Deciding to buy a CNC mill feels a lot like picking out the perfect car—there’s so much to consider, and you want to get it right.

When buying a CNC mill, think about the complexity of the parts you’ll make, the materials you’ll use, and the precision you need. Also, look at the machine’s spindle power, feed system, table size, and automation features to find the right fit for you.

You know how when you’re planning a big trip, you start with the basics but soon dive into the nitty-gritty details? That’s what it’s like choosing a CNC mill. From understanding performance specs to weighing automation benefits and cost factors, each element is vital. Let’s explore these crucial factors to ensure you’re making a savvy investment.

A CNC mill is necessary for processing simple planes.False

Simple planes can often be processed with less complex machinery than a CNC mill.

Five-axis mills are essential for aerospace part production.True

Five-axis mills provide the precision and flexibility needed for complex aerospace components.

How does part complexity influence your CNC mill choice?

Choosing a CNC mill? It’s like finding the perfect dance partner for your parts! Let’s talk about how part complexity can sway your decision.

Part complexity plays a crucial role in selecting the right CNC mill by dictating the machine’s necessary axes, precision, and power. Intricate parts often demand multi-axis machines with advanced spindles and control systems, while simpler parts can be handled by basic configurations.

Understanding Part Complexity

Imagine you’re about to bake a cake. The complexity of the design you envision, like intricate layers and delicate frosting patterns, directly affects the tools you’ll need. Similarly, when I look at a part I need to machine, I have to consider its geometrical intricacies and precision demands. I remember once working on a project involving aerospace components—those intricate curves and tight tolerances were no joke! The parts needed to perform flawlessly under demanding conditions, much like crafting a cake that holds its shape and tastes divine.

Multi-Axis Requirements

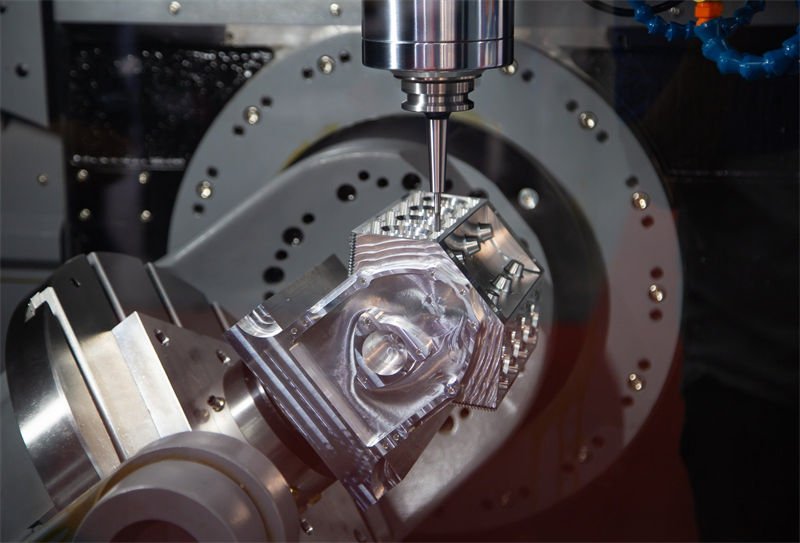

Think of a traditional three-axis CNC mill as a trusty old bicycle—it can take you places but has its limits. Now, envision a five-axis CNC mill as a sleek sports car, agile and capable of navigating complex terrains effortlessly. When I’m faced with complex geometries, like the time I was machining components for a cutting-edge drone, the additional axes provided the flexibility I needed. It reduced my setup time and ensured precision by allowing the tool to approach the part from multiple angles. For such tasks, multi-axis CNC mills1 become essential.

Precision Needs

Precision in machining is akin to hitting the perfect note in music—it requires skill, attention, and the right equipment. Parts that demand high accuracy need mills with superior spindle performance. I recall a project where even a tiny deviation would have spelled disaster; maintaining strict precision was non-negotiable. Precision measurement systems2 became my best friends, ensuring that each piece met stringent quality standards.

Material Considerations

Choosing the right CNC mill also means understanding the material you’re working with—like knowing whether you’re slicing through butter or chiseling stone. Complex parts made from tough materials like titanium need machines with robust power and torque. I once had to work with superalloys, and let me tell you, they required every bit of power the machine could muster to cut through them efficiently.

Automation and Control Systems

Advanced control systems are like having a seasoned sous chef in the kitchen—they enhance efficiency and reduce errors. When dealing with complex parts, features such as automatic tool changers become indispensable. A sophisticated control system3 saved me hours on a project by managing nuanced movements seamlessly.

Cost vs. Complexity Balance

It’s all about striking the right balance between cost and complexity. High-end machines might be tempting, but I learned early on that it’s vital to evaluate if such an investment aligns with my production needs and budget constraints. Understanding part complexity helps me make informed decisions without overspending or compromising on quality.

Five-axis CNC mills are needed for complex 3D surfaces.True

Complex 3D surfaces require simultaneous multi-axis movement, achievable with five-axis CNC mills.

High spindle speed is needed for processing hard materials.False

Hard materials often require lower spindle speeds to ensure sufficient cutting force.

Why Is Material Type Crucial When Selecting a CNC Mill?

Have you ever wondered why the type of material is so important when choosing a CNC mill? It’s more than just a technical detail—it’s a game-changer.

Material type is crucial in CNC milling because it dictates the machine’s specifications for achieving optimal performance and quality. Different materials require specific tool capabilities, spindle speeds, and machine setups. Knowing material properties like hardness and machinability ensures efficient and effective milling.

Understanding Material Properties

The selection of material is not just a preliminary step but a critical decision point in CNC milling. Each material presents unique challenges due to its inherent properties such as hardness, toughness, and thermal conductivity. For example, high-strength steels require a CNC mill with robust cutting tools and a powerful spindle to handle greater cutting forces4. Conversely, softer materials like plastics necessitate precise control over spindle speed to avoid deformation and ensure a smooth finish.

I remember the first time I dealt with high-strength steel on a CNC mill. It was like trying to slice through a rock with a butter knife. That’s when I realized just how much the material properties could influence the milling process.

Impacts on Tooling and Spindle Specifications

Different materials necessitate specific tooling requirements. For instance, machining titanium alloys demands the use of carbide-coated tools to reduce wear. The spindle speed must also be adjustable to accommodate the diverse cutting speeds required for different materials. High-speed spindles might be necessary for aluminum to achieve a high-quality surface finish, whereas materials like cast iron may need slower speeds to maintain tool integrity5.

When I first machined titanium alloys, I learned the hard way that not all tools are created equal. The wear on the tools was incredible until I switched to carbide-coated ones.

Influencing Milling Machine Configuration

Material type heavily influences the configuration of the CNC mill itself. Machines that frequently handle composite materials may need enhanced dust management systems to prevent clogging and overheating. Meanwhile, CNC mills processing ferrous metals often require integrated coolant systems to dissipate heat effectively6. The choice between a 3-axis or 5-axis mill can also hinge on the complexity of the material’s geometry and the precision required in final parts.

I once worked with composite materials that required a dust management system to keep things running smoothly, which was something I hadn’t considered initially.

Cost Implications and Efficiency

Material selection directly impacts cost-efficiency in CNC milling operations. Harder materials might increase tool wear and energy consumption, leading to higher operational costs. Thus, understanding the machinability of each material helps in selecting a CNC mill that optimizes operational efficiency7 while maintaining quality output.

I quickly learned that selecting the right material isn’t just about machining; it’s about balancing cost-efficiency.

Five-axis CNC mills are essential for simple part shapes.False

Simple shapes don't require five-axis CNC mills; they're for complex surfaces.

High spindle power is crucial for processing hard materials.True

Hard materials need high spindle power for sufficient cutting force.

Why Are Performance Parameters Crucial When Choosing a CNC Mill?

Choosing the perfect CNC mill feels like piecing together a puzzle, where each performance parameter is a critical piece that affects the whole picture. It’s like trying to find the right tool for a job—only this tool could make or break your manufacturing dreams.

Performance parameters in CNC mills, like spindle speed, torque, and precision, are vital as they dictate how efficiently and accurately the mill can handle specific tasks. Evaluating these factors ensures the CNC mill aligns with your production needs and material specifications.

Understanding Spindle Performance

Picture this: I was once at a crossroads, deciding which CNC mill to invest in. The spindle speed was a real game-changer for me. Think of it as choosing between a sports car and a truck—each has its strengths depending on the road ahead. High spindle speeds were ideal for cutting through softer materials, like a hot knife through butter, but slowed down significantly when dealing with harder metals. And let’s not forget about torque; it’s the muscle behind every cut, especially when you’re dealing with rough machining of hard materials8.

Spindle precision was another crucial factor that I couldn’t ignore. It’s the equivalent of needing a surgeon’s steady hand for delicate operations. In industries like aerospace, where even the smallest error can have significant repercussions, ensuring minimal deviations is non-negotiable.

Feeding System Performance Matters

Once upon a time, during a particularly challenging project, I learned the importance of a mill’s feeding system. Imagine trying to paint a mural with a roller brush versus a fine-tip pen—each stroke needs to be precise, and that’s where feeding speed and precision come into play. A variable feeding speed allowed me to transition smoothly from rough cuts to fine finishes, keeping my projects on point.

The resolution was another eye-opener. With higher resolution, I could make those tiny adjustments that transformed my designs into reality, especially when tackling complex shapes9.

Worktable Considerations

I remember the first time I underestimated the size of a worktable; it’s like trying to fit an elephant into a Mini Cooper. Ensuring the worktable matched my material dimensions saved me countless headaches. And believe me, the load capacity played a pivotal role in maintaining stability during machining.

The precision of the worktable was equally vital. Just as you wouldn’t want a wobbly dining table while carving a turkey, I needed assurance that the table would stay flat and straight to maintain part accuracy.

Automation and Control Systems

Embracing automation was akin to having an extra set of hands during busy production cycles. Automatic tool changing became my trusty sidekick, especially when facing frequent tool changes10 in batch production.

The control systems offered intuitive programming capabilities that integrated seamlessly with CAD/CAM tools. Real-time monitoring was my safety net, providing feedback that allowed me to dynamically adjust operations and ensure consistent quality throughout each production cycle.

A five-axis CNC mill is necessary for simple 2D contours.False

Simple 2D contours can be processed with a common CNC mill, not five-axis.

High spindle speed is ideal for cutting aluminum alloys.True

Aluminum requires high spindle speed for efficient and quality cutting.

Why Are Automation Features Vital in CNC Milling Machines?

Ever wondered if automation in CNC milling machines is a game-changer or just another tech fad?

Automation features in CNC milling machines are crucial for enhancing productivity, precision, and efficiency in manufacturing. By reducing manual intervention, these features ensure consistent quality, faster production cycles, and lower operational costs. This makes them indispensable for companies aiming to stay competitive in modern manufacturing.

Enhancing Productivity and Efficiency

When I first delved into the world of CNC milling machines, the sheer magic of automation took me by surprise. Imagine working in an environment where tools seamlessly switch themselves, thanks to automatic tool changing11, without the need for a coffee break or a shift change. This was particularly evident during my visit to an automotive plant, where machines hummed with efficiency, never missing a beat even as they changed tools to handle various car components. It was like watching a perfectly synchronized dance.

Automated loading and unloading12 systems played a significant role, too, by keeping the production line flowing without those pesky pauses for manual material handling. This feature was a game-changer in high-volume production settings, where every second counts.

Achieving Precision and Consistency

I remember witnessing the meticulous nature of aerospace manufacturing, where a fraction of a millimeter could mean the difference between success and catastrophe. Automation in CNC milling was pivotal here, ensuring that each component was crafted to precise specifications, minimizing human errors. Advanced numerical control systems13 allowed for exact control over every aspect of the machining process, from speed to position.

Imagine the peace of mind knowing that when you’re manufacturing parts for critical applications—like medical devices—the machine is as precise as your expectations. No more sleepless nights worrying about compliance with those stringent industry standards.

Reducing Operational Costs

Yes, the initial investment in CNC machines with advanced automation might cause a few sleepless nights contemplating the budget. But here’s the catch: over time, these machines significantly slash operational costs. Faster production cycles, reduced labor costs, and minimized material wastage all contribute to the bottom line.

For small businesses like mine that dream of scaling without ballooning labor costs, these features are a lifesaver. Even maintenance automation features14, like predictive maintenance alerts, ensure longevity and reliability by flagging potential issues before they become costly headaches.

Adaptability and Flexibility

The flexibility offered by automation is akin to having a Swiss Army knife at your disposal. With the integration of smart technologies like IoT and AI, CNC machines adapt in real-time. This adaptability was particularly crucial when I was involved in electronics manufacturing, where every batch had unique requirements.

I recall a project where an adaptive control system15 enabled the machine to tweak its operations based on sensor feedback. It optimized cutting parameters on-the-fly for different materials or shapes without needing manual recalibration—a marvel of modern engineering that allowed us to pivot quickly as market demands changed.

Five-axis CNC mills are essential for simple 2D contours.False

Five-axis CNC mills are not needed for simple 2D contours; they are for complex shapes.

High spindle power is crucial for cutting hard materials.True

High spindle power provides the necessary force to cut through hard materials efficiently.

Conclusion

Before purchasing a CNC mill, consider part complexity, material types, performance parameters, automation features, and cost to ensure the machine meets your production needs effectively.

-

Discover how multi-axis mills enhance machining flexibility. ↩

-

Learn how precision systems ensure machining accuracy. ↩

-

Explore how control systems optimize CNC operations. ↩

-

Learn how high-strength steels affect CNC mill selection. ↩

-

Discover how to maintain tool integrity when milling cast iron. ↩

-

Find out why coolant systems are vital for machining metals. ↩

-

Explore ways to boost efficiency through smart material choices. ↩

-

Discover how high torque benefits rough machining of hard materials. ↩

-

Explore methods for handling complex shapes with CNC milling. ↩

-

Learn about automatic tool changing systems in CNC mills. ↩

-

Learn how automatic tool changing boosts efficiency in CNC operations. ↩

-

Explore automated systems for seamless material handling. ↩

-

Discover the role of numerical control in precision machining. ↩

-

Find out how predictive maintenance reduces downtime. ↩

-

Understand how adaptive controls optimize CNC processes. ↩