Have you ever wondered how intricate designs are engraved on jewelry or how serial numbers appear on metal parts? Enter the world of fiber laser marking machines!

Fiber laser marking machines utilize a powerful laser beam to engrave or mark surfaces by changing their properties. These machines are highly efficient and versatile, ideal for metals and some non-metals, making them essential in sectors like electronics and jewelry.

But there’s so much more to discover! Let’s explore the fascinating inner workings of these machines, their diverse applications, and how to choose the perfect one for your needs.

Fiber lasers are ideal for marking metals.True

Fiber lasers excel in metal marking due to their high precision and efficiency.

How Do Fiber Laser Marking Machines Operate?

Discover the inner workings of fiber laser marking machines and their industrial significance.

Fiber laser marking machines function by using a high-intensity laser beam to modify the surface properties of materials. This process involves directing the laser through a fiber-optic cable, enabling precise, efficient marking on metals and some non-metals, crucial for industries like electronics and automotive.

The Basics of Fiber Laser Technology

Fiber laser marking machines utilize a solid-state laser source where the gain medium is an optical fiber doped with rare-earth elements such as erbium or ytterbium. This technology is known for its stability and efficiency in converting electrical energy into light energy.

How the Marking Process Works

The machine operates by emitting a laser beam through a fiber-optic cable. The beam’s intensity and focus can be precisely controlled, allowing it to engrave or mark intricate patterns on various materials. The high precision of fiber lasers means minimal thermal distortion, making them ideal for sensitive applications.

The process involves three main steps:

- Laser Generation: The fiber-optic cable guides the laser from the source to the workpiece.

- Focusing the Beam: Lenses focus the laser beam onto a small spot on the material’s surface.

- Marking: The laser alters the material’s surface through various mechanisms such as ablation, engraving, or annealing, depending on the material and desired outcome.

| Mechanism | Description |

|---|---|

| Ablation | Removes material to create markings. |

| Engraving | Creates grooves in the material. |

| Annealing | Alters the material’s color without removing it. |

Advantages of Fiber Laser Marking

- Precision and Versatility: Capable of marking a wide range of materials including metals, polymers, and some fabrics.

- High Efficiency: They convert electrical energy into laser energy more efficiently than traditional methods.

- Low Maintenance: With no moving parts or mirrors, they require less maintenance and have longer lifespans.

Industrial Applications

Fiber lasers are extensively used in industries such as electronics for circuit board marking, automotive for part identification, and jewelry for engraving intricate designs. Their ability to produce high-quality, permanent marks makes them invaluable in product identification and traceability.

Considerations When Operating a Fiber Laser Marker

Operators must consider factors such as the type of material being marked, required precision levels, and production speed needs. Understanding these can help in optimizing machine settings for different applications. For example, the importance of choosing the right laser marker1 cannot be overstated when it comes to meeting specific industrial needs.

Fiber lasers use a gas medium for light generation.False

Fiber lasers use a solid-state medium, not gas, for light generation.

Fiber laser marking causes minimal thermal distortion.True

The precision of fiber lasers ensures minimal thermal distortion.

What Are the Key Applications of Fiber Laser Marking Machines?

Fiber laser marking machines are revolutionizing various industries with their precision and versatility.

Fiber laser marking machines are predominantly used for engraving metals and certain non-metals, making them essential in industries such as electronics, automotive, jewelry, and aerospace. Their high precision and speed make them ideal for applications requiring detailed and durable markings.

Industrial Applications

Fiber laser marking machines are extensively employed in the industrial sector for marking trademarks and logos2, serial numbers, barcodes, and QR codes on metal parts. The automotive industry benefits greatly, as these lasers are used to mark engine components, ensuring traceability and authenticity. Moreover, in electronics manufacturing, they are perfect for marking PCBs, connectors, and microchips with high precision.

Jewelry and Luxury Goods

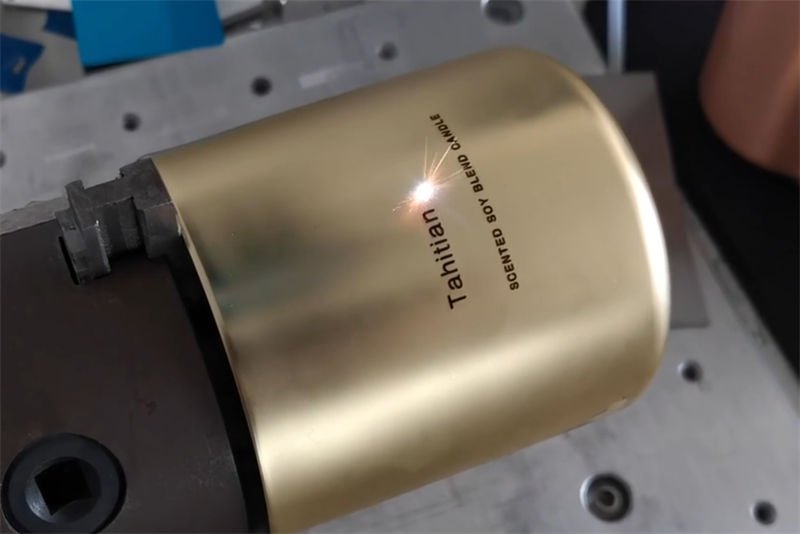

In the jewelry industry, fiber laser marking machines provide an efficient way to engrave intricate designs on metals such as gold, silver, and platinum. The ability to create fine details without damaging the surface makes them ideal for personalizing luxury goods like watches and high-end accessories.

Aerospace and Defense

The aerospace sector utilizes fiber laser marking for creating permanent, legible marks on critical components like turbines and engine parts. These markings are essential for maintaining compliance with industry standards and ensuring component traceability. The defense industry also relies on this technology to mark equipment and tools with unique identifiers.

Medical Device Manufacturing

Precision is crucial in the medical field, where fiber lasers are used to mark surgical instruments and medical devices with part numbers, logos, and regulatory information. The non-contact process ensures that no residue is left behind, maintaining the sterility of the devices.

E-commerce and Branding

For e-commerce platforms focusing on personalized products, fiber laser marking offers a high-profit margin by enabling the customization of a wide range of items. This adaptability makes fiber lasers particularly appealing for businesses looking to expand their product offerings without compromising on quality.

Fiber laser marking machines prove indispensable across diverse industries due to their ability to produce durable, precise markings on a variety of materials. Understanding the potential applications can help businesses leverage this technology effectively for improved product identification and branding.

Fiber lasers are used to mark jewelry with intricate designs.True

They engrave metals like gold and silver without surface damage.

Fiber lasers cannot mark medical devices due to residue issues.False

They use a non-contact process, leaving no residue on devices.

How Do Fiber Laser Marking Machines Compare to Other Laser Technologies?

Exploring the nuances of fiber laser marking versus other laser technologies.

Fiber laser marking machines stand out for their speed, precision, and versatility compared to CO2 and UV lasers. They excel in metal marking, offering durability and high contrast. CO2 lasers are better suited for non-metals, while UV lasers are ideal for ultra-fine marking on sensitive materials.

Key Differences Between Fiber, CO2, and UV Lasers

When comparing fiber laser marking machines with CO23 and UV lasers4, it’s crucial to understand each technology’s strengths and limitations.

| Feature | Fiber Lasers | CO2 Lasers | UV Lasers |

|---|---|---|---|

| Material Compatibility | Metals and some non-metals | Primarily non-metals | Most materials |

| Precision | High | Moderate | Very high |

| Typical Applications | Electronics, hardware, jewelry | Wood, plastics, acrylic | Food packaging, silicon wafers |

| Speed | Fast | Moderate | Slow |

| Cost | Medium to high | Low to medium | High |

Material Compatibility

Fiber lasers are particularly suitable for metals like stainless steel, aluminum, and brass due to their ability to produce high-contrast marks without additional consumables. In contrast, CO2 lasers5 excel in cutting and engraving non-metallic materials like wood and leather. Meanwhile, UV lasers are known for their ultra-fine marking abilities on delicate surfaces such as glass or silicon, making them indispensable for industries requiring precision.

Precision and Speed

The precision of fiber lasers stems from their smaller beam diameter, allowing for detailed engravings and markings. This makes them the preferred choice for applications demanding high accuracy, such as barcodes or QR codes in industrial settings. On the other hand, while CO2 lasers are not as precise, they offer a reasonable balance between cost and capability for less demanding tasks.

Cost Considerations

While fiber lasers often come with a higher initial investment, their long lifespan and low maintenance requirements can lead to cost savings over time. Comparatively, CO2 and UV lasers may have lower upfront costs but can incur higher ongoing expenses due to consumables or more frequent maintenance needs.

Application-Specific Considerations

Industries like electronics and automotive often opt for fiber lasers due to their efficiency and the need for durable markings. In contrast, artisans and craftspeople may lean towards CO2 lasers for their versatility with organic materials. UV lasers find a niche in sectors like pharmaceuticals where micro-marking is essential.

Understanding these differences helps businesses choose the right laser technology for their specific needs, ensuring optimal performance and cost-efficiency across various applications.

Fiber lasers are best for metal marking.True

Fiber lasers excel in marking metals with high contrast and durability.

CO2 lasers are faster than fiber lasers.False

Fiber lasers are generally faster than CO2 lasers, especially on metals.

What Factors Should You Consider When Choosing a Fiber Laser Marker?

Selecting the right fiber laser marker is pivotal for optimizing industrial operations.

When choosing a fiber laser marker, consider the material types, required precision, production volume, and budget. Evaluating these factors ensures optimal performance and cost-effectiveness.

Material Compatibility

Before investing in a fiber laser marker6, determine the types of materials you intend to mark. Fiber lasers excel in marking metals like aluminum, stainless steel, and titanium but are also effective on non-metals such as certain plastics and ceramics. Understanding your material needs will help narrow down your choices.

Precision Requirements

Different applications demand varying levels of precision. For instance, industries requiring intricate designs or detailed markings may benefit from higher precision capabilities. Evaluate whether a standard precision level meets your needs or if you require advanced features for ultra-fine marking.

Production Volume and Speed

The production requirements of your operation significantly impact the choice of laser marker. Consider how fast and deep you need the marking to be. A 20-watt fiber laser is generally sufficient for most applications, but high-volume operations might necessitate more powerful options for quicker processing times.

Budget Considerations

Balancing quality with budget constraints is crucial. Assess the upfront cost of the machine against its long-term benefits, including maintenance and operational costs. While high-end models offer numerous features, ensure these align with your actual needs to avoid unnecessary expenditure.

User Interface and Software Compatibility

A user-friendly interface can streamline operations and reduce training time. Consider machines with intuitive controls and software that integrates seamlessly with existing systems. Ensuring compatibility with design software can enhance efficiency and precision in marking processes.

Additional Features and Support

Evaluate any additional features that could be beneficial for your operations, such as automation capabilities, safety features, or customization options. Furthermore, consider the manufacturer’s support services, including warranty, training, and after-sales support, to ensure smooth operation and quick resolution of potential issues.

Fiber lasers are best for marking metals.True

Fiber lasers excel at marking metals like aluminum and titanium.

All fiber laser markers have the same precision level.False

Precision levels vary; some applications need higher precision.

Conclusion

Fiber laser marking machines offer unmatched precision and efficiency for industrial marking tasks. Understanding their functions and applications empowers businesses to optimize processes and enhance product quality. Delve deeper to make informed choices tailored to your material and production requirements.

-

Explore crucial factors in selecting a suitable laser marker.: Selecting the appropriate laser marking system necessitates compatibility with the materials intended for marking or engraving. ↩

-

Explore in-depth industrial uses for branding and identification purposes.: Laser marking systems are ideal track-and-trace solutions for use in the production of medical equipment, electronic components, and more. ↩

-

Discover the wide range of materials CO2 lasers can process.: A CO2 laser cutting machine uses electricity and a gas mixture containing carbon dioxide to generate high-intensity infrared light. ↩

-

Explore why UV lasers are ideal for fine detail work.: Laser marking makes it easy to identify parts and authenticity without a physical tool etching the surface of the part or transmitting any substances onto the … ↩

-

Understand the main differences in application and performance.: Fiber lasers provide higher cut precision than CO2. They have 10 times the working life of CO2 devices, often reported as 25,000 working hours. ↩

-

Explore compatible materials to ensure versatility in your marking projects.: Number #1: Aluminum. Aluminum is a material with wide industrial applications because of its lightweight and impeccable mechanical properties. Aluminum is … ↩