Are you ready to revolutionize your welding operations? Let me introduce you to handheld laser welding machines—your new best friend in the metalworking world!

Handheld laser welding machines become the best choice because they have high welding quality, beautiful weld seams, high strength, and a small heat-affected zone. They are flexible in operation. They can be handheld to handle complex shapes and positions without the need for complex fixtures. They have high processing efficiency, fast welding speed, and are easy to automate. They are applicable to a wide range of materials and have good safety performance with perfect protective measures.

While this overview gives a glimpse of their advantages, let’s dive deeper into each benefit. Understanding everything from cost considerations to the ability to weld different materials will empower you to make a well-informed decision tailored to your needs.

Handheld laser welders are cost-effective for small businesses.True

Their lower initial investment and reduced training expenses make them economical.

How Does a Handheld Laser Welding Machine Operate?

Curious about the inner workings of handheld laser welding machines? Discover their operational secrets.

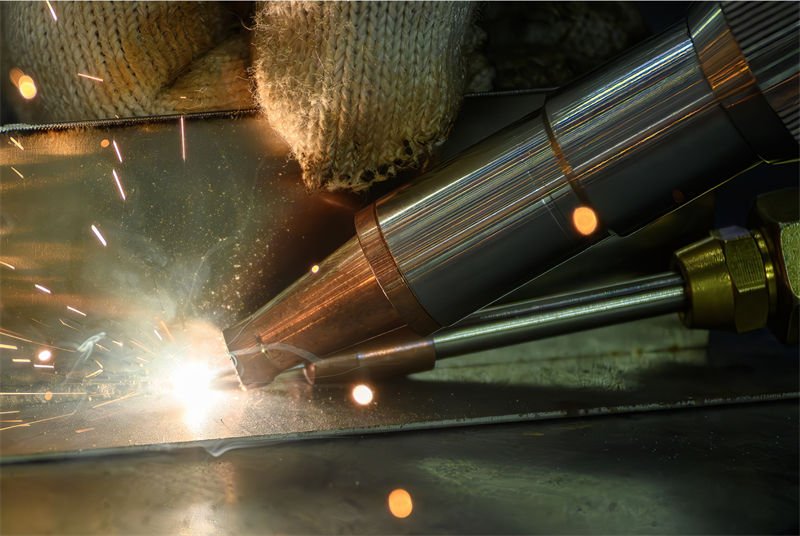

The operation of handheld laser welding machine is as follows: first, check the equipment connection and environment, prepare protective gas, select parameters and wear protective equipment. Start up and preheat, and debug parameters. During welding, hold the welding head to align with the part and move at a constant speed while observing the weld quality. After completion, turn off the laser generator, cooling system and main power supply in sequence and clean up the site.

The Basics of Laser Welding Technology

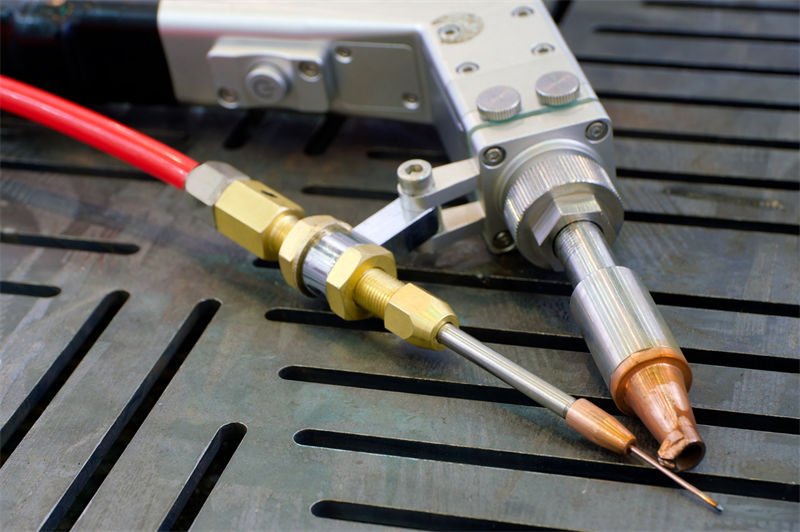

At the heart of a handheld laser welding machine1 is the laser source, which generates a focused beam of light. This beam is directed through an optical fiber and emitted via a handheld gun, allowing operators to melt and fuse metal surfaces. The laser’s high energy density ensures efficient melting with minimal heat-affected zones, reducing the risk of warping or structural weaknesses.

Operational Flexibility

One of the standout features of handheld laser welders is their unparalleled flexibility. Unlike traditional welding equipment bound by fixed setups, these machines allow operators to freely navigate around intricate workpieces. For instance, when repairing an ornate metal sculpture, operators can precisely target specific damage points without needing cumbersome fixtures or repositioning.

On-Site Versatility

Handheld laser welding machines are particularly advantageous in situations where transporting large components to a workshop is impractical. At construction sites, such as during steel structure installations, these machines can be deployed directly on-site, saving both time and transportation costs. Their portability ensures that even temporary reinforcement tasks are handled with ease.

| Feature | Benefit |

|---|---|

| Portability | Ideal for on-site operations and hard-to-reach areas |

| Precision | High accuracy with less post-processing |

| Efficiency | Reduced heat distortion for stronger welds |

Adjusting Parameters for Optimal Performance

Operators must adjust parameters like power and speed to match the material’s thickness and type. For example, welding 2mm aluminum alloy may require a power setting of 800-1000W, with a welding speed of 2-3m/min. Proper adjustments ensure optimal weld quality while preventing defects.

Furthermore, the ability to change welding modes—from spot welding to continuous—offers versatility in applications, whether sealing long seams or fixing smaller components. This adaptability makes handheld laser welders indispensable across various industries.

Safety Considerations

Safety is paramount when operating these devices. Protective goggles are essential to shield eyes from harmful laser exposure, while appropriate clothing protects skin from potential burns. Maintaining a clean work environment further enhances safety and welding quality by minimizing dust and impurities that could affect the weld.

Maintenance and Upkeep

Regular maintenance extends the life of handheld laser welders and ensures consistent performance. Cleaning the welding head and optical lenses prevents contamination that can degrade beam quality. Routine inspections and professional servicing keep the equipment in peak condition, supporting ongoing production needs.

Handheld laser welders reduce heat distortion.True

The concentrated laser beam minimizes heat-affected zones, reducing distortion.

Laser welding machines require no safety gear.False

Operators must wear protective goggles and clothing for safety.

What Are the Cost Benefits of Using Handheld Laser Welders?

Handheld laser welders offer impressive cost advantages, from lower initial investments to reduced training expenses, revolutionizing small to medium enterprises.

Handheld laser welding machines have significant cost-effectiveness. In terms of cost, the purchase price is reasonable. Compared with large equipment, the investment is small. Moreover, it has a simple structure and low maintenance cost. In terms of benefits, fast welding speed can increase production. Good weld quality reduces scrap rate and rework cost. Flexible operation can also reduce the investment in tooling fixtures and labor.

Lower Initial Investment

Handheld laser welders present a more affordable option compared to large-scale automated systems. They require less capital outlay, making them particularly attractive to small and medium-sized enterprises. Unlike traditional welding machines, which might involve significant upfront costs, handheld laser welders allow businesses to invest more prudently, aligning with their production needs.

| Equipment Type | Average Cost Range (USD) |

|---|---|

| Traditional Automated Systems | $50,000 – $150,000 |

| Handheld Laser Welders | $10,000 – $40,000 |

This affordability is especially beneficial for small hardware factories2 and individual processing units where high precision is not mandatory. These machines can handle simple tasks effectively without imposing financial strain.

Reduced Training Costs

Operating a handheld laser welder is relatively straightforward, minimizing the need for extensive training. Unlike complex automated systems that might require weeks or even months of training, workers can learn to operate these machines efficiently within days. This rapid learning curve translates into cost savings on training and allows businesses to get up and running swiftly.

For instance, a new employee can become proficient enough to contribute productively to the workflow after just a few days of practice. This reduction in downtime and quicker transition to full operation can significantly enhance overall productivity.

Operational Flexibility and Savings

The ability to transport these machines easily leads to direct cost savings in scenarios where moving the workpiece to a fixed location is impractical. Construction sites or large equipment maintenance areas benefit significantly from this portability. This flexibility saves both time and money by reducing transportation costs and setup time.

Moreover, handheld laser welders support various welding methods—such as spot and continuous welding—allowing operators to select the most efficient approach for each task. This adaptability not only enhances the quality of the weld but also optimizes resource usage, further contributing to cost efficiency.

Explore more about portable welding solutions3 that suit your industry needs and enable operational excellence.

Economical Maintenance

Maintenance of handheld laser welders is generally less costly compared to larger systems. The simplicity of design and the availability of parts make repairs and upkeep more manageable. Regular maintenance ensures longevity and consistent performance, keeping operational costs down in the long run.

Understanding the maintenance requirements4 of your laser welder can help in planning and budgeting effectively, ensuring that your equipment remains in top condition without incurring excessive expenses.

Handheld laser welders have lower initial costs than automated systems.True

Handheld laser welders cost between $10,000 to $40,000, cheaper than automated systems.

Training for handheld laser welders is more expensive than traditional systems.False

Training is cheaper due to the simplicity and user-friendly nature of handheld welders.

How Do Handheld Laser Welders Ensure High-Quality Welds?

Explore how handheld laser welders consistently deliver top-notch welds with precision and versatility.

Handheld laser welding machines need multiple aspects of cooperation to ensure high-quality welding. Parameters such as laser power and frequency should be accurately set according to material characteristics, and the focus should be finely adjusted. Select a suitable shielding gas to ensure sufficient flow and good coverage. Welding materials need to be clean and free of impurities. During operation, hold it stably and move at a constant speed, and the wire feeding speed should be appropriate.

Achieving Precision with Laser Parameters

The key to high-quality welding with handheld laser welders lies in the precise adjustment of laser parameters5. Operators can tailor the laser power, speed, and pulse frequency to match the specific material and thickness, ensuring optimal penetration and seam quality. This adaptability allows for deep penetration welds with minimal heat distortion.

- Laser Power: Adjusting the power setting is crucial. For instance, a higher power setting is ideal for thicker materials like stainless steel or aluminum.

- Welding Speed: By altering the speed, operators can control the heat input, preventing defects like warping or burning.

- Pulse Frequency: Especially useful in pulsed laser welders, it can be adjusted for materials with varying thermal conductivities.

Versatility in Material Handling

Handheld laser welders are known for their strong adaptability to different materials6 and thicknesses. This versatility is achieved through:

- Material Compatibility: Capable of welding various metals such as steel, copper, and aluminum. This flexibility is particularly beneficial in industries requiring mixed-material welding.

- Thickness Adaptability: Effective for a range of material thicknesses, from thin sheets in automotive parts to thicker components in construction.

| Material | Typical Thickness Range (mm) |

|---|---|

| Aluminum | 0.5 – 5 |

| Stainless Steel | 0.5 – 5 |

| Carbon Steel | 0.5 – 5 |

Ensuring Seam Quality

The hallmark of handheld laser welders is their ability to produce high-quality weld seams. These machines excel in creating joints with high strength and aesthetic appeal through:

- Narrow Weld Seams: The precision of laser welding results in narrow seams that are both strong and visually appealing.

- Minimal Heat-Affected Zone: Reduced thermal distortion preserves the integrity of the surrounding material.

- Seam Aesthetics: Ideal for applications where visual appearance is critical, such as in consumer products and decorative elements.

By mastering these aspects, handheld laser welders ensure superior welding outcomes across various industrial applications.

Handheld laser welders minimize heat distortion.True

They achieve this by precise control of laser parameters, reducing thermal impact.

Laser welders are unsuitable for welding thin aluminum.False

Handheld laser welders can effectively weld aluminum as thin as 0.5 mm.

Can Handheld Laser Welders Handle Diverse Materials and Thicknesses?

Exploring the capabilities of handheld laser welders in managing varied materials and thicknesses.

No, The handheld laser welding machine cannot handle various materials and thicknesses. For materials, it is good at handling common metals such as stainless steel, carbon steel, and aluminum alloy. However, it is difficult to weld highly reflective metals (such as gold and silver). In terms of thickness, thinner materials can be welded well. But when the thickness exceeds the power range of the welding machine, it is difficult to fuse effectively. Its welding ability is limited by factors such as laser power, pulse frequency, and spot size.

Versatility in Material Compatibility

Handheld laser welders excel in versatility, capable of handling a broad range of metal materials such as steel, aluminum, copper, and their alloys. This capability is crucial in industries where different materials are often used together or interchangeably. For instance, in the manufacturing of electronic enclosures7, a single device might require the welding of both aluminum and stainless steel components. The precise control of laser parameters allows for seamless transition between materials without compromising the integrity of the weld.

Adapting to Material Thickness

The ability to adjust to various material thicknesses is another standout feature of handheld laser welders. Generally, they can handle thicknesses ranging from 0.5mm to 5mm efficiently. This adaptability is achieved through the adjustment of laser power, speed, and focus. For example, when working with a thin automotive sheet metal of around 1mm, a lower power setting and faster speed are ideal to avoid burn-through and ensure clean welds.

Conversely, for thicker materials, such as a 5mm steel plate, higher power settings with slower speeds allow for deeper penetration and stronger weld seams.

| Material Type | Thickness Range | Recommended Settings |

|---|---|---|

| Aluminum | 0.5 – 3mm | 600-800W, 2-3 m/min |

| Stainless Steel | 1 – 5mm | 800-1000W, 1-2 m/min |

| Copper | 0.5 – 2mm | 700-900W, 2-3 m/min |

Practical Applications and Examples

In practical scenarios, these welders are invaluable in construction and maintenance operations where material diversity is common. For instance, when repairing a sculpture made from mixed metals or reinforcing steel beams on-site, the handheld laser welder’s flexibility allows operators to adjust quickly to each unique task without needing separate equipment for each material type.

Moreover, their compact design and portability make them ideal for on-site operations where transporting large machinery is impractical. For example, repairing large equipment8 directly at a construction site reduces downtime and logistic costs significantly.

Overall, the ability of handheld laser welders to manage a range of materials and thicknesses not only enhances operational efficiency but also broadens their applicability across different sectors.

Handheld laser welders handle up to 5mm thickness.True

They can adjust parameters for material thicknesses from 0.5mm to 5mm.

Handheld laser welders are unsuitable for aluminum.False

They can weld aluminum efficiently, adjusting settings for best results.

Conclusion

Handheld laser welding machines redefine versatility and efficiency in welding. Embrace this technology to optimize operations and explore new possibilities in metalworking.

-

Learn the mechanics of laser welding machines for better operational understanding.: But how does it work? In simple terms, the laser power density melts the metal, eliminating the need to strike an arc; the wobble function … ↩

-

Discover how small factories benefit financially from using these welders.: Explore the costs of laser welding machines, from handheld models to industrial units, and the factors that influence their prices. ↩

-

Learn about portable options enhancing site operations and reducing costs.: Find construction and fabrication solutions to help increase welding productivity on your jobsite. Browse relevant videos and articles, Miller welding … ↩

-

Understand key maintenance practices for optimal welder performance.: 01 Periodically check and replace the conductive nozzle to prevent issues such as unstable arcs, deterioration of weld appearance, or wire … ↩

-

Learn how to optimize laser settings for precise welding.: By carefully adjusting these laser welding parameters – power density, pulse duration, spot size, beam diameter, and welding speed – … ↩

-

Discover the range of materials suitable for laser welding.: Material Compatibility: Commonly welded materials include steel, aluminum, stainless steel, titanium, and various alloys. Surface Finish: A clean surface allows … ↩

-

Explore techniques for combining aluminum and stainless steel in electronic enclosures.: Protocase manufactures fully finished custom electronic enclosures and associated parts from a wide variety of materials and components, in 2-3 days with no … ↩

-

Learn how on-site welding reduces downtime and logistical challenges.: The most common way of fixing machines on the Jobsite is through welding or soldering. Both of these are good options to fix heavy machinery … ↩