Ever wondered why fiber lasers are the talk of the town in welding circles?

Fiber laser sources boost handheld welder reliability through energy efficiency, minimal maintenance, and top-notch beam quality. They’re built to last over 100,000 hours, perfect for tough industrial tasks across various materials and settings.

I remember the first time I encountered a fiber laser welder. It was like discovering a hidden superpower in the world of welding. Suddenly, I was able to handle materials that used to be a nightmare with such ease. What blew me away was the laser’s durability. Over 100,000 hours of operation! It’s like having a trusty sidekick that never lets you down. And the best part? Maintenance is a breeze because these lasers practically take care of themselves. It’s like having a self-cleaning oven, only way cooler. Dive in with me as I unravel how these fiber laser sources are redefining reliability in our welding adventures.

Fiber lasers have a lifespan over 100,000 hours.True

Fiber lasers are known for their durability, often lasting over 100,000 hours.

Handheld welders with fiber lasers require frequent maintenance.False

Fiber lasers are low maintenance, reducing downtime for handheld welders.

Why Are Fiber Laser Sources Considered More Durable Than Other Lasers?

Ever wondered why fiber lasers are the superheroes of the laser world? Let me walk you through their unmatched durability and why they’re my go-to choice in tough situations.

Fiber laser sources are incredibly durable due to their solid-state design, which eliminates moving parts and reduces wear. They thrive in tough environments with minimal maintenance, outlasting other lasers by offering over 100,000 operational hours.

The Solid-State Advantage

Imagine a car engine that never needs an oil change—sounds like magic, right? That’s the kind of reliability you get with fiber lasers. Their solid-state design means fewer parts that can break down, just like an engine running smoothly for miles without hiccups. This durability stems from having no moving parts that are prone to mechanical wear and tear1, unlike traditional gas or diode lasers that rely on mirrors and other components which can degrade over time.

Performance in Harsh Environments

In my experience working in environments where dust and vibrations are constant companions, fiber lasers have been my trusty allies. They’re like that one friend who remains calm in chaos, delivering consistent performance even when the going gets tough. Their robust construction makes them perfect for industrial settings where conditions are far from ideal.

Longevity and Low Maintenance

The lifespan of a fiber laser is akin to a marathon runner who just keeps going—and going. With over 100,000 hours of operation, these lasers are built for endurance, not sprinting. The beauty of it? They require minimal maintenance; no constant mirror adjustments or gas refills like CO₂ lasers demand. Plus, many come equipped with self-monitoring systems to nip potential issues in the bud.

| Feature | Fiber Lasers | CO₂ Lasers | Diode Lasers |

|---|---|---|---|

| Design | Solid-State | Gas-Based | Semiconductor |

| Lifespan | >100,000 hours | 20,000 – 30,000 hours | 10,000 – 20,000 hours |

| Maintenance | Low | High (mirrors & gas) | Medium |

Energy Efficiency and Beam Quality

Fiber lasers remind me of those energy-efficient LED bulbs—brighter with less power. They convert electrical energy into laser light with impressive efficiency, often exceeding 30%, which is a game-changer compared to the modest 10-15% of CO₂ lasers. This means they use less power and generate less heat, allowing for longer operational periods without needing a cool down.

Versatility Across Materials

Working with a variety of materials can be challenging, but fiber lasers excel at it. From reflective metals like aluminum to tricky surfaces like copper, these lasers adapt effortlessly. This adaptability enhances reliability2 across various industrial applications.

Compact and Ergonomic Design

Fiber lasers are like those multi-tools that fit in your pocket—compact yet powerful. Their lightweight nature makes them easy to handle and integrate into handheld tools, reducing operator fatigue during long work sessions.

Enhanced Safety Features

Safety is paramount when dealing with powerful equipment. Fiber lasers are less prone to misalignment issues that can cause dangerous beam divergences. With built-in safety interlocks, they ensure safe operations, giving me peace of mind when working with them.

Fiber lasers require no mirrors or gas refills.True

Fiber lasers are solid-state and don't need mirrors or gas, unlike CO₂ lasers.

Fiber lasers have a lifespan of 10,000 hours.False

Fiber lasers exceed 100,000 hours in lifespan, far surpassing 10,000 hours.

How Do Fiber Lasers Improve Welding Precision and Consistency?

Imagine transforming the world of welding with the flick of a switch—fiber lasers make this dream a reality.

Fiber lasers elevate welding precision and consistency by delivering superior beam quality, energy efficiency, and adaptability across various materials. Their stable, high-quality beams ensure reliable welds with minimal defects.

The Science Behind Beam Quality

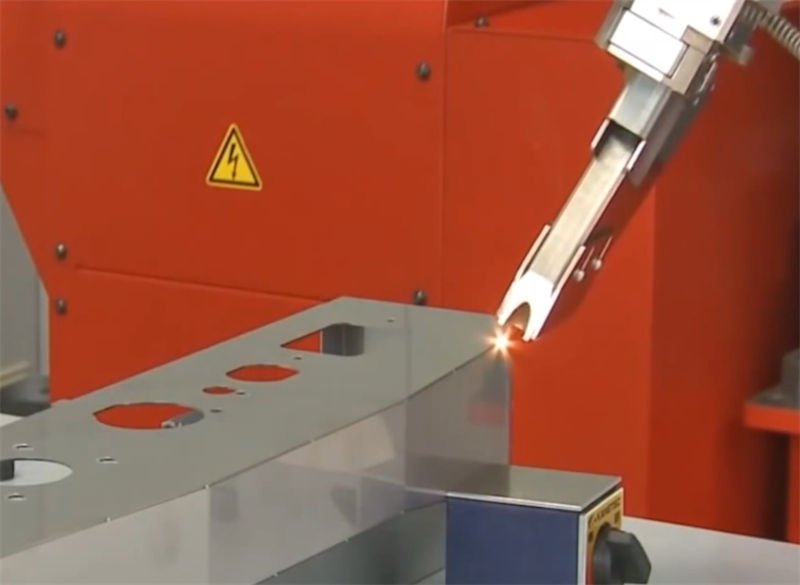

I remember the first time I witnessed a fiber laser in action. The beam’s precision was mesmerizing, like watching a master artist at work. Fiber lasers produce a highly focused beam with a small focal diameter—crucial for those of us needing pinpoint accuracy in our projects. This means cleaner, more accurate welds with minimal spatter or distortion, unlike the old CO₂ lasers that would often waver over long distances.

Energy Efficiency and Its Impact

Have you ever felt the heat of wasted energy in your wallet? That’s what traditional lasers can do. Fiber lasers, however, are like the energy-efficient bulbs of the welding world. With conversion efficiencies over 30%, they don’t just save energy—they save you money. I’ve noticed this efficiency reduces my operational costs significantly and keeps everything running smoothly during those long shifts.

Material Versatility and Adaptability

I once had a project involving different metals—aluminum, copper, you name it. Fiber lasers were a lifesaver here. They can handle a variety of materials without breaking a sweat. This versatility is invaluable, especially when you’re switching between substrates on the fly.

| Material Type | Fiber Laser Suitability | Traditional Laser Suitability |

|---|---|---|

| Aluminum | High | Moderate |

| Copper | High | Low |

| Stainless Steel | High | High |

| Brass | High | Low |

Role of Advanced Control Systems

These systems remind me of having a co-pilot on board. They allow real-time monitoring and adjustments, which is crucial when conditions change unexpectedly. With features like self-monitoring diagnostics, potential issues are flagged before they become problems, ensuring the quality of each weld remains top-notch.

For more insights into advanced control systems3, dive into external resources to see how these technologies are transforming laser welding precision.

The Compact Advantage

I’ve worked in tight spots where space is a luxury. The compact design of fiber lasers is a blessing. They’re easier to handle, reducing fatigue during long shifts, which makes a noticeable difference in my performance. Their small size also means they fit into spaces where larger systems simply can’t.

Safety and Reliability Considerations

Safety is non-negotiable in my line of work. Fiber lasers, with their solid-state design, reduce risks like beam divergence or misalignment. The built-in safety interlocks mean I can focus on the task without worrying about my safety being compromised.

To explore how safety features4 in fiber lasers contribute to operational consistency, check out specialized safety analyses that provide deeper insights.

Fiber lasers maintain beam quality over long distances.True

Fiber lasers ensure consistent beam quality, ideal for tight tolerances.

Traditional lasers are more efficient than fiber lasers.False

Fiber lasers have over 30% efficiency, surpassing traditional laser efficiency.

What Materials Can Be Welded with Fiber Laser Technology?

Have you ever wondered just how versatile fiber laser technology can be when it comes to welding?

Fiber laser technology excels in welding metals like aluminum, stainless steel, copper, and brass. Its precision and adaptability make it suitable for highly reflective materials and intricate applications.

Metals Suited for Fiber Laser Welding

I remember the first time I saw a fiber laser in action—like a dance of light and metal, it was mesmerizing! At that moment, it struck me how this technology could weld so many different metals with such precision. Fiber laser technology is known for its ability to weld various metals5 with unmatched accuracy. Let me walk you through some of the most common metals that benefit from this cutting-edge method.

| Material | Characteristics |

|---|---|

| Aluminum | High reflectivity; requires precise focus to avoid back-reflection issues |

| Stainless Steel | Excellent for detailed work due to precision and minimal distortion |

| Copper | Highly reflective; fiber lasers handle it better than other laser types |

| Brass | Similar to copper; benefits from the adaptability of fiber lasers |

Aluminum: A Reflective Challenge

Aluminum was one of those materials that initially seemed like a tough nut to crack because of its high reflectivity. Imagine trying to shine a light on a mirror; that’s how back-reflection6 issues can mess with other laser types. But with fiber lasers’ superior beam quality and focus, it’s like having a secret weapon that turns this challenge into a victory lap.

Stainless Steel: Precision Perfected

When you’re dealing with stainless steel, fiber laser technology is like having a magic wand that waves away distortion. It’s perfect for projects where tight tolerances7 are non-negotiable, ensuring every weld is just right without the hassles of traditional methods.

Copper and Brass: Mastering Reflectivity

Copper and brass were the metals that had me scratching my head at first. Their reflectivity makes them notoriously tricky, but fiber lasers handle them with grace. It feels like being able to complete intricate puzzles that others struggle with, which is a real game-changer in industries needing those crucial, detailed welds.

Advantages of Using Fiber Lasers

- Minimal Heat Distortion: I’ve seen firsthand how fiber lasers offer precise control over the heat-affected zone, which means less thermal distortion compared to traditional methods.

- High Efficiency: The energy efficiency is astounding! Fiber lasers convert more energy into laser light, which not only cuts costs but also boosts productivity.

- Adaptability: It’s amazing how versatile fiber lasers are—they’re like the Swiss Army knife of welding tools, capable of tackling a variety of metals and applications.

Every time I think about fiber lasers, I’m reminded of how they not only meet the demands of welding these metals but also uplift the overall productivity and quality in manufacturing settings. If you’re as curious as I was about the fiber laser advantages8, you’ll find their energy efficiency and adaptability across diverse materials and applications truly impressive.

Fiber lasers can weld aluminum without back-reflection issues.True

Fiber lasers' superior beam quality mitigates aluminum's reflectivity.

Copper cannot be welded with fiber laser technology due to reflectivity.False

Fiber lasers handle copper's reflectivity better than other laser types.

How Does Fiber Laser Efficiency Affect Cost and Performance?

Imagine running a business where every penny saved on operations directly boosts your bottom line. That’s the magic fiber lasers can bring to your industry.

Fiber laser efficiency slashes operational costs by cutting down on energy use while boosting performance with high beam quality and minimal maintenance needs.

The Energy Efficiency Advantage

Every time I think about energy efficiency, I remember my first apartment. The heating bill was astronomical until I found out about energy-efficient bulbs. It’s a similar story with fiber lasers. These lasers turn electrical energy into laser light with over 30% efficiency—compare that to the CO₂ lasers’ meager 10-15%. It’s like switching from incandescent to LED lights. Less electricity wasted means lower bills and longer operation without overheating. Perfect for when you need things running smoothly in industrial settings9.

| Laser Type | Efficiency | Energy Cost Impact |

|---|---|---|

| Fiber | >30% | Lower |

| CO₂ | 10-15% | Higher |

This reduction in energy consumption not only saves money but also allows operations to run for extended periods without overheating, making them ideal for continuous use.

Performance and Beam Quality

I’ve always admired precision—like how my grandma would meticulously cut cookies from dough with perfect edges. Fiber lasers are the same in the manufacturing world. They offer superior beam quality, ensuring fewer defects, especially in fields like aerospace manufacturing10 where perfection is key. This means your end product isn’t just good—it’s flawless.

Cost Implications

Let’s face it, we all flinch at upfront costs. Fiber lasers might initially seem like a splurge, but think of them as an investment, like when I finally bought that fancy coffee machine. It hurt my wallet initially, but saved me tons in café expenses over time. Fiber lasers, with their long lifespans over 100,000 hours, reduce downtime and replacement costs, making them a smart financial decision in the long haul.

Long-Term Savings vs. Initial Investment

- Initial Investment: Higher upfront cost

- Operational Savings: Lower energy and maintenance costs

- Maintenance: Minimal due to solid-state design

Balancing these factors can really optimize your business finances, making fiber lasers a cost-effective option for many industrial applications.

Maintenance and Reliability

I can’t help but think of fiber lasers as the ‘set it and forget it’ appliances of the industrial world—no mirrors to adjust or gases to refill, unlike their CO₂ counterparts. Their solid-state design just screams reliability, even in harsh environments. Some even come with self-monitoring systems that catch issues before they spiral into big problems—like having a car that tells you when it needs a check-up, ensuring maximum productivity in various manufacturing sectors11.

Fiber lasers convert over 30% of electrical energy into laser light.True

Fiber lasers have higher efficiency, converting over 30% of energy.

CO₂ lasers have a longer lifespan than fiber lasers.False

Fiber lasers typically exceed 100,000 operational hours, longer than CO₂.

Conclusion

Fiber laser sources enhance handheld welder reliability through energy efficiency, low maintenance, and superior beam quality, making them ideal for diverse industrial applications with long operational lifespans.

-

Learn how solid-state design eliminates moving parts, reducing wear and enhancing durability. ↩

-

Discover how fiber lasers handle diverse materials, boosting their reliability in industrial settings. ↩

-

Learn about how advanced control systems enhance laser welding precision and stability. ↩

-

Discover how built-in safety features ensure secure operations without sacrificing precision. ↩

-

Learn about the different metals compatible with fiber laser welding, enhancing your understanding of its versatile applications. ↩

-

Discover how fiber lasers effectively manage aluminum’s reflectivity challenges, improving welding outcomes. ↩

-

Explore why fiber lasers are perfect for precise stainless steel welding, minimizing distortion. ↩

-

Understand the key benefits of using fiber lasers for welding, including energy efficiency and material versatility. ↩

-

Explore how fiber lasers enhance industrial efficiency and reduce operational costs with detailed case studies. ↩

-

Discover how fiber lasers improve precision and consistency in aerospace manufacturing processes. ↩

-

Learn about the low-maintenance benefits of fiber lasers that contribute to their reliability in industry. ↩