Diving into the realm of Chinese CO2 laser cutters can feel like wandering through a maze, yet choosing wisely is vital for your business triumph.

To ensure quality and reliability when buying Chinese CO2 laser cutters, I always verify supplier credentials, meticulously evaluate product specifications, request samples, scrutinize quality control processes, and confirm robust after-sales support. Prioritizing suppliers with stellar reviews, industry certifications, and operational transparency is key.

While these initial steps lay the groundwork for making a confident purchase, taking a closer look at each aspect can uncover more insights and subtleties. By truly understanding the nuances of supplier relationships and machine specifications, you can make the most of your investment.

Chinese CO2 laser cutters lack quality control processes.False

Many suppliers have robust quality control to ensure product reliability.

Supplier credentials are crucial for buying Chinese CO2 lasers.True

Verifying supplier credentials ensures you choose reliable and reputable sources.

What Are the Key Supplier Credentials to Look For?

Choosing a supplier feels like finding the perfect teammate for your business. It’s a blend of trust, reliability, and shared goals. So, what should you really look for?

When evaluating suppliers, focus on credentials like ISO certifications, financial stability, operational transparency, and positive customer reviews. These aspects reflect a supplier’s reliability and commitment to industry standards.

Certifications and Standards

Whenever I’m on the hunt for a new supplier, the first thing I check is their certifications1. It’s like a badge of honor that tells me they mean business when it comes to quality. ISO 9001 is my go-to for quality management. It’s reassuring to know they have systems in place to consistently meet customer needs and comply with regulations.

| Certification | Purpose |

|---|---|

| ISO 9001 | Quality Management |

| CE | European Conformity |

| UL | Safety Compliance for the US Market |

Financial Health

I remember this one time I almost partnered with a supplier who had amazing products but turned out to be financially shaky. Lesson learned! Now, I always dive into their financial health. A stable financial standing means they can keep up with orders and invest in improving quality. I make it a point to request financial statements or credit reports—just like getting a health check-up.

Operational Transparency

Transparency is my litmus test for reliability. If a supplier is open about their production processes, it’s usually a good sign. I often ask for a tour of their production line through photos or videos. It’s comforting to see them proudly share their quality control2 measures.

Customer Feedback and Reviews

I’ve found that customer reviews are like gold mines of information. Platforms like Alibaba are treasure troves for feedback from other businesses. Positive reviews often signal good customer service and product quality, which is crucial for building trust.

Compliance with Industry Standards

Ensuring compliance with industry standards is non-negotiable for me. It’s not just about safety but also about avoiding legal headaches down the road. I check if suppliers follow necessary guidelines and regulations, including environmental standards and specific safety features3.

Experience and Reputation

Experience speaks volumes. An established supplier usually has a proven track record, which means less hassle in managing large orders. I always ask for references or case studies—real stories that show how they’ve handled past clients successfully.

By focusing on these credentials, I can more confidently assess whether a supplier is equipped to meet my business needs and help strengthen our supply chain.

ISO 9001 certification ensures quality management.True

ISO 9001 certification indicates adherence to quality management standards.

Financially unstable suppliers are more reliable.False

Financial instability in suppliers often leads to inconsistent order fulfillment.

How Do Product Specifications Influence Performance?

Ever wondered how a detailed product specification can make or break performance?

Product specifications are like the unsung heroes of performance, shaping outcomes by defining material quality, design features, and operational capabilities. They ensure products not only meet standards but also operate efficiently and reliably.

The Role of Material Quality

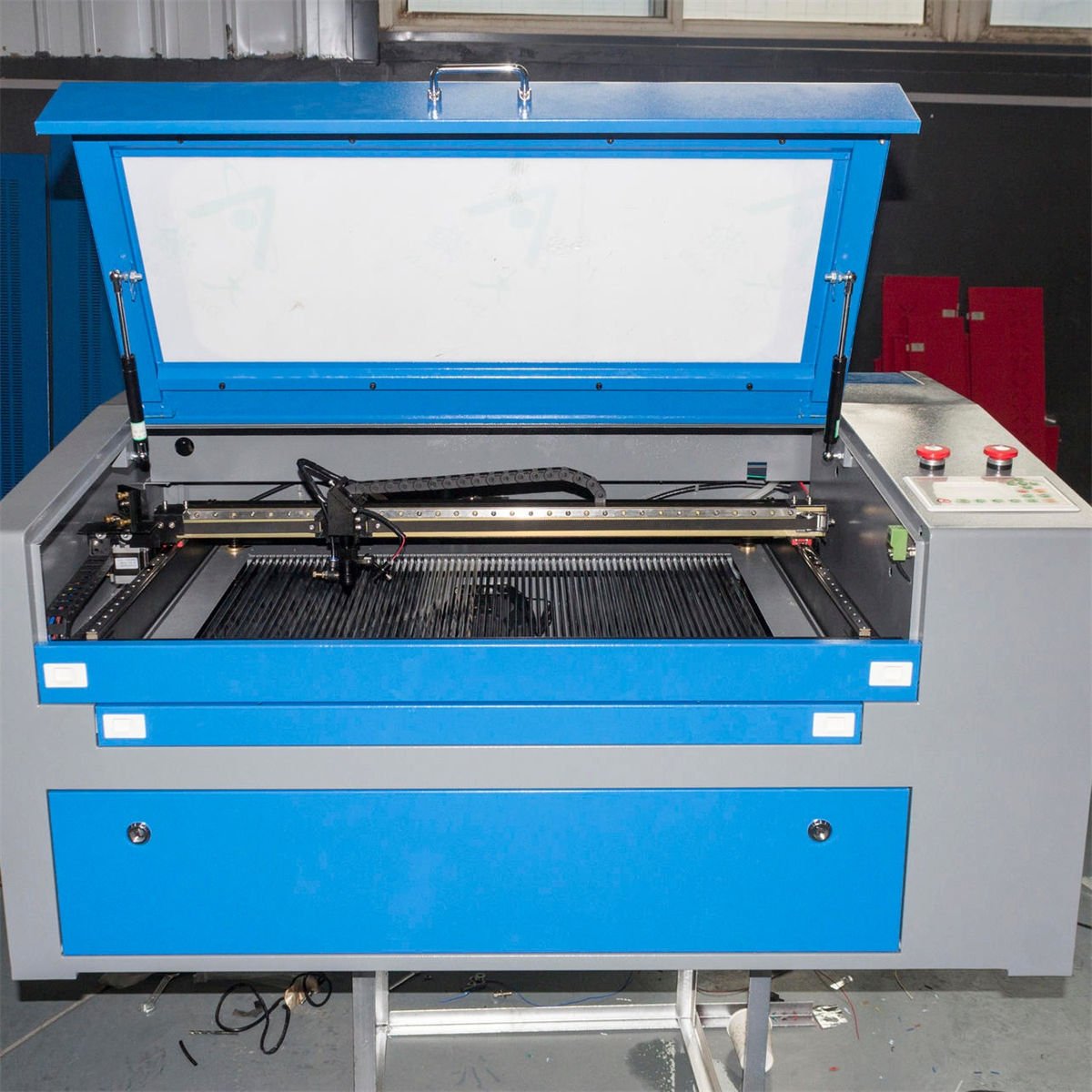

Imagine you’re piecing together a puzzle, where each piece must fit perfectly to reveal the full picture. That’s how I see material quality in product specs. I once handled a CO2 laser cutter4 that was a beast in industrial settings because its components were tough and heat-resistant. It was like watching a superhero withstand every battle without a scratch.

Choosing materials that match these specs makes everything last longer and perform under pressure. It’s like opting for a metal laser tube over glass because you know it’ll go the distance without wavering.

Design Features and Their Impact

I remember the first time I dealt with design specs. It felt like unlocking a treasure chest of possibilities. Think of the cutting speed5 in laser cutters. When you have precise speed controls, it’s like being able to dance through materials, cutting effortlessly without losing precision.

Good design specs make a product versatile, ready to tackle any task you throw at it, just like having the right tools makes any job easier.

Operational Capabilities

Specifications are where the magic happens. Details about power output and precision directly affect how well a product performs its intended role. Picture a laser power6 scenario: higher wattage is your best friend when slicing through thicker materials, essential for precise cuts in robust industries.

Detailed specs ensure products not only meet basic requirements but also excel in efficiency, making them reliable allies in any situation.

| Specification Aspect | Impact on Performance |

|---|---|

| Material Quality | Durability and Resistance |

| Design Features | Versatility and Task Efficiency |

| Operational Capabilities | Precision and Power Efficiency |

Practical Examples and Insights

There was this time an e-commerce platform seller I knew had to ensure their sheet metal workshops7 got the right laser equipment. Detailed specs were their saving grace, reducing operational errors and downtime, ultimately boosting customer satisfaction.

Or take a procurement manager at a laser equipment manufacturer using specs to negotiate better supplier terms, ensuring all components meet quality and performance standards.

In essence, detailed product specifications are the roadmap to superior performance, aligning design and material choices with operational demands. They’re crucial for businesses aiming to not just meet but exceed customer expectations.

Metal laser tubes last longer than glass ones.True

Metal laser tubes are more durable and stable, enhancing longevity.

Higher laser wattage reduces precision in cutting.False

Higher wattage increases cutting power, not reducing precision.

Why Is Sample Testing Crucial Before Making a Purchase?

Ever felt that gut-wrenching fear of buying something big, only to realize it’s not what you expected?

Sample testing is essential before purchasing because it lets you verify the product’s quality and performance firsthand, ensuring it matches your needs and minimizing the risk of expensive blunders.

Validating Product Quality and Performance

Sample testing allows you to verify that the product meets the promised quality and performance standards. For instance, a CO2 laser cutter8 should deliver precise cuts and a smooth finish. By requesting a sample, you can check these aspects and decide if the product aligns with your expectations.

Reducing Purchase Risks

Purchasing without sample testing is like buying a car without taking it for a spin—you just don’t know what surprises await. Testing samples mitigates these risks by providing tangible evidence of how a product will perform in real-world conditions. For example, testing a new laser tube9 can highlight potential wear-and-tear issues before a full-scale purchase.

Ensuring Specification Accuracy

Ever compared a recipe’s picture-perfect dish with your own attempt? Sometimes, what’s on paper doesn’t match reality. Sample testing allows you to confirm that product specifications, such as cutting speed and precision, are accurate. This is crucial when the specifications determine10 the operational efficiency of your business.

Building Supplier Trust

Requesting samples can also be a way to gauge a supplier’s reliability and transparency. Suppliers willing to provide samples are often confident in their products and customer service. This builds trust, which is essential for long-term business relationships.

Cost-Benefit Analysis

Yes, requesting samples can incur costs upfront, but let me tell you—it’s an investment. It saved me from making costly mistakes that could have drained my finances later on. Here’s a simple comparison:

| Action | Potential Outcome |

|---|---|

| Sample Testing Conducted | High confidence in purchase |

| No Sample Testing | Increased risk of faulty goods |

Ultimately, spending time on sample testing gave me confidence and aligned purchases with my business needs. Whether it’s CO2 laser cutters11 or any other equipment, it’s a step I can’t afford to skip.

Sample testing confirms product quality standards.True

Sample testing verifies if the product meets promised quality standards.

Skipping sample testing increases purchase risks.True

Not testing samples can lead to unforeseen issues and poor performance.

What Should You Expect from After-Sales Support?

Have you ever bought something and felt like the real adventure began only after the purchase? That’s where after-sales support comes in!

After-sales support includes technical assistance, warranty services, spare parts availability, and customer training. These elements are essential for ensuring ongoing product satisfaction and can significantly enhance customer loyalty.

Technical Assistance and Troubleshooting

Imagine this: you’ve just set up your new laser cutter12, and suddenly, a blinking light or an unusual noise leaves you scratching your head. We’ve all been there, right? That’s when having access to timely technical assistance feels like having a superhero on speed dial. Whether it’s through a quick phone call, an email, or a chat, knowing there’s someone who understands your equipment inside and out can make all the difference.

Warranty and Return Policies

I remember the first time I learned about warranty terms—my eyes glazed over with all the fine print! But now, I know how crucial it is to understand these details. A good warranty is like a safety net that catches you when things go awry. It should cover repairs or replacements for defects that pop up during a specified period. Make sure you’re clear on how long the coverage lasts and what’s included or excluded. Some companies even offer extended warranties for peace of mind, and let me tell you, they’ve saved my bacon more than once!

| Warranty Feature | Description |

|---|---|

| Duration | Length of coverage period |

| Coverage | Parts and labor included |

| Exclusions | What is not covered |

Spare Parts Availability

Have you ever been stuck waiting for a critical part to arrive? It’s frustrating! Reliable after-sales support means having spare parts ready to go when you need them. Check if your supplier has a spare parts inventory13 that’s easily accessible. Quick dispatch of these parts can prevent your operations from coming to a grinding halt.

Customer Training and Resources

I’ll admit, I once underestimated the value of training—until I had to learn a new machine on the fly! Good after-sales support offers training that equips you to use your equipment safely and efficiently. Whether it’s through user manuals, online resources, or even onsite training14, these resources are invaluable for getting the most out of your purchase.

Investing in robust after-sales support doesn’t just solve problems—it builds lasting relationships between companies and their customers. When done right, it becomes a cornerstone of customer satisfaction and loyalty.

Timely technical assistance prevents prolonged downtimes.True

Quick support helps resolve issues, minimizing equipment downtime.

Extended warranties are always included at no extra cost.False

Extended warranties often require an additional purchase.

Conclusion

To ensure quality and reliability when purchasing Chinese CO2 laser cutters, verify supplier credentials, evaluate specifications, request samples, and confirm after-sales support.

-

Understanding common certifications helps ensure suppliers meet international standards, boosting reliability and quality assurance. ↩

-

Learning about quality control procedures helps verify a supplier’s commitment to maintaining product standards and reducing defects. ↩

-

Knowing key safety features ensures compliance with regulations and enhances user safety, avoiding potential hazards. ↩

-

Explore the recommended materials for CO2 laser cutters to ensure durability and performance. ↩

-

Learn how cutting speed specifications can enhance the efficiency of laser cutters. ↩

-

Understand the significance of high power output in achieving precise cuts. ↩

-

Discover how detailed specs improve efficiency in sheet metal operations. ↩

-

Learn about how sample testing ensures products meet quality standards and customer expectations. ↩

-

Explore potential wear-and-tear issues with laser tubes before full-scale purchasing. ↩

-

Understand how sample testing confirms product specifications for operational efficiency. ↩

-

Discover why upfront sample testing costs can prevent greater financial losses later. ↩

-

This link will guide you to find detailed information on technical assistance for laser cutters, enhancing your understanding of available support options. ↩

-

Learn how to verify spare parts availability for your equipment, ensuring minimal operational disruptions when replacements are needed. ↩

-

Discover the various customer training programs offered by suppliers, which can help optimize your equipment usage and safety. ↩