving Parts: Regularly check for signs of wear and lubricate as necessary.

By staying on top of maintenance, you’re not just fixing problems—you’re preventing them. It’s like flossing for your machine; a little effort goes a long way.

What are the top advantages of a fiber laser machine?

So, why all the hype about fiber lasers?

The top advantages of a fiber laser machine include high efficiency, superior cutting speed, low operating costs, minimal maintenance, and excellent beam quality. They’re especially effective for cutting reflective metals, reducing production time and increasing profitability.

Unpacking the Benefits

From my years tinkering and troubleshooting, I’ve seen firsthand how fiber lasers outshine the competition.

- High Efficiency: They convert a greater percentage of electrical energy into laser light, meaning less waste.

- Superior Cutting Speed: Time is money, and fiber lasers save you both by cutting faster.

- Low Operating Costs: Less energy consumption and minimal maintenance add up to significant savings.

- Versatility6: Capable of cutting a variety of metals, even those pesky reflective ones like copper and brass.

It’s like upgrading from a bicycle to a motorcycle—you’ll get to your destination faster and with less effort.

How to choose the power of a fiber laser cutting machine?

Picking the right power level7is a bit like choosing the right engine for your car—it depends on what you need it to do.

To choose the power of a fiber laser cutting machine, consider the thickness and type of materials you’ll be cutting. Higher power lasers can cut thicker materials but come at a higher cost. Assess your specific needs to balance performance and budget effectively.

Finding Your Perfect Match

Let’s break it down:

- Material Thickness8: If you’re mostly cutting thin sheet metal, a lower power (e.g., 1kW) machine might suffice. For thicker materials, you’ll need more power.

- Production Volume: Higher power lasers cut faster, boosting your throughput.

- Budget Considerations: Higher power machines are more expensive—not just upfront but also in operating costs.

It’s a bit like ordering coffee. Do you need a single shot, or are you running on a triple-shot kind of day? Tailor it to your needs.

How much does a fiber laser cutting machine cost?

Let’s get to the million-dollar question—or hopefully, much less than that.

A fiber laser cutting machine can cost anywhere from $20,000 to over $500,000, depending on its power, size, brand, and additional features. Entry-level machines are suitable for small businesses, while industrial-grade machines are a significant investment for large-scale operations.

Breaking Down the Price Tag

Here’s a rough guide:

| Machine Type | Price Range |

|---|---|

| Entry-Level | $20,000 – $50,000 |

| Mid-Range | $50,000 – $200,000 |

| High-End Industrial | $200,000+ |

Factors that influence cost:

- Power Output: More power generally means a higher price.

- Brand Reputation: Established brands might charge more but offer better support.

- Features: Automation, advanced software, and safety features add to the cost.

- After-Sales Service: Don’t underestimate the value of good customer support.

Think of purchasing a fiber laser cutter like buying a house. You have to consider location (brand), size (power), and amenities (features). It’s a significant investment, but the right choice pays off in the long run.

Conclusion

Understanding how fiber laser cutting machines work isn’t just for engineers and tech enthusiasts. Whether you’re a technician like Ferudun in Turkey, an e-commerce seller like Alexander in Russia, or a procurement manager like Terasa in the U.S., knowing the ins and outs helps you make informed decisions. After all, in the world of laser cutting, knowledge isn’t just power—it’s precision.

-

I added this link to "laser cutter" to help you understand the advanced technology that enables such accurate and clean cuts. ↩

-

I included this link for "fiber laser cutting machines" so you can explore the specific advantages and innovations that fiber lasers bring to the cutting process. ↩

-

I added this link to "lasers" to help you explore the various laser technologies and their applications in metal cutting. ↩

-

I included this link for "Fiber lasers" so you can understand how fiber laser technology enhances both accuracy and efficiency in slicing through sheet metal. ↩

-

I included this link for "Cooling Systems" so you can learn more about the importance of maintaining proper cooling to ensure your laser machine operates efficiently. ↩ ↩

-

I included this link for "Versatility" so you can explore the diverse applications and materials that fiber lasers can effectively handle. ↩

-

I added this link to "power level" to help you understand how choosing the appropriate power settings can enhance the performance and precision of your laser cutting tasks. ↩

-

Why this link:** I included this link for "Material Thickness" so you can explore how varying the thickness of materials influences the necessary laser power for optimal cutting results. ↩