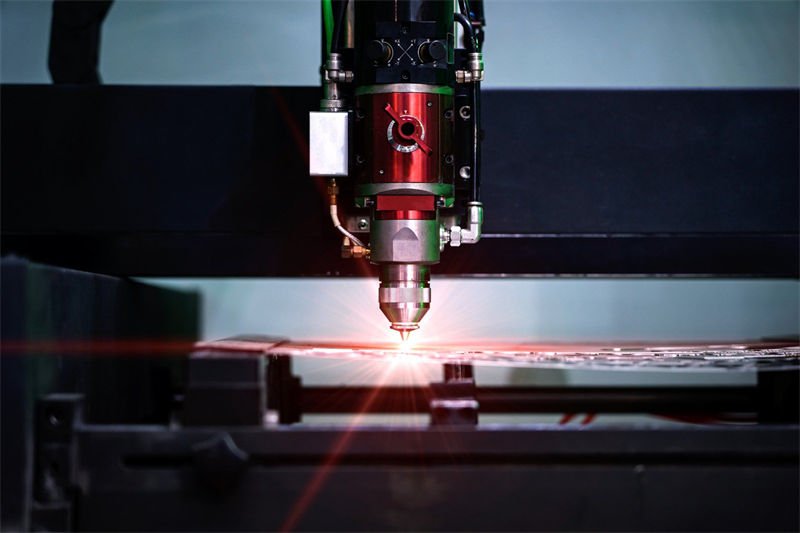

Curious about the potential of CO2 lasers for metal cutting? You’re not alone! These tools have become increasingly popular for their precision and versatility.

CO2 laser cutting of metal is highly efficient. In terms of cutting speed, for 1 – 3mm mild steel, the speed can reach several meters per minute. Although the speed of thick metal decreases, it still has advantages over traditional cutting. It has high cutting quality with smooth edges, low roughness and narrow heat-affected zone, reducing secondary processing. It has good cutting efficiency for stainless steel and can effectively cut aluminum alloy by adjusting parameters. This cutting method is widely used in many industries and improves production efficiency.

While a CO2 laser is effective for certain metals, understanding its capabilities and limitations is essential before making a purchase. In the sections that follow, I’ll dive deeper into the specifics that could influence your decision.

CO2 lasers can cut stainless steel up to 3mm thick.True

With the right setup and oxygen assist gas, CO2 lasers efficiently cut stainless steel.

What Types of Metals Can a CO2 Laser Cut?

Unleash the potential of CO2 lasers to cut a variety of metals with precision and efficiency.

CO2 laser can cut various metals. It includes carbon steel (low carbon steel, medium carbon steel, high carbon steel), widely used in the field of mechanical manufacturing. It can cut stainless steel which absorbs laser energy well and is used in kitchenware processing. It can also cut alloy steel. For non-ferrous metals, such as aluminum and aluminum alloys, copper and copper alloys after adjusting parameters, it is applied in aerospace and electronics industries.

Understanding Metal Compatibility

CO2 lasers are versatile tools used in various industries for cutting metals. However, not all metals are equally suited for CO2 laser cutting. Light gauge metals, such as stainless steel, aluminum, and brass, are the primary candidates. This is largely due to their thinness and reflective properties that align well with the CO2 laser’s capabilities.

Stainless Steel

Stainless steel is a popular choice because of its durability and aesthetic appeal. With CO2 lasers ranging from 150 to 650 watts, you can effectively cut stainless steel up to 3mm thick when using oxygen as an assist gas. The oxygen aids in creating a cleaner cut by accelerating the cutting process.

Aluminum

Aluminum poses some challenges due to its reflective nature. However, with advanced technology enhancements like circularly polarized beams, these challenges can be mitigated. CO2 lasers can cut aluminum up to 1.5mm thick, provided that the laser system is equipped with sufficient power and the appropriate setup.

Brass

Brass is another metal that can be effectively cut using CO2 lasers. Its relatively low melting point allows for smooth cutting processes. Like aluminum, brass requires careful attention to laser setup and power settings to prevent reflections and achieve optimal results.

| Metal Type | Maximum Thickness | Assist Gas |

|---|---|---|

| Stainless Steel | Up to 3mm | Oxygen |

| Aluminum | Up to 1.5mm | Nitrogen |

| Brass | Varies | Oxygen/Nitrogen |

Role of Power Settings and Enhancements

The power setting is crucial when determining which types of metal a CO2 laser can cut. Lower power lasers may struggle with thicker materials or those with high reflectivity. For example, a 500W laser can handle mild steel up to 4.8mm thick, but for thicker metals, adjustments in power or even opting for different laser technologies might be necessary.

Technological Enhancements

To cut metals effectively, CO2 lasers can benefit from technology enhancements such as automatic capacitance sensing height followers. This feature ensures that the laser maintains the correct focus across material surface variations, which is critical for achieving clean cuts.

For reflective metals like aluminum and brass, using circularly polarized beams helps reduce reflection issues, thus enhancing the quality of the cut.

The Importance of Setup and Assist Gases

Equipping your CO2 laser with the right setup is fundamental for cutting metal. This includes choosing the right cutting nozzle and using assist gases such as oxygen or nitrogen. These gases play a significant role in determining the quality of the cut and can influence which types of metals are processed efficiently.

In conclusion, while CO2 lasers offer versatility in cutting various metals, understanding the specific requirements for each type is crucial for optimal performance. Whether it’s adjusting power settings or using advanced technologies, these factors collectively determine the success of metal cutting projects.

CO2 lasers can cut stainless steel up to 3mm thick.True

With oxygen as an assist gas, CO2 lasers effectively cut up to 3mm.

Aluminum cannot be cut with CO2 lasers due to reflectivity.False

Advanced technology like polarized beams enables cutting aluminum.

How Does Power Affect CO2 Laser Cutting Capabilities?

Power is the driving force behind a CO2 laser’s ability to cut through metal. But how does it truly affect performance?

Power is a key factor in CO2 laser cutting. High power can enhance cutting ability and cut thicker metals. For example, low power may only be able to cut materials a few millimeters thick, while under high power, it can cut metals more than ten millimeters or even thicker. At the same time, high power can also speed up cutting speed and improve production efficiency, but it will also increase costs and heat-affected zones.

The Role of Power in CO2 Laser Cutting

Power is a crucial element in determining the cutting capabilities1 of CO2 lasers. Generally, the higher the power, the thicker the material a laser can cut. For instance, a 150W CO2 laser might only manage to engrave or cut thin materials like plastics or wood, while a 500W laser can handle mild steel up to 4.8mm thick.

Power vs. Thickness

The correlation between laser power and material thickness is pivotal. Below is a simple guide:

| Power (Watts) | Material Type | Max Thickness (mm) |

|---|---|---|

| 150W | Stainless Steel | ~1mm |

| 300W | Aluminum | ~1.5mm |

| 500W | Mild Steel | ~4.8mm |

The above table shows that increasing power enables cutting thicker metals, but it’s also essential to consider other factors like the beam quality and material reflectivity.

Impact on Different Metals

Different metals require different power levels due to their physical properties. Stainless steel, for example, is more difficult to cut than mild steel due to its toughness. A higher power setting may be necessary to achieve a clean cut, especially when dealing with thicker sections or reflective surfaces.

Power and Cutting Quality

While more power typically means better cutting capabilities, it can also lead to issues such as excessive heat affecting the material’s properties or causing burn marks. Thus, precise power control is crucial for maintaining high cutting quality and efficiency.

Energy Efficiency Considerations

Another aspect to consider is energy efficiency. Operating at maximum power isn’t always the most efficient choice. Power settings should be optimized based on the material type and thickness to ensure a balance between speed, quality, and energy consumption.

To summarize, while power is a significant factor in determining what a CO2 laser can cut, it must be considered alongside other parameters such as beam quality, material properties, and operational setup to maximize efficiency and output quality.

Higher power allows cutting thicker materials.True

Increased power enhances a CO2 laser's ability to cut thicker metals.

150W CO2 lasers can cut mild steel up to 4.8mm thick.False

A 500W CO2 laser is required to cut mild steel up to 4.8mm thick.

What Technology Enhancements Improve CO2 Laser Cutting?

Discover how technology enhancements can elevate the performance of CO2 laser cutters, turning them into precision powerhouses.

In the field of CO2 laser cutting, there are many technical improvements. One is the beam quality optimization technology, which makes the laser beam more focused and the energy more concentrated, improving the cutting accuracy. The second is the adoption of a high-speed cutting head, which can move quickly and effectively increase the cutting speed. There is also the application of an intelligent control system, which can automatically adjust parameters according to material characteristics, making the cutting process more stable and efficient.

Advanced Sensors and Automation

One of the most significant improvements in CO2 laser cutting2 technology is the integration of automatic capacitance sensing height followers. These sensors keep the laser head at an optimal distance from the material surface, adapting to variations in surface height. This feature is essential for maintaining consistent focus, ensuring high-quality cuts even when dealing with irregular materials.

Beam Modulation Techniques

Another technological enhancement is the use of circularly polarized beams. Traditional laser beams can reflect off shiny metal surfaces, leading to inefficient cutting and potential damage to the equipment. By altering the beam’s polarization, these reflections are minimized, allowing for smoother cuts on reflective metals like aluminum and stainless steel.

Specialized Nozzles and Gas Integration

The design of cutting nozzles also plays a crucial role in enhancing cutting capabilities. New nozzle technologies enable more precise delivery of assist gases such as oxygen or nitrogen, which help achieve cleaner cuts and reduce oxidation. For instance, using oxygen as an assist gas can improve cutting speeds on thicker materials.

| Enhancement | Benefit |

|---|---|

| Automatic Capacitance Sensing | Maintains focus for consistent cutting quality |

| Circularly Polarized Beams | Reduces reflection issues on shiny surfaces |

| Specialized Nozzles | Enhances gas flow for cleaner cuts |

Focus Position Adjustments

For thicker materials, adjusting the focus position of the laser beam is critical. Typically, this involves fine-tuning the focus beneath the surface of the material being cut. Such adjustments help in achieving precise cuts without compromising on speed or quality. Innovations in this area have made it easier to shift focus automatically based on pre-set parameters, reducing manual intervention and errors.

Understanding these advancements helps maximize the effectiveness of CO2 laser cutters, especially when working with various metals. By investing in systems that incorporate these enhancements, manufacturers can improve their production capabilities and cut quality significantly.

Automatic capacitance sensing improves cut consistency.True

Automatic capacitance sensing maintains optimal laser focus on materials.

Circularly polarized beams increase reflection issues.False

Circularly polarized beams reduce reflections, improving cutting efficiency.

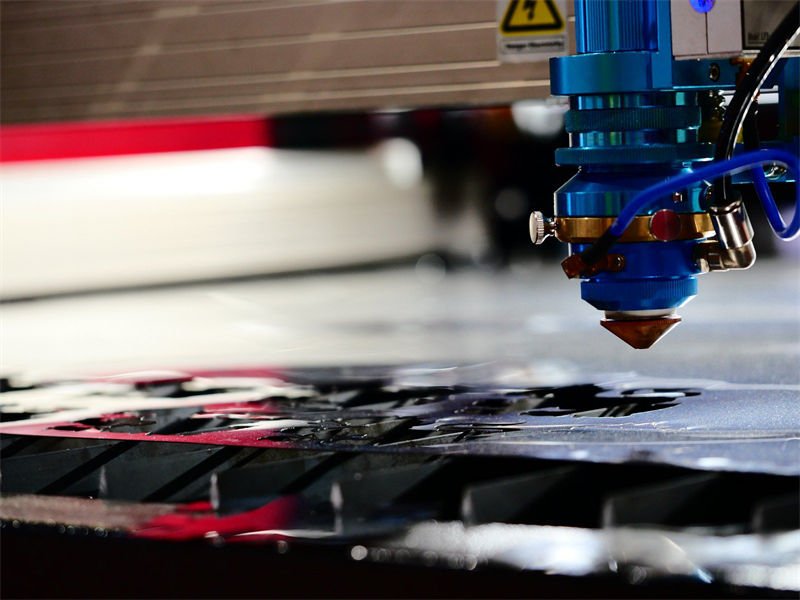

How Do Assist Gases Influence CO2 Laser Cutting Efficiency?

Assist gases play a crucial role in enhancing the performance of CO2 laser cutting systems. But how exactly do they work?

Auxiliary gases have an important impact on the efficiency of CO2 laser cutting. When oxygen is used as an auxiliary gas, it can have a violent oxidation reaction with metals, providing additional heat and speeding up the cutting speed. It is often used for cutting carbon steel. Inert gases such as nitrogen can prevent material oxidation and improve cutting quality. It has a better effect when cutting metals with high surface quality requirements such as stainless steel and can effectively improve the overall cutting efficiency.

The Role of Assist Gases in CO2 Laser Cutting

In CO2 laser cutting, assist gases are introduced into the cutting zone to enhance the cutting process. These gases serve multiple functions, including improving cut quality, increasing cutting speed, and extending the range of materials that can be efficiently cut.

Oxygen as an Assist Gas

One of the primary assist gases used in CO2 laser cutting is oxygen. It is particularly effective when cutting thicker metals. Oxygen reacts exothermically with the metal, which means it not only aids in the cutting process by clearing away molten material but also adds extra heat to the cutting area. This additional heat helps in cutting through materials like mild steel more efficiently. However, one downside is that it can cause some oxidation on the cut surface, which might require additional processing depending on the application.

Nitrogen’s Role in Cutting Quality

Nitrogen, on the other hand, is used when a clean, oxidation-free edge is required. Unlike oxygen, nitrogen does not react with the metal. Instead, it serves as a shielding gas that prevents oxidation and keeps the cut edge clean. This makes nitrogen an ideal choice for cutting stainless steel and aluminum, where surface finish and edge quality are critical.

Comparative Analysis of Assist Gases

| Gas Type | Benefits | Ideal for |

|---|---|---|

| Oxygen | Enhances cutting speed via exothermic reaction | Thicker metals (e.g., steel) |

| Nitrogen | Provides clean cuts with no oxidation | Metals where finish is crucial |

Impact on Cutting Speed and Quality

The choice of assist gas directly influences both the speed and quality of the cut. For example, using oxygen3 can significantly increase cutting speed because of its exothermic properties, making it suitable for thicker sections of mild steel. In contrast, nitrogen4 might slow down the process slightly but results in superior edge quality, making it ideal for applications where appearance is critical.

Understanding these dynamics can help operators optimize their CO2 laser setups for different materials and desired outcomes. Exploring more about these gases’ specific applications5 can provide further insights into achieving optimal performance.

Oxygen increases CO2 laser cutting speed.True

Oxygen's exothermic reaction adds heat, boosting cutting speed.

Nitrogen causes oxidation in CO2 laser cutting.False

Nitrogen prevents oxidation, ensuring clean cuts.

Conclusion

CO2 lasers offer impressive capabilities for cutting light gauge metals when used with the right setup and enhancements. Evaluate your specific needs to decide if they are the best fit for your projects.

-

Explore how power levels dictate cutting capabilities and impact efficiency.: Higher wattage lasers can cut through thicker materials and achieve faster cutting speeds, but they also require careful management to avoid … ↩

-

Explore further to understand technological improvements in CO2 laser cutting.: Locating the laser spot point in the depth of the workpiece leads to increases the laser cutting quality. Abstract. Laser cutting technology … ↩

-

Learn how oxygen boosts cutting speed and efficiency.: A higher level of purity results in higher productivity: oxygen produces a chemical reaction (exothermic reaction), as well as a mechanic action … ↩

-

Discover nitrogen’s role in achieving cleaner cuts.: Laser cutting requires the use of assist gas. Here are several gas … Nitrogen gas (N2) is a common assist gas that helps to reduce the amount of CO2 … ↩

-

Explore detailed uses of assist gases across industries.: Commonly used assist gases in laser cutting include compressed air, nitrogen and oxygen. The choice of assist gas depends on the material being … ↩