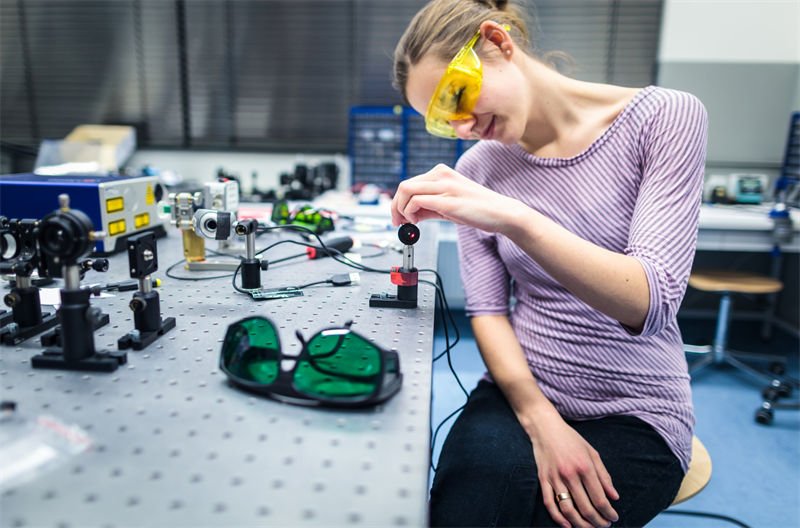

When working with lasers, ensuring eye safety is paramount. The right laser safety eyewear protects against harmful exposure while maintaining clarity and comfort.

Essential requirements for laser safety eyewear include protection against specific laser wavelengths, appropriate optical density, suitable visible light transmission, and high optical quality. These ensure effective safety and performance in laser-prone environments.

While these basics provide a foundation for choosing laser safety eyewear, delving deeper into each requirement can significantly enhance your understanding and help you make a well-informed choice. Let’s explore these elements in greater detail.

Laser safety eyewear must comply with ANSI Z136 standards.True

ANSI Z136 sets criteria for laser eyewear, ensuring effective eye protection.

How Do Laser Wavelengths Affect Eyewear Selection?

Choosing the right laser eyewear means understanding how specific wavelengths impact protection needs.

Laser wavelengths directly influence the selection of eyewear by determining the lens material or coating required to absorb, reflect, or scatter those wavelengths. This ensures adequate protection against eye damage from specific laser types used in various applications.

Understanding Laser Wavelengths and Their Impact

Laser wavelengths are crucial in determining the type of eyewear needed for safety. Each laser operates at a particular wavelength, such as 1064nm for Nd:YAG lasers, requiring eyewear that can adequately protect against this frequency. Selecting glasses with the correct wavelength protection involves understanding the laser’s operational range and potential exposure risks.

In environments where multiple lasers are used, like research labs, eyewear must cover a wide wavelength spectrum to ensure complete protection. Safety glasses designed for a single wavelength might not suffice in such settings.

Matching Lens Materials to Laser Types

The lens materials or coatings on laser safety eyewear are pivotal in their effectiveness. For instance, polymer lenses infused with organic dyes can absorb specific wavelengths, while glass lenses doped with absorptive agents offer stability and durability. Knowing which material offers the best protection for your specific laser wavelength is key.

- Absorptive Lenses: Suitable for medium-power lasers, these lenses absorb laser light within certain wavelength ranges but may degrade under prolonged high-power exposure.

- Reflective Lenses: These utilize thin metal coatings to reflect particular wavelengths, ideal for high-power applications where reflecting laser energy is critical to avoid damage.

The Role of Optical Density and Visible Light Transmission

The optical density (OD) of eyewear determines how much laser energy is attenuated. Higher OD levels mean more protection against high-power lasers, a vital consideration when selecting eyewear for specific wavelengths.

Visible Light Transmission (VLT) affects how well you can see while wearing the glasses. Adequate VLT ensures visibility while still providing necessary protection against laser light. For tasks requiring precision, like medical procedures, a balance between protection and visibility is crucial.

| Lens Type | Suitable Applications | Key Benefits |

|---|---|---|

| Absorptive | Medium-power lasers | Lightweight, good for specific wavelength ranges |

| Reflective | High-power lasers | High reflection efficiency, broad wavelength coverage |

| Composite | Multi-laser environments | Combines absorptive and reflective properties |

For more insights on selecting the best laser eyewear1 for your needs, consider factors like optical quality and comfort to ensure safe and effective use in various settings.

Laser eyewear must match the laser's wavelength for protection.True

Eyewear needs to absorb, reflect, or scatter specific wavelengths.

Reflective lenses are best for low-power laser applications.False

Reflective lenses are ideal for high-power lasers to avoid damage.

Why Is Optical Density Critical for Laser Safety Glasses?

Understanding optical density (OD) is key to choosing effective laser safety glasses that protect your eyes from harmful laser exposure.

Optical density (OD) measures the attenuation of laser energy by safety glasses. High OD values indicate stronger protection, reducing laser transmittance significantly. Choosing the correct OD ensures safety across different laser power levels, protecting against eye damage.

Understanding Optical Density (OD) in Laser Safety

Optical density is a measure that indicates how much light or laser energy is reduced as it passes through a medium, such as laser safety glasses. It is expressed logarithmically, meaning each unit increase in OD reduces the laser’s energy transmission by a factor of ten. For instance, an OD of 3 will allow only 0.1% of the laser energy to pass through.

Determining the Right OD for Your Needs

The specific laser wavelength and power level2 determine the necessary OD for safety glasses. For high-power industrial lasers, a higher OD is required to ensure minimal energy reaches the eyes, whereas lower-power demonstrations might need less intense protection. As a rule of thumb, select glasses with an OD that offers comprehensive protection without compromising on visibility.

| Laser Power Level | Minimum Recommended OD |

|---|---|

| Low (e.g., pointers) | 2-3 |

| Medium (e.g., research lasers) | 4-5 |

| High (e.g., industrial lasers) | 6+ |

The Importance of Uniform OD Across Lenses

Uniformity in OD across the entire lens ensures consistent protection from laser exposure, avoiding weak spots where energy could penetrate. This consistency is especially crucial in dynamic work environments where unpredictable laser angles might occur. Selecting high-quality safety glasses that guarantee uniform OD helps prevent potential eye hazards.

Optical Density vs. Visible Light Transmission (VLT)

While a high OD is crucial for protection, balancing it with appropriate visible light transmission is essential to maintain clarity and comfort in vision. Excessively high OD may unnecessarily darken the lenses, reducing visibility in low-light conditions. Ideal glasses provide optimal protection while ensuring that the user can see their work clearly without eye strain.

Selecting Glasses Based on Application

Different applications may require specific considerations when selecting safety glasses. For example, industrial environments3 often use high-power lasers demanding greater OD, while medical procedures might balance OD with higher VLT for precision tasks. Therefore, understanding your specific use case ensures that your choice of glasses provides both protection and practicality.

OD of 3 allows 0.1% laser energy to pass through.True

Each unit increase in OD reduces transmission by a factor of ten.

High OD values decrease visible light transmission significantly.True

High OD can darken lenses, affecting clarity and visibility.

What Role Does Visible Light Transmission Play in Laser Eyewear?

Understanding Visible Light Transmission (VLT) is crucial for ensuring both safety and functionality in laser eyewear.

Visible Light Transmission (VLT) ensures clear vision while wearing laser safety glasses by allowing a controlled amount of light to pass through. It balances protection and visibility, making it essential for safe and effective laser operations.

Understanding VLT in Laser Eyewear

Visible Light Transmission (VLT) refers to the percentage of visible light that passes through a lens. In the context of laser eyewear, it’s vital to maintain a balance between sufficient protection from harmful laser wavelengths and adequate visibility for the wearer. Generally, VLT values between 20% and 80% are deemed ideal depending on the operational environment.

Importance of VLT for Clear Vision

Laser environments can vary significantly in brightness. For instance, in high-brightness laser environments, lower VLT values might be preferred to reduce glare and prevent distraction. However, in low-light conditions or precision work, higher VLT values are necessary to ensure that the wearer can see clearly without straining their eyes.

VLT and Visual Clarity

The choice of VLT affects how well a user can see details while wearing the glasses. For example, in surgical applications where precise vision is necessary, glasses with higher VLT allow surgeons to see clearly without any color distortion or blurriness, thereby preventing errors.

| VLT Percentage | Application Scenario | Benefits |

|---|---|---|

| 20% – 40% | High-brightness areas | Reduces glare and eye strain |

| 41% – 60% | General usage | Balances visibility with protection |

| 61% – 80% | Low-light settings | Enhances visibility for detailed work |

Avoiding Visual Interference

Proper VLT can help avoid visual issues such as glare and color distortion, which are common when the transmission levels are not aligned with the specific needs of the task. Poorly chosen VLT can lead to an unsafe working environment, as users may not accurately perceive their surroundings. This is especially critical in fields requiring color differentiation, like certain medical procedures or intricate engineering tasks.

Evaluating the Right VLT for Your Needs

Determining the correct VLT involves assessing the specific demands of your laser environment. Consider factors like ambient lighting conditions, the precision required for the task, and personal comfort preferences. Considerations for selecting VLT4 can include consulting with safety experts or conducting trials with different eyewear options to find the optimal balance.

By understanding and choosing the right VLT, users can achieve effective protection while maintaining the clarity necessary to perform their tasks safely and efficiently.

VLT values above 80% are ideal for laser eyewear.False

VLT values between 20% and 80% are recommended for laser eyewear.

Higher VLT is necessary for low-light laser environments.True

Higher VLT enhances visibility in low-light settings, aiding clarity.

How Can You Ensure Your Laser Safety Glasses Meet Standards?

Ensuring your laser safety glasses meet the necessary standards is crucial for optimal protection and compliance in various laser applications.

To ensure your laser safety glasses meet standards, verify compliance with recognized certifications like ANSI Z136 or CE EN 207. Check for accurate wavelength protection, appropriate optical density, and ensure high optical quality for effective performance.

Understanding Compliance Requirements

Laser safety glasses must adhere to recognized standards, such as ANSI Z1365 in the USA or CE EN 2076 in Europe. These standards set forth specific criteria that eyewear must meet to be considered safe for laser work. Compliance with these standards ensures that the glasses provide adequate protection against laser radiation.

- Local Regulations: In addition to international standards, local regulations may also apply. For example, China has its own set of guidelines under GBT17736-19997.

Key Features of Compliant Laser Safety Glasses

-

Wavelength Protection: Ensure that the glasses offer protection for the specific laser wavelengths you are working with. For instance, glasses should protect against common industrial wavelengths like 1064nm or medical wavelengths such as 755nm.

-

Optical Density (OD): The OD value determines how much laser energy is attenuated. It’s crucial to select glasses with an appropriate OD for the laser power level you are using. For high-power lasers, an OD of 5 or more might be necessary.

-

Visible Light Transmission (VLT): While protecting from laser light, the glasses should allow enough visible light for clear vision. A VLT range between 20% and 80% is generally recommended.

Evaluating Optical Quality

High optical quality is vital to ensure that the user can see clearly and perform tasks without distortion. Look for lenses with low aberration and high resolution.

- Low Aberration: This ensures a clear, undistorted view, which is especially important in precision applications like micromachining.

- High Resolution: Necessary for tasks requiring fine detail observation.

Assessing Durability and Comfort

Durability and comfort are also important factors to consider. Choose glasses with:

- Ergonomic Design: Comfortable fit to encourage prolonged use without discomfort.

- Quality Materials: Impact-resistant lenses and durable frames that withstand rigorous environments.

Ensuring your laser safety glasses meet these standards and features not only safeguards your eyesight but also contributes to a safer working environment overall.

ANSI Z136 is a standard for laser safety glasses in the USA.True

ANSI Z136 sets criteria for laser eyewear protection in the U.S.

CE EN 207 does not cover laser eyewear requirements in Europe.False

CE EN 207 specifies standards for laser eyewear in Europe.

Conclusion

By understanding these essential requirements, you can choose laser safety eyewear that ensures optimal protection and performance, enhancing both safety and productivity in laser environments.

-

Learn detailed factors influencing eyewear selection for different laser types.: Know your laser’s wavelength. Determine the protection level needed based on your laser’s output parameters, or look for the recommended Optical Density (OD). ↩

-

Learn how to select the correct optical density for different laser uses.: This convenient online tool will calculate the recommended optical density for use with a laser system of a given power. ↩

-

Understand optical density needs for high-power industrial laser environments.: The required OD determined by the World Laser Safety in the USA found in ANSI Z136.1 are dependent upon several factors, including the wavelength of the laser. ↩

-

Explore guidelines for selecting optimal VLT based on specific needs.: Most eyewear offer protection from specific wavelengths and allow other wavelengths in the visible light spectrum to pass through for unhindered vision. ↩

-

Learn about U.S. standards ensuring effective laser eye protection.: ANSI Z136.1 provides guidance on the appropriate PPE, such as laser safety goggles or face shields, to protect individuals working with lasers. ↩

-

Discover European requirements for comprehensive laser protection.: EN 207 was written to address this problem and takes account of both the Optical Density and the damage threshold of the eyewear. EN 207 Markings Explained. ↩

-

Explore local guidelines ensuring legal and safe eyewear use in China.: This standard specifies for the protection of laser damage to the human eye lens material personal protective equipment laser eye protection … ↩