Welcome to the fascinating realm of CNC machines, where innovation meets precision!

CNC machines are automated tools controlled by computers, crucial for high-precision machining tasks. The main types include CNC Lathes for rotational parts, CNC Milling Machines for diverse shapes, CNC Machining Centers for multi-process tasks, CNC EDMs for complex molds, CNC Laser Machines for high-speed cuts, and CNC Plasma Cutters for thick metals.

Let’s embark on this journey together to explore the unique functions and applications of each type of CNC machine!

CNC Lathes are used for machining rotational parts.True

CNC Lathes automate precision machining of rotational parts like shafts.

How Do CNC Lathes Enhance Manufacturing Processes?

Discover the transformative impact of CNC lathes on modern manufacturing efficiency.

CNC lathes enhance manufacturing by automating the precision machining of rotational parts, reducing human error, and increasing production speed. They enable the creation of complex designs with high accuracy, making them indispensable in automotive and hardware industries for components like shafts and discs.

Precision and Efficiency in Machining

CNC lathes bring unparalleled precision to manufacturing processes. By automating the turning operations, they minimize human error and ensure consistent quality across large production runs. This automation allows for tight tolerances and intricate designs, which are crucial in industries such as automotive and aerospace.

The ability to consistently produce parts with exact specifications reduces waste and rework, ultimately saving time and resources. Additionally, the automated nature of CNC lathes means they can operate continuously with minimal supervision, significantly increasing production efficiency1.

Versatility Across Industries

CNC lathes are incredibly versatile, capable of machining a wide range of materials from metals to plastics. This versatility makes them suitable for various applications, including the production of automotive components like brake discs and half-shafts. In the hardware industry, they are used to create handles for tools, showcasing their ability to handle both precision and heavy-duty tasks.

This adaptability not only enhances manufacturing processes but also expands the potential for innovation, as designers can experiment with different materials and geometries without worrying about machining limitations.

Integration With Modern Manufacturing Technologies

The integration of CNC lathes with advanced technologies2 such as computer-aided design (CAD) and computer-aided manufacturing (CAM) further enhances their utility. These technologies enable the seamless transition from digital design to physical product, ensuring that even the most complex shapes can be produced accurately.

Moreover, the use of CNC lathes in smart manufacturing environments, where machines communicate with each other via the Internet of Things (IoT), represents a significant leap towards fully automated production lines. This integration allows for real-time monitoring and adjustments, optimizing processes and reducing downtime.

Cost-Effectiveness and Scalability

While the initial investment in CNC lathes can be significant, their long-term benefits in terms of cost savings and scalability are undeniable. Once set up, CNC lathes can produce large quantities of parts at a fraction of the cost compared to traditional machining methods.

Scalability is another crucial advantage. As demand increases, manufacturers can easily ramp up production without sacrificing quality or incurring significant additional costs. This scalability is particularly beneficial in industries that experience fluctuating demand, such as consumer electronics or seasonal goods.

By understanding how CNC lathes improve precision, versatility, integration, and cost-effectiveness, manufacturers can better leverage these tools to enhance their production capabilities.

CNC lathes reduce human error in machining.True

CNC lathes automate processes, minimizing human intervention and errors.

CNC lathes are only used for metal components.False

CNC lathes can machine various materials, including metals and plastics.

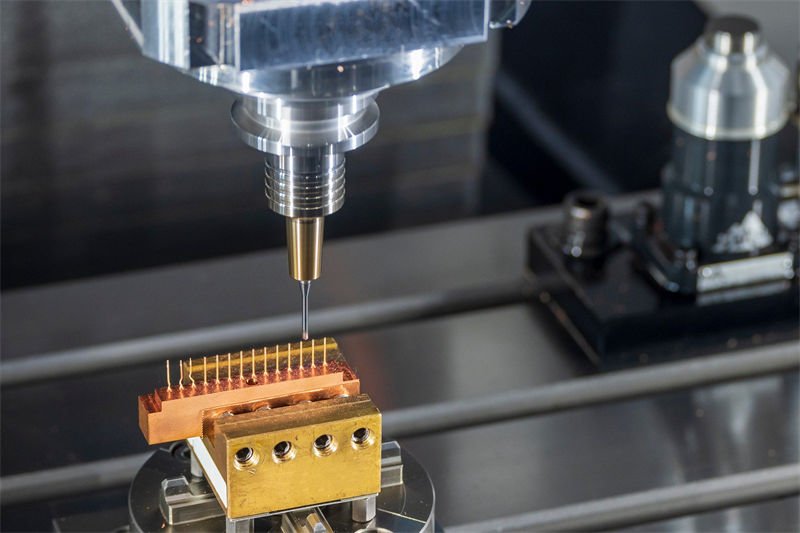

What Makes CNC Milling Machines Indispensable?

In the realm of modern manufacturing, CNC Milling Machines stand as pillars of precision and versatility.

CNC Milling Machines are indispensable due to their ability to perform complex machining tasks with precision and efficiency, making them vital in industries such as aerospace, automotive, and electronics for producing intricate parts.

Precision and Versatility in Machining

CNC Milling Machines offer unparalleled precision, enabling manufacturers to produce parts with exact dimensions and complex geometries. This precision is achieved through computer-controlled commands that guide the cutting tool, allowing for consistent and repeatable results. The versatility of CNC Milling Machines is evident in their ability to machine a wide range of materials, from metals to plastics, which is crucial for industries requiring varied material capabilities3.

Applications Across Industries

The applications of CNC Milling Machines span numerous industries, showcasing their indispensability. In the aerospace sector4, these machines are utilized to craft components such as aircraft wings and engine parts, where precision and reliability are critical. Similarly, in the automotive industry, CNC Milling Machines are employed to create engine blocks and transmission housings. The electronics industry benefits from their use in manufacturing intricate housings for devices, demonstrating the machines’ versatility in handling complex shapes.

Efficiency Through Multi-Axis Machining

One of the defining features of CNC Milling Machines is their ability to perform multi-axis machining. This capability allows for the creation of intricate parts with complex spatial curves, which is essential for high-precision components. Multi-axis CNC Milling Machines can operate along three to five axes simultaneously, providing the flexibility needed for complex contour machining5. This not only enhances efficiency but also reduces the need for multiple setups, thereby decreasing production time and cost.

Automation and Repeatability

CNC Milling Machines have revolutionized manufacturing with their automation capabilities. They can execute pre-programmed sequences with minimal human intervention, ensuring high repeatability and reducing the margin for error. This automation is particularly beneficial in large-scale production settings where consistency across thousands of parts is required. By minimizing manual input, manufacturers can achieve higher throughput without sacrificing quality.

Table: Benefits of CNC Milling Machines

| Feature | Benefit |

|---|---|

| Precision | High accuracy in dimensional tolerances |

| Versatility | Ability to machine various materials |

| Multi-Axis Machining | Capability for complex geometrical machining |

| Automation | Reduced need for manual intervention |

| Repeatability | Consistent quality across large production runs |

By examining these facets of CNC Milling Machines, it’s clear why they remain an integral part of modern manufacturing processes across various industries.

CNC Milling Machines can machine only metal materials.False

CNC Milling Machines can machine a variety of materials, including plastics.

Multi-axis machining reduces production time and cost.True

Multi-axis machining enhances efficiency by reducing the need for multiple setups.

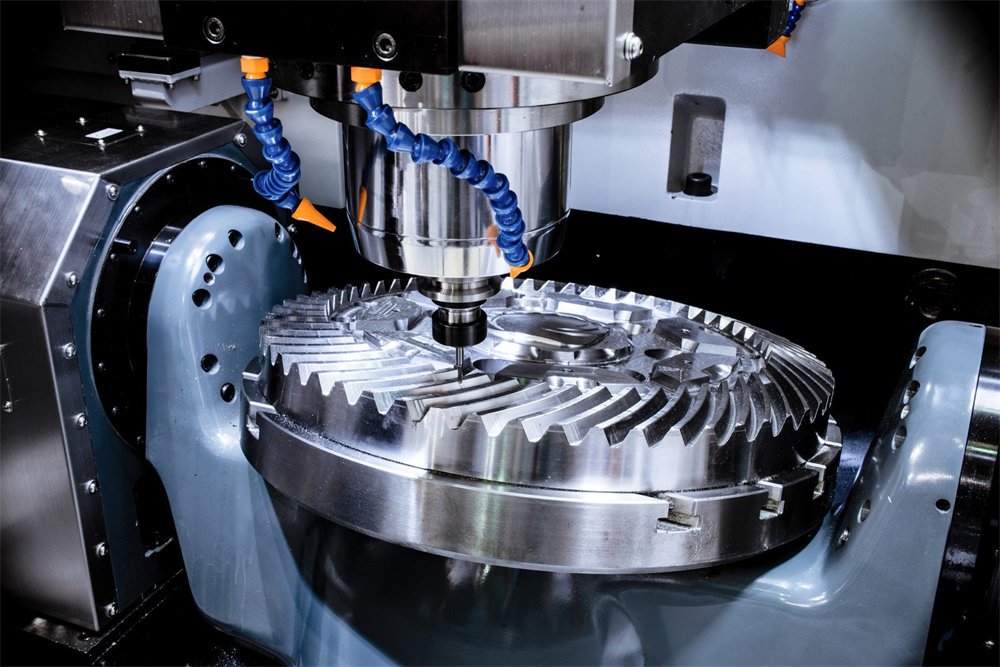

Why Are CNC Machining Centers Ideal for Mass Production?

Discover why CNC Machining Centers are the go-to solution for efficient mass production in manufacturing industries.

CNC Machining Centers are ideal for mass production due to their ability to perform multiple operations such as milling, drilling, and tapping in one setup, minimizing handling time and increasing precision and efficiency.

The Multifaceted Operations of CNC Machining Centers

CNC Machining Centers stand out in mass production because they seamlessly integrate various machining tasks into a single unit. They feature a tool magazine and an automatic tool changer (ATC), allowing them to perform diverse operations like milling, drilling, and boring6 without manual intervention. This automation reduces setup times and enhances throughput efficiency, essential for high-volume production.

Precision and Consistency in Mass Production

In mass production, achieving consistent quality across thousands of units is crucial. CNC Machining Centers excel in maintaining precision due to their computer-controlled processes, which minimize human error. They also ensure that each component produced adheres to exact specifications, which is vital for industries like automotive and aerospace where precision is non-negotiable.

Reduced Downtime and Increased Productivity

Another reason CNC Machining Centers are favored in mass production is their ability to reduce downtime. With the capability to handle various tasks without needing multiple machines, they save significant time on workpiece re-clamping and transfers7. This consolidation of processes means that once a workpiece is set up, it can undergo multiple operations in sequence without interruption, significantly boosting productivity.

| Feature | Benefit in Mass Production |

|---|---|

| Automatic Tool Changer (ATC) | Quick tool swaps without manual intervention |

| Multi-axis capabilities | Complex part machining in fewer setups |

| Integrated software controls | Precision and repeatability across large runs |

Versatility Across Industries

CNC Machining Centers are not just limited to one type of product or industry. They are versatile enough to be used in automotive, aerospace, electronics, and more8. This adaptability makes them an investment worth considering for manufacturers aiming to scale operations without compromising on quality or efficiency.

By incorporating CNC Machining Centers into their operations, manufacturers can realize significant cost savings and efficiency gains, positioning themselves competitively in the global market.

CNC Machining Centers reduce setup time by 50%.False

While CNC centers reduce setup time, the exact percentage varies.

CNC Machining Centers improve precision in mass production.True

They use computer controls to minimize human error, ensuring precision.

How Does CNC Laser Machining Revolutionize Precision Cutting?

Discover how CNC laser machining transforms precision cutting with unrivaled speed and accuracy.

CNC laser machining revolutionizes precision cutting by using a high-energy laser beam to achieve high-speed, high-accuracy cuts on both metal and non-metal materials. This method minimizes heat-affected zones, making it ideal for intricate designs and delicate materials.

The Science Behind CNC Laser Machining

CNC laser machining utilizes a focused beam of light to cut materials with incredible precision. This process involves directing a laser beam, which can reach extremely high temperatures, onto the material to melt, burn, or vaporize it. The high level of control over the laser allows for intricate designs and tight tolerances, making it an essential tool in industries where precision is paramount.

Applications Across Various Industries

Metal Fabrication

In the metal fabrication9 industry, CNC laser machines are employed to cut stainless steel, aluminum, and other metals with exceptional accuracy. The ability to cut complex shapes without the need for additional tooling significantly speeds up production times and reduces costs.

Electronics and Circuit Boards

CNC laser machining is critical in the electronics sector, particularly for cutting circuit boards. The precision of lasers allows for the creation of micro-sized components essential for modern electronic devices.

Benefits of Using CNC Laser Machining

High Precision and Speed

One of the primary advantages of CNC laser machining is its ability to perform high-speed operations while maintaining precision. This makes it suitable for mass production environments where time is of the essence.

Minimal Material Waste

The precise nature of laser cutting reduces material wastage. This efficiency not only lowers costs but also aligns with sustainable manufacturing practices.

Versatility in Material Handling

CNC laser machines are versatile enough to handle various materials, including metals, plastics, ceramics, and even glass. This versatility makes them invaluable across multiple sectors.

Challenges and Considerations

While CNC laser machining offers numerous advantages, it is essential to consider factors such as initial setup costs and maintenance. The technology requires skilled operators to manage complex programming and ensure optimal machine performance. Additionally, understanding the laser cutting process10 is crucial for achieving the best results.

Table: Comparison of CNC Laser Machining with Other CNC Technologies

| Feature | CNC Laser Machining | CNC Milling | CNC Plasma Cutting |

|---|---|---|---|

| Precision | High | Medium | Low |

| Speed | Fast | Moderate | Fast |

| Material Versatility | High | High | Medium |

| Initial Setup Cost | High | Moderate | Low |

| Heat-Affected Zone (HAZ) | Minimal | Moderate | Significant |

Exploring these facets of CNC laser machining reveals its transformative impact on precision cutting across diverse industries.

CNC laser machining reduces material waste significantly.True

Laser precision cuts minimize excess material, aligning with sustainability.

CNC laser machines are only used for metal cutting.False

They cut various materials, including plastics and ceramics.

Conclusion

Understanding the various types of CNC machines empowers you to choose the right tool for your projects. Reflect on their capabilities to ensure optimal performance and efficiency.

-

Learn how CNC lathes reduce waste and increase output.: Proper workpiece setup is the foundation of efficient machining. Ensure precise fixturing, alignment, and part placement. Accuracy here can … ↩

-

Discover how CAD/CAM boosts precision in CNC lathe operations.: Software integration in CNC machining enhances manufacturing efficiency, enabling you to machine parts faster, more accurately and precisely. ↩

-

Learn about materials CNC milling machines can effectively process.: What Materials Can Be Used in a CNC Machine? · Metals: Such as aluminum, brass or steel · Plastics: Such as Acetal (POM), Acrylics (PMMA), … ↩

-

Explore how CNC milling supports aerospace component production.: Other applications of aerospace CNC machining include cabin parts, wing ribs, fuselage components, actuators, motion controls, engine housings, … ↩

-

Understand the benefits of multi-axis machining in complex part creation.: Increased Part Accuracy. Multi-axis machining can produce complex parts in a single setup. · Optimized Production of Complex Parts. · Long Tool Lifespan. ↩

-

Explore the operations CNC Machining Centers can perform efficiently.: CNC drilling and CNC boring have some similarities, but they are not the same thing. Learn about the difference from JBC Machine. ↩

-

Learn how CNC reduces time spent on workpiece handling.: 1) The process positioning platform eliminates the need for table alignment and tool set in the x and y directions when installing the workpiece. ↩

-

Discover the variety of industries benefiting from CNC technology.: Discover the top industries using CNC machinery like medical, aerospace, and more. Learn about CNC material selection and custom components … ↩

-

Discover how CNC lasers enhance efficiency and precision in metal fabrication.: Design Versatility and Customization … The ability to coordinate the motion of two or more axes lets us do things that just weren’t possible before CNC. ↩

-

Learn the intricate steps involved in the CNC laser cutting process.: What is a CNC Laser Cutter? It is a piece of CNC equipment that uses a focused, high-powered laser beam to mark, cut, or engrave a material. ↩