Imagine wielding a tool that can slice through glass as effortlessly as a hot knife through butter. That’s the magic of laser cutting!

Laser cutting is an advanced, non-contact method that uses a focused beam to melt and evaporate glass at specific points, enabling precise cuts without physical contact. This method ensures smooth edges, minimal waste, and high precision, making it ideal for both artistic and industrial applications.

But understanding the basics is just the beginning! Join me as we dive deeper into the specific techniques and tools that can elevate your glass cutting projects.

Laser cutting glass reduces material waste significantly.True

Laser cutting uses precise beams, minimizing offcuts compared to traditional methods.

What Are the Key Benefits of Using Lasers for Glass Cutting?

Laser technology offers unparalleled precision and efficiency in glass cutting, setting new industry standards.

The main benefits of laser glass – cutting are high precision and quality. It can achieve micron – level accuracy and cut complex shapes. The edge is smooth with little internal damage. Moreover, it’s efficient. The cutting speed is fast and it’s easy to automate. It’s also flexible, suitable for various glasses and allows for easy adjustment during cutting.

Enhanced Precision and Clean Edges

One of the standout benefits of using lasers for glass cutting is the enhanced precision1 it offers. The laser beam is focused at a precise point, allowing for cuts with tolerances as fine as ±0.005 mm. This precision is crucial in industries where exact dimensions are required, such as in the production of optical lenses or intricate decorative pieces.

The non-contact nature of laser cutting ensures that the glass remains undisturbed during the process. This results in clean edges without the burrs or chips commonly associated with mechanical cutting methods. Such smooth finishes reduce the need for additional polishing, saving both time and resources.

Reduced Material Waste

Laser cutting’s precision also translates into reduced material waste. Traditional methods can lead to significant offcuts, but lasers use only the necessary amount of material for each cut. This efficiency not only conserves resources but also lowers production costs, an important consideration in mass manufacturing.

Moreover, because the process involves no physical blades or saws, there’s no risk of tool wear that could lead to inaccuracies over time. The consistent quality delivered by laser technology makes it a preferred choice for manufacturers aiming to maximize material utilization.

Environmental Benefits

The environmental advantages of laser cutting are noteworthy. Compared to conventional methods, laser cutting generates minimal waste and eliminates the need for water cooling, which can produce wastewater. This contributes to a more sustainable operation, aligning with growing environmental standards and regulations across industries.

Furthermore, laser technology reduces energy consumption during the cutting process. As industries move towards greener practices, these energy savings become increasingly valuable.

Versatility Across Applications

Lasers are highly versatile tools capable of handling a wide range of glass thicknesses—from delicate 0.1 mm sheets to robust 22 mm panels. This adaptability makes them suitable for diverse applications, from artistic endeavors to industrial uses.

For example, in the automotive industry2, lasers provide the precision needed for creating complex shapes in car windows and mirrors. Similarly, in architecture, laser-cut glass can add intricate designs to building facades without compromising structural integrity.

Overall, the key benefits of laser cutting in glass include unmatched precision, reduced waste, environmental sustainability, and versatility across various applications.

Laser cutting glass produces no waste.False

Laser cutting minimizes waste but does not eliminate it entirely.

Lasers cut glass with tolerances as fine as ±0.005 mm.True

Lasers offer high precision, crucial for exact dimensions in glass cutting.

How Does Laser Technology Compare to Traditional Glass Cutting Methods?

As industries evolve, the debate between laser and traditional glass cutting intensifies, sparking innovation and efficiency.

Laser technology surpasses traditional glass cutting by offering higher precision, reduced waste, and improved safety. Unlike mechanical methods, laser cutting is non-contact, preventing glass contamination and ensuring smoother edges. This makes it a superior choice for both intricate designs and industrial applications.

Precision and Quality

Traditional glass cutting often involves physical tools like diamond-tipped cutters or water jets. These methods rely on applying pressure to score and break the glass along a predefined line. While effective, they can lead to micro-cracks and uneven edges, especially in thicker glass.

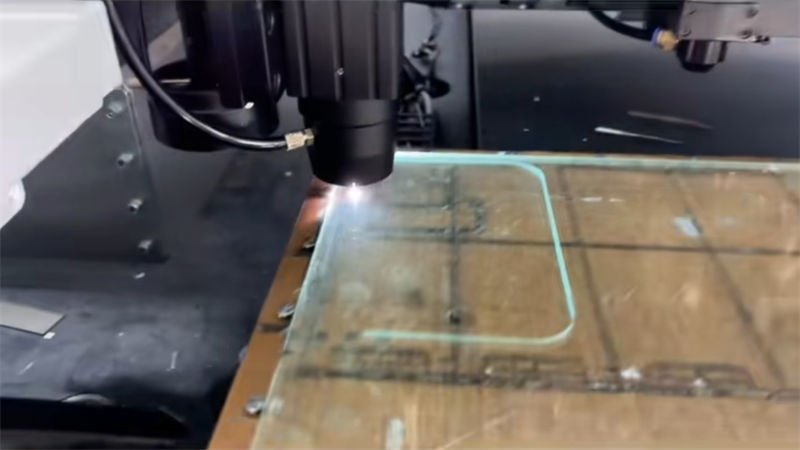

In contrast, laser technology uses a high-energy beam focused through an axicon prism to create a Bessel beam. This beam melts and vaporizes the glass at precise points without physical contact, resulting in smooth edges and minimal defects. The precision is unparalleled, with tolerances reaching up to ±0.005 mm. Such accuracy is particularly beneficial for applications requiring exact dimensions and flawless finishes.

Environmental Impact

Traditional cutting methods can generate significant material waste and often require lubricants or coolants, leading to wastewater emissions. Laser cutting significantly reduces these issues by eliminating the need for additional materials and minimizing waste through precise cuts.

Moreover, the environmental benefits3 of laser technology extend to lower energy consumption compared to some traditional methods. By reducing both material and energy waste, laser cutting supports sustainability goals.

Versatility and Applications

While traditional methods are limited by the thickness and type of glass, laser technology is versatile, handling glass thicknesses from 0.1 mm to 22 mm with ease. This flexibility allows for a broader range of applications, from artistic projects requiring intricate designs to industrial-scale production demanding rapid, consistent results.

For instance, laser technology applications4 include creating complex shapes or patterns on mirrors or glass panels without the risk of breaking or chipping the material.

Safety Considerations

Handling traditional glass cutting tools poses risks of cuts or injuries due to sharp edges or tool mishaps. Laser cutting, being non-contact, reduces the risk of operator injury significantly. However, it requires stringent safety measures like protective eyewear and proper ventilation to manage laser emissions effectively.

In conclusion, while traditional methods have served industries well, laser technology offers a superior alternative by enhancing precision, reducing waste, and improving safety across various applications.

Laser cutting reduces glass waste significantly.True

Laser cutting's precision minimizes material waste, unlike traditional methods.

Traditional glass cutting offers better safety than laser.False

Laser cutting is non-contact, reducing injury risks compared to traditional tools.

What Equipment Is Required for Laser Cutting Glass and Mirrors?

Discover the essential tools and technologies needed to master laser cutting for glass and mirrors.

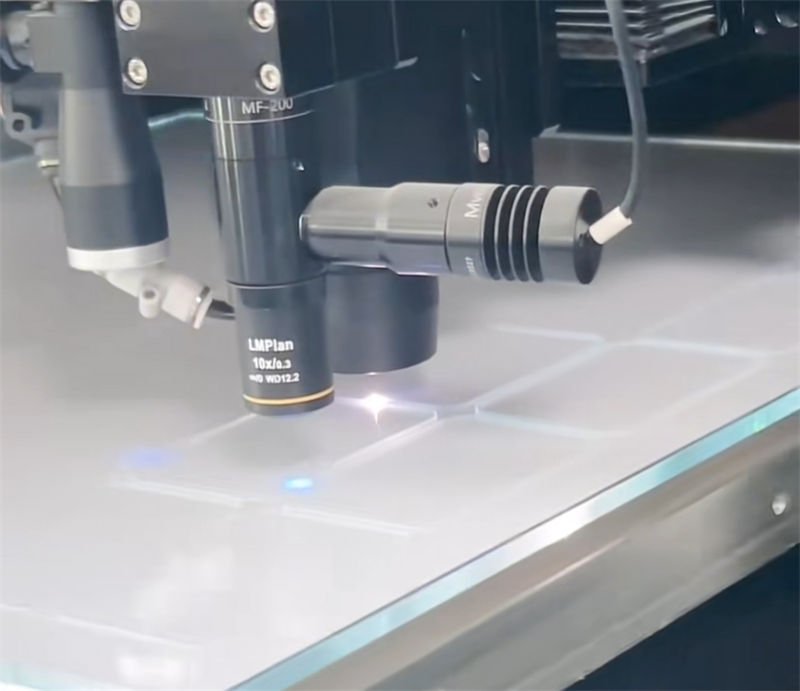

Essential equipment for laser cutting glass includes a laser machine with a Bessel cutting head, axicon prism, and double-star optical system. These components work together to focus the laser beam, allowing precise cuts with minimal waste and high-quality finishes.

Core Components of Laser Cutting Machines

Laser cutting glass and mirrors requires specialized equipment designed to handle the unique properties of these materials. The core components include:

-

Bessel Cutting Head: This is crucial as it transforms the laser into a Bessel beam. The Bessel beam is essential for creating precise cuts without physical contact, reducing the risk of cracks or imperfections.

-

Axicon Prism: The axicon prism plays a vital role in shaping the laser beam. It alters the beam into a non-diffractive Bessel form, focusing energy on a small point to cut through glass effectively.

-

Double-Star Optical System: This system ensures that the focused laser maintains its energy at the intersection point, crucial for achieving high precision and smooth edges on glass surfaces.

The Role of Laser Machines

Laser machines designed for glass cutting are equipped with features that optimize performance:

- Adjustable Power Settings: These allow for fine-tuning the laser’s intensity based on the glass’s thickness, which can range from 0.1 mm to 22 mm.

- Precision Control: High-precision control systems ensure tolerances as tight as ±0.005 mm, essential for intricate designs.

Environmental Considerations

One significant advantage of using laser cutting over traditional methods is its environmental benefits. Traditional methods often result in more waste and require additional finishing processes, which can be resource-intensive. In contrast, laser cutting minimizes material waste and eliminates the need for wastewater treatment associated with other methods.

To explore more on how laser technology outperforms traditional methods, you might want to check out this comprehensive guide5.

Advanced Automation Options

Modern laser cutters offer automation features that enhance efficiency:

- Automated Loading Systems: These systems reduce manual handling time and increase production speed.

- Software Integration: Advanced software solutions enable precise control over the cutting process, accommodating complex designs with ease.

For deeper insights into how automation can transform your laser cutting process, consider reading this article on automation in laser technology6.

A Bessel cutting head is crucial for laser cutting glass.True

It transforms the laser into a Bessel beam, enabling precise cuts.

Traditional glass cutting methods produce less waste than laser cutting.False

Laser cutting minimizes material waste compared to traditional methods.

What Challenges Might You Face When Cutting Glass with a Laser?

Laser cutting glass presents unique challenges that require careful consideration and expertise to overcome.

When using laser to cut glass, there are several challenges. Firstly, heat stress can cause cracks as glass is a poor heat conductor. Secondly, edge quality problems like micro – cracks and roughness may occur. Thirdly, different glass materials have various properties affecting the cutting. Lastly, precision control is difficult due to the laser beam width and high reflectivity of glass.

Thermal Stress and Fracturing

One of the primary challenges when cutting glass with a laser7 is managing thermal stress. As the laser heats the glass, it can cause uneven expansion and contraction, leading to fractures or breaks. This is especially problematic with thicker glass, where the heat may not dissipate evenly. To combat this, operators often use controlled cooling techniques or adjust the laser’s power settings to minimize thermal impact.

Edge Quality Concerns

While laser cutting provides smooth edges, achieving consistent edge quality can be difficult. Edge chipping or roughness may occur due to improper alignment or incorrect laser settings. Utilizing a Bessel beam, as mentioned in expert insights, can help focus the energy precisely, reducing the risk of poor edge quality. Regular calibration and maintenance of the laser equipment are crucial to maintaining optimal performance.

Material Limitations

The type of glass being cut also influences the challenges faced. For instance, tempered glass is more challenging to cut due to its inherent structural properties. Specialized techniques or equipment may be necessary to handle such materials effectively, increasing both the complexity and cost of the operation.

Equipment Complexity

Operating and maintaining laser cutting equipment can be complex and requires specialized knowledge. The setup involves adjusting multiple parameters such as beam focus, power output, and cutting speed. Mistakes in setup can lead to inefficient cuts or equipment damage. Training and experience are key to overcoming these challenges effectively.

Environmental and Safety Concerns

Laser cutting involves high energy levels that produce fumes and require proper ventilation. Additionally, the bright laser light poses potential hazards to operators’ eyes. Implementing safety measures, like using protective gear and ensuring adequate extraction systems, is vital for safe operation.

By understanding these challenges and adopting best practices, operators can optimize their processes and achieve high-quality results in laser glass cutting.

Thermal stress causes glass to fracture during laser cutting.True

Uneven heating leads to expansion and contraction, causing fractures.

Tempered glass is easier to cut with a laser than regular glass.False

Tempered glass's structural properties make it harder to cut.

Conclusion

In summary, laser cutting offers incredible precision and sustainability for glass projects. Embrace this technology to unlock new creative possibilities!

-

Learn about the precision capabilities lasers offer in glass cutting.: Laser cutting has allowed manufacturers to produce high-quality glass displays rapidly, resulting in lower costs and even lower defect rates. … ↩

-

Discover how lasers enhance glass cutting in automotive design.: In the automotive industry, laser cutting is used for shaping glass components, ensuring exact fit and finish. Laser technology’s ability to … ↩

-

Discover how laser cutting promotes eco-friendliness over traditional methods.: While laser cutting reduces material waste compared to traditional cutting methods, some scrap and offcuts are inevitable in the production process. ↩

-

Explore diverse and creative uses of laser cutting in various sectors.: Nowadays, with the improvement of the laser technology, laser can realize more and more functions, such as precision drilling, fine cutting, selective material … ↩

-

Learn about the efficiency and precision of laser cutting.: The most efficient laser-based kerf-less methods are the controlled fracture technique [1] and glass scribing by introducing intra-volume voids, … ↩

-

Discover how automation enhances efficiency in laser cutting.: Automate your TruLaser laser cutting machine. For this, TRUMPF offers you a wide selection of modular components. ↩

-

Learn about managing thermal stress during laser glass cutting effectively.: Thermal stress analysis based on three different types of glasses revealed that stress generated by laser heating is highly correlated to thermal expansion … ↩