Are you considering investing in a CNC milling machine but unsure about the cost? You’re not alone.

The cost of a CNC milling machine can range from $6,000 for basic models to over $100,000 for advanced units. Factors such as machine size, brand, and features significantly influence the price. Researching these aspects will help you budget effectively.

While this gives a general idea of the price spectrum, understanding what drives these costs is key. Let’s delve deeper into the specifics of different types of CNC milling machines, the features that affect their prices, and how to choose the right one for your needs.

CNC milling machines can cost over $100,000.True

Advanced CNC milling machines with enhanced features can exceed $100,000.

What Factors Influence CNC Milling Machine Prices?

Curious about what affects the pricing of CNC milling machines? Let’s break it down.

CNC milling machine prices are primarily influenced by factors such as machine type, size, brand, and features. The complexity of the machine’s capabilities, materials used in construction, and technological advancements also play crucial roles. Understanding these elements can guide you in making an informed purchasing decision.

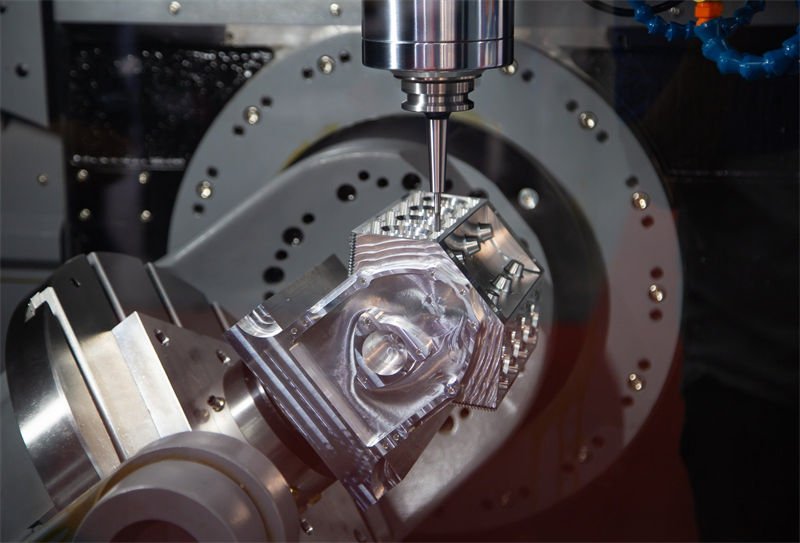

The Type of CNC Milling Machine

Different types of CNC milling machines come with varying price tags. For instance, vertical machining centers tend to be more affordable compared to horizontal ones due to their simpler design and fewer moving parts. Gantry-style machines, used for larger projects, are generally on the higher end of the price scale.

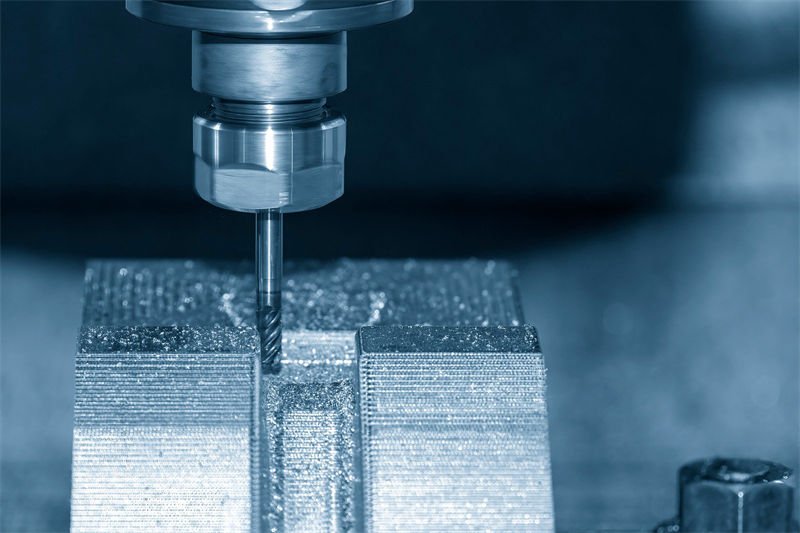

Size and Capacity

The physical size and operational capacity of the machine significantly impact its cost. Larger machines that can handle bigger workpieces naturally require more materials and stronger structural components, which increases their cost. For example, a small CNC milling machine like the Wanhui small CNC milling machine 7124/71261 is priced around $9,413.66, while larger models can exceed $50,000.

Brand and Manufacturer

Brand reputation plays a pivotal role in pricing. Established brands with a history of reliability and quality often command higher prices. For instance, machines from well-known manufacturers like Haas or Mazak are typically more expensive than lesser-known brands due to their proven track record and customer service support.

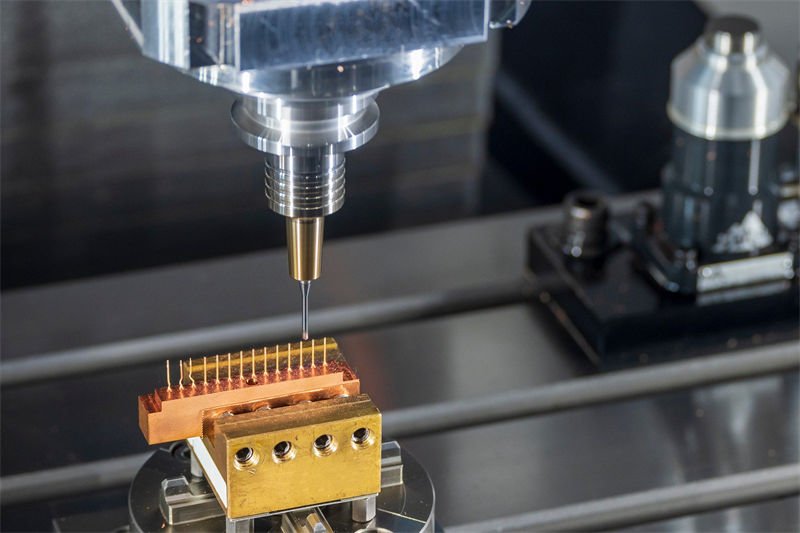

Features and Technology

Modern CNC milling machines come equipped with various features such as automatic tool changers, advanced software, and high-speed spindles. These add-ons can significantly increase the cost. A machine with a higher spindle speed or better positioning accuracy will usually cost more.

| Feature | Impact on Price |

|---|---|

| Automatic Tool Changer | Increases cost due to complexity |

| High-Speed Spindle | More expensive because of advanced engineering |

| Enhanced Software | Leads to higher prices for better control and precision |

Material Quality and Durability

The materials used in constructing the machine influence its longevity and cost. Machines built with higher-grade metals or featuring protective coatings will last longer but come at a premium price. For instance, a high-rigidity VMC1050 machining center2 costs more due to its robust construction.

Understanding these factors will help you determine the right CNC milling machine that meets your specific needs without overspending. Consider what features are essential for your operations and how much you’re willing to invest in long-term durability and performance.

Vertical CNC machines are pricier than horizontal ones.False

Vertical CNC machines are typically cheaper due to simpler design.

Brand reputation affects CNC milling machine prices.True

Established brands often command higher prices due to reliability.

How Do Different Types of CNC Milling Machines Compare?

Are you wondering which CNC milling machine best suits your needs? The variety can be overwhelming!

CNC milling machines vary by type, including vertical, horizontal, and gantry models, each offering unique advantages. Vertical mills are versatile and compact, while horizontal mills provide greater strength and rigidity. Gantry mills are ideal for large-scale projects. Choosing the right type depends on your specific manufacturing needs.

Vertical vs. Horizontal CNC Milling Machines

Vertical CNC milling machines are often the go-to choice for those seeking versatility and a compact footprint. They are particularly effective for smaller workpieces and intricate designs. A standout feature is their ease of use, which makes them ideal for beginners.

Horizontal CNC milling machines, on the other hand, are known for their strength and rigidity. These machines excel in cutting harder materials and handling larger workpieces due to their robust design. Their layout allows for longer tool life and higher precision in certain tasks.

Gantry CNC Milling Machines

When it comes to large-scale manufacturing, gantry CNC milling machines are unmatched. Their design supports the machining of very large and heavy workpieces without compromising precision. These machines are commonly used in industries like aerospace and shipbuilding, where large component fabrication is frequent.

Comparing Features and Costs

| Machine Type | Typical Price Range | Key Features |

|---|---|---|

| Vertical | $6,000 – $50,000 | Compact, versatile, user-friendly |

| Horizontal | $20,000 – $80,000 | Strong, durable, precise |

| Gantry | $50,000 – $200,000+ | Large-scale, high capacity |

When comparing CNC milling machines3 based on type, it’s essential to consider the features that most closely align with your needs. A vertical mill may be more budget-friendly for hobbyists or small businesses, while a horizontal mill might be better suited for manufacturing that requires heavy-duty capabilities.

Advanced Features and Customization

The cost of a CNC milling machine also correlates with additional features like automatic tool changers, cooling systems, and advanced software integration. Machines with these features can command higher prices but offer increased efficiency and productivity.

Choosing a machine with the right combination of features and cost will depend on the specific demands of your production processes. Consider consulting industry experts or peers to gain insights into the best CNC milling solutions4 for your operation.

Vertical CNC mills are ideal for large-scale projects.False

Gantry CNC mills, not vertical, are suited for large-scale projects.

Horizontal CNC mills offer greater strength than vertical mills.True

Horizontal mills are known for their strength and rigidity.

Are There Hidden Costs in Owning a CNC Milling Machine?

Investing in a CNC milling machine involves more than just the initial purchase price. Uncover the hidden costs.

Hidden costs of owning a CNC milling machine include maintenance, tooling, software updates, and training. Regular upkeep is essential to ensure optimal performance, while tooling and software updates maintain efficiency. Training helps operators maximize machine capabilities, which can incur additional expenses.

Maintenance and Upkeep Costs

Purchasing a CNC milling machine is just the beginning. Regular maintenance5 is crucial to keeping the machine in peak condition, which can add up over time. This includes periodic servicing, part replacements, and potential repairs. For instance, the cost of replacing worn-out components can range from hundreds to thousands of dollars annually. Establishing a maintenance schedule can help mitigate unexpected downtimes and extend the machine’s lifespan.

Tooling and Accessories

Beyond the machine itself, you’ll need an array of tooling and accessories. These can be expensive depending on the material and complexity of the tools. For example, high-quality end mills and cutting tools are essential for precision but can significantly add to your budget. Additionally, specialized fixtures or jigs might be necessary depending on your production requirements.

Software Updates and Licensing

CNC machines often rely on sophisticated software for operation. Regular software updates6 are necessary to improve functionality and security, but they may come at a cost. Some manufacturers require annual licensing fees to keep the software up-to-date, which is an essential consideration when budgeting for operational costs.

Training and Skilled Labor

Operating a CNC milling machine effectively requires skilled labor. Investing in training7 programs ensures that operators can fully utilize the machine’s capabilities, minimizing waste and maximizing productivity. While initial training is crucial, ongoing education can help keep operators informed about the latest technologies and techniques.

Energy Consumption

CNC milling machines consume considerable amounts of energy. Calculating the energy costs based on your expected usage can provide a clearer picture of long-term expenses. Energy-efficient models may offer savings over time, but it’s vital to weigh these against their initial higher costs.

Understanding these hidden costs will enable you to make an informed decision when purchasing a CNC milling machine. By considering these factors early on, you can better prepare for future expenses and ensure a smoother ownership experience.

Maintenance costs are negligible for CNC machines.False

Regular maintenance is crucial and can be costly over time.

Software updates for CNC machines are free.False

Software updates often require licensing fees, adding to costs.

Is It Better to Buy New or Used CNC Milling Machines?

Deciding between a new or used CNC milling machine can be challenging, but understanding the pros and cons helps.

Choosing between a new or used CNC milling machine depends on budget, technology needs, and operational requirements. New machines offer advanced technology and reliability but at a higher cost, while used machines are more affordable but may come with hidden maintenance issues.

Advantages of Buying a New CNC Milling Machine

Purchasing a new CNC milling machine means investing in the latest technology, which often translates to enhanced precision, speed, and efficiency. New models also come with the benefit of manufacturer warranties and customer support, ensuring peace of mind and reduced downtime.

For businesses prioritizing cutting-edge technology and reliability, a new machine might be worth the investment. For instance, the VMC650 vertical machining center small three-axis linear rail comes with high precision and rigidity, making it suitable for intricate tasks requiring absolute accuracy.

Pros and Cons of Purchasing a Used CNC Milling Machine

Buying a used CNC milling machine can significantly reduce upfront costs, often allowing businesses to acquire models they might not afford new. For example, the used Taiwan Gaoming 3-meter CNC gantry milling machine is available at a fraction of the price of a new unit.

However, it’s crucial to consider potential drawbacks. Used machines may lack the latest features and could have unseen wear that might lead to increased maintenance costs. It’s wise to conduct thorough inspections and possibly involve a professional before purchase.

Key Considerations in Making Your Decision

When deciding between new and used, consider these factors:

| Factor | New Machines | Used Machines |

|---|---|---|

| Cost | Higher initial investment | Lower upfront cost |

| Technology | Latest advancements | Possibly outdated |

| Warranty & Support | Manufacturer warranty and support | Limited or no warranty |

| Maintenance | Minimal initially | Potentially higher over time |

Ultimately, whether to choose a new or used CNC milling machine depends on your specific needs and financial capacity. If budget constraints are significant, researching used CNC machine evaluations8 could provide insight into viable options. Alternatively, if long-term reliability is paramount, investing in a new machine might prove beneficial in the long run.

New CNC machines have higher initial costs.True

New machines are more expensive due to advanced technology and warranties.

Used CNC machines always come with a warranty.False

Used machines may not have a warranty, increasing risk of maintenance costs.

Conclusion

In conclusion, understanding CNC milling machine costs involves evaluating your needs and budget. By comparing options and considering additional costs, you can make a well-informed decision that supports your goals.

-

Explore user feedback on this affordable CNC machine model.: The machine’s a pretty solid piece of work for what you pay for it. It’s nowhere near as plug-and-play as a cheap 3D printer, and it’s definitely a bit hands … ↩

-

Discover why this model is considered high-rigidity and durable.: Product Details ; Max. worktable load, kg, 500 ; T slot(number-width-pitch), 5-18×100 ; Max. spindle speed, rpm, 1-8000 ; Spindle taper, mm, BT40 ; Main motor power … ↩

-

Explore various types of CNC mills to understand their specific applications.: Learn the basics of the CNC milling machine process and how different types of cnc machines are used to produce various components. ↩

-

Find tailored solutions that enhance CNC milling efficiency.: The Best Desktop CNC Milling Machines · PCNC 440 CNC Mill · Pocket NC — Penta Machine Co. · Bantam Tools Desktop CNC Milling Machine · Snapmaker 2.0 Modular 3-in-1. ↩

-

Explore maintenance schedules to ensure optimal CNC machine performance.: After every six months or 1000 hours of use, the machines will need professional care from Flint Machine. Make sure you get the following maintenance services:. ↩

-

Learn the benefits of regular software updates for CNC machines.: Updating CNC controller software ensures access to the latest features and optimizations, improving toolpath algorithms and CAD/CAM integration. ↩

-

Discover why operator training is crucial for CNC machine efficiency.: Gain the skills and knowledge needed to pursue a career as a CNC technician. · Learn from instructors who have years of real-world experience. ↩

-

Understand the potential risks and benefits of buying used machines.: The average selling price of a Horizontal Machining Center is around $80,000. Year – The newer the better, especially when it comes to CNC … ↩