Choosing the right laser cutter isn’t just a decision; it’s a game changer in your manufacturing journey!

CO2 and fiber laser cutters differ primarily in their laser generation methods, wavelength, material compatibility, speed, precision, energy efficiency, maintenance needs, cost, and lifespan. CO2 lasers excel with non-metals, while fiber lasers are ideal for metals, especially reflective ones.

But this is just the tip of the iceberg! Let’s explore the nuanced benefits and challenges of each type to find out which one truly suits your unique needs.

Fiber lasers are more energy-efficient than CO2 lasers.True

Fiber lasers convert 30-40% of power into laser light, while CO2 only 10-20%.

How Do CO2 and Fiber Lasers Generate Their Beams?

Understanding how CO2 and fiber lasers generate their beams reveals their unique applications and efficiencies.

CO2 lasers generate beams using a gas-filled tube with carbon dioxide, while fiber lasers utilize solid-state technology involving fiber optic cables doped with rare earth elements. These fundamental differences dictate their operational capabilities and suitable applications in industrial processes.

CO2 Laser Beam Generation

CO2 lasers produce beams through a gas laser technology1 process, where carbon dioxide gas is the primary medium. The mechanism involves a gas-filled tube, typically containing CO₂ along with auxiliary gases like nitrogen and helium. This mixture is subjected to high voltage, causing ionization, which forms plasma. Within this plasma, carbon dioxide molecules are excited to higher energy levels by electrical discharge.

Once excited, the carbon dioxide molecules undergo energy level transitions. As they return to their ground state, they release photons in the form of a laser beam. This beam has a characteristic wavelength of 10.6 micrometers, making it suitable for materials like wood, acrylic, and plastics.

The complexity of this process involves precise control over the gas mixture and the high-voltage excitation system. Regular maintenance is required to ensure optimal performance, including replacing gases and aligning mirrors.

Fiber Laser Beam Generation

On the other hand, fiber lasers utilize a solid-state technology2 approach. Here, the beam generation occurs within optical fibers doped with rare earth elements such as ytterbium or erbium. The process begins with a semiconductor laser acting as a pump source that injects light into these optical fibers.

Inside the fibers, the light interacts with rare earth ions, exciting them to higher energy levels. This excitation leads to stimulated emission as these ions return to lower energy states, amplifying the laser beam within the fiber. The resulting beam, typically around 1.064 micrometers in wavelength, is highly efficient for cutting metals, especially reflective ones like copper and aluminum.

Fiber laser technology is noted for its high energy efficiency and minimal maintenance needs due to fewer moving parts and no necessity for gas refills. The light amplification within fibers offers a compact and stable design compared to CO2 lasers.

Comparative Table: CO2 vs. Fiber Laser Generation

| Feature | CO2 Laser | Fiber Laser |

|---|---|---|

| Medium | Gas (CO₂, N₂, He) | Optical Fiber Doped with Rare Earth Elements |

| Excitation Method | Electrical Discharge | Semiconductor Pump Source |

| Wavelength | 10.6 micrometers | ~1.064 micrometers |

| Material Suitability | Non-metals (wood, acrylic) | Metals (copper, aluminum) |

| Efficiency | Moderate (10-20% conversion) | High (30-40% conversion) |

| Maintenance | Regular gas replacement and mirror alignment | Minimal due to solid-state design |

Understanding these fundamental generation methods highlights why each laser type excels in different applications, influencing their use in various industrial sectors.

CO2 lasers use a gas-filled tube for beam generation.True

CO2 lasers generate beams using a gas-filled tube containing CO₂.

Fiber lasers require regular gas replacement for operation.False

Fiber lasers use solid-state technology, not requiring gas refills.

Which Materials Are Best Cut by CO2 vs. Fiber Lasers?

Choosing the right laser cutter material compatibility is crucial for achieving optimal results.

CO2 lasers are ideal for cutting non-metallic materials such as wood, acrylic, and plastics, while fiber lasers excel at cutting metals, particularly reflective ones like aluminum and copper. Each type of laser cutter offers distinct advantages depending on the material’s properties and desired precision.

Understanding Material Compatibility with Laser Types

When selecting a laser cutter, understanding the interaction between the laser and the material is essential. CO2 and fiber lasers operate on different principles and wavelengths, influencing their effectiveness with various materials.

CO2 Lasers: The Non-Metal Experts

CO2 lasers are particularly effective for non-metallic materials due to their longer wavelength (10.6 micrometers), which is absorbed efficiently by organic compounds. This makes them perfect for cutting and engraving:

- Wood: Achieves clean cuts and detailed engravings, making it suitable for furniture and decorative items.

- Acrylic: Produces polished edges without additional finishing, ideal for signage and displays.

- Plastics: Capable of cutting a wide range of plastic types with precision, used in packaging and automotive components.

The capability to process thick materials further enhances the versatility of CO2 lasers in industries relying on non-metallic substrates.

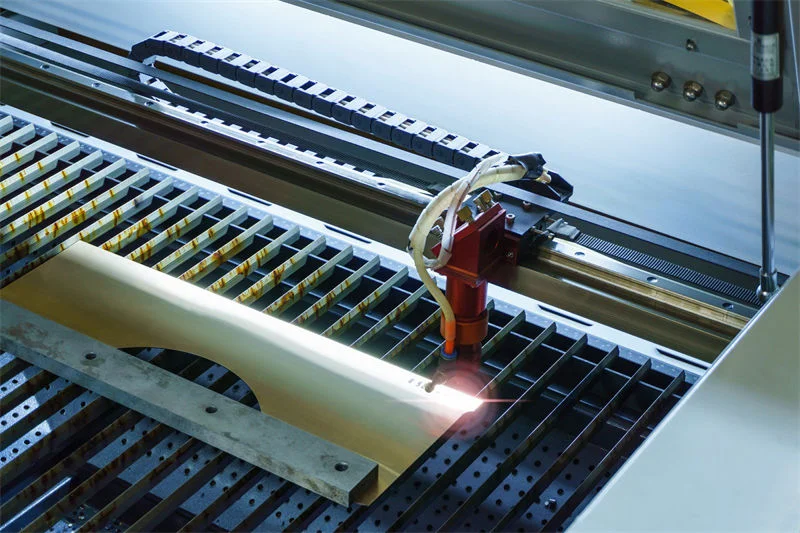

Fiber Lasers: Masters of Metal

Fiber lasers operate at a shorter wavelength (around 1.064 micrometers), allowing them to focus energy more intensely on metal surfaces. They excel at cutting:

- Aluminum: The high reflectivity of aluminum poses challenges for other lasers, but fiber lasers handle it efficiently, crucial for aerospace and automotive sectors.

- Copper: Known for its conductivity, copper is cut cleanly by fiber lasers, benefiting electrical and electronic applications.

- Stainless Steel: With high precision, fiber lasers are widely used in manufacturing medical devices and kitchen equipment.

Fiber lasers’ ability to maintain precision on thin metals makes them indispensable in high-tech industries.

Comparing Cutting Efficiency and Quality

| Material | CO2 Laser Efficiency | Fiber Laser Efficiency | Quality Considerations |

|---|---|---|---|

| Wood | High | Low | Smooth edges, no burn marks |

| Acrylic | High | Low | Polished finish |

| Plastics | High | Moderate | Minimal melting |

| Aluminum | Low | High | Minimal burrs |

| Copper | Low | High | Precision cuts |

| Stainless Steel | Low | High | Clean cuts, minimal dross |

Both laser types offer unique advantages depending on the application requirements. Evaluating material types alongside other factors like thickness and desired quality will guide you in choosing the appropriate laser cutter for your needs.

For further insights on enhancing your laser cutting processes, explore resources that detail cutting techniques3 and material handling4.

CO2 lasers are best for cutting metals.False

CO2 lasers are better for non-metallic materials like wood and acrylic.

Fiber lasers excel at cutting aluminum.True

Fiber lasers handle reflective metals like aluminum efficiently.

What Are the Cost Implications of Each Laser Cutter?

Understanding the cost implications of laser cutters is crucial for budget planning and operational efficiency.

CO2 lasers generally have lower initial costs but higher operating expenses due to energy consumption and maintenance. In contrast, fiber lasers demand a higher upfront investment but benefit from reduced operational costs, attributed to greater energy efficiency and minimal maintenance needs.

Initial Investment Costs

When considering the purchase of a laser cutter, the initial investment is a primary concern. CO2 laser cutters typically come with a lower price tag, making them attractive for businesses with limited budgets. However, the technological advancements and efficiency of fiber lasers mean they often carry a higher initial cost. This price difference is largely due to the advanced components and sophisticated technology embedded in fiber lasers.

| Type of Laser Cutter | Typical Initial Cost Range |

|---|---|

| CO2 Laser Cutter | $10,000 – $50,000 |

| Fiber Laser Cutter | $20,000 – $100,000 |

Operating Costs

Operating costs are another critical factor in assessing laser cutter expenses. CO2 lasers generally incur higher operating costs due to their energy consumption and maintenance requirements. They require regular refills of gases such as carbon dioxide, nitrogen, and helium. Additionally, CO2 lasers have a lower electro-optical conversion efficiency of about 10-20%, leading to increased power usage.

In contrast, fiber lasers boast an electro-optical conversion efficiency of 30-40%. This translates to lower electricity consumption and reduced utility bills. Moreover, fiber lasers demand less auxiliary gas, further decreasing operational expenses.

Maintenance Expenses

Maintenance is an ongoing cost that can significantly impact the overall expense of laser cutters. CO2 laser systems require frequent maintenance due to their complex structure involving gas and mirrors that need alignment. Regular inspection and replacement of gases are necessary to maintain performance.

Fiber lasers, with fewer moving parts and no gas system, have simpler maintenance requirements. Their design minimizes wear and tear, thus reducing maintenance frequency and associated costs.

Lifespan Considerations

The lifespan of laser cutters also plays a role in cost implications. Fiber lasers tend to offer a longer operational lifespan, often exceeding 25,000 working hours, compared to CO2 lasers. This extended lifespan implies fewer replacements over time, thereby impacting long-term financial planning.

Total Cost of Ownership

When evaluating the total cost of ownership (TCO), businesses must consider both initial and operational costs over the machine’s lifespan. While CO2 lasers may appear more affordable initially, the cumulative operating and maintenance expenses can surpass the initial savings. Conversely, despite their higher upfront cost, fiber lasers can prove more economical in the long run due to their efficiency and longevity.

Understanding these cost factors enables businesses to make informed decisions that align with their financial goals and production needs. For more on understanding laser cutter maintenance5 protocols or exploring energy-efficient machinery6, delve into specialized resources tailored to your industry needs.

Fiber lasers have lower operational costs than CO2 lasers.True

Fiber lasers have higher energy efficiency and less maintenance needs.

CO2 lasers require more frequent maintenance than fiber lasers.True

CO2 lasers have complex systems needing regular gas refills and alignments.

How Do Maintenance Requirements Compare Between CO2 and Fiber Lasers?

Regular maintenance is crucial for keeping laser cutters efficient and cost-effective.

Fiber lasers require less maintenance than CO2 lasers, primarily due to their fewer moving parts and lack of gas systems. CO2 lasers need frequent mirror alignments, gas refills, and component cleaning, making their upkeep more complex and time-consuming.

Comparing Maintenance Complexity

CO2 Laser Maintenance:

- Gas System Management: CO2 lasers rely on a gas-filled tube that requires regular monitoring and refilling of gases like carbon dioxide, nitrogen, and helium.

- Optical Alignment: Frequent adjustments of mirrors are necessary to maintain optimal laser paths and output efficiency.

- Component Aging: Components such as discharge tubes may wear out over time and need replacement or repair.

Fiber Laser Maintenance:

- Simplified Structure: Lacking a gas system, fiber lasers have fewer components that require regular checks.

- Minimal Optical Adjustments: Fiber optics eliminate the need for frequent mirror alignments.

- Basic Cleaning Needs: Routine cleaning of lenses and fiber couplers to prevent dust accumulation is usually sufficient.

Cost Implications of Maintenance

The maintenance costs between these two types of lasers can differ significantly. CO2 laser maintenance7 involves consumables like gases and more frequent servicing, which can quickly add up. Conversely, fiber lasers8 tend to have lower ongoing costs due to their higher efficiency and minimal maintenance needs.

| Aspect | CO2 Lasers | Fiber Lasers |

|---|---|---|

| Gas Management | Regular refilling required | Not applicable |

| Mirror Alignment | Frequent | Rarely needed |

| Component Wear | High due to gas exposure | Low due to solid-state design |

| Cleaning Frequency | Regular for optimal performance | Periodic, less frequent |

Implications for Operational Downtime

Frequent maintenance for CO2 lasers can lead to increased downtime, affecting productivity. Exploring efficient maintenance strategies9 can help minimize these interruptions. Fiber lasers, on the other hand, benefit from fewer maintenance-related disruptions, allowing for more continuous operation and reduced downtime impacts10.

Fiber lasers require fewer optical adjustments than CO2 lasers.True

Fiber lasers use fiber optics, eliminating frequent mirror alignments.

CO2 lasers have lower maintenance costs than fiber lasers.False

CO2 lasers incur higher costs due to gas refills and frequent servicing.

Conclusion

Deciding on a laser cutter? Reflect on your materials, budget, and operational requirements to find the best fit for your projects.

-

Learn how gas mixtures affect CO2 laser efficiency.: Carbon-dioxide lasers are the highest-power continuous-wave lasers that are currently available. They are also quite efficient. ↩

-

Discover the role of rare earth elements in fiber lasers.: Fiber lasers are a special form of solid-state lasers, often having attractive features such as high output power in combination with high beam quality. ↩

-

Learn advanced techniques to improve laser cutting efficiency.: 1. High Laser Power One of the easiest ways to improve the laser cutting quality is to use high laser power. ↩

-

Explore methods for better handling materials during laser cutting.: Modern material handling systems can help metal fabricators keep up with the cutting prowess of high-powered lasers. ↩

-

Gain insights into effective maintenance strategies for prolonging laser cutter lifespan.: You should do the laser machine maintenance tasks, including cleaning and checking the lens and mirrors. In addition, you should also check the … ↩

-

Discover how energy-efficient machines can reduce long-term operational costs.: Industrial fiber laser with 5’x10′ table. Cuts steel, brass, aluminum. Power from 1000W to 2000W. ↩

-

Understand why CO2 lasers incur higher ongoing maintenance costs.: When it is dead, depending on manufacturer the tube can cost anywhere from 100$ onwards (in Chinese lasers, depending on Wattage of the tube) to … ↩

-

Discover why fiber lasers are easier and cheaper to maintain.: Three months maintenance of fiber laser cutting machine. It is recommended to maintain and maintain the voltage stabilizer every three months. ↩

-

Learn strategies to reduce downtime from CO2 laser maintenance.: Good CO2 laser maintenance boils down to keeping the machine clean. This includes the beam path and cooling system. ↩

-

Explore how fiber lasers minimize downtime with simpler maintenance.: There are many benefits to performing preventative maintenance on laser-cutting machines. Keeping up with maintenance increases the longevity of … ↩