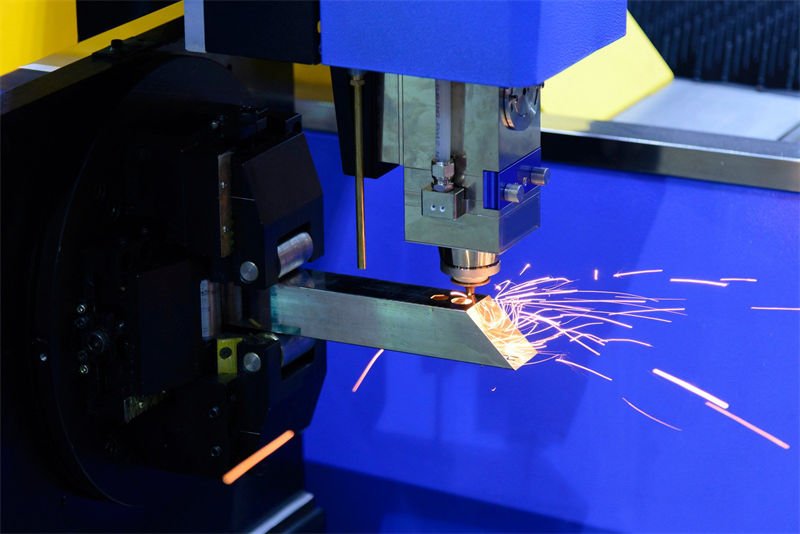

Have you ever marveled at the precision of a beautifully cut metal piece or a striking advertisement that catches your eye? That’s the magic of fiber laser cutting machines!

Fiber laser cutting machines are widely used in the metal processing industry. They can precisely cut carbon steel, stainless steel and other plates in fields such as automobiles and architectural decoration. They can also cut pipes for furniture and mechanical manufacturing. In the electronics industry, they can finely cut circuit boards and process metal casings of electronic equipment. In the advertising signage industry, they are used to make various metal signage.

But there’s so much more beneath the surface! Let’s dive deeper into how fiber laser cutting machines are making waves in these sectors and what unique advantages they offer.

Fiber laser cutting is used in the automotive industry.True

Fiber lasers cut complex automotive parts efficiently, enhancing precision and speed.

How Does Fiber Laser Cutting Improve Manufacturing Processes?

Fiber laser cutting technology has revolutionized manufacturing by enhancing precision, speed, and efficiency. Discover how it transforms production workflows and reduces operational costs.

Fiber laser cutting improves the manufacturing process in multiple ways. It can achieve high-precision cutting with a minimum cutting width of just a few tenths of a millimeter, enhancing product fineness. Its cutting speed is fast, effectively improving production efficiency. Moreover, the cutting surface quality is high, reducing subsequent grinding and other processes. It can also precisely cut complex shapes through software control to optimize the process.

Precision and Speed: The Hallmarks of Fiber Laser Cutting

One of the primary advantages of fiber laser cutting is its unparalleled precision and speed. Unlike traditional cutting methods, fiber lasers can handle intricate designs and complex geometries without compromising accuracy. This capability is vital in industries such as aerospace and electronics, where precision is non-negotiable.

For instance, when dealing with thin materials like sheet metal or reflective metals like aluminum, fiber lasers offer clean cuts with minimal heat-affected zones. This reduces the risk of distortion and improves the quality of the final product.

Versatility Across Materials

Fiber laser cutting machines are highly versatile, capable of cutting through a wide range of materials, from metals to plastics. This adaptability allows manufacturers to use a single machine for multiple applications, optimizing both space and resources.

In the manufacturing sector, this versatility means less equipment is needed to achieve the same output, leading to cost savings. Additionally, it reduces the time spent on changing tools or adjusting settings, as fiber lasers can switch between different materials with minimal setup time.

Efficiency and Cost Reduction

By reducing waste and improving cutting speed, fiber lasers significantly enhance operational efficiency. The nozzle technology1 used in these machines allows for precise control over cutting conditions, ensuring optimal performance without excessive material use.

Furthermore, the maintenance requirements for fiber lasers are relatively low compared to other cutting technologies, which translates to reduced downtime and maintenance costs. Their energy efficiency also means lower operational costs in terms of power consumption.

Advanced Control Systems

Modern fiber laser cutting machines are equipped with sophisticated control systems that automate many processes. These systems can optimize cutting paths and adjust parameters in real-time based on material type and thickness.

Such automation not only speeds up production but also ensures consistent quality across large batches. As a result, manufacturers can meet high-quality standards without extensive manual oversight.

Improving Complex Manufacturing Processes

In industries where complex components are required, such as automotive or medical devices, fiber laser cutting facilitates the production of detailed parts with high repeatability. This is particularly crucial for prototyping2 and mass production scenarios where precision is essential.

Moreover, the ability to quickly adapt to design changes without significant retooling makes fiber laser cutting ideal for agile manufacturing environments. This flexibility helps companies respond faster to market demands while maintaining high standards of quality.

Fiber lasers reduce waste in manufacturing processes.True

Fiber lasers provide precise cuts, minimizing material waste.

Fiber laser cutting is unsuitable for reflective metals.False

Fiber lasers effectively cut reflective metals like aluminum.

What Are the Key Benefits of Fiber Laser Cutting in Automotive Industry?

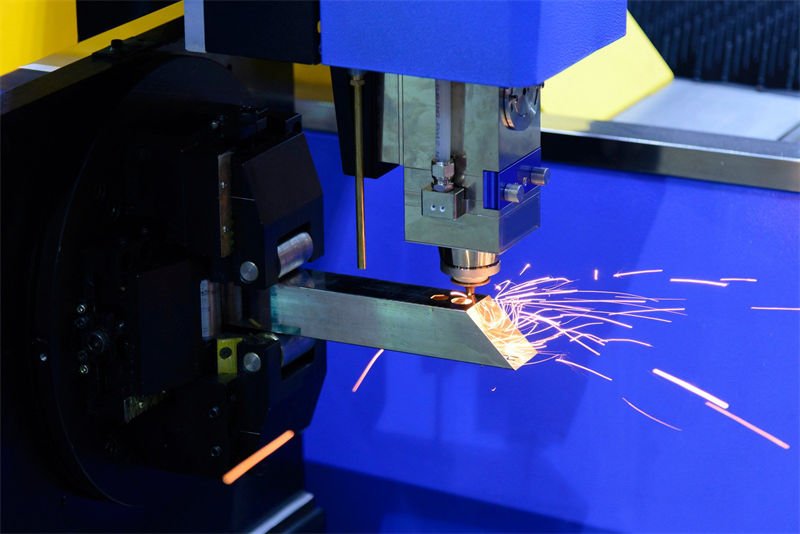

Fiber laser cutting is revolutionizing the automotive industry by enhancing precision and efficiency, crucial for modern vehicle production.

In the automotive industry, fiber laser cutting has obvious advantages. It has high precision and can control the error of parts within a very small range. For example, the cutting precision of body panels can reach ±0.1mm. It has fast cutting speed and can improve production efficiency. The cutting surface has good quality with smooth edges, reducing subsequent processing. It can also cut parts with complex shapes to meet the needs of automobile manufacturing.

Enhanced Precision and Accuracy

Fiber laser cutting provides high precision due to its focused laser beam, which enables the production of complex and intricate parts with minimal error. This precision is crucial for the automotive industry, where even minor discrepancies can lead to significant problems in vehicle assembly. Unlike traditional cutting methods, fiber lasers maintain consistency over large production runs, ensuring uniformity across all components.

Increased Efficiency and Speed

One of the standout benefits of fiber laser cutting3 in the automotive sector is its speed. Fiber lasers can cut materials quickly without compromising on quality, which reduces production time significantly. This efficiency is particularly beneficial for manufacturers aiming to meet tight deadlines or scale up production without incurring additional costs.

Versatility in Materials and Applications

Fiber lasers are not limited to a single material type; they can cut a range of materials including steel, aluminum, and other alloys commonly used in automotive manufacturing. This versatility extends to different parts of a vehicle, from body panels to engine components. The ability to cut various materials with a single machine reduces the need for multiple cutting technologies, saving on both space and equipment costs.

| Material | Application | Benefit |

|---|---|---|

| Steel | Chassis and body panels | Durable cuts with minimal waste |

| Aluminum | Engine and transmission components | Lightweight parts with precise detailing |

| Alloys | Exhaust systems | Complex shapes with reduced processing time |

Cost-Effectiveness

Though the initial investment in fiber laser technology can be high, the long-term savings are substantial. By reducing waste, increasing production speed, and minimizing tool wear, fiber lasers lower overall manufacturing costs. Moreover, their energy efficiency compared to other laser types translates into lower operational costs over time.

Safety and Environmental Impact

Automotive manufacturers4 are increasingly prioritizing sustainable practices. Fiber lasers contribute to this goal by producing fewer emissions compared to traditional cutting methods. They also enhance workplace safety by minimizing the need for manual intervention during the cutting process, reducing the risk of accidents.

Fiber lasers maintain precision over large production runs.True

Fiber lasers ensure uniformity and minimal errors across components.

Fiber laser cutting is limited to steel materials.False

Fiber lasers cut various materials, including steel, aluminum, and alloys.

How Is Fiber Laser Cutting Utilized in the Advertising Sector?

Fiber laser cutting is revolutionizing the advertising sector by enabling high-precision, customizable signage and displays.

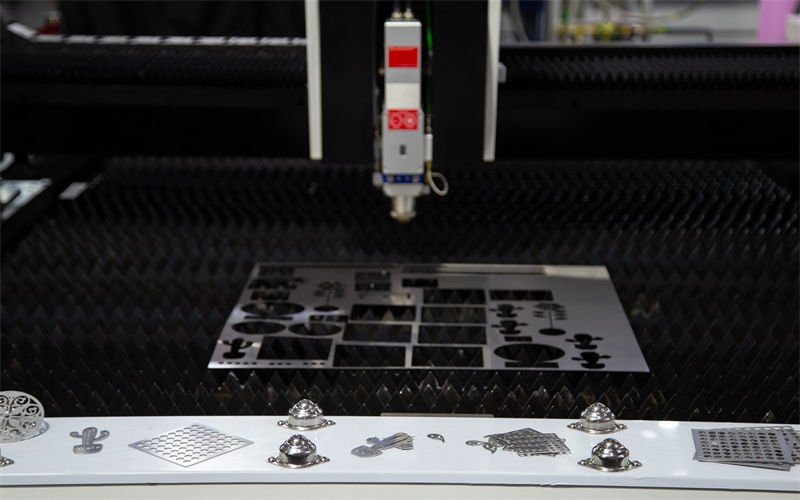

In the advertising industry, fiber laser cutting is very useful. It can precisely cut various metal materials and is used to make metal letter signs and signboards. It can cut complex shapes and exquisite patterns, such as artistic fonts and fine logos. Moreover, the cutting surface is smooth, enhancing the texture of advertising products and providing technical support for the realization of advertising creativity.

Precision and Customization in Signage

One of the most compelling uses of fiber laser cutting in advertising is in the creation of customized signage. Advertisers can achieve intricate cuts with high precision, allowing for unique and eye-catching designs that stand out in competitive markets. The capability to cut through various materials like acrylic, wood, and metals means that advertisers are no longer restricted by material limitations.

For instance, an advertising agency can use a fiber laser to create a multi-layered logo cut from stainless steel, which can be backlit for dramatic effect. The intricate detail5 achievable with this technology ensures that even the most complex designs can be brought to life, meeting client specifications with ease.

Enhancing Visual Merchandising

In addition to static signage, fiber laser cutting is used to craft dynamic display elements that enhance visual merchandising. From creating 3D models to delicate engravings, fiber lasers offer a range of possibilities for retail displays. This capability is crucial in sectors where visual impact translates directly to consumer engagement.

For example, a retail store can employ fiber laser-cut displays to highlight seasonal promotions or new product launches. The precision of the laser ensures each piece fits perfectly within a display unit, enabling quick assembly and disassembly as needed for different campaigns.

Cost Efficiency and Speed

Fiber lasers not only enhance design but also improve operational efficiency. Compared to traditional cutting methods, fiber lasers reduce production time significantly while lowering material waste. This efficiency is crucial in the advertising sector, where time-to-market can be a determining factor for campaign success.

A comparison of traditional vs. fiber laser cutting might look like this:

| Method | Setup Time | Production Speed | Material Waste |

|---|---|---|---|

| Traditional | Long | Moderate | High |

| Fiber Laser | Short | Fast | Low |

Incorporating fiber laser technology allows advertising firms to rapidly prototype and iterate designs, responding quickly to client feedback and market trends.

Leveraging Technological Advancements

As advancements continue in laser technology, the opportunities6 for advertising expand. Features like automated controls and enhanced precision settings mean that complex projects can be executed with minimal manual intervention. This technological progress is driving innovation in how advertisements are conceptualized and realized.

These cutting-edge features allow advertisers to push creative boundaries while maintaining a high standard of quality. With every advancement, fiber laser cutting becomes an even more integral tool in the toolkit of modern advertisers.

Fiber lasers enable customizable signage in advertising.True

Fiber lasers allow for high-precision cuts, enabling unique designs.

Traditional cutting methods are faster than fiber lasers.False

Fiber lasers are faster and more efficient than traditional methods.

What Challenges Are Associated with Fiber Laser Cutting and How to Overcome Them?

Navigating the world of fiber laser cutting can present a series of challenges, but understanding and addressing them effectively can lead to optimal performance and results.

Fiber laser cutting faces some challenges. Firstly, during high-power cutting, the heat-affected zone may cause material deformation, which can be improved by optimizing cutting parameters and using auxiliary gases. Secondly, the equipment cost is high. For this, the cost can be reduced by leasing equipment or increasing equipment utilization. At the same time, the technical requirements for operators are high, so it is necessary to strengthen personnel training to let operators be familiar with equipment performance and cutting processes to ensure cutting quality and efficiency.

Layering in the Cut Section

Layering can disrupt the quality of cuts made by fiber laser machines, often caused by incorrect speed or gas pressure settings. Solutions include:

- Modifying the cutting speed7 for smoother transitions.

- Adjusting the gas pressure to ensure clean cuts.

- Altering nozzle aperture and defocus settings for precision.

Dross on the Cut Surface

Dross formation leads to an uneven finish and is a common issue. Overcome this by:

- Calibrating cutting speed and gas pressure.

- Adjusting the negative defocus amount and nozzle spacing.

- Consistently checking for nozzle integrity8.

Slow Cutting Speed

A slow cutting speed can affect productivity. Address this by:

- Inspecting optical lenses for dirt or damage.

- Fine-tuning gas pressure and defocus settings.

- Ensuring laser power is adequate, potentially using a different nozzle model.

Yellowing of the Cutting Surface

Yellowing can occur due to impure gases or incorrect settings. To prevent this:

- Verify the purity of cutting nitrogen.

- Balance cutting speed with frequency and duty cycle adjustments.

- Manage gas pressure efficiently.

Nozzle Overheating

Overheating leads to wear and tear on equipment. Solutions include:

- Using a larger aperture nozzle to dissipate heat better.

- Regularly checking and cleaning protective lenses.

- Carefully lowering the focus while maintaining cut quality.

Piercing Bursts

Sudden bursts during piercing can be minimized by:

- Reducing piercing frequency and duty cycle.

- Increasing piercing spot size and power density appropriately.

- Fine-tuning piercing height and gas pressure settings.

Uneven Cut Surface

Uneven cuts are often due to equipment wear or misalignment. To address this:

- Examine nozzles for damage or misalignment regularly.

- Inspect ceramic body for microcracks which can affect cuts.

- Ensure the cutting nozzle is well-centered for consistency.

By tackling these challenges with strategic adjustments and regular maintenance, fiber laser cutting can achieve superior results across various applications.

Layering in fiber laser cuts is due to high gas pressure.False

Layering is often caused by incorrect speed or low gas pressure settings.

Dross formation can be reduced by adjusting nozzle spacing.True

Adjusting nozzle spacing helps achieve a cleaner cut surface, reducing dross.

Conclusion

In summary, fiber laser cutting machines stand at the forefront of innovation, enhancing efficiency and precision across industries. Reflect on how this technology could reshape your own operations and drive you toward success.

-

Discover how advanced nozzle technology enhances cutting precision and efficiency.: The nozzle is usually installed at the front end of the laser cutting head, which helps to control the auxiliary gas and protect the focus lens. ↩

-

Learn why fiber lasers are ideal for rapid prototyping with intricate designs.: CO2 and Fiber lasers are the primary types of laser cutting technology. High accuracy and ease of control make the CO2 laser popular, and it is the most widely … ↩

-

Discover specific advantages of using fiber lasers in automotive manufacturing.: Fiber laser machines are helpful in the automotive industry for machining complex functional material properties. They have excellent … ↩

-

Learn how fiber lasers contribute to sustainable automotive production.: One of the most significant environmental benefits of fiber laser cutting is its contribution to waste reduction. … Lifecycle analysis reveals … ↩

-

Explore intricate design possibilities with fiber laser technology.: Laser cutting can eliminate the mould opening process and improve efficiency. Laser cutting machine can cut any plane graphics on metal and non-metal materials. ↩

-

Discover upcoming technological improvements in laser cutting.: 1. Increased Power and Cutting Speeds: Fiber lasers are becoming more powerful, allowing for faster cutting speeds and the ability to cut thicker materials. ↩

-

Learn how to adjust cutting speed for optimal performance.: Balancing speed with power and other parameters is key to achieving efficient and precise cuts. Speed is a critical parameter as it affects both … ↩

-

Discover maintenance tips for ensuring nozzle integrity.: 1. Protective lenses. The protective lens is also one of the frequently wearing parts of the fiber laser cutting machine, as shown in figure 7. ↩