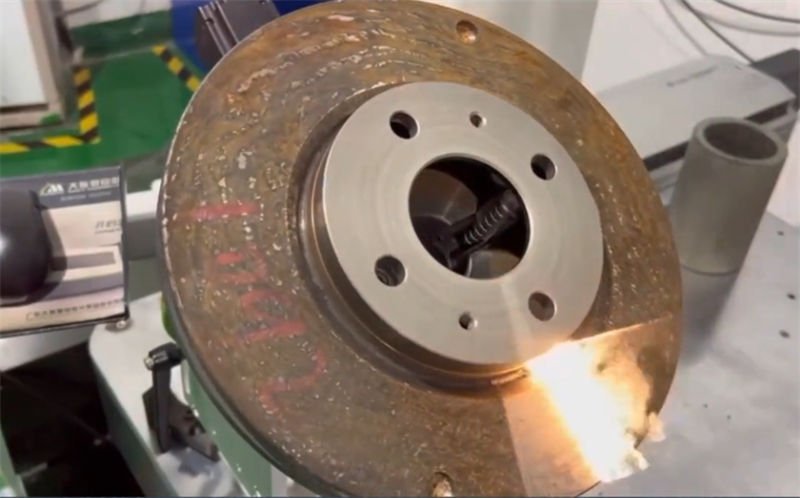

Ever wondered why China’s laser cleaning machines are catching everyone’s eye? Let’s dive in!

Chinese laser cleaning machines stand out due to their affordability, cutting-edge technology, and versatile applications. They are often equipped with the latest innovations, making them ideal for a range of industrial cleaning tasks. Their competitive pricing and quality make them a top choice worldwide.

I remember the first time I heard about these machines from a friend who runs a small factory. He was raving about the savings and efficiency he gained after switching to a Chinese model. The blend of advanced tech and reasonable costs seemed almost too good to be true.

So, what exactly sets these machines apart? For starters, their price-to-performance ratio is hard to beat. Unlike some of the pricier European models, Chinese machines offer similar, if not better, capabilities without breaking the bank. Plus, they come with diverse applications—from rust removal to paint stripping—which is a game-changer for many businesses looking to streamline operations.

It’s this combination of innovation and affordability that makes these machines not just tools but strategic assets for businesses worldwide. Whether you’re in manufacturing, restoration, or even small-scale maintenance work, these machines can significantly elevate your operations.

Chinese laser cleaners are the most affordable globally.True

China offers competitive pricing due to lower production costs.

Chinese laser cleaners lack technological innovation.False

Chinese machines are known for cutting-edge technology advancements.

How Do Chinese Laser Cleaning Machines Compare to European Models?

Choosing between Chinese and European laser cleaning machines feels like standing at a crossroad, each path leading to unique advantages.

Chinese laser cleaning machines are more affordable and accessible, while European models boast advanced technology and precision. Opt for Chinese models for cost-effectiveness, and European ones for cutting-edge performance.

Cost and Affordability

You know that moment when you’re shopping for a big-ticket item, like a car, and you find yourself weighing the cost against the features? That’s exactly how I felt when comparing Chinese laser cleaning machines1 and European laser cleaning machines. Chinese machines often come with a lower price tag, which makes them incredibly appealing if you’re like me and always have an eye on those profit margins. It’s like finding a great deal at your favorite store.

In contrast, European models often come at a premium. This higher cost is attributed to superior build quality and cutting-edge technologies integrated into the machines. It’s akin to investing in a luxury vehicle that promises both performance and longevity.

| Feature | Chinese Models | European Models |

|---|---|---|

| Price | Lower | Higher |

| Build Quality | Standard | Premium |

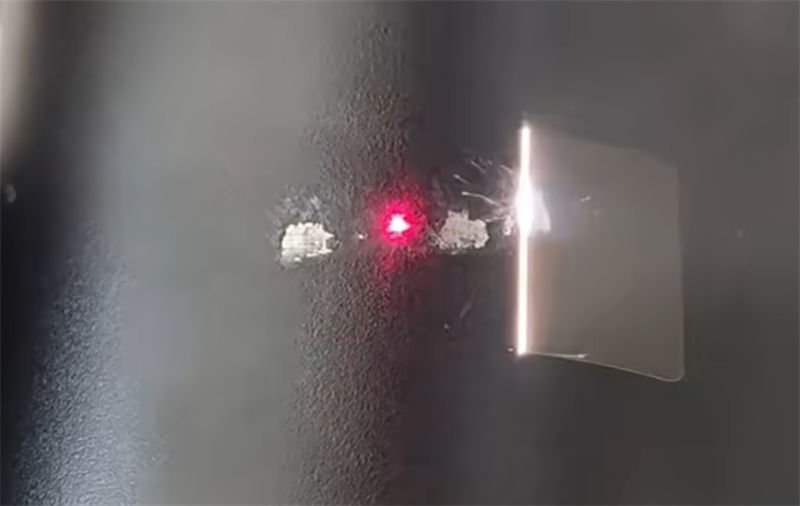

Technology and Innovation

Now, let’s talk tech! European manufacturers are renowned for their innovative laser technologies2, often incorporating the latest advancements in precision and efficiency. These machines are ideal for applications that demand high accuracy and reliability.

Meanwhile, Chinese models are catching up fast, offering competitive features with each new release. It’s exciting to see how they’re evolving.

Market Access and Support

For folks like Alexander, who need timely shipments, Chinese machines are a dream come true due to quicker access through direct channels like Alibaba. However, if you’re someone like Terasa, prioritizing long-term reliability, the comprehensive support from European companies can be a game-changer.

Environmental Impact and Efficiency

I’ve noticed both regions take environmental standards seriously. Yet, European models often lead the pack with energy efficiency due to stringent regulations. If you’re environmentally conscious, this might tip the scales for you.

| Aspect | Chinese Models | European Models |

|---|---|---|

| Environmental Impact | Improving | Leading |

| Energy Efficiency | Good | Excellent |

In the end, choosing between these machines is all about aligning with what matters most to you—whether it’s cost, technology, or sustainability. Each option has its charm, just like picking between two equally delicious desserts! Align your choice with your business needs3.

Chinese laser machines are more affordable than European models.True

Chinese machines have lower production costs, reducing their price.

European laser machines lack technological innovation.False

European models are known for cutting-edge technology and precision.

How Are Chinese Manufacturers Innovating in Technology?

Ever wondered how China became the innovation powerhouse it is today? Their technological strides are reshaping industries globally, and it’s fascinating to see how these advancements impact our everyday lives.

Chinese manufacturers are at the forefront of technological innovations, offering AI-driven automation, IoT integration, and green energy solutions that boost efficiency and sustainability globally, establishing China as a leader in manufacturing technology.

AI-Driven Automation

Imagine walking through a factory where machines almost seem to think for themselves. That’s the magic of AI-driven automation4 in Chinese manufacturing. A friend of mine, who works with a tech company, once shared how their entire production line was transformed by AI. What used to take hours of manual labor is now done with precision and speed, saving both time and money. These advanced algorithms optimize processes, ensuring top-notch quality while cutting down on labor costs.

Internet of Things (IoT)

I remember the first time I heard about IoT in manufacturing; it sounded like something out of a sci-fi movie. But now, it’s a reality that Chinese companies are embracing wholeheartedly. With IoT-enabled smart factories5, real-time monitoring and data analysis become a breeze, allowing for smarter decision-making. Imagine your equipment telling you it needs maintenance before it breaks down—saving headaches and downtime.

Green Energy Solutions

Sustainability isn’t just a buzzword; it’s a way forward. Chinese manufacturers are pioneering green energy solutions6 that transform how we think about production. Picture solar-powered factories and energy-efficient machinery reducing environmental footprints. It’s inspiring to see how eco-friendly methods are not just possible but profitable too.

Advanced Robotics

The future is here with advanced robotics in manufacturing. I once visited a facility where robotic arms performed intricate tasks like precision welding7 with an accuracy that humans could only dream of achieving consistently. These robots don’t just increase speed and accuracy; they also reduce waste, making the whole process more efficient.

Blockchain Technology

Blockchain isn’t just for cryptocurrency enthusiasts anymore. It’s making waves in supply chains by providing transparency and traceability. I know businesses that have started using blockchain solutions8 to ensure every step of production is tracked and secure, building trust with global partners.

Summary Table

| Technology | Benefit | Example Use Case |

|---|---|---|

| AI Automation | Cost reduction & quality | Automated assembly lines |

| IoT | Real-time monitoring | Predictive maintenance |

| Green Energy | Environmental sustainability | Solar-powered factories |

| Robotics | Increased accuracy & speed | Precision welding |

| Blockchain | Transparency & traceability | Secured supply chains |

Each of these innovations isn’t just about improving efficiency; they’re about reimagining what manufacturing can be, creating a future that’s both technologically advanced and environmentally sustainable. It’s an exciting time to witness these changes and think about how they might influence our own industries.

Chinese factories use AI to reduce labor costs.True

AI-driven automation optimizes production, lowering labor expenses.

Blockchain is not used in Chinese manufacturing supply chains.False

Blockchain ensures transparency and traceability in supply chains.

Are Chinese Laser Cleaning Machines Cost-Effective for Your Business?

Choosing the right laser cleaning machine for your business can feel like a big decision, especially with so many options out there. But are those Chinese models worth it? Let’s dive into the numbers and see if they can actually save you some cash.

Chinese laser cleaning machines can be a cost-effective option for businesses, thanks to their competitive prices and efficient performance. To determine if they’re right for you, consider factors like initial costs, operational expenses, and long-term savings, matching your specific needs with available models.

Evaluating Initial Costs

When I first started exploring laser cleaning machines, the sticker shock from Western brands was real. But then I stumbled upon some Chinese models that seemed like a steal. Imagine paying $5,000 for a basic model when others were asking over $10,000 for similar specs! Suddenly, my budget had room to breathe.

| Brand | Model | Price Range |

|---|---|---|

| Brand A | Model X | $5,000 – $7,500 |

| Brand B | Model Y | $6,000 – $9,000 |

I found that doing a little homework—like comparing prices9 among different suppliers—really helped me snag the best deal. Lower upfront costs made it feasible for my small business to enter the market without sacrificing the essentials.

Operational Efficiency and Costs

Once past the initial price tag, the real question is: how much will this thing cost me to run? From what I’ve seen, Chinese laser cleaning machines are champs at being energy-efficient. It’s like having a fuel-efficient car; you just end up spending less over time. They also require minimal maintenance, which means fewer headaches and less downtime.

Some models even come with solid warranties, covering repairs and replacements for up to two years. It’s reassuring knowing that if something goes wrong, I won’t be left hanging with a costly repair bill.

Long-term Savings and ROI

The more I looked into it, the more it seemed like these machines could pay for themselves in no time. Businesses have shared stories of increased productivity and less waste, which naturally boosts ROI. It’s like getting a new employee who never calls in sick!

Before jumping in, I made sure to explore user reviews10 and read through case studies to see how these machines performed under real-world conditions.

Considerations for Specific Business Needs

Of course, not every machine is a perfect fit for every business. For me, the volume of work and the type of materials I deal with were big factors in choosing the right model. If your business handles complex or high-volume tasks, you might need something a bit more advanced with automated settings or higher precision.

Getting insights from industry experts11 was invaluable. They helped me figure out if a Chinese laser cleaning machine would truly align with my business goals.

In conclusion, while Chinese laser cleaning machines can be a smart financial move for many businesses, it’s crucial to weigh the benefits against your specific operational needs before making a final decision.

Chinese laser machines are more affordable than Western ones.True

Chinese models start at $5,000, while Western ones often exceed $10,000.

All businesses benefit equally from Chinese laser machines.False

Suitability depends on specific business needs and task complexity.

What Are the Potential Drawbacks of Choosing Chinese Laser Equipment?

I once thought I’d struck gold with a cheap laser cutter from China, but it didn’t take long for reality to set in. Let’s explore the possible drawbacks of Chinese laser equipment and how to dodge those pitfalls.

Chinese laser equipment, while budget-friendly, may come with downsides like variable quality, lackluster after-sales support, and tough-to-find spare parts. Weigh these risks thoroughly to avoid costly surprises.

Quality Variability

I remember eagerly unpacking my first Chinese laser machine, only to find it wasn’t quite what I’d expected. While some of my peers have had great luck with their purchases, others, like me, found that quality inconsistency12 can be a bit of a mixed bag. This inconsistency can stem from differing manufacturing standards, so it’s vital to thoroughly research and stick to well-reviewed suppliers.

After-Sales Service Challenges

After-sales support can be a lifeline when your equipment acts up. However, I’ve heard stories from colleagues about the frustrations of navigating after-sales service with some Chinese suppliers. The time and effort it takes to resolve even minor issues can affect a machine’s long-term usability13, which is why finding a supplier with a solid reputation for support is crucial.

Spare Parts Availability

In my experience, waiting on spare parts can feel like an eternity. Chinese machines often use specific components that aren’t readily available locally. This can lead to costly downtime. Before purchasing, I now ensure there’s a reliable source for necessary parts14 to keep my operations running smoothly.

| Factor | Risk Level | Impact on Business |

|---|---|---|

| Quality Variability | High | Inconsistent product performance |

| After-Sales Service | Medium | Delayed problem resolution |

| Spare Parts Availability | High | Increased downtime and costs |

Warranty and Certifications

I’ve learned that warranty terms from Chinese suppliers might not align with Western norms. It’s essential to dive deep into understanding the warranty’s coverage and any certification discrepancies15 to prevent future headaches.

Cultural and Language Barriers

Communication can be tricky. I’ve faced situations where language barriers led to misunderstandings about technical specifications and support. Miscommunication can turn promising deals sour, so clear, concise communication is key when dealing with international suppliers.

Before making any commitments, I recommend conducting detailed research and reaching out to industry forums or reviews. They offer firsthand accounts that could save you from potential issues down the line.

Chinese laser equipment often has quality inconsistency.True

Quality varies significantly among manufacturers, affecting reliability.

Spare parts for Chinese laser machines are easy to find locally.False

Local availability of spare parts is often limited, causing delays.

Conclusion

Chinese laser cleaning machines are popular for their affordability, advanced technology, and versatility, making them a cost-effective choice for various industrial cleaning applications worldwide.

-

Discover cost-effective benefits of Chinese laser cleaning machines for budget-conscious businesses. ↩

-

Learn about the latest technological advancements in European laser equipment. ↩

-

Explore factors to consider when selecting a laser cleaning machine for your business needs. ↩

-

Discover how AI is transforming manufacturing efficiency in China through automation. ↩

-

Learn how IoT integration enhances operational efficiency in Chinese smart factories. ↩

-

Explore China’s commitment to sustainability through innovative green energy solutions. ↩

-

Understand the role of advanced robotics in enhancing manufacturing precision in China. ↩

-

Find out how blockchain ensures transparency and reliability in China’s supply chains. ↩

-

Comparing prices can help you find budget-friendly options without sacrificing quality. ↩

-

User reviews offer insights into real-world performance and reliability. ↩

-

Consulting experts can provide tailored advice to align investments with business needs. ↩

-

Learn about quality variations in Chinese laser equipment and how to identify reputable manufacturers. ↩

-

Understand the challenges of obtaining after-sales support from Chinese manufacturers. ↩

-

Explore the challenges and solutions for sourcing spare parts for Chinese laser equipment. ↩

-

Investigate warranty and certification differences to prevent future disputes. ↩