Curious about laser cleaning? This cutting-edge technology might just revolutionize your cleaning routine!

Laser cleaning is generally safe for metal surfaces when properly applied. It uses high-energy laser pulses that evaporate contaminants without affecting the underlying metal, thanks to precise control of laser parameters.

Understanding the intricacies of laser cleaning is essential to harness its full potential. Let’s dive into how this technology works, its numerous benefits, and the important safety measures you should consider.

Laser cleaning can damage metal surfaces.False

When properly applied, laser cleaning removes contaminants without harming metal.

What is Laser Cleaning and How Does it Work?

Laser cleaning offers a precise, contact-free method to remove contaminants from surfaces using high-energy laser pulses.

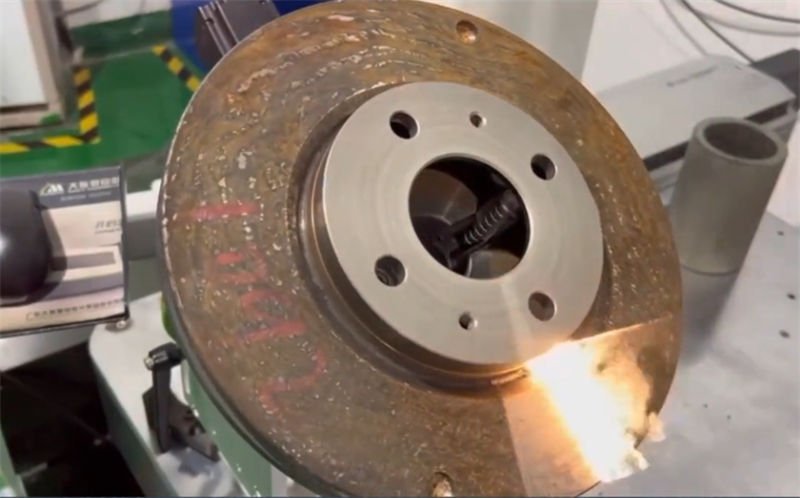

Laser cleaning involves directing high-frequency laser pulses onto a surface to remove contaminants like rust or paint. The energy from the laser is absorbed by the surface layer, leading to the vaporization of unwanted materials without damaging the underlying substrate. This process is efficient, eco-friendly, and preserves surface integrity.

The Mechanics of Laser Cleaning

Laser cleaning is an advanced technique that capitalizes on the properties of laser light to clean surfaces effectively and precisely. This method hinges on a few key principles that make it both efficient and adaptable.

1. Absorption and Evaporation

When a laser beam targets a surface, its energy is absorbed by the contaminants on that surface. This absorption leads to rapid heating and subsequent evaporation of these contaminants. For instance, rust or paint can be effectively removed without affecting the base metal.

2. No Physical Interaction

A significant advantage of laser cleaning is the absence of physical contact between the cleaning tool and the workpiece. This ensures that delicate components remain unharmed during the cleaning process, unlike abrasive methods that might scratch or damage surfaces.

3. Selective Ablation

Selective ablation is at the heart of laser cleaning’s effectiveness. It relies on differing thresholds for vaporization between contaminants and the substrate. Metals typically have higher ablation thresholds than rust or paint, allowing for precise removal of unwanted layers.

Parameters Influencing Laser Cleaning

Several parameters must be controlled to optimize laser cleaning for different applications:

| Parameter | Description |

|---|---|

| Power | Determines how much energy is delivered per pulse. |

| Pulse Length | Affects how long each pulse interacts with the surface. |

| Wavelength | Determines absorption efficiency by different materials. |

Adjusting these parameters allows customization of the cleaning process to match specific needs, ensuring that only unwanted materials are removed.

Environmental and Safety Benefits

Laser cleaning is not only effective but also environmentally conscious. Unlike chemical methods, it produces minimal waste, with only small amounts of non-toxic, solid residue remaining. Furthermore, implementing fume extraction systems during the process helps maintain air quality by capturing any airborne particles.

Practical Applications and Considerations

While highly effective, laser cleaning isn’t universally applicable. Its effectiveness can be limited by factors such as the reflectivity and thermal conductivity of the material being cleaned. Surfaces with complex geometries may pose challenges for uniform cleaning, as lasers may not reach all areas evenly.

For further insights into optimizing laser parameters for specific materials1, and understanding environmental benefits2, visit our detailed guides.

Laser cleaning involves physical contact with surfaces.False

Laser cleaning is contact-free, preventing damage to delicate surfaces.

Laser cleaning produces minimal waste compared to chemical methods.True

It generates only small amounts of non-toxic, solid residue.

Are There Any Risks Involved with Laser Cleaning?

Laser cleaning is renowned for its precision and efficiency, but are there hidden risks associated with its use?

Laser cleaning has some risks. For humans, laser beams can cause severe eye damage like retinal burns and potential blindness, and skin burns or lesions. For objects, improper energy can damage materials or lead to incomplete/over – cleaning. Environmentally, it may produce harmful fumes and dust. Also, laser radiation leakage can occur, affecting nearby electronics and human health if ventilation is poor or equipment fails.

Potential Risks of Laser Cleaning

-

Eye and Skin Exposure

Laser cleaning devices emit intense beams that can cause severe damage if they come into contact with skin or eyes. It is crucial to wear appropriate personal protective equipment (PPE) like laser safety goggles and gloves to shield against accidental exposure.

-

Material Incompatibility

Not all materials are suitable for laser cleaning. Metals with high reflectivity or thermal conductivity can reflect or disperse laser beams, reducing effectiveness and potentially causing harm to the equipment or operator. Understanding the ablation threshold of materials is vital to ensure compatibility.

-

Fume Generation

The vaporization process during laser cleaning can release harmful fumes, especially when removing organic contaminants like paint. Implementing a fume extraction system3 is essential to maintain air quality and protect the environment from airborne pollutants.

-

Equipment Handling

Improper handling of laser equipment can lead to accidents or suboptimal results. Operators should be trained to understand laser parameters and operational procedures to avoid mishaps.

-

Fire Hazards

The high-energy pulses used in laser cleaning can ignite flammable materials if not carefully managed. Keeping a fire extinguisher on hand and ensuring a clear, debris-free work area can mitigate this risk.

Safety Protocols and Training

- Training Programs: Engaging in comprehensive training programs ensures operators understand both the capabilities and risks associated with laser cleaning. Proper knowledge enhances both safety and effectiveness.

- Routine Maintenance: Regular maintenance of laser equipment helps identify potential faults that could lead to accidents, ensuring reliable operation.

By acknowledging and addressing these risks, laser cleaning remains a highly efficient and safe method for removing surface contaminants across various industries.

Laser cleaning can cause eye damage without PPE.True

Laser beams can harm eyes if appropriate safety goggles aren't worn.

All materials are suitable for laser cleaning.False

Some materials reflect lasers, reducing effectiveness and causing harm.

How Does Laser Cleaning Compare to Traditional Methods?

As industries seek efficient and eco-friendly cleaning solutions, laser cleaning emerges as a promising alternative. How does it stack up against traditional methods?

Laser cleaning differs from traditional methods in several ways. Compared to chemical cleaning, it’s more environmentally – friendly as it doesn’t use harsh chemicals. It’s also more precise than mechanical cleaning like sandblasting. Laser cleaning can target specific areas precisely, reducing damage to the substrate. Traditional methods might leave residues, while laser cleaning can achieve a cleaner surface. However, traditional methods may be less expensive initially and sometimes more straightforward for large – scale, less – precise jobs.

Efficiency and Precision

One of the standout features of laser cleaning4 is its precision. Traditional methods, such as sandblasting or chemical stripping, can be effective but often lack the ability to target specific areas without affecting surrounding materials. Laser cleaning excels in targeting contaminants like rust or paint with pinpoint accuracy, preserving the integrity of the underlying surface.

- Traditional Methods: May involve physical abrasion or harsh chemicals that can affect surface quality.

- Laser Cleaning: Utilizes adjustable laser parameters to ensure contaminants are removed without damaging the substrate.

Environmental Impact

In the quest for sustainable industrial practices, the environmental impact of cleaning methods is crucial. Traditional cleaning often results in chemical waste or significant dust and debris, posing environmental and health risks.

- Traditional Methods: Generate significant waste and potentially harmful emissions.

- Laser Cleaning: Produces minimal waste, typically in the form of non-toxic solid residues, and requires no harsh chemicals.

| Method | Waste Type | Environmental Impact |

|---|---|---|

| Traditional | Chemical/Abrasive | High |

| Laser Cleaning | Minimal/Non-Toxic | Low |

Cost and Safety Considerations

While the upfront cost of laser equipment can be high, its operational costs tend to be lower over time due to the absence of consumables like sand or chemicals. Moreover, laser cleaning enhances workplace safety as it eliminates exposure to hazardous materials.

- Traditional Methods: Lower initial costs but higher ongoing expenses due to consumable materials and waste management.

- Laser Cleaning: Higher initial investment with potential long-term savings and safer work environments.

Applications and Limitations

Laser cleaning is gaining traction across various industries such as automotive, aerospace, and manufacturing. However, it’s essential to recognize its limitations. For example, it may not be effective on reflective surfaces or complex geometries that prevent uniform laser application.

- Traditional Methods: Versatile but can be less precise in delicate applications.

- Laser Cleaning: Ideal for precision work but may require adjustments for challenging surfaces or materials.

Overall, while laser cleaning offers numerous advantages over traditional methods, its suitability depends on specific application needs and material properties. As technology advances, its role in industrial cleaning is likely to expand further.

Laser cleaning produces less waste than traditional methods.True

Laser cleaning generates minimal non-toxic residues, unlike chemical waste.

Traditional methods are more precise than laser cleaning.False

Laser cleaning offers pinpoint accuracy, preserving surface integrity.

What Precautions Ensure Safe Use of Laser Cleaning?

Ensuring safety in laser cleaning involves understanding the equipment and following best practices to protect both operators and materials.

To ensure the safe use of laser cleaning, several precautions are essential. Operators must wear appropriate personal protective equipment such as laser – safe goggles to protect the eyes. The work area should have good ventilation to disperse harmful fumes. Regular equipment maintenance is crucial to prevent laser radiation leakage. Also, proper training is necessary for operators to understand how to set correct laser parameters to avoid over – exposure and damage to the objects being cleaned.

Understanding Laser Safety Standards

Compliance with industry standards is crucial. Operators should be familiar with laser safety regulations5 specific to their region and adhere to guidelines such as those from the American National Standards Institute (ANSI) or the International Electrotechnical Commission (IEC). These standards cover aspects like safety classifications and required protective measures.

Personal Protective Equipment (PPE)

Operators must wear appropriate PPE, including laser safety goggles, gloves, and protective clothing. Laser safety goggles are critical as they protect the eyes from potentially damaging laser beams. Depending on the laser’s wavelength, different types of goggles might be needed.

Equipment Maintenance and Calibration

Regular maintenance of laser cleaning equipment ensures it operates efficiently and safely. Calibration is essential to ensure laser parameters are correctly set for the specific task, preventing accidental damage to materials or surfaces. Regular checks help avoid unexpected malfunctions.

Managing Laser Settings

Proper management of laser settings is vital for safe operation. Operators should be trained to adjust parameters such as power, pulse duration, and frequency according to the material being cleaned. Incorrect settings can lead to ineffective cleaning or damage to the substrate.

| Parameter | Importance |

|---|---|

| Power | Determines intensity; too high can damage substrate |

| Pulse Duration | Affects precision; must match material properties |

| Frequency | Controls repetition rate; influences cleaning speed |

Fume Extraction Systems

Laser cleaning generates fumes and particles that need to be managed. A reliable fume extraction system is necessary to maintain air quality and protect both the operator and the environment from harmful emissions. This system should be regularly serviced to ensure optimal performance.

Safe Operating Environment

The workspace should be organized to prevent accidental exposure to laser beams. This includes setting up barriers or curtains around the cleaning area and ensuring proper signage is displayed. Only trained personnel should operate the equipment to minimize risks.

By implementing these precautions, companies can harness the benefits of laser cleaning technology while ensuring a safe working environment for operators and maintaining the integrity of materials being treated.

Laser safety goggles protect eyes from laser beams.True

Laser safety goggles are essential to prevent eye damage from laser exposure.

Fume extraction systems are optional in laser cleaning.False

Fume extraction systems are necessary to manage harmful emissions during laser cleaning.

Conclusion

By embracing laser cleaning, we can ensure metal surfaces are preserved while efficiently removing contaminants. Understanding its principles allows for safe and effective applications.

-

Learn how to tailor laser settings for different material types.: Laser parameters are the different properties that characterize a particular laser’s behavior. Learn more about them here. ↩

-

Explore how laser cleaning minimizes ecological impact.: Eco-friendly technology: Laser cleaning reduces chemical waste and has a lower environmental footprint. Safety and Compliance: Laser cleaning is safer for … ↩

-

Learn how fume extraction systems protect air quality during laser cleaning.: Eliminate fumes and odors in your workspace with Boss Laser’s efficient fume and odor extractors. Ensure a clean and safe environment. ↩

-

Explore how laser cleaning achieves precision without damaging surfaces.: Lasers offer reduced overhead costs when compared to traditional media blasting and chemical etching methods. Explore the benefits of using … ↩

-

Explore detailed standards ensuring safe laser operations worldwide.: The purpose of this standard is to provide guidance the safe use of lasers and laser systems found in research, development, or testing environments, where … ↩