Imagine the thrill of creating a perfect weld, where everything just clicks into place.

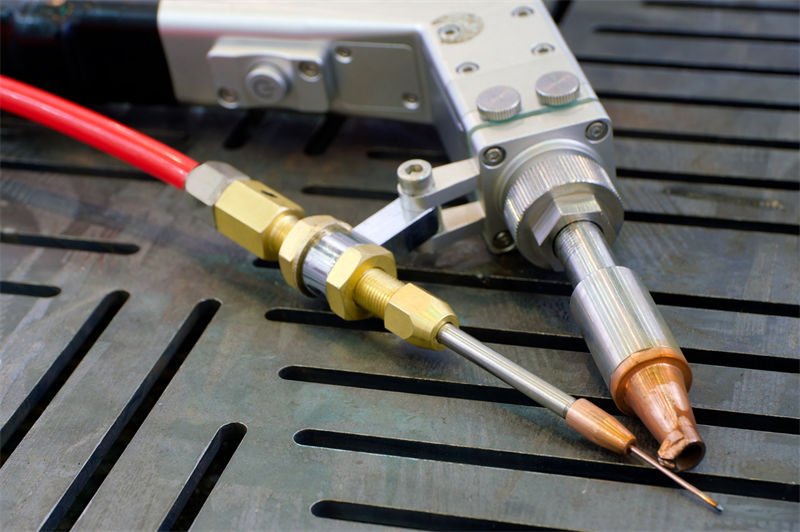

To set up handheld laser welders for optimal material compatibility, I tweak laser power, focus, welding speed, and shielding gas based on the material’s thickness, reflectivity, and thermal conductivity. Testing and adjusting these settings ensures flawless, high-quality welds.

Every time I start a welding project, I think of it as an opportunity to fine-tune my skills. Just like a chef perfecting a new recipe, I meticulously adjust the laser parameters to suit each material’s unique properties. This attention to detail transforms ordinary tasks into extraordinary results. Let’s delve into how I achieve this harmony with handheld laser welders.

Laser power adjustment is crucial for material compatibility.True

Adjusting laser power ensures the weld suits the material's properties.

Welding speed doesn't affect material compatibility.False

Welding speed must match the material to avoid defects and ensure quality.

What adjustments should I make for different materials?

Ever wondered how tweaking just a few settings can turn a good project into a great one?

Adjusting key parameters like power, speed, focus, and shielding gas according to the material’s properties is essential for optimal results. Each setting plays a crucial role in the final output, ensuring precision and quality in processes like CNC machining and laser cutting.

Understanding Material Properties

You know, before I even think about grabbing the tools and diving into adjustments, I take a moment to really understand the material I’m working with. It’s kind of like getting to know a new friend—each has its quirks. For example, I found out the hard way that materials like aluminum, which have high thermal conductivity1, don’t play well with settings meant for low conductivity materials.

Key Material Characteristics:

- Thermal Conductivity: This determines how fast heat is transferred. It’s like when you’re cooking and need to adjust the flame for different pots.

- Reflectivity: Affects how much laser energy is absorbed, much like sunglasses that reflect sunlight.

- Thickness: Thicker materials need a little more elbow grease (or power).

Adjusting Power Settings

Power settings can make or break a project. I remember once using too high a power on a delicate stainless steel sheet—it was like using a sledgehammer to crack a nut! Since then, I’ve learned that high power is best reserved for those tough cookies like thick copper.

| Material Type | Power Setting |

|---|---|

| Thick Copper | High |

| Thin Stainless | Low |

Fine-Tuning Speed and Focus

Speed adjustments remind me of pacing myself during a long hike; too fast and you might miss the view, too slow and it might take forever. Fast speeds help avoid overheating thin materials, while slower speeds are great for thicker pieces. And focus? It’s about delivering energy exactly where it’s needed.

- Faster Speeds: Ideal for thin materials.

- Slower Speeds: Better for thicker materials.

- Focus: Adjust for precise energy delivery.

Selecting Shielding Gas

I learned early on that not all gases are created equal. Argon is my go-to for stainless steel because it keeps things smooth and clean. But for metals like copper, helium works wonders by dispersing heat effectively.

Common Gases:

- Argon: Used for stainless steel and aluminum.

- Helium: Suitable for copper and aluminum to disperse heat.

Experimentation and Testing

Ah, the fun part—testing! Conducting sample welds is like practicing scales on a guitar; it helps fine-tune everything until it sounds just right. Most machines offer pre-set modes that are great starting points, but nothing beats personal adjustments based on test runs.

Monitor Weld Quality2 closely to catch any defects like undercutting or porosity. Testing isn’t just a step in the process; it’s where magic happens, turning settings into seamless results across various materials.

Aluminum has high thermal conductivity.True

Aluminum efficiently transfers heat, requiring specific settings.

Argon is unsuitable for stainless steel welding.False

Argon is commonly used for stainless steel to protect welds.

How does material reflectivity influence laser welding?

Reflectivity isn’t just a fancy term for shiny surfaces; it’s a game-changer in laser welding.

Reflectivity in materials affects laser welding by altering energy absorption, which impacts weld penetration and efficiency. Highly reflective surfaces can cause energy loss, while less reflective materials ensure better energy use. Adjustments like changing laser settings or using coatings can help manage these challenges.

The Science Behind Reflectivity

Reflectivity is a bit like how some people can just brush off criticism while others take it to heart. In the world of laser welding, materials like copper3 and aluminum act like those easygoing folks—they reflect over 90% of the laser energy aimed at them, making them tricky to work with. On the other hand, stainless steel is more of a team player, soaking up more laser light for a more efficient weld.

I remember the first time I encountered this challenge. It was like trying to sunbathe with a mirror—you end up with more reflection than a tan! Overcoming this required some tinkering, much like finding the perfect radio station on a road trip.

Practical Implications in Laser Welding

When you’re dealing with highly reflective materials, it’s like trying to get your cat to wear a sweater—most of the effort seems wasted as the energy bounces back. This means you need to crank up the power just to get that laser to penetrate properly. Using anti-reflective coatings or choosing laser wavelengths that don’t bounce back so much can make a big difference.

| Material | Reflectivity (%) | Welding Adjustment |

|---|---|---|

| Copper | > 90 | Use higher power, adjust wavelength |

| Aluminum | 85-90 | Optimize shielding gas, focus beam |

| Stainless Steel | 60-65 | Standard settings often suffice |

Strategies to Manage Reflectivity

To handle these reflective challenges, imagine shaping your laser beam like molding clay until it fits just right. Tools that shape the beam or switching to pulsed beams can help prevent overheating and distortion. It’s a bit like adjusting your driving style from city cruising to highway speeds—different strategies for different conditions.

Pre-testing with sample materials is also a key move. Think of it as trying out new dance steps before hitting the main floor; you want to ensure everything flows smoothly without unexpected stumbles. Using wobble welding heads4 can also help smooth out any kinks in your welds.

By understanding how reflectivity plays into laser welding, you can tailor your approach and equipment for top-notch results, much like customizing your playlist for a long drive. With the right techniques, you can turn those reflective challenges into opportunities for efficiency and quality in your welding projects.

Copper's reflectivity in laser welding exceeds 90%.True

Copper reflects over 90% of laser energy, complicating welding.

Stainless steel requires high power settings for laser welding.False

Stainless steel absorbs more light, often needing standard settings.

Which Shielding Gases Are Best for Various Metals?

Ever wondered why your welds aren’t as strong or clean as you’d like? The secret often lies in choosing the right shielding gas!

For welding various metals, argon works wonders for aluminum and stainless steel, helium excels with copper, and nitrogen can be useful for some steels. Each gas is essential for preventing oxidation and enhancing weld quality.

Understanding Shielding Gases

When I first started welding, I had no idea that the type of gas I used could make such a huge difference in my results. Shielding gases are like unsung heroes—they protect the weld pool from atmospheric contamination, ensuring that oxidation and porosity don’t ruin your hard work. The gas you choose can make or break the strength, appearance, and corrosion resistance of your weld.

| Metal | Recommended Gas | Reason |

|---|---|---|

| Aluminum | Argon | Provides smooth, clean welds |

| Stainless Steel | Argon | Enhances bead appearance and prevents oxidation |

| Copper | Helium | Aids in heat dispersion |

Argon: The Go-To Gas

Argon is my trusty sidekick when it comes to TIG welding5. It’s versatile and produces some of the cleanest, most precise welds I’ve seen, especially on non-ferrous metals like aluminum and magnesium. Using argon with stainless steel is a game-changer; it keeps oxidation at bay and gives the bead a sleek look.

Helium: High Heat Transfer

Whenever I’m working with copper, helium is my go-to. It’s perfect for welding copper6 because it helps with heat transfer, allowing deeper penetration without porosity issues. Though it’s pricier, the results often justify the cost.

Nitrogen: A Cost-Effective Alternative

I’ve found nitrogen to be a budget-friendly option when welding some steels. It prevents nitrogen loss during welding but steer clear of using it with aluminum—it can form nitrides and lead to brittle welds.

Custom Gas Mixtures

Sometimes, I need a custom mix to get the job just right. Adding a bit of carbon dioxide to argon can stabilize the arc and improve penetration when I’m welding mild steel7. These mixes let me balance cost, quality, and arc stability perfectly.

Understanding each shielding gas’s unique properties helps me achieve the best weld quality. It’s all about considering factors like metal type, thickness, and the finish I’m aiming for when selecting my gas mix.

Argon is best for aluminum welding.True

Argon provides smooth, clean welds on aluminum by preventing oxidation.

Nitrogen is ideal for welding aluminum.False

Nitrogen forms nitrides with aluminum, leading to brittle welds.

What Common Challenges Might You Face and How Can You Overcome Them?

We’ve all faced those moments when life throws curveballs our way. But tackling them head-on is where real growth happens. Let’s dive into practical tips to turn challenges into stepping stones.

Common challenges like time management, communication barriers, and stress can be tackled by setting clear goals, improving interpersonal skills, and practicing mindfulness. These strategies enhance productivity and emotional resilience.

Navigating Time Management Issues

I remember when balancing work, family, and personal time felt like juggling with one too many balls. I’d often find myself overwhelmed, unsure of where to start. What helped me turn the tide was prioritization. Breaking down tasks using calendars or task management apps can create a sense of order. It’s all about distinguishing between what’s urgent and what’s important, allowing us to focus on what truly matters without feeling buried under a mountain of to-dos.

Tackling Communication Barriers

When I think back to some miscommunications I’ve had, they usually stemmed from different communication styles. Maybe you’ve been there too, right? It’s like speaking two different languages while trying to solve a puzzle. Practicing active listening became a game-changer for me. By really tuning into someone else’s perspective, I found that many misunderstandings simply melted away. Tools like language translation apps8 or cultural training can also bridge those gaps beautifully.

Managing Stress Effectively

Stress—our constant companion that often overstays its welcome. I’ve found that mindfulness and meditation are like taking a mini-vacation for the mind. There was a time when I joined a mindfulness class, and it was transformative. Now, even simple practices like daily meditation using apps such as Headspace9 keep stress at bay. Regular physical activity also works wonders, lifting my mood when the days feel heavy.

Overcoming Financial Constraints

Financial struggles can feel like carrying an invisible weight. I’ve been there, trying to make sense of numbers that just won’t add up. Setting a realistic budget was my starting point—it was like drawing a map to navigate through financial uncertainty. Personal finance software became my trusted ally, keeping track of every penny. Having an emergency fund as a buffer has also brought peace of mind.

Enhancing Problem-Solving Skills

Problems are opportunities in disguise, or so I’ve learned over time. Developing a systematic approach to problem-solving has been like building my own toolkit. Brainstorming with others often brings fresh perspectives I hadn’t considered before. Adopting problem-solving frameworks10 has helped structure my thinking, turning potential roadblocks into learning opportunities.

| Challenge | Solution |

|---|---|

| Time Management | Use prioritization tools and calendars |

| Communication Barriers | Practice active listening; use translation tools |

| Stress | Engage in mindfulness practices; exercise regularly |

| Financial Constraints | Set budgets; use finance tracking tools |

| Problem-Solving Skills | Develop systematic approaches; engage in brainstorming |

Time management improves with task prioritization.True

Prioritizing tasks helps allocate time effectively, reducing overwhelm.

Stress cannot be managed through mindfulness.False

Mindfulness techniques are proven to help manage and reduce stress.

Conclusion

To optimize handheld laser welders, adjust laser power, focus, speed, and shielding gas based on material properties like thickness and reflectivity for high-quality, defect-free welds.

-

Understanding thermal conductivity is crucial as it affects heat transfer during processing, influencing power and speed settings. ↩

-

Monitoring weld quality helps identify defects early, allowing for timely adjustments to enhance material processing outcomes. ↩

-

Learn about copper’s high reflectivity and its impact on laser welding processes. ↩

-

Understand how wobble welding heads enhance seam uniformity in difficult joints. ↩

-

Explore this link to understand TIG welding applications and why argon is the preferred shielding gas. ↩

-

Discover how helium enhances copper welding by improving heat transfer and reducing porosity. ↩

-

Find out how different gas mixtures affect mild steel welding and their benefits. ↩

-

Enhancing communication skills through language apps bridges gaps in understanding. ↩

-

Mindfulness apps like Headspace offer guided sessions to reduce stress effectively. ↩

-

Understanding problem-solving frameworks boosts your ability to tackle challenges. ↩