The world of 3D printing is evolving at a breakneck pace, with speed being a crucial factor for enthusiasts and professionals alike.

The latest 3D printers, such as the Creality K1 Max and Bambu Lab P1S, boast speeds up to 600 mm/s, marking significant advancements over previous models. These high speeds facilitate faster prototyping and production but may impact print quality.

While these numbers are impressive, understanding the nuances of speed versus quality is key. In the following sections, we’ll explore how manufacturers achieve these speeds, compare leading models, and consider the implications for various applications.

The FLSUN T1E can print at speeds up to 1000 mm/s.True

The FLSUN T1E achieves high speeds with advanced motor systems.

What Factors Influence 3D Printer Speed?

Achieving optimal speed in 3D printing involves a complex interplay of various factors and components.

3D printer speed is influenced by the type of printer, nozzle size, layer height, material type, and software settings. Adjusting these parameters can enhance speed without compromising print quality.

The Role of Printer Type

The type of 3D printer significantly impacts speed. Fused Deposition Modeling (FDM) printers, like the Creality K1 Max1, often achieve higher speeds due to their mechanical simplicity. In contrast, Stereolithography (SLA) printers, such as the Formlabs Form 4L2, offer slower speeds but finer details.

Printer Type Comparison:

| Printer Type | Typical Speed Range | Best For |

|---|---|---|

| FDM | Up to 600 mm/s | Prototyping |

| SLA | Up to 80 mm/h | High-detail models |

Nozzle Size and Layer Height

Nozzle size is a crucial factor in determining print speed. Larger nozzles allow for quicker filament deposition, reducing print times. However, this may affect detail resolution.

Similarly, reducing layer height increases the number of layers required, slowing down the print. Finding the right balance can optimize both speed and quality.

Material Considerations

Different materials have varying melting points and viscosities, affecting how fast they can be printed. For instance, high-speed filaments designed for AnkerMake M53 or other high-speed models can drastically reduce print times.

| Material Type | Impact on Speed |

|---|---|

| PLA | Moderate |

| ABS | Slower |

| High-Speed Resins | Fastest |

Software Settings and Hardware Innovations

Modern 3D printers, like the Bambu Lab P1S4, incorporate advanced software algorithms that adjust speed dynamically based on model complexity and printer capabilities. Features such as vibration compensation ensure stability at high speeds.

Innovative Technologies:

- Vibration Compensation

- Acceleration Control

- Smart Slicing Algorithms

Software settings also allow users to fine-tune acceleration and jerk settings, which can improve speed without sacrificing quality.

Understanding these factors and how they interact is crucial for maximizing the efficiency of 3D printing projects. By optimizing each component, users can achieve faster print times while maintaining or even enhancing output quality.

FDM printers are faster than SLA printers.True

FDM printers achieve up to 600 mm/s, while SLA tops at 80 mm/h.

Larger nozzles always improve print quality.False

Larger nozzles increase speed but may reduce detail resolution.

How Do Different 3D Printing Technologies Compare in Speed?

Speed is a vital parameter that distinguishes various 3D printing technologies, shaping their application potential and efficiency.

The speed of 3D printing technologies varies widely, with FDM printers like FLSUN T1E reaching up to 1000 mm/s, while SLA printers such as Formlabs Form 4L operate at about 80 mm/hour. The choice between technologies depends on the balance between speed and detail required for specific applications.

Understanding the Speed Dynamics of FDM and SLA Printers

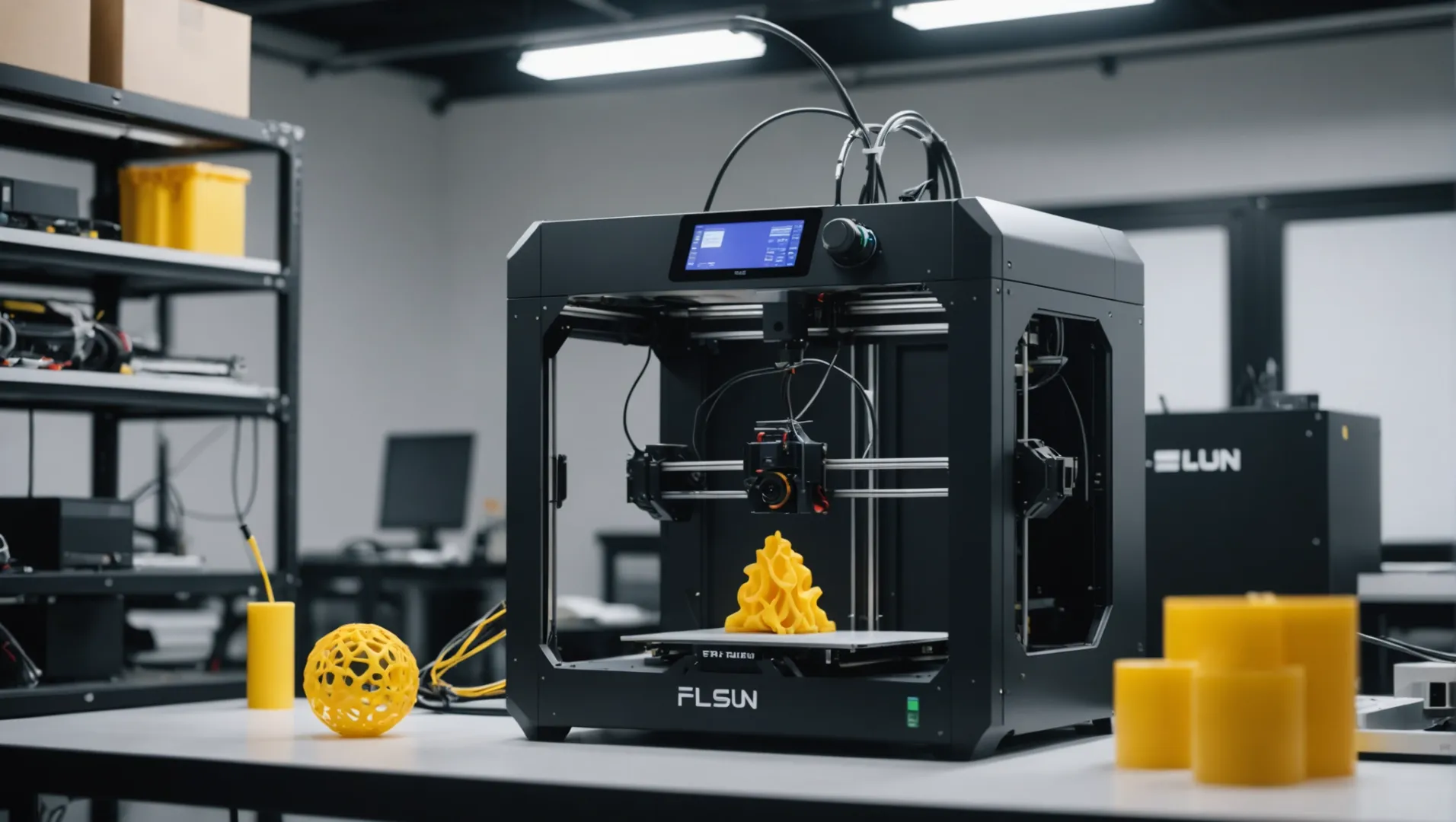

Fused Deposition Modeling (FDM) and Stereolithography (SLA) are two prominent 3D printing technologies, each with unique speed profiles. FDM printers, such as the FLSUN T1E5, can reach impressive speeds up to 1000 mm/s, thanks to advanced motor systems and optimized hardware designs. These printers are ideal for projects where speed and volume are prioritized over intricate detail.

Conversely, SLA printers like the Formlabs Form 4L6 operate at a slower pace, around 80 mm/hour. This slower speed is a trade-off for higher precision, making them suitable for applications requiring intricate details, such as dental models or jewelry. Despite their slower speeds, SLA printers can handle complex geometries with a smoother finish than most FDM machines.

Comparing Resin-Based Technologies: DLP vs. MSLA

Digital Light Processing (DLP) and Masked Stereolithography (MSLA) both fall under resin-based printing technologies but differ in speed capabilities. Sprybuild’s DLP printers7 leverage a projector to cure each layer swiftly, achieving up to 150 mm/minute. This method is notably faster than traditional SLA due to its ability to cure entire layers at once.

On the other hand, MSLA printers, like those from Formlabs, use an LCD screen to mask each layer’s pattern, offering a balance between speed and resolution. While not as fast as DLP, MSLA provides better scalability for larger prints without compromising on detail.

Innovations Driving Speed in Modern 3D Printers

Recent innovations in 3D printing have pushed speed boundaries even further. For instance, Anycubic’s photocuring printer employs high-speed resin to achieve up to 170 mm/hour. These advancements are driven by improvements in material science8 and hardware design, ensuring that even consumer-level printers can deliver rapid prototyping capabilities without sacrificing quality.

Moreover, the integration of features like vibration compensation and optimized cooling systems in models such as the Bambu Lab P1S9 ensures that high-speed printing does not degrade output quality. Such features are crucial for maintaining the structural integrity and surface finish of printed parts.

Overall, when selecting a 3D printing technology based on speed, it’s essential to consider the trade-offs between rapid production and the level of detail required. Each technology offers unique advantages that cater to different needs, whether it’s fast prototyping or high-resolution manufacturing.

FDM printers reach speeds up to 1000 mm/s.True

FDM printers like FLSUN T1E achieve high speeds due to advanced motors.

SLA printers are faster than DLP printers.False

DLP cures layers faster, achieving 150 mm/min, while SLA is slower.

Which Models Offer the Best Speed-to-Quality Ratio?

With the latest 3D printers, speed often comes at the expense of quality, but some models strike an excellent balance.

Models like the FLSUN T1E and Formlabs Form 4B exemplify a great speed-to-quality ratio, offering rapid production without sacrificing precision. They utilize advanced technologies to maintain high standards even at faster speeds.

Understanding Speed-to-Quality Ratio in 3D Printing

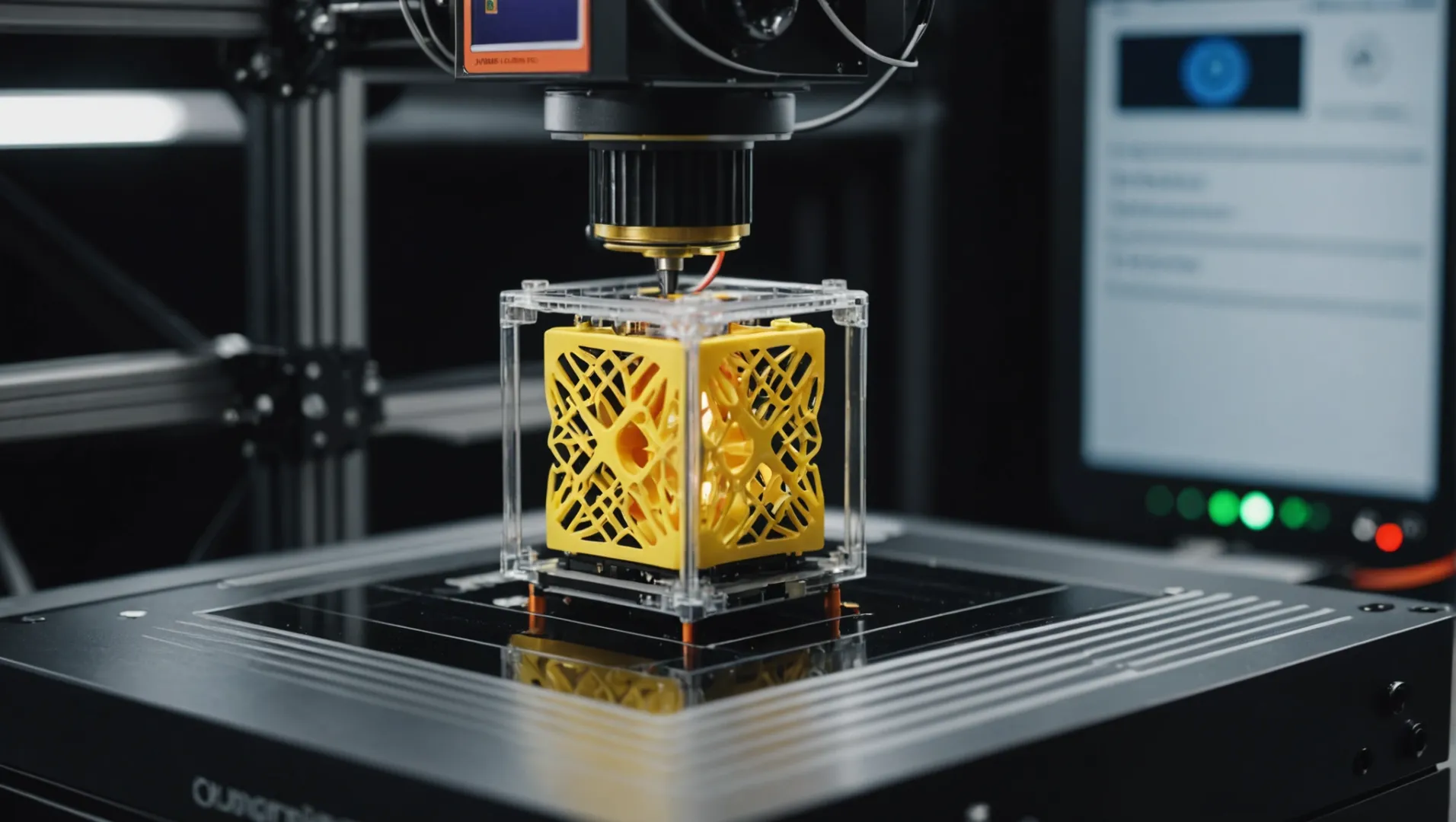

In the realm of 3D printing10, achieving a balance between speed and quality is essential. Not all models can excel at both due to technological limitations and material constraints. Manufacturers continually innovate to enhance both aspects, making it crucial for users to select models based on their specific needs.

Key Models Offering Exceptional Speed-to-Quality Ratios

FLSUN T1E

The FLSUN T1E is renowned for its high-speed capabilities, reaching up to 1000mm/s. Despite these impressive speeds, it maintains a high level of detail thanks to its advanced high-temperature hot end and CPAP high-pressure turbine fan. This makes it suitable for rapid prototyping without compromising on detail.

Formlabs Form 4B

Formlabs’ Form 4B model incorporates Low Force Stereolithography (LFS) technology, which allows for precision printing at significantly higher speeds compared to its predecessors. The 4B manages a speed increase of 2-5 times over previous models while maintaining accuracy, making it ideal for industries requiring detailed outputs quickly.

Factors Contributing to High Speed-to-Quality Ratios

Several factors contribute to achieving a high speed-to-quality ratio in these models:

- Advanced Extruders: Models like FLSUN utilize advanced extruder technologies to manage filament flow efficiently at high speeds.

- Enhanced Cooling Systems: Both FLSUN and Formlabs have integrated efficient cooling systems that prevent overheating, thus preserving print quality.

- Precision Engineering: The precision in engineering allows for consistent layer deposition, which is crucial for maintaining quality at high speeds.

Comparing with Other Technologies

While FDM11 technology dominates for speed, SLA printers like the Formlabs Form 4B offer superior quality in resin-based printing. Understanding these differences helps in choosing the right model for your project needs.

| Model | Max Speed (mm/s) | Key Technology | Ideal For |

|---|---|---|---|

| FLSUN T1E | 1000 | High-temperature hot end | Rapid prototyping |

| Formlabs Form 4B | Variable | Low Force Stereolithography | Detailed industrial parts |

| Creality K1 Max | 600 | Fast filament feed | Quick consumer projects |

Balancing Your Requirements

When selecting a printer, consider the type of projects you’ll be working on and whether speed or quality takes precedence. For detailed artistic work, slower speeds may be acceptable if they enhance quality. In contrast, industrial applications often demand faster speeds without significant quality loss.

By evaluating these elements and matching them with your project needs, you can make informed decisions about which model offers the best speed-to-quality ratio for your requirements.

FLSUN T1E reaches speeds up to 1000mm/s.True

The FLSUN T1E is designed for high-speed printing, achieving up to 1000mm/s.

Formlabs Form 4B uses FDM technology.False

Formlabs Form 4B employs Low Force Stereolithography (LFS), not FDM.

Why Is Balancing Speed and Quality Important in 3D Printing?

In the race for faster 3D printing, speed often comes at a cost: quality. But why does this balance matter?

Balancing speed and quality in 3D printing ensures that rapid production does not compromise the integrity and detail of the final product. Optimal balance leads to efficient processes while maintaining high standards of precision and durability.

The Intersection of Speed and Quality

In 3D printing, increasing speed often means adjusting parameters like layer height and print head movement, which can lead to decreased resolution and precision. For instance, printers like the Creality K1 Max12 achieve high speeds but recommend lower settings for better detail. This trade-off is crucial when printing intricate designs or functional parts where tolerance is tight.

Factors Influencing Print Quality

Several factors impact print quality when pursuing speed:

- Layer Height: Larger layer heights increase speed but reduce detail. Fine layers enhance smoothness but slow down the process.

- Material Properties: Some materials, such as flexible filaments, require slower speeds to prevent warping or defects.

- Printer Calibration: Misalignments can worsen at higher speeds, leading to inaccuracies.

Manufacturers often incorporate technologies like vibration compensation in models like Bambu Lab P1S13 to maintain quality at faster speeds.

Real-World Applications and Implications

In industries like automotive and aerospace, where precision is paramount, balancing speed with quality is non-negotiable. A flawed prototype due to excessive speed can lead to costly errors. Conversely, sectors like rapid prototyping benefit from quicker iterations even if some quality is sacrificed.

Table: Speed vs. Quality Considerations

| Aspect | High Speed | High Quality |

|---|---|---|

| Layer Resolution | Coarser | Finer |

| Detail Accuracy | Lower | Higher |

| Time Efficiency | Better | Slower |

| Material Use | Possible Increased Waste | Optimized Usage |

Balancing these factors helps tailor the 3D printing process to specific needs, whether prioritizing speed for time-sensitive projects or ensuring quality for critical components.

Innovations to Achieve Balance

Emerging technologies aim to bridge the gap between speed and quality. For instance, Formlabs Form 4L14 uses innovative resin formulations that cure rapidly without sacrificing detail. Such advancements are crucial for industries pushing the limits of what’s possible with 3D printing.

By understanding these dynamics, professionals can make informed decisions about how to leverage speed without compromising on the essential quality of their prints.

Higher speed in 3D printing reduces print quality.True

Increasing speed often decreases resolution and precision, impacting quality.

All 3D printers maintain quality at high speeds.False

Not all printers can maintain quality; some require adjustments for detail.

Conclusion

High-speed 3D printers are revolutionizing production with efficiency and precision. As technology advances, finding the right balance between speed and quality becomes crucial. Stay informed to leverage these innovations for your specific needs.

-

Discover why the Creality K1 Max is ideal for rapid prototyping.: K1 Max boasts a 300x300x300mm large build volume, great for rapid prototyping or design verification. It also offers a high build volume to printer size ratio … ↩

-

Learn about the Formlabs Form 4L’s high-detail printing capabilities.: Sharpest Details. Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for sub-pixel resolution. · Smoothest Surfaces. Lower peel forces, … ↩

-

Explore how AnkerMake M5 uses high-speed filaments for faster prints.: Glossy, Smooth Prints · High Adhesion Rate · Official AnkerMake Filament · Designed for High-Speed Printing · Eco-Friendly Material. ↩

-

Understand how Bambu Lab P1S maintains quality at high speeds.: As of FW 01.05. 00.00 yes, P1S has motor noise cancelling. Vibration compensation is accomplished by the table/bench/shelf/furniture/etc you … ↩

-

Learn about its unmatched speed capabilities and hardware innovations.: Self-designed 300℃ high-temp nozzle structure ensures excellent thermal conductivity and optimal heat distribution,with a 90mm³/s Max flow rate for smooth and … ↩

-

Discover its precision advantages in professional settings.: Personally, after working with Formlabs printers since Form 1, the Form 4 is an incredible machine in terms of capabilities and value. Steam … ↩

-

Explore how DLP achieves rapid curing speeds.: Sprybuild is an innovative startup headquartered in Israel, developing ground breaking autonomous 3D printing technologies. ↩

-

Understand how new materials enhance printing speeds.: One of the major advancements in 3D printing has been the development of new materials. Previously, 3D printing was restricted to plastic … ↩

-

See how it balances speed with print quality.: Product Features. Works right out of the box, set up in 15 minutes; Well-polished hardware and software; Enclosed-body for high-temperature filament … ↩

-

Understand why balancing speed and quality is crucial in 3D printing.: In general, a slower 3D printer print speed results in higher quality. Nonetheless, printing too slowly can cause issues of its own. These … ↩

-

Explore FDM technology’s role in achieving high-speed prints.: FDM technology is the process of making physical objects by building up successive layers of material with an extruded thermoplastic filament. ↩

-

Explore detailed settings balancing speed and quality in Creality K1 Max.: Volumetric speed limitation setting: 32mm³/s · Outerwall: 350mm/s · Innerwall: 500mm/s · Infill: 400/450mm/s · Gap Infill 100mm/s · Top Surfeace: … ↩

-

Discover how Bambu Lab P1S maintains quality at high speeds.: Product Features. Works right out of the box, set up in 15 minutes; Well-polished hardware and software; Enclosed-body for high-temperature filament … ↩

-

Learn about Formlabs Form 4L’s resin technology for fast, high-quality prints.: It cures resin quickly and precisely, delivering blazing fast print speeds with excellent print quality and accuracy anywhere on the build platform. ↩