Laser welding machines are revolutionizing the welding industry with precision and efficiency. But with so many types available, which one suits your needs best? Explore the various types of laser welding machines, their features, and applications to find your perfect match!

In today’s fast-paced market, the choice of marking technology can significantly influence your business’s success. Fiber laser marking machines offer unparalleled precision, versatility, and efficiency for a wide range of applications. Discover the key advantages of these innovative machines and learn how they can transform your operations.

In the world of material customization, laser engraving and etching stand out as two distinct methods for adding intricate designs to surfaces. While both techniques offer unique advantages, understanding their differences can help you choose the right one for your project needs. This guide breaks down the key technical differences, material compatibility, cost implications, and ideal applications for each method to help you make an informed decision.

Plasma cutting precision is influenced by several key factors including torch movement control, cutting speed, standoff distance, and the quality of consumables. Proper calibration of equipment is essential for achieving optimal results. Understanding how each element affects the cutting process helps technicians create smoother cuts with fewer defects. Regular maintenance and timely replacement of worn parts can significantly enhance performance and prolong the lifespan of the equipment. This guide explores these critical aspects in detail to help improve your plasma cutting outcomes.

Laser engraving machines are revolutionizing industries from jewelry to aerospace with their precision marking capabilities. This article dives into the inner workings of these fascinating machines, exploring their components, engraving processes, and the differences between engraving and etching. Get ready to uncover the technology that makes laser engraving a preferred choice for many!

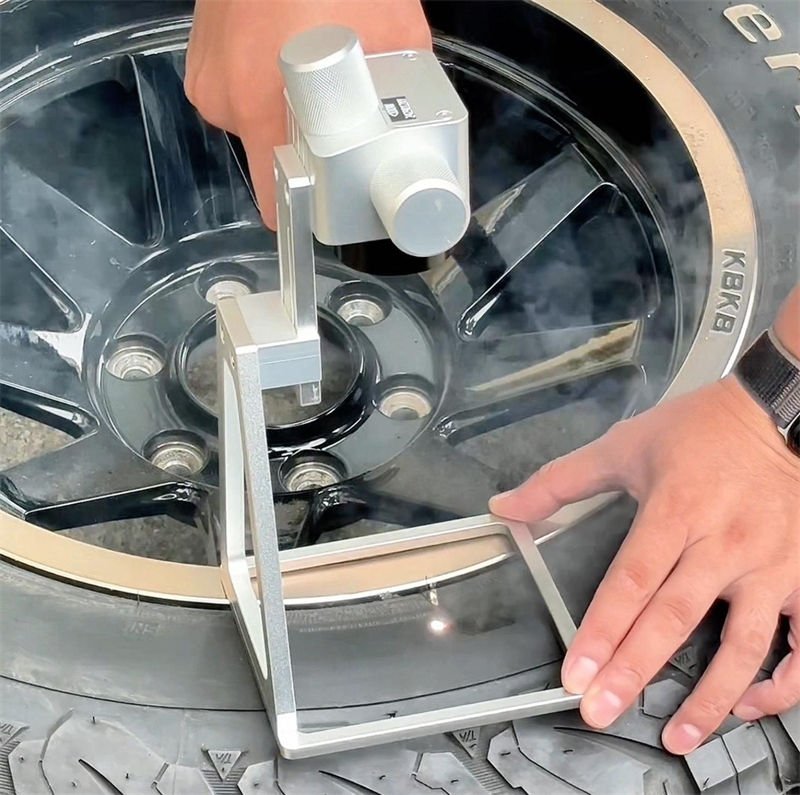

Handheld laser marking machines are transforming how businesses perform marking tasks, offering flexibility and precision like never before. From portability to versatility, these tools provide unmatched advantages across various industries. Discover how they can revolutionize your operations and why investing in this technology is a game-changer.

Laser engraving is a captivating blend of technology and artistry, but it raises essential safety questions. Understanding the potential dangers—like eye damage, skin burns, and harmful fumes—is crucial for anyone considering this practice. This article delves into those risks and offers protective strategies to ensure a safe engraving experience.

In the world of manufacturing and product customization, precision and efficiency are key. Laser technology offers powerful tools in the form of marking and engraving, but what sets them apart? Understanding these differences can significantly influence your project’s outcome.

Laser marking machines are transforming industries with their precision and efficiency. From electronics to pharmaceuticals, their ability to engrave, etch, and mark various materials ensures product quality and traceability. In this article, we explore the diverse applications of laser marking technology across sectors and how they can enhance operations.

Navigating the world of glass laser engraving machines can feel overwhelming with the many options available. However, understanding key features like laser type, bed size, software compatibility, and cost efficiency can help you make an informed decision. This guide dives deep into these crucial elements, ensuring you find the perfect machine for your needs.

Intersection of Li chen Highway and Tujing Avenue, changxing County, Huzhou City Zhejiang Province, China

Copyright @ 2025 Royelltec. All Rights Reserved.

WhatsApp us

Send us a message if you have any questions or request a quote. We will be back to you ASAP!